Hydraulic Cylinder Manufacturer

※ Easy to install

※ Cost reduction

※ Saves energy

※ Fast response

Product List

At Topa, we offer a comprehensive range of high-quality hydraulic cylinders designed to meet the demands of diverse industries. Our product range includes both standard and custom hydraulic cylinders, each engineered with premium materials and advanced technology to ensure long-lasting, efficient operation. With competitive pricing, timely delivery, and expert support, we’re here to help you achieve optimal performance for your operations. Get in touch now to place your order and experience the Topa difference!

Welded Hydraulic Cylinder

Welded hydraulic cylinder, the barrel is welded directly to the end caps and the ports are welded to the barrel.

Double Acting hHydraulic Cylinder

A double-acting hydraulic cylinder (Hydraulic stamp) has two piston surfaces, where hydraulic fluid can be applied bilaterally.

Single Acting Cylinder

A single-acting cylinder in a reciprocating engine is a cylinder in which the working fluid acts on one side of the piston only.

Hydraulic Llift Cylinder

Hydraulic Lifting Cylinders provide a controllable hydraulic lifting solution for heavy loads up to 100 Tonnes and even combined in some applications with accessories.

Hoist Cylinders

A hydraulic Hoist cylinder is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke.

Hand Pump Hydraulic Cylinder

Hand pump hydraulic cylinder Hand-operated hydraulic pumps convert mechanical energy into hydraulic energy (a combination of pressure and flow) by delivering hydraulic fluid under pressure through directly applied manual effort.

Forklift Hydraulic Cylinder

Forklift Hydraulic cylinder: Power Steering Cylinder. The power steering cylinder is a double-acting cylinder that is able to exert equal force in opposite directions.

Excavator Hydraulic Cylinder

Excavator hydraulic cylinder, engine hydraulic boom cylinder arm double acting for excavator.

Mini Hydraulic Cylinder

Mini hydraulic cylinder, small hydraulic cylinder.

Stainless Steel Hydraulic Cylinder

Stainless steel hydraulic cylinder, made of stainless steel, corrosion resistant.

Car Lift Hydraulic Cylinder

Car lift hydraulic cylinder, suitable for car lifing system.

Tractor Hydraulic Cylinder

Tractor hydraulic cylinder, hydraulic cylinder replacement for tractors.

Honed Tube

The honing process involves using abrasive polishing stones and abrasive paper to remove small amounts of material, to produce extremely precise ID dimensions and improved finishes.

Hydraulic Cylinder Seals

Hydraulic cylinder seals are used on hydraulic cylinders to prevent hydraulic fluid from leaking and help keep dirt and other contaminants from entering the cylinders.

Products Video

At Topa, we believe in full transparency, and we want you to see the care and precision that goes into each hydraulic cylinder we produce. Our exclusive video takes you behind the scenes to show the advanced manufacturing process we follow to create durable and reliable hydraulic cylinders.

From material selection to precision machining, every step in the production process is critical to ensuring the highest quality. Watch how we craft each cylinder with meticulous attention to detail, using state-of-the-art technology to deliver a product that meets your exact specifications.

Curious to see the process in action? Click the video below to discover how Topa’s hydraulic cylinders are made and how we can deliver solutions that meet your needs. Don’t miss out on seeing our commitment to quality—watch now!

Application

Topa’s hydraulic cylinders have many applications in cranes, truck handling, construction, mining, and aerial work, such as truck cranes, fire fighting equipment, aerial work platforms, concrete pump trucks, etc.

Construction Equipment

Hydraulic cylinders are widely used in construction machinery, such as excavators, cranes, bulldozers, and loaders. These cylinders are essential for controlling the movement of the machine’s arms, booms, and buckets. They provide the power needed for lifting, digging, and carrying heavy loads.

Agricultural Machinery

In agriculture, hydraulic cylinders are used in various equipment like tractors, harvesters, plows, and sprayers. These cylinders help with tasks such as lifting and lowering implements, adjusting angles of attachments, or steering systems.

Material Handling Systems

Hydraulic cylinders are crucial in material handling equipment, such as forklifts, lift tables, and conveyors. In forklifts, hydraulic cylinders are responsible for raising and lowering the fork to move heavy materials, while in lift tables, they assist in elevating loads to different working heights.

Industrial Automation

In industrial automation, hydraulic cylinders are used in machinery like robotic arms, presses, and molding machines. They provide precise motion control for various automated processes. These cylinders offer high force and speed control, which are critical for ensuring the accuracy and efficiency of automated manufacturing operations.

Ready to Optimize Your System with Topa Hydraulic Cylinders?

Contact us today to discuss your needs and get a customized solution that fits your requirements. Get in touch now!

Hydraulic Cylinder Features

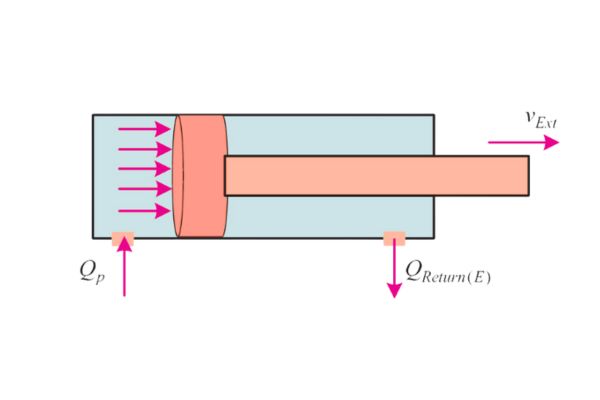

Working Principle

The basic working principle of a hydraulic cylinder is that it utilizes hydraulic fluid pressure to drive the piston in a reciprocating motion, thus providing linear force output. The structure of a hydraulic cylinder primarily consists of the cylinder tube, piston, piston rod, seals, and end caps.

Thrust and Retraction: Hydraulic cylinders can generate either thrust or retraction based on fluid pressure. The direction of thrust is generated when hydraulic fluid enters one side of the cylinder tube, causing the piston to move. Reverse pressure can drive the piston rod to extend or retract.

Single-Acting vs. Double-Acting Hydraulic Cylinders: A single-acting hydraulic cylinder can only generate movement in one direction, powered by fluid pressure applied to a single side of the piston. In contrast, a double-acting hydraulic cylinder allows fluid pressure to operate in two directions, offering more versatility in its functions, allowing it to generate force in both directions.

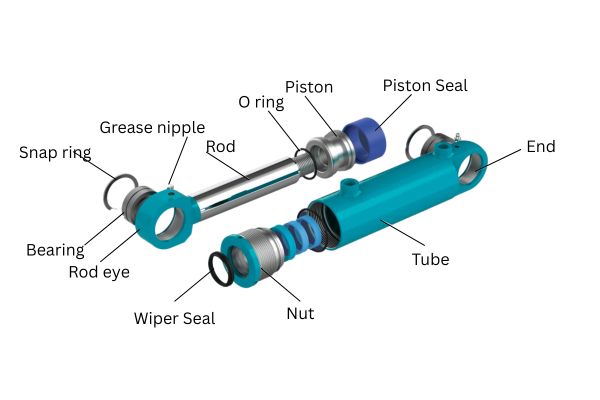

Construction & Components

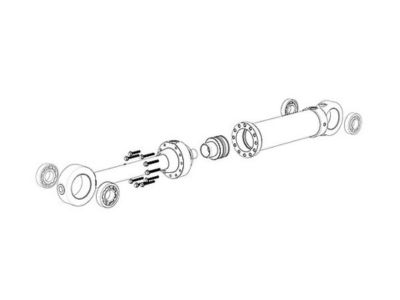

Cylinder Tube: The main body of the hydraulic cylinder is typically made of high-strength steel, providing excellent pressure resistance. The internal surface of the cylinder tube must be precisely finished to ensure smooth movement of the piston and reduce wear.

Piston: The piston divides the cylinder into two chambers and converts hydraulic energy into mechanical energy. The surface of the piston is specially treated to reduce wear and enhance sealing properties.

Piston Rod: The piston rod connects the piston to external mechanical systems, such as actuators, machinery, or other hydraulic devices.

Seals: Seals are vital components that prevent hydraulic fluid from leaking out and help maintain the internal pressure of the cylinder. Common seals include O-rings and V-rings.

End Caps & Piston Rings: The end caps are used to seal both ends of the hydraulic cylinder, ensuring that hydraulic fluid remains contained within the cylinder.

Performance Features

Working Pressure: The working pressure of a hydraulic cylinder determines its load-bearing capacity and range of applications. Common working pressures are 700 PSI, 2000 PSI, 5000 PSI, and higher, depending on the hydraulic system design.

Temperature Range: Hydraulic cylinders typically operate within a temperature range of -40°C to +100°C. However, special designs can extend the operational temperature range for use in extreme conditions.

Stroke Speed: The speed of the piston’s stroke is controlled by the fluid flow rate and pressure within the hydraulic system. Stroke speed can vary from several meters per minute to tens of meters per minute, depending on the application requirements. The flow rate and pressure adjustments directly impact the speed of movement, which is crucial for optimizing machine efficiency and response time.

Materials & Surface Treatment

Material Selection: The primary materials used for hydraulic cylinders include high-strength alloy steel, stainless steel, and cast iron. Alloy steel is the most commonly used material because of its excellent compressive strength and resistance to wear and tear. Stainless steel is used for environments requiring additional corrosion resistance, while cast iron is employed for low to medium-pressure applications.

Surface Treatment: To enhance corrosion resistance and wear resistance, hydraulic cylinders are typically treated with coatings such as chrome plating, nickel plating, or spray coatings. Chrome plating, in particular, helps reduce friction and wear on the piston rod, significantly extending its operational life.

Corrosion Protection: For extreme environments such as offshore platforms or chemical plants, hydraulic cylinders are often coated or made from materials with additional corrosion resistance. These coatings help prevent degradation from exposure to saltwater, chemicals, and other corrosive substances, ensuring long-term reliability in harsh operating conditions.

Customized Hydraulic Cylinders: Tailored to Your Specific Needs

At Topa, we specialize in providing customized hydraulic cylinders that meet the unique requirements of your specific applications. Our team of experts is dedicated to offering solutions that are precisely engineered for optimal performance, durability, and efficiency. Whether you’re in agriculture, construction, or any other industry requiring hydraulic systems, we ensure our products meet your exact specifications.

Customized Sizes and Dimensions

We can produce hydraulic cylinders in a variety of sizes to fit your machinery or system requirements, ensuring the best fit for your operations.

Material Selection

Choose from a wide range of materials, including high-strength alloy steels, stainless steel, and corrosion-resistant materials, to meet specific durability and environmental conditions.

Pressure and Load Ratings

Our cylinders can be designed to handle different pressure levels and load capacities, from light-duty applications to high-pressure, heavy-duty industrial uses.

Stroke Length and Speed

We can customize the stroke length and movement speed based on the needs of your machinery, ensuring smooth operation in any environment.

Sealing and Leak-Proof Systems

Select from a variety of sealing systems designed for different pressures, temperatures, and fluid types to ensure zero leakage and optimal performance.

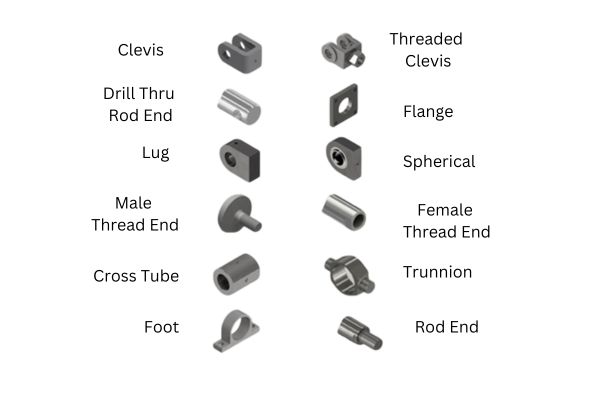

End Cap and Mounting Options

We provide different mounting styles and end cap configurations to ensure easy integration with your system.

How to Customize Your Hydraulic Cylinder with Topa

Understand Your Requirements

Clearly define the operational needs of your hydraulic system: pressure, stroke length, mounting styles, and any special features you may require (e.g., corrosion resistance or non-standard sizes).

Consult with Our Experts

Contact us directly through email at info@cntopa.com or via phone to discuss your specific requirements with our experienced engineers. Our team will guide you in determining the most suitable materials, pressure ratings, and design features.

Provide Technical Details

Share the technical drawings, diagrams, or sketches of your hydraulic system, including dimensions, pressure specifications, and any custom features you would like.

Receive a Custom Quote

Based on your specifications, we will provide you with a detailed quote that includes pricing, production time, and delivery schedules. Our pricing is competitive, ensuring you get the best value for your investment.

Approve the Design

Once you approve the design, we will begin manufacturing the custom hydraulic cylinders in our advanced production facilities.

Fast Production and Delivery

We offer fast production and reliable shipping to ensure your customized hydraulic cylinders reach you on time and are ready for installation.

Avoid Common Pitfalls

Standardization vs. Customization Conflict

Pain Point: Customers often face difficulty deciding between standardized products, which are cost-effective but may not fully meet specific requirements, and custom-made products, which perfectly fit their needs but come with higher costs and longer lead times.

Topa’s Solution: We offer a balanced approach by providing flexible customization options at competitive prices. Our efficient production process allows for faster turnaround times for customized products, and we work closely with customers to find the most cost-effective solution without compromising on performance.

Technical Parameter Matching Issues

Pain Point: Customers struggle to select hydraulic cylinders with the right dimensions, stroke length, and thread types. A mismatch can lead to installation issues, reduced performance, or even system failure.

Topa’s Solution: Our experienced technical team assists customers in accurately selecting the correct specifications based on their equipment and operational needs. We provide detailed technical documentation, ensuring that customers choose the perfect hydraulic cylinder for their system, avoiding costly mistakes.

Durability and Reliability Concerns

Pain Point: Hydraulic cylinders often work under high pressure and frequent movement, causing concern over their lifespan, seal performance, and the risk of leakage, which can lead to system failures and maintenance downtime.

Topa’s Solution: We use premium materials and implement stringent quality control to ensure that every hydraulic cylinder is durable and reliable. Our cylinders undergo extensive testing to ensure they meet the highest standards, and we offer extended warranties to reassure customers of long-lasting performance.

Delivery and Lead Time Uncertainty

Pain Point: Delays in delivery, especially for customized hydraulic cylinders, can disrupt customers’ production schedules, causing delays in entire projects and increasing costs.

Topa’s Solution: We prioritize on-time delivery with predictable lead times for both standard and customized cylinders. With multiple production lines and optimized supply chain management, we ensure timely delivery, even for large or customized orders. Additionally, we offer real-time order tracking for transparency.

Looking for Reliable Hydraulic Cylinders?

Don’t settle for less. Explore our range of high-performance hydraulic cylinders and experience top-quality craftsmanship. Request a quote today!

Your Reliable Hydraulic Cylinder Supplier

At Topa, we pride ourselves on producing high-quality hydraulic cylinders that offer exceptional performance across a wide range of applications. Our cylinders are engineered to adapt to a variety of environmental conditions, ensuring they can handle even the most demanding environments with ease.

Whether you’re operating in extreme temperatures, corrosive atmospheres, or high-pressure systems, our hydraulic cylinders are designed to perform reliably. With flexible designs that allow for easy handling and movement, they are perfect for applications in tight spaces, ensuring maximum efficiency without compromising on power.

Our hydraulic cylinders are more than just powerful—they’re designed to optimize energy usage, utilizing physical principles to deliver significant energy savings. Built for heavy-duty systems, they are robust enough to handle the toughest jobs, ensuring long-lasting performance and durability. No matter your application, Topa hydraulic cylinders are the trusted solution for reliable and efficient operation.

Why Choose Topa for Your Hydraulic Cylinder Needs?

At Topa, we understand that selecting the right hydraulic cylinders is critical to your business’s success. That’s why we stand out in the industry with a commitment to delivering high-quality products, exceptional customer service, and tailored solutions that meet your unique needs. Here’s why you should choose us:

Custom Solutions for Every Need

We offer customized hydraulic cylinders to fit your specific applications. Whether it’s a unique size, pressure rating, or material requirement, we have the flexibility to provide exactly what you need, with a quick turnaround time and at competitive prices.

Durable and Reliable Products

Our hydraulic cylinders are built to last, and designed using high-quality materials and precision manufacturing techniques. We rigorously test every cylinder to ensure they meet the highest performance standards, so you can rely on them for long-lasting and efficient operation.

On-Time Delivery

We understand the importance of timely delivery to your operations. With our optimized production processes and strong logistics network, we ensure on-time delivery for both standard and custom hydraulic cylinders, helping you keep your projects on track.

Comprehensive Support and Service

From pre-sales consultation to after-sales support, we are committed to helping you every step of the way. Our technical team is always available to provide expert guidance on selection, installation, and maintenance, ensuring your hydraulic systems perform optimally.

Competitive Pricing

We offer affordable solutions without compromising on quality. Our transparent pricing ensures you get the best value for your investment, and with our flexible customization options, we cater to various budgets and needs.

FAQ

What is a hydraulic cylinder?

A hydraulic cylinder is a mechanical actuator that uses hydraulic fluid to create linear motion and force. It is used in various applications to move heavy loads in industrial and machinery systems.

How does a hydraulic cylinder work?

Hydraulic cylinders work by converting hydraulic energy (fluid pressure) into mechanical force. The fluid enters the cylinder and pushes against the piston, causing it to move in a linear direction.

What are the types of hydraulic cylinders?

The main types of hydraulic cylinders are single-acting (which uses pressure on one side of the piston) and double-acting (which uses pressure on both sides of the piston for movement in both directions).

What materials are used in hydraulic cylinders?

Hydraulic cylinders are typically made from high-strength steel, stainless steel, and cast iron. The materials are chosen based on the need for strength, durability, and resistance to corrosion.

How do I choose the right hydraulic cylinder for my application?

Choose based on factors like the required pressure, stroke length, mounting style, load capacity, and environmental conditions. Consulting a hydraulic specialist can help determine the best fit.

What causes hydraulic cylinder failure?

Common causes of hydraulic cylinder failure include excessive pressure, lack of maintenance, contamination of hydraulic fluid, worn seals, and improper installation.

How often should I maintain my hydraulic cylinder?

Regular maintenance should be performed according to usage and operating conditions. Typically, inspect hydraulic cylinders every 6 months to ensure seals, fluid, and components are in good condition.

How can I prevent leaks in my hydraulic cylinder?

To prevent leaks, ensure that seals and gaskets are intact, install the cylinder correctly, and avoid over-pressurizing the system. Regular inspection and maintenance can help prevent leaks.

Can hydraulic cylinders be repaired?

Yes, hydraulic cylinders can be repaired. Damaged seals, piston rods, or other components can be replaced. However, if the cylinder tube or other critical parts are severely damaged, it may need to be replaced entirely.

What is the typical lifespan of a hydraulic cylinder?

The lifespan of a hydraulic cylinder depends on usage, maintenance, and operating conditions. With proper maintenance, hydraulic cylinders can last from 10 to 20 years or longer in many applications.

Get More Information About Products