Product Lists

Swept adapters have emerged to meet these requirements with a unique curved design that optimizes fluid flow and reduces pressure drop. Constructed from high-strength materials such as steel, these adapters are long-lasting, durable, and meet international standards. Although they have a slightly higher initial cost, their long-term performance advantages make them a cost-effective investment. Their design makes them particularly effective in high-pressure and complex systems. In addition, their robust construction reduces long-term maintenance costs. All in all, swept hydraulic adapters are the perfect combination of quality and economy and are a valuable addition to any hydraulic system. If you need Swept hydraulic adaptors, please contact us!

45° JIC Female to Female ORFS

Elbow 45° JIC female to female ORFS Swept adapters

90° BSP Male to Male

Elbow 90° BSP male to male Swept adapters

45° BSP Female to Female

Elbow 45° BSP female to female Swept adapters

45° BSP Male to Male

Elbow 45° BSP male to male Swept adapters

90° JIC Male to Female

Elbow 90° JIC male to female Swept adapters

90° JIC Female to Female BSP

Elbow 90° JIC female to Female BSP Swept adapters

45° JIC Male to Female

Elbow 45° JIC male to Female Swept adapters

95° JIC Female to Female Metric

Elbow 95° JIC female to Female metric Swept adapters

Swept Adapters Feature

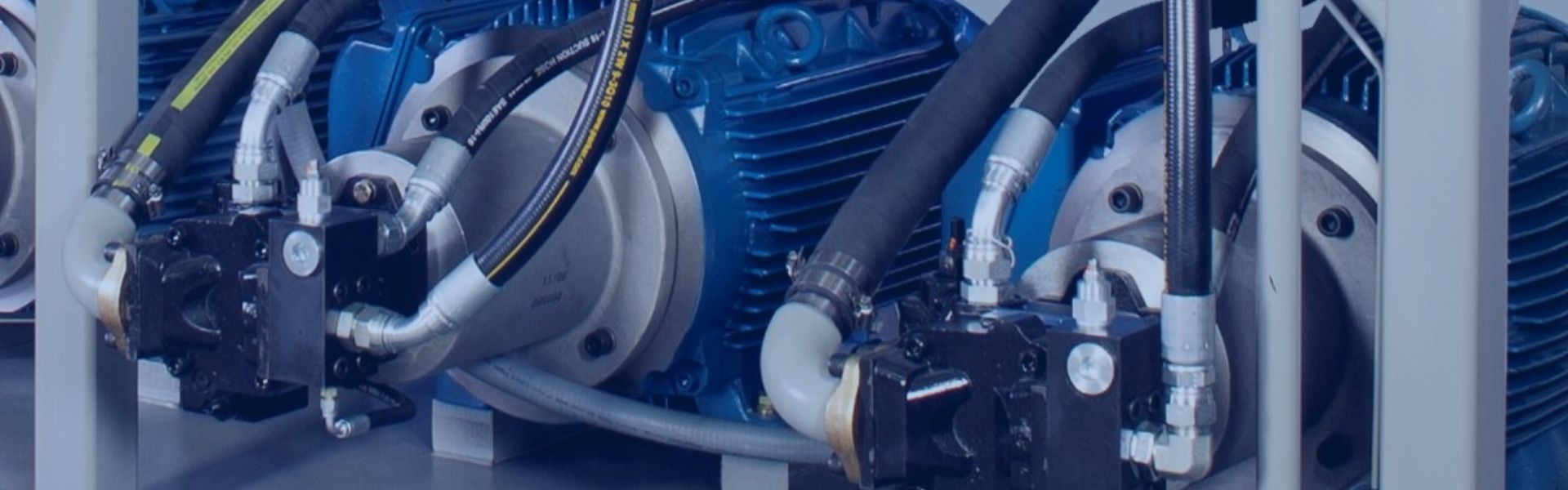

When it comes to hydraulic systems, efficiency, and reliability are of paramount importance. Swept adaptors have emerged as game-changers in the hydraulic components sector, playing a vital role in maximizing performance. Here’s a deep dive into the various facets of swept connectors for professionals like you who demand both quality and affordability.

Design & Construction

Swept adapters feature a curved design as opposed to the traditional straight or 90-degree angle adapters. This unique geometry facilitates smoother flow paths for hydraulic fluid, reducing pressure drops and enhancing the overall efficiency of the system.

Material & Manufacturing

Typically made of high-strength steel or stainless steel, swept adapters are designed for high-pressure applications. Manufactured under strict quality controls, these components meet international standards to ensure durability and longevity. This feature is particularly valuable for our clients, who often face the challenge of sourcing reliable and high-quality components.

Performance Advantages

Reduced Pressure Drops: The curved design minimizes turbulence, ensuring a smooth flow of hydraulic fluid.

Optimized Efficiency: Lower pressure drops mean your hydraulic system can operate more efficiently, saving both time and money.

Enhanced Durability: High-quality materials and superior design make swept adapters robust enough for challenging industrial environments.

Cost-Efficiency

While they might be priced slightly higher than standard adapters, the long-term benefits such as reduced maintenance costs and enhanced system performance make them a highly cost-effective choice. And let’s not forget the impact on the system’s life span!

Video

Applications

High-Pressure Systems

The robust design and high-quality materials used in swept fittings make them particularly effective for high-pressure systems. Their curved design allows fluid to flow smoothly even at high velocities, ensuring the system performs optimally. This is a crucial advantage when the system operates in environments requiring quick and powerful hydraulic actions, such as in heavy machinery or high-capacity lifting devices.

Complex Systems

In hydraulic circuits where space is at a premium and system complexity is high, the efficiency of each component can significantly impact the system’s overall performance. Swept couplings, with their optimized flow path, are excellent for these scenarios. They can be easily fitted into tighter spaces and corners, thereby reducing the need for additional fittings or longer hoses. This design feature not only saves space but also minimizes potential leak points in your system.

Maintenance & Care

The durability of swept adapters means they don’t just perform well—they last. Unlike standard adapters that might wear out or fail under challenging conditions, swept fitting adapters are built for longevity. Thanks to the robust construction, maintenance requirements for swept adapters are generally lower. This is especially beneficial for maintenance professionals who aim to keep operational downtime to a minimum.

Why Choose Topa

When it comes to hydraulic systems, choosing the right components can make the difference between optimum performance and the constant headache of maintaining your system. At Topa, we’ve built a reputation for providing quality hydraulic components, such as hydraulic swept adapters, that meet the exacting requirements of hydraulic industry professionals. Here’s why choosing Topa Hydraulic is a smart move for you:

Competitive pricing

We pride ourselves on being a direct sales factory. We are able to offer competitive prices without compromising on quality, so you get your money’s worth. With Topa, you don’t have to choose between affordability and high performance – you can have both.

International Standards, Made in China

Our products are manufactured in China under strict quality control to ensure compliance with international standards in terms of durability, performance, and reliability. This is especially important for customers who face challenges in sourcing reliable components. Rest assured that our products offer a better price/performance ratio and are perfectly suited to your needs.

One-stop shop

No more traveling between different suppliers for different hydraulic needs. We offer a full range of products from hydraulic cylinders to fittings and adapters, providing you with the convenience of one-stop shopping.

Customized Solutions

We know that not all hydraulic systems are created equal. Our team of highly skilled professionals can customize solutions to meet the specific needs and challenges of your hydraulic applications.

FAQ

Q: What is a swept adaptor?

A: A swept adapter is a specialized hydraulic adapter featuring a curved design that optimizes fluid flow, reduces pressure drops, and enhances the overall efficiency of your hydraulic system.

Q: What makes the design of a swept connector unique?

A: Unlike traditional straight or 90-degree angle adapters, swept adopter fittings have a curved geometry that facilitates smoother flow paths for hydraulic fluids, leading to reduced turbulence and pressure drops.

Q: What materials are swept couplings made from?

A: Swept hydraulic adapters are generally made from high-strength steel or stainless steel to withstand high-pressure applications and offer long-lasting durability.

Q: How do swept adapters improve system performance?

A: The unique design of swept connectors minimizes turbulence, ensuring a smooth flow of hydraulic fluid. This results in optimized efficiency, allowing your system to operate more effectively while also saving both time and money.

Q: What types of hydraulic systems benefit most from swept adapters?

A: Swept adapters are particularly effective in high-pressure systems requiring high fluid velocities. They are also ideal for use in complex hydraulic circuits where space is limited, and efficient flow is crucial.

Q: Are swept adapters more expensive than standard adapters?

A: While the initial cost may be slightly higher than standard adapters, the long-term benefits such as reduced maintenance costs and enhanced system performance make swept adapters a highly cost-effective choice.

Q: How do you maintain a swept adapter?

A: Maintaining swept adapters is generally straightforward. Their robust construction means they require less frequent replacement, thereby lowering long-term operational costs.

Q: Do swept adapters corrode easily?

A: Due to the high-quality materials used in their construction, swept hydraulic adapters are less susceptible to corrosion, enhancing their durability and reducing maintenance needs.

Q: Why should I buy swept elbow adapters from Topa Hydraulic?

A: At Topa Hydraulic, we offer products that are manufactured under strict quality controls and meet international standards. Our swept elbow adapters offer an excellent cost-performance ratio and come with the added benefit of our one-stop service for all your hydraulic needs.

Q:What is MOQ of swept hydraulic adapters?

A: 100piece

Get More Information About Products