FAQ

Do I have to align the banjo bolts to use it?

No, alignment doesn’t affect them working properly.

Why are Banjo fittings used in hydraulic braking systems?

Because Banjo fittings can withstand high pressure.

What materials of the banjo fittings from TOPA?

TOPA’s Banjo fittings are make of carbon steel and stainless steel.

Why do Banjo fittings need Gaskets?

Gaskets keep banjo fittings from leaking.

Where are banjo fittings used?

Brake system

Hydraulic power systems

Power steering fluid

Hydraulic clutch systems

Fuel systems

How can I stop a banjo bolt from leaking?

Using squeeze washers on each side of the banjo joint can prevent leakage of the banjo bolts

Are the tighter banjo bolts the better?

Do not over-tighten or they will break. Just put the banjo bolt against the washer and you’ll get a good seal. As long as it doesn’t leak it’s fine.

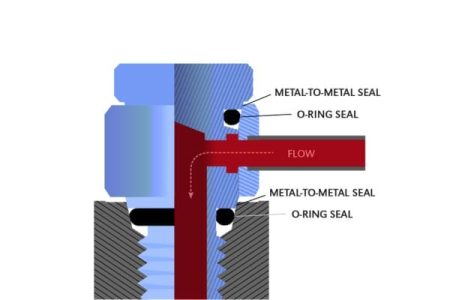

How do banjo fittings work?

The banjo bolt goes through the center of the fitting, this hollow bolt has a hole that allows fluid to transfer to another part of the fitting.

When should banjo hose fittings be used?

When your hydraulic system needs 360° range of motion and high pressure operation, you can use Banjo hose fittings

Can the copper Banjo fittings gasket be used multiple times?

Copper banjo bolt washers are best for single use.