British Standard Pipe (BSP) threads are a cornerstone of many industrial applications, playing a critical role in ensuring secure and leak-proof connections in a variety of systems. Originating in Britain, BSP threads have become a globally recognized standard, particularly in industries such as plumbing, gas, and hydraulics. Their design allows for tight, reliable seals, which are essential for maintaining the integrity and efficiency of piping and fitting assemblies. For professionals involved in these fields, a thorough understanding of BSP threads is not just beneficial but necessary. This knowledge ensures that installations are performed correctly, maintenance is effectively managed, and system failures are minimized.

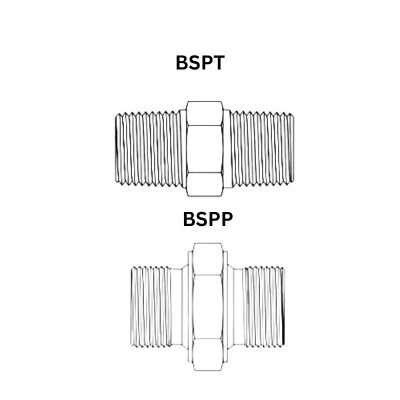

BSPP threads, also known as G threads, are parallel threads, meaning they maintain a constant diameter along their entire length. This design necessitates the use of a sealing washer or O-ring to create a leak-proof connection. The threads themselves do not provide the seal; instead, the seal is achieved through the compression of the washer or O-ring when the fitting is tightened.

BSPT threads, also known as R threads, are tapered threads. This means the diameter of the thread decreases along its length, creating a conical shape. The tapering of the threads facilitates a tighter and more secure fit as the male and female threads are screwed together, deforming slightly to create a seal. This self-sealing property of BSPT threads eliminates the need for additional sealing components, relying instead on thread deformation to achieve a leak-proof connection.

The primary difference between BSPP and BSPT threads lies in their shape: BSPP threads are parallel, maintaining a constant diameter, while BSPT threads are tapered, with the diameter decreasing along the length of the thread. This distinction influences how each type of thread achieves a seal. BSPP threads require additional sealing components such as washers or O-rings, whereas BSPT threads rely on the deformation of the threads themselves to create a seal.

Specific Use Cases:

BSPP: Ideal for low-pressure applications and situations where easy disassembly is required. Examples include hydraulic systems with frequent maintenance needs and pneumatic systems where precise alignment is critical.

BSPT: Preferred for high-pressure applications where a more secure seal is necessary. Examples include gas pipelines, high-pressure hydraulic systems, and other applications where the risk of leaks must be minimized and the connection must withstand significant pressure variations.

BSP threads are governed by several key standards that ensure compatibility and reliability across various applications and industries.

BS 21:

BS 21 is the original British Standard for pipe threads, providing the foundational specifications for BSP threads. This standard encompasses both parallel and taper threads used in pipework and fittings. It ensures that threaded components are compatible and can form pressure-tight joints when needed.

ISO 228:

ISO 228 is an international standard that specifies the requirements for pipe threads where pressure-tight joints are not made on the threads. This standard applies primarily to BSPP (British Standard Pipe Parallel) threads. The focus here is on ensuring that threads maintain consistent dimensions and profiles, allowing for the use of sealing washers or O-rings to achieve a pressure-tight connection.

ISO 7:

ISO 7 outlines the specifications for pipe threads where pressure-tight joints are made on the threads themselves. This standard applies to BSPT (British Standard Pipe Taper) threads, which are designed to deform slightly when tightened to create a secure, leak-proof seal. ISO 7 ensures that the taper angle and thread profiles are consistent, providing reliable performance in high-pressure applications.

BSPP:

Defined by ISO 228: BSPP threads are parallel, maintaining a constant diameter along their length.

Thread Profile: The threads are designed with a 55-degree angle, consistent with the Whitworth thread form.

Sizes: BSPP thread sizes range from 1/16 inch to 6 inches, catering to a wide variety of applications in hydraulic, pneumatic, and plumbing systems.

BSPT:

Defined by ISO 7: BSPT threads are tapered, featuring a diameter that decreases along the length of the thread.

Taper Angle: The threads have a taper angle of 1:16, which helps in creating a tight seal as the threads are tightened.

Sizes: BSPT thread sizes also range from 1/16 inch to 6 inches, suitable for high-pressure applications such as gas pipelines and high-pressure hydraulic systems.

Identifying BSP threads involves understanding their distinctive characteristics. BSP threads, whether BSPP (British Standard Pipe Parallel) or BSPT (British Standard Pipe Taper), feature a Whitworth thread profile, which is defined by a 55-degree thread angle. This unique profile sets BSP threads apart from other thread types, such as NPT (National Pipe Thread), which have a 60-degree thread angle.

BSPP Threads: These are parallel threads, meaning they maintain a constant diameter along their entire length. This characteristic makes them easy to identify visually as they do not taper and appear uniform from end to end.

BSPT Threads: These are tapered threads, where the diameter decreases along the length of the thread. When examining a BSPT thread, you’ll notice the tapering effect, which causes the thread to appear conical rather than cylindrical.

Accurate identification often requires precise measurement tools:

Thread Gauge: A thread gauge is an essential tool for measuring the pitch of the threads. By matching the threads against the gauge, you can determine the number of threads per inch or the thread pitch in millimeters.

Calipers: These are used to measure both the outer diameter (OD) and inner diameter (ID) of the threads. For BSPP threads, the OD should be consistent along the length, whereas, for BSPT threads, the OD will decrease from one end to the other.

To measure:

Use the calipers to measure the OD at several points along the thread length. Consistency in measurement indicates BSPP, while a decrease in diameter suggests BSPT.

Use the thread gauge to check the thread pitch. Ensure the gauge fits snugly into the threads for an accurate reading.

Once the fittings are hand-tightened and properly aligned, use a wrench to tighten them further. Adjustable wrenches or pipe wrenches are suitable for this task. Be cautious not to over-tighten the fittings, as this can damage the threads and cause leaks. Tighten the fittings until they feel secure and snug. If you feel resistance indicating the threads are fully engaged, stop tightening to avoid damaging the fittings.

Thread markings and labels provide valuable information about the type and size of the thread. Typically, these markings include:

Thread Type: Indicated by letters such as “G” for BSPP threads and “R” for BSPT threads.

Thread Size: Usually noted after the thread type (e.g., G1/2, R3/4), indicating the nominal bore size of the pipe.

To ensure accurate identification:

Compare the markings with standard designations. For example, “G1/2” indicates a BSPP thread with a nominal bore of 1/2 inch, while “R3/4” indicates a BSPT thread with a nominal bore of 3/4 inch.

Confirm that the thread dimensions match the markings by measuring the pitch and diameter using the tools mentioned.

NPT Threads:

Tapered with a 60-degree thread angle: NPT threads are designed with a taper and a 60-degree thread angle. The taper ensures that as the threads are tightened, they deform slightly to create a tight, leak-proof seal.

Primarily used in North America: NPT threads are widely adopted in the United States and Canada, serving as the standard for plumbing and pipe fittings in these regions.

Comparison:

Thread Angle and Pitch:

BSPT threads: These have a 55-degree thread angle and a unique pitch that differs from NPT threads. The slight difference in thread angle and pitch means BSPT and NPT threads are not interchangeable.

BSPP threads: These are parallel threads, maintaining a constant diameter along their length, unlike the tapered NPT threads. This fundamental difference in design affects how each type achieves a seal and their respective applications.

Usage and Compatibility:

BSPT vs NPT: While both BSPT and NPT threads are tapered and designed to form a seal through thread deformation, the different angles and pitches make them incompatible without specialized adapters.

BSPP: These threads require additional sealing components, such as O-rings or washers, unlike NPT threads, which rely on the thread taper to achieve sealing.

Metric Threads:

Defined by ISO 261 with a 60-degree thread angle: Metric threads follow the ISO 261 standard and feature a 60-degree thread angle. They are widely used in European machinery and manufacturing due to their standardized nature.

Commonly used in European machinery: Metric threads are the go-to choice for various applications across Europe, especially in the automotive and mechanical engineering sectors.

Comparison:

Thread Angle and Form:

BSP Threads: BSP threads have a 55-degree angle, differing from the 60-degree angle of metric threads. Additionally, the thread form of BSP threads is distinct, characterized by the Whitworth profile.

Sizing:

Metric Threads: These use the nominal outer diameter (OD) for sizing, providing a direct measurement of the thread’s external diameter.

BSP Threads: These use the nominal bore, which refers to the internal diameter of the pipe, not the thread’s outer diameter. This difference in sizing methodology can lead to confusion if not properly understood.

Proper installation of BSP threads is crucial for ensuring leak-free and reliable connections. Here are some best practices:

Ensure Clean and Undamaged Threads: Before starting the installation, inspect the threads for any dirt, debris, or damage. Clean the threads using a brush or cloth to remove any contaminants. Damaged threads should be repaired or replaced to prevent leaks and ensure a secure connection.

Use Appropriate Sealing Components for BSPP Threads: BSPP threads require sealing components like washers or O-rings to achieve a leak-proof connection. Ensure that these components are in good condition and compatible with the fluids being used in the system.

Having the right tools and equipment is essential for the proper installation of BSP threads:

Wrenches: Adjustable wrenches or spanners are needed to tighten the fittings.

Thread Gauges: These are used to measure the thread pitch and ensure compatibility with other components.

Calipers: Useful for measuring the outer and inner diameters of the threads.

Sealant Tapes: PTFE (Polytetrafluoroethylene) tape or similar thread sealants are used for enhancing the sealing of BSPT threads.

Thread Sealant: For BSPT threads, applying thread sealant can help ensure a tight and leak-free seal. Choose a sealant that is compatible with the system’s fluids.

To achieve a reliable and leak-free connection, follow these tips:

Tighten Threads to Manufacturer Specifications: Over-tightening can damage the threads or sealing components while under-tightening can result in leaks. Always follow the manufacturer’s torque specifications to ensure optimal tightness.

Use Thread Sealants Appropriately: For BSPT threads, apply an appropriate amount of thread sealant or PTFE tape. Wrap the tape in the direction of the threads to prevent it from unraveling during assembly.

Regular maintenance is vital for the longevity and reliability of BSP threaded connections:

Regularly Inspect Connections: Periodically check the connections for signs of wear, corrosion, or damage. Look for any leaks or signs of fluid seepage.

Replace Worn-Out Sealing Components: Washers, O-rings, and other sealing components can degrade over time. Replace them promptly to maintain the integrity of the connection.

Check for Leaks and Retighten or Reseal as Necessary: If leaks are detected, identify the source and address it immediately. Retighten the connections to the specified torque or reapply the thread sealant if necessary.

By following these best practices and maintenance tips, you can ensure that BSP threaded connections remain secure, leak-free, and reliable throughout their service life. Proper installation and regular maintenance not only enhance the performance of the system but also prevent costly downtimes and repairs.

In summary, BSP threads are a vital component in various industrial applications, offering reliable and standardized pipe connections. Understanding the differences between BSPP and BSPT, recognizing the relevant standards, and knowing how to identify and install these threads are essential skills for professionals in the field. For further reading and exploration, consult additional resources and industry standards to deepen your knowledge and expertise.

BSP stands for British Standard Pipe. It refers to a family of standard screw threads used internationally for interconnecting and sealing pipes and fittings.

BSPP threads are parallel and require sealing components like washers or O-rings, while BSPT threads are tapered and achieve sealing through thread deformation.

BSPP and BSPT threads are not typically used together due to their different sealing mechanisms. BSPP threads require a sealing component, whereas BSPT threads rely on the taper for sealing.

BSP threads have a 55-degree Whitworth profile. BSPP threads maintain a constant diameter along their length, while BSPT threads taper. Thread markings, such as “G” for BSPP and “R” for BSPT, and measurements with thread gauges can also help in identification.

BSP threads are not compatible with NPT (National Pipe Thread) threads due to differences in thread angle (55 degrees for BSP, 60 degrees for NPT) and pitch. Special adapters are required to connect BSP and NPT threads.

Essential tools for installing BSP threads include adjustable wrenches or spanners, thread gauges, calipers, PTFE tape or thread sealant (for BSPT threads), and sealing components like washers or O-rings (for BSPP threads).