Interlock Ferrules

Interlock ferrules are used with steel wire hydrauloic hoses, such as 4SH/R13 hoses. They are made of high-quality carbon steel or stainless steel. Topa can supply all sizes and types of ferrules.

If you have any questions of interlock hose ferrules, please contact us!

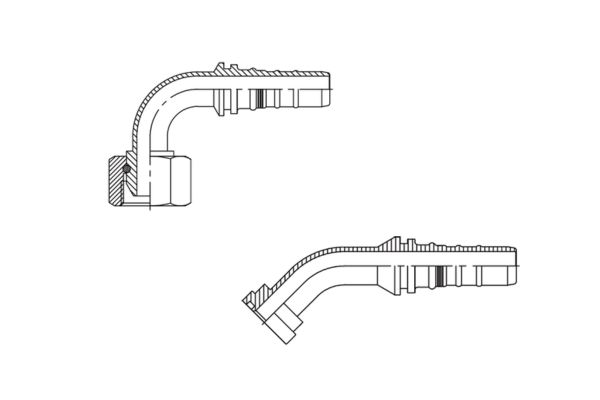

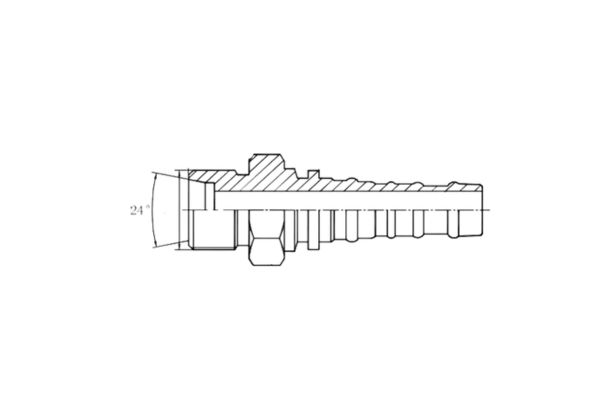

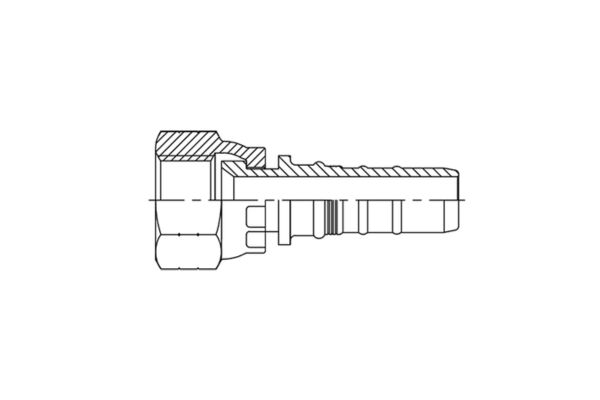

00421 Interlock Ferrule

00621 Interlock Ferrule

ORFS Interlock Ferrules Video

This video is about the details of Topa interlock hose ferrules.

Interlock ferrules are made of high-quality carbon steel, and stainless steel. Those fittings are applied with high-pressure hydraulic hoses.

Please contact with us if you have any questions about hydraulic hose ferrule or other products.

Interlock Hose Fitting Catalog

This catalog is about interlock hose fitting.

Topa can offer all kind of hydraulic interlock hose fittings, and our catalog also including all of them.

Please contact us If you need more information of hydraulic hose fittings, or would like some free samples.