FAQ

What is a bulkhead fitting?

Bulkhead fitting is a kind of fitting that can provide a watertight connection to prevent liquid leakage, mostly used to connect two hoses separated by walls or other panels.

Why use a bulkhead fitting?

Bulkhead fittings provide a secure and watertight connection to prevent fluid leakage and can maintain system pressure and flow rates.

How to install a bulkhead fitting?

First, drill a hole in the wall where the bulkhead fitting is to be installed, then pass the bulkhead fitting through the hole and fix it with a nut.

What are the applications of hydraulic bulkhead fittings?

Bulkhead fittings are commonly used in plumbing systems, in addition to plumbing systems, they are also found in hydraulic systems.

What are the sizes of bulkhead connectors?

Leakage of hydraulic bulkhead fittings may be caused by damaged gaskets or fittings that are not screwed in tightly or too tightly.

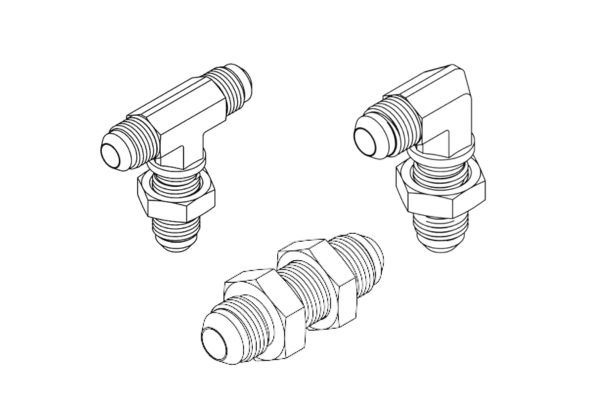

What types of bulkhead fittings are available?

Commonly used bulkhead fittings are hose fittings, tees, brake fittings, and barbed fittings.

What needs to consider before buying a bulkhead fitting?

There are three main factors you need to consider: hose size, material, and pressure. Once you have determined the criteria you can purchase as needed.

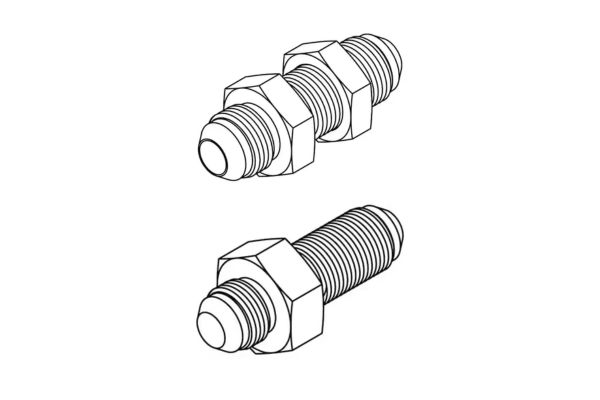

What are the parts of the bulkhead fitting?

It consists of the body which has threads on it and a nut. In some cases, there will be a gasket as well.

What are the advantages of bulkhead fitting?

bulkhead fittings provide a watertight connection to prevent fluid leakage, and they also ensure the free flow of fluid. Sometimes they are also used as diversion outlets in piping systems.

What are bulkhead connectors made of?

Metal, PVC, or plastic, but Topa only offers metal bulkheads.