Mining Hose Fittings Supplier in China

※ Abrasion Resistant

※ Vibration resistant

※ High pressure resistant

※ Safety

Product List

Mining hose fittings are designed for the hydraulic systems of mining and transportation machinery. Whether in the laboratory or the field, Topa Hydraulics’ range of fittings offers robustness, reliability, and efficiency. Our extensive catalog covers almost all areas of mining applications. In addition to the usual hose couplings and andquick-releasee couplings, we also offer mining hydraulic ferrules, spike lock inserts, and spike lock adapters. Our couplings will keep your mining machinery running smoothly, so choose our products with confidence.

1NY

NPT MALE/STECKO MALE

1OY

SAE O-RING BOSS/STECKO MALE

1Y

STECKO MALE

2BY4

45° BSP MALE 60° SEAT/STECKO FEMALE

2NY

NPT MALE/STECKO FEMALE

2NY4

45° NPT MALE/STECKO FEMALE

2NY9

90° NPT MALE/STECKO FEMALE

2NY9-L

90° LONG NPT MALE/STECKO FEMALE

2OY

SAE O-RING BOSS/STECKO FEMALE

2OY4-OG

45° SAE O-RING BOSS/STECKO FEMALE

2OY9-OG

90° SAE O-RING BOSS/STECKO FEMALE

2TY4

45° BSPT MALE/STECKO FEMALE

2Y9

90° STECKO MALE/STECKO FEMALE

2ZY

BSP MALE/STECKO FEMALE

3BY

BSP FEMALE 60° CONE/STECKO FEMALE

3BY4

45° BSP FEMALE 60° CONE/STECKO FEMALE

3BY9

90° BSP FEMALE 60° CONE/STECKO FEMALE

3Y

STECKO FEMALE

3Y4

45° STECKO FEMALE

3Y9

90° STECKO FEMALE

4Y

STECKO MALE PLUG

5NY

NPT MALE/STECKO FEMALE

5Y9

STECKO MALE/STECKO FEMALE

7Y

STECKO FEMALE

7Y9

90° STECKO FEMALE

9Y

STECKO FEMALE CAP

DQ-Y

BACK-UP RING

DY

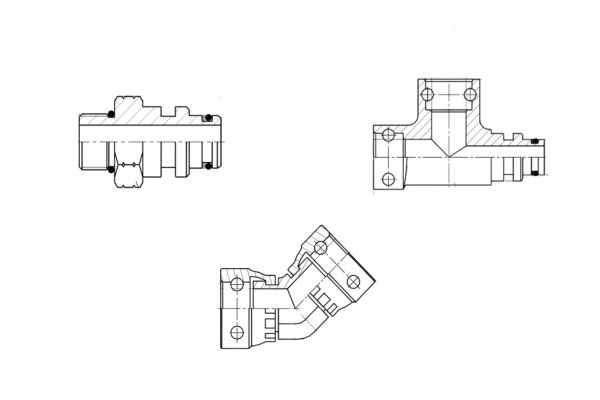

TEE STECKO FEMALE

GY

TEE STECKO FEMALE

HY

STECKO FEMALE/STECKO FEMALE/STECKO MALE

U-Y

STAPLE

EY

STECKO FEMALE/STECKO MALE/STECKO FEMALE

YY

Y TYPE STECKO FEMALE

ZY

CROSS STECKO FEMALE

Staple lock hose inserts

Staple lock inserts for mining systems.

Mining Hydraulic Hose Fitting

Common hydraulic hose fitttings, for mining applications.

Mining Adapter

Staple lock mining adaptors, different types and sizes.

Mining Hose Ferrule

Hose ferrule for mining hoses, high-quality and reliable.

Mining Quick Coupler

Commcon quick coupler fitting, for mining systems.

Topa Video

This video takes you behind the scenes at Topa, showcasing our state-of-the-art manufacturing process for mining hose fittings. You’ll get an exclusive look at how we meticulously design, test, and produce fittings that meet the highest standards of quality and performance. From raw materials to finished products, every step of our process is carried out with precision to ensure maximum durability and reliability in mining operations.

In addition to the manufacturing process, the video also highlights our advanced factory environment. Equipped with cutting-edge technology and operated by a skilled team of professionals, our facility is the backbone of our production capabilities. With strict quality control measures at every stage, we guarantee that each mining hose fitting leaving our factory is built to last and perform under the most demanding conditions.

We invite you to watch the video and learn more about how Topa’s mining hose fittings can benefit your operations. If you have any questions or would like to request a quote, feel free to reach out to us.

Application

Mining hose fittings are built to perform in the harshest industrial environments. Below are key application scenarios where these fittings prove critical:

Underground Mining Hydraulic Systems

Mining hose fittings are essential for operating underground hydraulic systems such as roof supports, tunnel jumbos, and drilling arms. Their durability and sealing reliability help maintain system integrity under extreme pressure, humidity, and abrasive debris.

Mining Loaders, Excavators & Haul Trucks

Heavy-duty mobile machinery such as front-end loaders, hydraulic excavators, and dump trucks rely on mining hose fittings to connect critical hydraulic circuits. These fittings withstand continuous vibration, shock loads, and temperature swings during long operating cycles.

Drilling & Blasting Equipment

Mining hose fittings are widely used in hydraulic drilling rigs and blasting machines. They connect hoses in systems that power rotating heads, feed mechanisms, and positioning arms—helping maintain drilling efficiency and operator safety.

What Are Mining Fittings?

Mining hose fittings are heavy-duty connection components designed to link high-pressure hydraulic hoses to machinery and equipment operating in the demanding environments of the mining industry. These fittings are engineered to withstand extreme pressures, abrasive materials, intense vibrations, and harsh weather conditions typically encountered in both surface and underground mining operations.

Built from rugged materials such as carbon steel or stainless steel, mining hose fittings are often coated for superior corrosion resistance and long-term durability. They are available in various thread types (BSP, NPT, JIC, ORFS) and configurations (straight, elbow, flange) to ensure secure and leak-free connections across complex hydraulic systems.

Whether you’re dealing with earthmoving equipment, rock drilling rigs, haul trucks, or hydraulic support systems, mining hose fittings play a critical role in maintaining fluid power and preventing unexpected downtime. They’re suitable for use in hydraulic circuits that demand high flow, pulse resistance, and leak-proof sealing—even under extreme pressure and environmental stress.

Customization Capabilities

At Topa, we understand that no two mining projects are the same. Harsh environments, unique machinery layouts, and varying pressure demands call for fittings that go beyond off-the-shelf options. That’s why we offer full customization for mining hose fittings to match your exact specifications and operational challenges.

What We Can Customize:

- Thread Type: BSP, NPT, JIC, ORFS, Metric, UNF, custom non-standard threads

- Fitting Lengths & Angles: Straight, 45°, 90°, extended body, compact build

- Materials: Carbon steel, stainless steel (304/316), brass, or aluminum alloy

- Surface Treatment: Zinc plating, trivalent chromate, phosphate coating, nickel/zinc-nickel alloy, or stainless polishing

- Branding Options: Laser-engraved or stamped company logo, QR codes for tracking

- Packaging Solutions: Individual bagging, custom boxes, export crates with customer label and barcode integration

What You Can Provide to Start Your Custom Order:

To deliver the perfect-fit solution, we welcome the following details from your engineering or procurement team:

- Technical Drawing or Sample – Precise specs help us match threads and dimensions

- Working Pressure & Burst Pressure – Determines material and wall thickness

- Operating Environment – Exposure to dust, moisture, chemicals, or extreme temperatures

- Fluid Type – Helps select seal material and corrosion protection

- Installation Space & Routing Limits – We’ll design fittings to avoid interference or clearance issues

Whether you’re dealing with a legacy system requiring obsolete threads or building a next-gen mining rig with cutting-edge fluid systems, Topa’s technical team is ready to create a fully customized fitting that meets your requirements—fast, precisely, and affordably.

Advantage of Mining Hose Fitting

High Pressure Resistance

- Handles continuous working pressures up to 600 bar and beyond

- Designed for compatibility with SAE 100R15, 4SP, 4SH, and other high-pressure hoses

- Built with a standard 4:1 safety factor to prevent blowouts or failures under surge pressure

Superior Abrasion Resistance

- Optional surface treatments include phosphate coating, zinc-nickel plating, and electroplating

- Rugged fitting structure performs well in dusty, sand-filled environments

- Enhanced sealing surface design minimizes wear from vibration and movement

Impact & Vibration Resistance

- Reinforced structure and threads designed for heavy-duty machine operations

- Manufactured from high-strength carbon steel or stainless steel for extended service life

- Maintains sealing integrity under high-frequency impacts and vibration

Versatile Thread & Connection Options

- Available in BSP, NPT, JIC, ORFS, Metric, and Flange thread types

- Both standard and non-standard (custom) designs are supported to match global mining equipment

- Easy to install and replace, minimizing downtime during field maintenance

Corrosion Protection

- Material options include stainless steel, nickel plating, or customized anti-rust coatings

- Performs reliably in humid, acidic, and salt-laden environments, such as underground mines or open-pit sites

- Extended lifespan reduces maintenance frequency and long-term costs

Heavy-Duty Application Ready

- Purpose-built for large-scale mining equipment including drilling rigs, excavators, and hydraulic supports

- Designed for 24/7 operation in demanding systems

- Compatible with extreme temperatures, corrosive fluids, and other harsh media

Topa Services

Fast Quotation Turnaround

Receive accurate pricing and technical quotes within 12–24 hours, helping you speed up procurement decisions.

OEM & Custom Manufacturing

We support full customization: threads, dimensions, materials, coatings, logos, and packaging—tailored to your drawings or samples.

Rapid Prototyping

Need samples fast? We provide prototype fittings for validation and testing before bulk production.

Strict Quality Control

100% inspection for threads, sealing surfaces, and pressure resistance. ISO-compliant processes ensure reliable quality every time.

Flexible Packaging & Labeling

Export-grade packaging with options like custom logos, part numbers, barcodes, and box printing.

Technical Support & Drawing Assistance

Our engineers help you confirm dimensions, threads, and fitting compatibility.

Logistics & Shipping Support

We offer FOB, CIF, DDP terms, and work with trusted carriers for sea, air, and express deliveries worldwide.

After-Sales Guarantee

Responsive after-sales service with problem-solving focus. We support replacements and technical troubleshooting.

Your Reliable Mining Hose Fittings Manufacturer

At Topa, we specialize in providing top-quality mining hose fittings designed to withstand the toughest conditions in the mining industry. With years of expertise in manufacturing and supplying durable hydraulic components, we understand the critical importance of reliability, safety, and performance in mining operations. Our fittings are engineered to handle high pressures, extreme temperatures, and harsh environments, ensuring your equipment runs smoothly and efficiently without compromising safety.

We take pride in our commitment to innovation and precision. Topa’s mining hose fittings are made from premium materials that guarantee long-lasting durability, even in challenging conditions such as heavy vibrations, abrasive materials, and exposure to chemicals. Whether you need quick couplings, hydraulic hoses, or any other type of hose fitting, we provide a comprehensive range of products tailored to meet the specific needs of your mining equipment.

Customer satisfaction is at the core of everything we do. Our experienced team is dedicated to offering personalized support, from helping you select the right fittings to providing expert advice on installation and maintenance. At Topa, we prioritize delivering products that meet international standards, ensuring your systems remain reliable and efficient. Choose us as your trusted partner, and experience the difference of working with a manufacturer who is focused on your success.

FAQ

What material are your mining hose fittings made from?

We use high-strength carbon steel and stainless steel, depending on pressure and corrosion requirements.

What sizes are available for mining hose fittings?

Sizes range from 1/4″ to 2″, with custom dimensions available upon request.

What is the maximum working pressure?

Our mining hose fittings support up to 600 bar (8700 psi), depending on the model and hose type.

Which hose types do these fittings support?

They are compatible with SAE 100R15, 4SP, 4SH, R12, and other spiral and braided hoses.

What thread types are available?

We offer BSP, NPT, JIC, ORFS, Metric, UNF, and flange types for global compatibility.

Do you offer one-piece and two-piece designs?

Yes, both one-piece crimp fittings and two-piece configurations are available.

Are the fittings reusable?

No, crimp fittings are designed for permanent installation and should not be reused.

What surface treatments are offered?

Zinc plating, phosphate coating, trivalent chrome, and zinc-nickel plating are available for corrosion protection.

Do fittings include protective caps or plugs?

Yes, all fittings are shipped with plastic caps or plugs to protect threads and sealing surfaces.

Can your fittings be used with hydraulic fluids, water, or air?

Yes, depending on the seal and material type, fittings are compatible with hydraulic oil, water-based fluids, and compressed air.

Get More Information About Products