Hydraulic Tube Assembly Manufacturer in Chinna

▷ Built to Withstand Pressure

▷ Perfect Tubing, Every Time

▷ Seamless Tubes

▷ Stronger Lines

Product List

Hydraulic tubes involve a wide variety of types. In terms of material, stainless steel, steel, and carbon steel are commonly used. We also provide seamless and welded hydraulic tube assemblies. You can check the pictures below to find the product. If you don’t find the product you need, we also offer custom hydraulic tube assemblies.

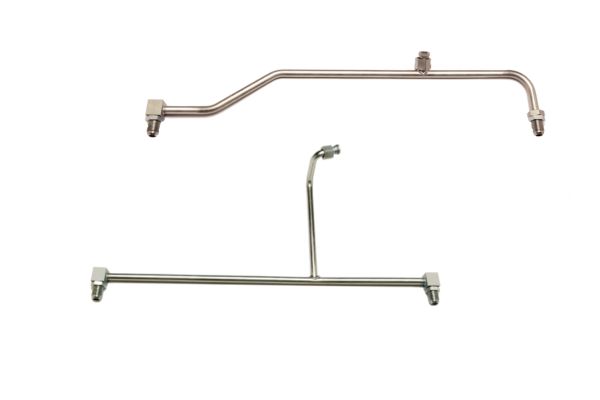

Hydraulic Tube Assembly

Hydraulic tube assembly, made of steel, and carbon steel.

Stainless steel Hydraulic Tube Assembly

High-quality stainless steel, corrosion-resistence.

Hydraulic Steel Tube Assembly

Made of strong steel, for use with heavy machines.

Carbon Steel Hydraulic Tube Assembly

Carbon steel hydraulic tube assembly, an economical choice.

CDS Hydraulic Tube Assembly

Cold bending seamless tube assembly.

Custom Hydraulic Tube Assembly

Topa offers custom hydraulic tube assembly services.

Cold Bending Hydraulic Tube Assembly

CDS/Cold bending hydraulic tube assembly.

Weld Hydraulic Tube Assembly

Weld hydraulic tube assembly, can weld with hydraulic fittings.

Cold Drawn Seamless Hydraulic Tube Assembly

Cold drawn seamless hydraulic tube assembly.

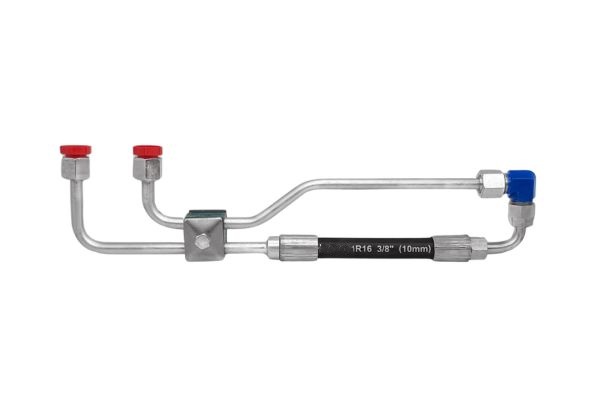

Cutting Sleeve Hydraulic Tube Assembly

Cutting sleeve hydraulic tube assembly, for use with machines.

Hydraulic Seamless Tube Assembly

Hydraulic seamless tube assembly, no leaks.

Liugong Heavy Equipment 915EHD Tube Assembly

For use with the Liugong tractor, forklift, and dumper.

LonKing 6075 Hydraulic Tube Assembly

For use with Lonking heavy equipment.

Lovol Agriculture Equipment 130 Tube Assembly

Foer use with Lovol agriculture heavy machine.

SK305LC-10 Hydraulic Tube Assembly

SK305LC-10 type hydraulic tube assembly, made of heavy steel.

SY55 Steel Tube Assembly

SY55 steel tube assembly, for use with agriculture machines.

Topa Video

This video showcases the full production process of our hydraulic tube assemblies — from precise tube cutting and cold bending to final packaging and quality inspection. You’ll see how we transform raw steel tubing into ready-to-install hydraulic lines with accurate bends, clean cuts, and secure ends, all performed under strict quality controls. These assemblies are engineered to handle high pressure and deliver consistent fluid flow with zero leakage.

Need custom lengths, special fittings, or just want to learn more about our process? Feel free to contact our team — we’re ready to assist with technical guidance, fast quotations, and tailored solutions.

Applications

Hydraulic tube assemblies are engineered for performance in high-stress, high-pressure environments. Their rigid structure, superior pressure handling, and long-term durability make them ideal for both fixed installations and mobile equipment where system integrity is critical. Topa’s precision-bent hydraulic tubes are trusted across industries where failure is not an option.

Construction Equipment

Heavy-duty construction equipment demands reliable hydraulic systems capable of withstanding continuous impact, vibration, and extreme working conditions.

- Loaders: High-pressure control lines and lift mechanisms

- Excavators: Boom cylinder piping and swing drives

- Bulldozers: Blade control and undercarriage actuation

- Cranes: Stabilizer hydraulics and telescopic boom feed

Industry Application

Hydraulic tube assemblies play a crucial role in fixed industrial setups where precision, repeatability, and resistance to environmental factors are essential.

- Factory automation: Powering linear actuators and robotic arms

- Stamping presses: High-force cylinder connections

- Injection molding: Clamp and ejector hydraulic circuits

- Machine tools: Hydraulic slides and indexing mechanisms

Agricultural Machinery

Hydraulic tube assemblies are widely used in agriculture for their ability to deliver high-pressure performance with minimal maintenance.

- Tractors: Steering hydraulics and loader arms

- Harvesters: Header lift systems and auger drives

- Sprayers: Boom control lines and tank agitation circuits

Products Features

Hydraulic tube assemblies are rigid, pre-bent tubing systems designed to transfer pressurized hydraulic fluid between key components in heavy equipment, industrial machinery, and mobile systems. Unlike flexible hoses, hydraulic tubing provides a permanent and highly stable path for fluid flow, offering unmatched performance in high-pressure and high-vibration environments. These assemblies are engineered to precise specifications using seamless or welded steel tubing, ensuring leak-free operation under demanding conditions.

Components

Each hydraulic tube assembly includes several integral components that work together to deliver reliable performance:

Tubing

Made from carbon steel or stainless steel, selected based on pressure, temperature, and corrosion requirements.

Tube Fittings

Connection options include JIC 37°, ORFS, DIN 2353, BSPP, or NPT threads.

Clamps and Mounting Accessories

Help minimize vibration, maintain alignment, and reduce wear.

Surface Finish

Zinc-plated, phosphate-coated, or uncoated stainless steel for corrosion resistance.

Connection Options & Port Standards

Hydraulic tube assemblies can be equipped with a wide variety of end connections to suit different system standards and sealing methods:

Threaded Ends

BSPT, NPT, JIC, and SAE threads for compatibility with international systems.

Compression Fittings

Used in DIN/ISO-based systems for reliable metal-to-metal sealing.

Welded Ends

Ideal for permanent, high-pressure applications.

Flared & Flange Options

For ultra-secure connections in heavy-duty mobile equipment.

Tube Size & Dimensional Specs

Our assemblies are available in both metric and imperial units, making them fully compatible with international hydraulic standards and systems. Whether you’re replacing existing pipework or building a new fluid power system from scratch, we provide cut-to-length, pre-bent hydraulic tubes tailored to your exact specifications.

Outer Diameter Range

- Metric Sizes: 6 mm to 50 mm

- Imperial Sizes: 1/4” to 2”

Wall Thickness Options

- Light Series (L): Used in lower-pressure or weight-sensitive applications.

- Medium Series (M): A balance of strength and flexibility for most systems.

- Heavy Series (H): Designed for high-pressure hydraulic tubing installations in demanding environments.

Tube Lengths & Custom Forming

- Straight Lengths (commonly 6m or 20ft stock)

- Custom-Cut Pieces based on your hydraulic schematics

- Custom-Cut Pieces based on your hydraulic schematics

Material Overview

All our materials are sourced from certified mills, tested for mechanical properties, and verified for compatibility with global hydraulic fitting standards. Whether you’re designing a fixed installation or working with dynamic mobile equipment, our material selection supports both performance and cost efficiency.

Carbon Steel

- ST 37.4 (Mild Steel): Suitable for standard-pressure systems, easy to bend and flare

- ST 52 (High Strength): Designed for high-pressure hydraulic applications with higher yield strength

- Surface Options: Zinc-plated, phosphate-coated, or oiled to prevent corrosion

Stainless Steel

- 304: General-purpose corrosion resistance with excellent formability

- 316: Enhanced protection against chlorides, acids, and aggressive chemicals

- Surface Finish: Bright annealed or polished for aesthetic and hygiene-sensitive systems

Copper & Aluminum Tubing (On Request)

- Copper Tubing: Excellent thermal conductivity, used in HVAC fluid lines, brake systems, or low-pressure lube systems

- Aluminum Tubing: Lightweight and corrosion-resistant, often used in pneumatic or low-pressure hydraulic circuits

Our Services

Quality Control

100% inspection to guarantee product quality.

Flexible Orders

Handling small to large-scale orders flexibly.

After-Sales Support

Professional ongoing after-sales services.

Training Services

On-site installation and usage training.

Fast Response

24-hour response to customer inquiries.

Global Shipping

Reliable and swift logistics solutions.

Technical Support

Real-time consultation from technical experts.

Customized Solutions

Personalized product design and manufacturing.

Why Choose Us

At Topa, we do more than supply hydraulic tube assemblies — we deliver complete fluid power solutions with technical confidence and global responsiveness.

Whether you’re a machinery manufacturer, system integrator, or industrial maintenance provider, our service model is built to support your workflow from design to delivery.

✅ Custom Engineering Support

Bring us your drawings, 3D models, or just a concept — our experienced technical team will help you select the right tube material, connection standard, wall thickness, and bending path. We support everything from prototyping to bulk production.

✅ Precision CNC Tube Bending

Our CNC mandrel bending ensures every tube meets your exact angle, radius, and length — even for multi-plane configurations. Every assembly is formed to tight tolerances with smooth interior flow paths.

✅ Seamless Assembly Integration

We can pre-install end fittings, nuts, sleeves, and flared ends — delivering ready-to-install assemblies that drop straight into your line. Fewer fittings. Fewer leak points. Faster installation.

✅ Cleanliness & Quality Control

Every Topa tube is cleaned, deburred, flushed, and pressure-checked before shipment. We follow ISO cleanliness standards to ensure zero contamination at installation.

50+

Manufacturing Facilities

20+

Countries Served

50+

Employees Worldwide

2,000+

Products

30+

Years

100+

Customers

FAQ

What sizes of hydraulic tube assemblies are available?

We provide tubing in outer diameters ranging from 6 mm to 50 mm (or 1/4″ to 2″), with custom lengths and bends based on your requirements.

What materials are your tubes made from?

Our hydraulic tubes are available in carbon steel (ST 37.4 / ST 52), 304/316 stainless steel, and aluminum or copper for low-pressure applications.

What wall thickness options are offered?

We support Light (L), Medium (M), and Heavy (H) wall series to accommodate varying pressure ratings and mechanical strength.

What is the maximum working pressure for these assemblies?

Pressure ratings vary by material and size but can reach up to 6000 PSI for thick-walled carbon or stainless steel tubes.

Are the hydraulic tubes seamless or welded?

We primarily offer cold-drawn seamless hydraulic tubes to meet DIN 2391, EN 10305-1, and SAE J524 precision standards.

What surface treatments are available?

Tubes can be supplied with zinc plating, phosphate coating, powder coating, or natural stainless steel finish for corrosion resistance.

What type of ends and fittings are compatible?

Our tube ends support JIC, ORFS, BSPP, NPT, DIN 2353 compression, flare, or welded connections. Custom thread machining is also available.

Do the tubes meet international hydraulic standards?

Yes. Our tubing complies with ISO 8434-1, SAE J524, DIN 2391, and other global hydraulic fluid conveyance standards.

Are the tubes suitable for high-temperature environments?

Yes. Stainless steel tubes can operate up to +400°C, while carbon steel tubes are typically rated up to +120°C depending on surface treatment.

Can your hydraulic tubes be bent into complex shapes?

Yes. We use CNC mandrel bending for precise, multi-plane tube geometry while maintaining internal flow integrity and structural strength.

Get More Information About Products