An exhaust flex pipe is a flexible, braided metal component installed in the exhaust system of a vehicle. It acts as a vibration damper and thermal compensator between the engine and the exhaust pipe. Built primarily from stainless steel, a flex pipe allows slight movements within the exhaust line to prevent cracks, leaks, and long-term structural damage—especially in vehicles with front-wheel drive or transverse engine configurations.

Unlike rigid exhaust sections, the flex pipe absorbs engine movement, exhaust vibrations, and the expansion and contraction of components caused by extreme temperature changes. This flexibility is what makes it such a vital piece of the overall exhaust system. Without it, constant stress from vibrations and motion would damage more critical and expensive exhaust parts, such as the manifold or catalytic converter.

Exhaust flex pipes may seem like small components, but they play a crucial role in the performance, comfort, and durability of various vehicle types. These pipes are designed to manage engine motion, absorb vibration, and reduce thermal stress—making them essential in a wide range of applications from compact passenger cars to heavy-duty industrial vehicles.

Larger vehicles equipped with high-torque engines generate more vibration and movement in the drivetrain. Flex pipes in these vehicles are typically reinforced to handle greater loads.

Why It’s Needed:

Commercial delivery vans, long-haul trucks, and service vehicles run under demanding conditions. These vehicles often use high-durability flex pipes with inner liners and double braiding.

Why It’s Needed:

High-performance and race-modified vehicles generate higher exhaust temperatures and stronger engine pulses, especially in turbocharged setups. Flex pipes with interlock liners or smooth inner sleeves are preferred in this category.

Why It’s Needed:

At its core, the flex pipe is designed to compensate for engine motion, absorb vibration, and manage thermal expansion within the exhaust path. Without it, other rigid exhaust components—such as manifolds, catalytic converters, and mufflers—are more vulnerable to cracking, separation, or fatigue due to constant mechanical and thermal stress.

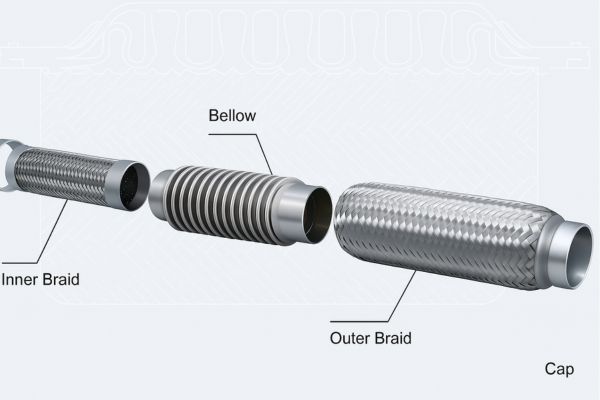

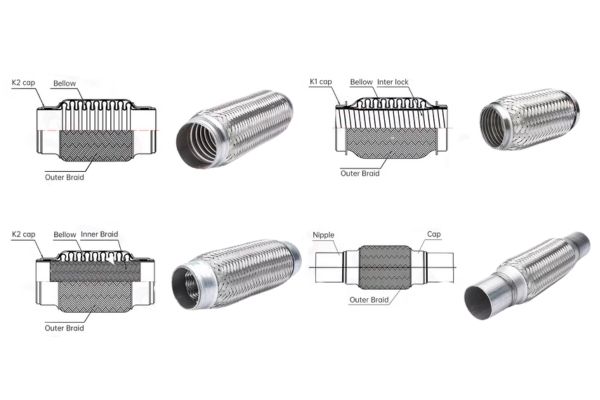

Corrugated Inner Tube (Bellows):

This is the heart of the flex pipe. The bellows are made of thin, flexible stainless steel formed into a corrugated shape that can compress and extend.

Outer Braid (Mesh Layer):

Surrounding the bellows is a tightly woven steel mesh. This layer doesn’t just protect the bellows—it reinforces the pipe structure by resisting external abrasion and preventing overextension or buckling.

Inner Liner (Sleeve or Smooth Pipe):

Some high-performance or premium flex pipes include an inner liner, usually a perforated or smooth metal sleeve. This feature improves exhaust flow by reducing turbulence, minimizing internal wear caused by hot gases, and slightly lowering overall noise. It’s especially useful in turbocharged engines or vehicles with sensitive downstream sensors.

End Connectors:

These are the attachment points on both ends of the flex pipe. Depending on the application, the pipe may come with plain tubing ends for welding, flanged ends for bolted connections, or even clamp-on interfaces.

The primary role of an exhaust flex pipe is to absorb dynamic movement within the exhaust system without transferring that force to other components. Here’s how it works during typical operation:

Engine Movement Compensation:

During acceleration, deceleration, or gear changes, the engine shifts slightly on its mounts. This movement can stress exhaust joints. The flex pipe allows limited movement in multiple directions—axial, lateral, and angular—reducing stress on the system.

Vibration Damping:

Engines naturally produce vibration, especially under load or at idle. The flex pipe acts as a mechanical buffer, preventing these vibrations from traveling down the entire exhaust line, which could otherwise cause rattling or fatigue cracking.

Thermal Expansion Management:

As the exhaust system heats up during operation, its metal components expand. Without a flexible connection point, these forces can push against fixed mounts or cause warping. The bellows in the flex pipe compress or extend slightly to accommodate this expansion, maintaining system integrity.

Though small in size, the exhaust flex pipe plays a major role in preserving the performance, comfort, and reliability of the entire exhaust system. When properly installed, a high-quality flex pipe delivers a range of mechanical and operational advantages that go far beyond just reducing engine noise.

A flex pipe acts as a flexible buffer, absorbing this vibration before it reaches sensitive components like the catalytic converter, muffler, or downstream piping.

Constant thermal cycling creates expansion and contraction forces that can warp or fracture rigid exhaust pipes. The bellows in a flex pipe are designed to compress and extend as needed, absorbing this expansion naturally.

By absorbing vibration and heat-related movement, a flex pipe shields nearby components from damaging stress.

A properly functioning flex pipe reduces the transmission of noise from engine vibration through the exhaust line and into the cabin.

Installing or replacing an exhaust flex pipe may seem straightforward, but a few critical factors can determine whether the new component will perform reliably or fail prematurely. A poorly installed flex pipe can lead to vibrations, leaks, premature cracking, or even damage to other exhaust components. To ensure durability, proper sealing, and optimal performance, pay close attention to the following considerations:

Why it matters:

The flex pipe must match the existing exhaust system in both outer diameter and length to maintain proper backpressure, flow efficiency, and alignment. Using an undersized pipe restricts flow and increases noise, while an oversized one may not seal correctly.

Tips:

Measure the outside diameter (OD) of the pipe you’re connecting to.

Ensure the flex section is long enough to absorb movement—but not so long that it droops or scrapes the ground.

Consider using calipers or an exhaust pipe sizing tool for accuracy.

Why it matters:

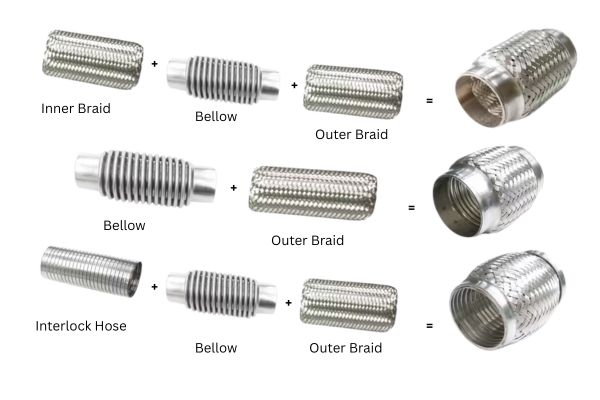

Not all flex pipes are built the same. The braid strength (single vs. double braid, interlock liner, etc.) should be matched to the vehicle type, engine output, and driving environment.

Use case examples:

Standard daily driving: Single-braided or basic bellows models are usually sufficient.

Off-road or heavy-load vehicles: Choose double-braided or interlock-liner types to resist fatigue and protect against impacts.

Turbocharged or performance cars: Use inner-sleeved pipes to handle exhaust pressure and reduce flow turbulence.

Why it matters:

The flex pipe is meant to absorb motion—not fight against it. If the pipe is installed with any twist, stretch, or angular misalignment, it will wear unevenly, leading to premature failure.

What to check:

The pipe should sit naturally in place without tension.

There should be enough room around the pipe to prevent contact with underbody components, heat shields, or suspension.

The system must have room to flex in multiple directions—axially, laterally, and angularly—without putting strain on welds or clamps.

Why it matters:

While clamp-on installations are quicker and more convenient, a welded joint offers better structural integrity, long-term durability, and leak resistance—especially in high-heat, high-vibration environments.

Installation tips:

TIG or MIG welding is recommended for stainless steel flex pipes.

Always clean surfaces before welding to prevent contamination and weak joints.

If welding isn’t an option, use high-quality band clamps and apply exhaust sealant to improve sealing.

While standard exhaust flex pipes cover most replacement needs, many applications—especially in industrial, performance, or modified vehicles—require custom-designed solutions. Customization ensures proper fit, reliable operation, and compliance with specific mechanical or environmental demands.

At Topa, we don’t just sell components—we deliver complete service solutions that help your business run smoother, faster, and more reliably. Whether you’re an importer, distributor, OEM, or maintenance provider, our full-service approach ensures you get the support, customization, and quality you need to stay competitive.

From drawings to reality—we support full customization for flex pipes, hydraulic fittings, hoses, and more.

Every product undergoes strict quality control before shipment.

Boost your brand’s presence with our tailored packaging services.

Not sure what fitting or pipe suits your application? We help you choose.

No delays. No confusion. We manage your shipping needs professionally.

We support flexible order volumes—from trial batches to full container loads.

Our commitment doesn’t end after delivery.

We speak your language—literally.

When it comes to sourcing high-quality exhaust flex pipes for your automotive or industrial applications, reliability, precision, and support matter.

Every flex pipe we offer is produced using precision CNC-formed bellows, high-strength stainless steel braiding, and strict ISO-certified quality checks.

From raw material selection to final inspection, we control every step of the process through long-term partnerships with our trusted factories.

Whether you need single-layer, double-braided, inner-lined, or interlock core designs, Topa delivers consistent, leak-free performance.

Stock-ready sizes available for immediate delivery.

Customized production completed quickly with competitive lead times—especially for bulk or repeat orders.

Experience smooth logistics with flexible shipping solutions (FOB, CIF, DDP available), backed by our responsive export team who understands customs, paperwork, and route efficiency.

Need something beyond the standard? Topa supports:

Custom pipe diameter, length, and bend angle

Reinforced braiding for high-vibration or turbocharged setups

Special coatings or flanged ends for marine, off-road, or generator applications

Whether you’re outfitting performance cars, diesel trucks, or stationary engines, we design to match your exact application requirements.

Topa isn’t just a flex pipe supplier. We offer:

Exhaust components (flanges, gaskets, clamps)

Hydraulic hoses, fittings, quick couplings, and valves

OEM and custom branding, packaging, and private labeling

Most flex pipes are constructed from stainless steel or carbon steel. High-end models may include 316 stainless steel for enhanced corrosion resistance.

A single-braided flex pipe has one layer of exterior mesh, suitable for light-duty use. A double-braided version includes two mesh layers for improved strength, vibration resistance, and longer lifespan—ideal for high-torque or off-road applications.

No. Only sleeved or interlock flex pipes include an inner liner. This inner tube reduces turbulence, protects the bellows from hot gas abrasion, and provides smoother flow.

Both options are possible. Clamp-on installation is quicker and easier, but welded installation provides a stronger, leak-proof connection.

Match the inner diameter (ID) to your existing exhaust pipe size. Measure the overall length needed based on your system’s configuration and movement range.

Common causes include vibration fatigue, thermal cycling, road salt corrosion, and improper installation. Over time, these stressors can lead to cracks in the bellow or fraying of the braided mesh.

Lifespan depends on material quality, vehicle type, and driving conditions.

No. A leaking flex pipe can increase engine noise, reduce fuel efficiency, affect sensor readings, and even allow toxic fumes into the cabin.

Flex pipes come in universal sizes (e.g., 2″, 2.5″, 3″ ID), but the length and connection style must match your system.

Yes. A properly installed flex pipe helps maintain backpressure and sensor accuracy, supporting fuel efficiency and emissions compliance.