FAQ

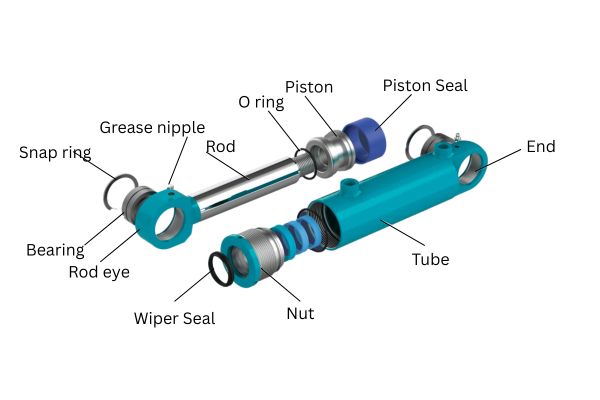

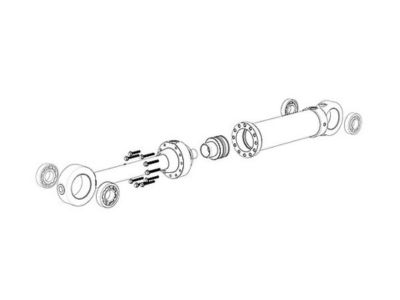

What is a hydraulic cylinder?

A hydraulic cylinder is a mechanical actuator that uses hydraulic fluid to create linear motion and force. It is used in various applications to move heavy loads in industrial and machinery systems.

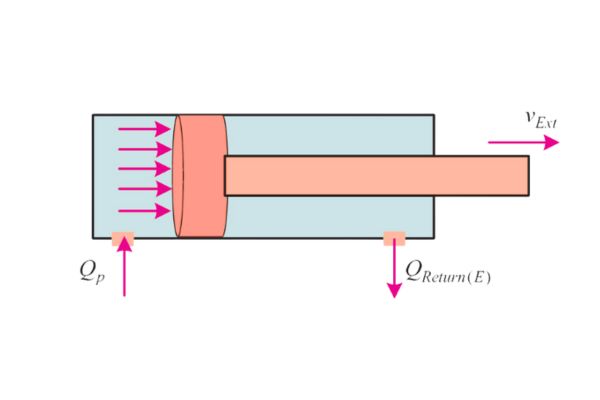

How does a hydraulic cylinder work?

Hydraulic cylinders work by converting hydraulic energy (fluid pressure) into mechanical force. The fluid enters the cylinder and pushes against the piston, causing it to move in a linear direction.

What are the types of hydraulic cylinders?

The main types of hydraulic cylinders are single-acting (which uses pressure on one side of the piston) and double-acting (which uses pressure on both sides of the piston for movement in both directions).

What materials are used in hydraulic cylinders?

Hydraulic cylinders are typically made from high-strength steel, stainless steel, and cast iron. The materials are chosen based on the need for strength, durability, and resistance to corrosion.

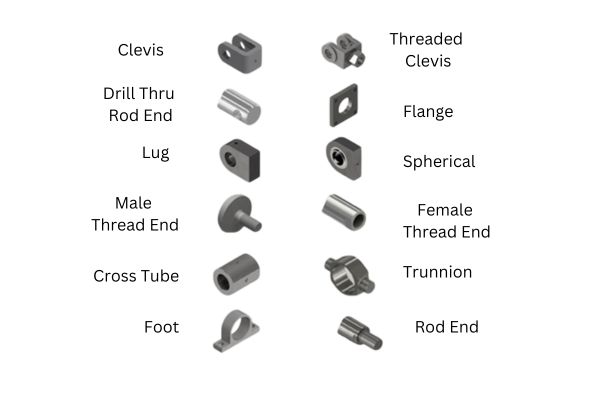

How do I choose the right hydraulic cylinder for my application?

Choose based on factors like the required pressure, stroke length, mounting style, load capacity, and environmental conditions. Consulting a hydraulic specialist can help determine the best fit.

What causes hydraulic cylinder failure?

Common causes of hydraulic cylinder failure include excessive pressure, lack of maintenance, contamination of hydraulic fluid, worn seals, and improper installation.

How often should I maintain my hydraulic cylinder?

Regular maintenance should be performed according to usage and operating conditions. Typically, inspect hydraulic cylinders every 6 months to ensure seals, fluid, and components are in good condition.

How can I prevent leaks in my hydraulic cylinder?

To prevent leaks, ensure that seals and gaskets are intact, install the cylinder correctly, and avoid over-pressurizing the system. Regular inspection and maintenance can help prevent leaks.

Can hydraulic cylinders be repaired?

Yes, hydraulic cylinders can be repaired. Damaged seals, piston rods, or other components can be replaced. However, if the cylinder tube or other critical parts are severely damaged, it may need to be replaced entirely.

What is the typical lifespan of a hydraulic cylinder?

The lifespan of a hydraulic cylinder depends on usage, maintenance, and operating conditions. With proper maintenance, hydraulic cylinders can last from 10 to 20 years or longer in many applications.