Topa

Swept Adaptor Supplier in China

Product Lists

Swept adapters have emerged to meet these requirements with a unique curved design that optimizes fluid flow and reduces pressure drop. Constructed from high-strength materials such as steel, these adapters are long-lasting, durable, and meet international standards. Although they have a slightly higher initial cost, their long-term performance advantages make them a cost-effective investment. Their design makes them particularly effective in high-pressure and complex systems. In addition, their robust construction reduces long-term maintenance costs. All in all, swept hydraulic adapters are the perfect combination of quality and economy and are a valuable addition to any hydraulic system. If you need Swept hydraulic adaptors, please contact us!

45° JIC Female to Female ORFS

Elbow 45° JIC female to female ORFS Swept adapters

90° BSP Male to Male

Elbow 90° BSP male to male Swept adapters

45° BSP Female to Female

Elbow 45° BSP female to female Swept adapters

45° BSP Male to Male

Elbow 45° BSP male to male Swept adapters

90° JIC Male to Female

Elbow 90° JIC male to female Swept adapters

90° JIC Female to Female BSP

Elbow 90° JIC female to Female BSP Swept adapters

45° JIC Male to Female

Elbow 45° JIC male to Female Swept adapters

95° JIC Female to Female Metric

Elbow 95° JIC female to Female metric Swept adapters

Products Video

Our hydraulic swept adapters are built with precision to deliver smoother fluid flow, lower pressure loss, and extended system life. Every curve is designed to reduce turbulence—making them ideal for high-flow, high-pressure applications.

Manufactured from premium carbon steel and stainless steel, our swept adapters undergo rigorous inspection—including thread testing and pressure sealing checks. Whether you’re working in construction, automation, or oil & gas, you can trust Topa to provide leak-free performance and long-term reliability.

If you’re looking for custom threads, special angles, or private labeling, we’re ready to support your needs. Watch the video now, then message our team for a fast quote and global delivery options.

Applications

Heavy Machinery

Hydraulic swept adapters play a vital role in heavy-duty equipment such as excavators, bulldozers, tractors, and mining trucks. These machines operate under extreme pressure, vibration, and continuous motion—conditions where standard fittings may fail prematurely. The curved design of swept adapters minimizes pressure drop and flow disruption, ensuring consistent hydraulic power delivery to critical components like cylinders and motors.

Industrial Automation

In manufacturing environments where hydraulic circuits control automated machinery, precision and efficiency are paramount. Swept adapters offer smooth directional changes in piping layouts, helping to maintain optimal flow velocity while minimizing turbulence. This results in faster response times for hydraulic actuators, improved system reliability, and reduced energy consumption.

Oil & Gas

The oil and gas sector demands components that can withstand extreme conditions—both offshore and onshore. Hydraulic swept adapters are commonly used in drill rigs, fracturing equipment, and wellhead control systems where high flow rates, pulsating pressure, and corrosive media are common. The swept design enhances flow stability, which is critical in long hydraulic circuits often found in large installations.

Products Features

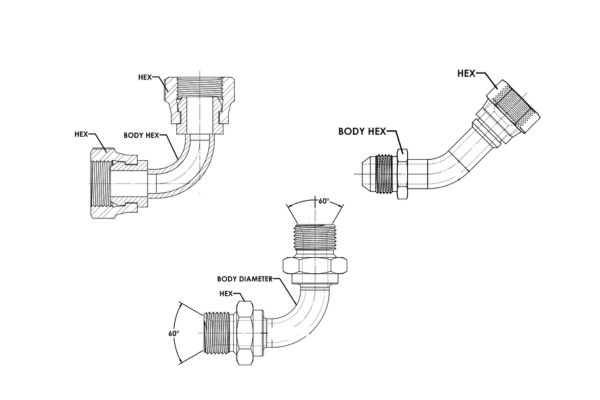

Hydraulic Swept Adapters are essential fittings used in high-pressure hydraulic systems to change fluid direction with minimal resistance. Unlike conventional elbow adapters, swept adapters feature a gradually curved design—typically in 45° or 90° bends—that significantly reduces turbulence and pressure loss. This not only improves overall flow efficiency but also extends the life of connected components by reducing internal stress caused by abrupt flow changes.

These adapters are precisely machined to deliver reliable, leak-proof connections between hoses, tubes, and system components such as valves, pumps, and cylinders. Available in a wide range of thread types—including BSP, BSPT, JIC, ORFS, NPT, Metric, UNF, and JIS—swept adapters can accommodate global system requirements with ease.

Product Details

Shape Options

- 45° and 90° bends are standard

- Some models available in 135° for special routing needs

Material

- Primarily carbon steel, offering strength and durability

- Stainless steel available for corrosive or offshore environments

Connection Types

- Male or Female threads

- Fixed or Swivel options

Available Configurations

- Male JIC

- Code 62 Flange Head

- BSP, NPT, ORFS, Metric, JIS, UNF,

Technical Design

- Purpose: Efficiently reroute hydraulic flow without sacrificing system performance Flow

- Advantage: Swept geometry minimizes backpressure and internal turbulence

Component Structure

- Precision-cut threads for secure mating

- High-integrity sealing surface for leak prevention under pressure

Manufacturing Standards

- Products typically meet or exceed J.I.C. / S.A.E. specifications

- Certified to ISO 9001, AS9100, or NADCAP for quality assurance

- Some adapters include manufacturing codes for full traceability

Swept Hydraulic Adapter VS Standard Hydraulic Adapter

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Swept Elbow Adaptors

- Gradual, curved bend design

- Minimizes internal flow resistance

- Reduces turbulence inside the hydraulic system

- Promotes more efficient fluid movement

- Results in lower pressure drop

- Ideal for high-flow applications

- Helps reduce energy loss in hydraulic circuits

- Standard Elbow Adaptors

- Sharp 90-degree angle bend

- Higher internal flow resistance

- Increased risk of turbulence

- May cause energy loss due to abrupt direction change

- More pressure drop across the fitting

- Suitable for general routing where flow efficiency is less critical

How to Customize Your Hydraulic Swept Adapter

At Topa, we understand that not every hydraulic system is built the same. That’s why we offer full customization options for swept adapters to meet your specific performance, installation, and material requirements. Whether you need non-standard threads, unique bend angles, or special coatings, we make it easy to get exactly what your project demands.

Provide Application Requirements

Provide your application scenario and parameters

- Industry/Equipment type

- Working pressure & temperature

- Media type specifications

Connection Selection

Choose your connection types and thread standards

- Thread types: BSP, NPT, JIC, etc.

- Swivel options available

- Port configurations: Male/Female

Angle & Dimensions

Define angles and sizing requirements

- Standard 45°, 90° angles

- Custom 135° available

- Thread sizes: 1/4" to 2" range

Material Selection

Select appropriate materials for your environment

- Carbon steel (zinc plated)

- Stainless steel (304, 316L)

- Special alloys: Brass, Aluminum

Special Requirements

Add custom features and finishing options

- Laser engraving/Logo marking

- Custom packaging solutions

- Surface treatments available

Production & Delivery

Technical confirmation and manufacturing

- CAD drawing approval

- Quality inspection reports

- Delivery with certifications

Why Choose Topa

When it comes to hydraulic systems, choosing the right components can make the difference between optimum performance and the constant headache of maintaining your system. At Topa, we’ve built a reputation for providing quality hydraulic components, such as hydraulic swept adapters, that meet the exacting requirements of hydraulic industry professionals. Here’s why choosing Topa Hydraulic is a smart move for you:

Competitive pricing

We pride ourselves on being a direct sales factory. We are able to offer competitive prices without compromising on quality, so you get your money’s worth. With Topa, you don’t have to choose between affordability and high performance – you can have both.

International Standards, Made in China

Our products are manufactured in China under strict quality control to ensure compliance with international standards in terms of durability, performance, and reliability. This is especially important for customers who face challenges in sourcing reliable components. Rest assured that our products offer a better price/performance ratio and are perfectly suited to your needs.

One-stop shop

No more traveling between different suppliers for different hydraulic needs. We offer a full range of products from hydraulic cylinders to fittings and adapters, providing you with the convenience of one-stop shopping.

Customized Solutions

We know that not all hydraulic systems are created equal. Our team of highly skilled professionals can customize solutions to meet the specific needs and challenges of your hydraulic applications.

Topa Services

Choosing the right hydraulic fitting supplier isn’t just about product specs—it’s about performance, reliability, and long-term support. Here’s why hundreds of buyers across the globe trust Topa for their hydraulic swept adapter needs:

Reliable Manufacturing Partnerships

Our factory equipped with CNC machining centers and strict QC systems. You get factory-direct pricing—without compromising on quality.

One-Stop Sourcing for Global Thread Standards

We support BSPP, BSPT, NPT, JIC, ORFS, Metric, UNF, Code 62, and more. Whether you're working with North American, European, or Asian systems, we deliver fittings that fit right the first time.

Fast Quotation & Technical Support

Our dedicated team responds to technical inquiries, RFQs, and drawing confirmations within 24 hours. Need a recommendation or a custom drawing? We've got you covered—fast.

Flexible Customization Options

Need a custom thread, bend angle, or private label? We handle OEM/ODM requests, laser marking, logo engraving, and special packaging for your brand or system requirement.

Global Export Experience

We ship to over 30+ countries, with customers across industries like construction, agriculture, mining, oil & gas, and manufacturing. Whether you're in the USA, Germany, UAE, or South Africa.

After-Sales Support

Our job doesn't stop after shipment. We offer fast after-sales service, technical troubleshooting, and warranty support—so you’re never left guessing.

20+

Years Experience

30+

Countries Served

10,00+

Products Delivered

500+

Customer

FAQ

What is the main difference between a swept adapter and a standard elbow fitting?

Swept adapters feature a gradual, curved bend that reduces turbulence and pressure loss, unlike standard elbow fittings that have sharp angles and can disrupt fluid flow.

What thread types are available for swept adapters?

We offer a wide range of thread types, including BSPP, BSPT, NPT, JIC, ORFS, Metric, UNF, JIS, and Code 62 flange connections.

Are these adapters available in both fixed and swivel ends?

Yes, many of our swept adapters are available with either fixed or female swivel ends for easier hose alignment during installation.

What materials are used for hydraulic swept adapters?

Our standard options include carbon steel with surface plating (zinc or zinc-nickel), stainless steel (304/316L), and brass for specific low-pressure or corrosion-resistant applications.

What is the maximum pressure these adapters can withstand?

Depending on size and material, swept adapters can handle pressures up to 6000 psi (≈420 bar) under standard hydraulic system conditions.

Can I request a non-standard angle, such as 135°?

Yes. While 45° and 90° are standard, we can manufacture custom-angle swept adapters like 135°, based on your system design or technical drawing.

Are these adapters compatible with international hydraulic systems?

Yes, our adapters comply with SAE, ISO, and DIN standards, making them compatible with most global hydraulic systems.

Do you offer private labeling or laser marking for branding?

Absolutely. We can laser engrave your logo, part number, or batch code on the adapter body and offer custom packaging to match your brand.

Can hydraulic swept adapters be used in both mobile and stationary systems?

Yes. Swept adapters are suitable for both mobile equipment (such as excavators and tractors) and stationary hydraulic systems (like industrial presses or marine platforms).

What surface treatments are available for corrosion protection?

We offer electroplated zinc, zinc-nickel alloy, phosphate coating, and stainless steel (304/316L) to suit various corrosion protection needs.

Get More Information About Products