FAQ

What is an air compressor hose fitting?

An air compressor fitting is a component used in air compressors to connect pipes to the compressor.

What are the materials for compressor air hose fittings?

Brass and stainless steel.

What are the common sizes of air compressor pipe fittings?

1/4, 3/8, and 1/2

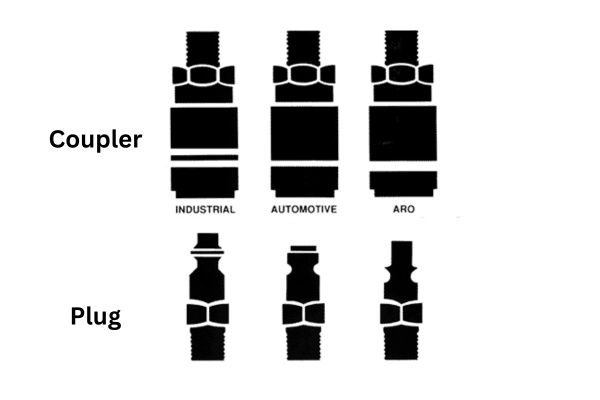

What kinds of air compressor fittings are available?

Couplers, fittings, regulators, and valves.

What are the common threads of air compressor fittings?

NPT and BSP.

Where can air compressor quick connect be used?

Automotive, industrial equipment, and medical equipment.

How to choose the most suitable compressor fitting?

Choose the size, material, type, and thread.

Can compressor air fittings be used in water applications?

No, the seal of the compressor fitting will be greatly reduced by water.

Can I customize my air compressor fittings?

Yes, you can.

How does Topa ship my order?

You can make your request.