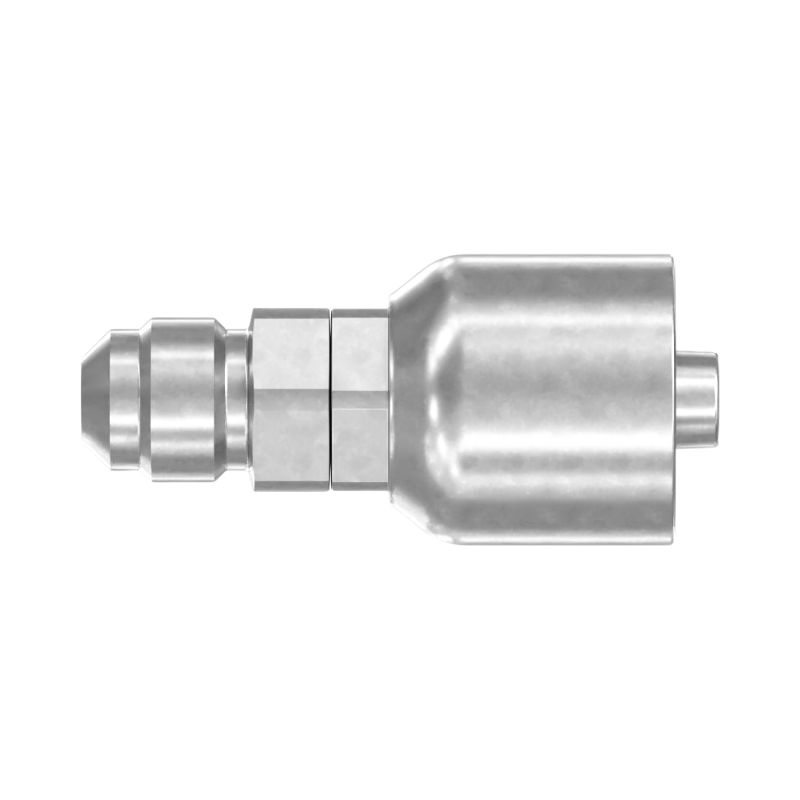

opa specializes in the research, development, and manufacturing of high-quality one-piece hydraulic fittings, aiming to provide efficient and reliable hydraulic system connection solutions to customers worldwide. Our range of one-piece hydraulic fittings covers a wide variety of specifications and types to meet the demands of different working conditions and application scenarios.

The main product categories include, but are not limited to: JIC 37° flare one-piece fittings compliant with international standards, ORFS flat-face seal one-piece fittings, BSPP/BSPT threaded one-piece fittings, DIN metric light/heavy series one-piece compression fittings, Custom-designed non-standard one-piece hydraulic connectors tailored to specific customer requirements. These products are compatible with and can replace Danfoss 4S series one-piece fittings. They offer superior quality at competitive prices. We welcome your inquiries and purchases!

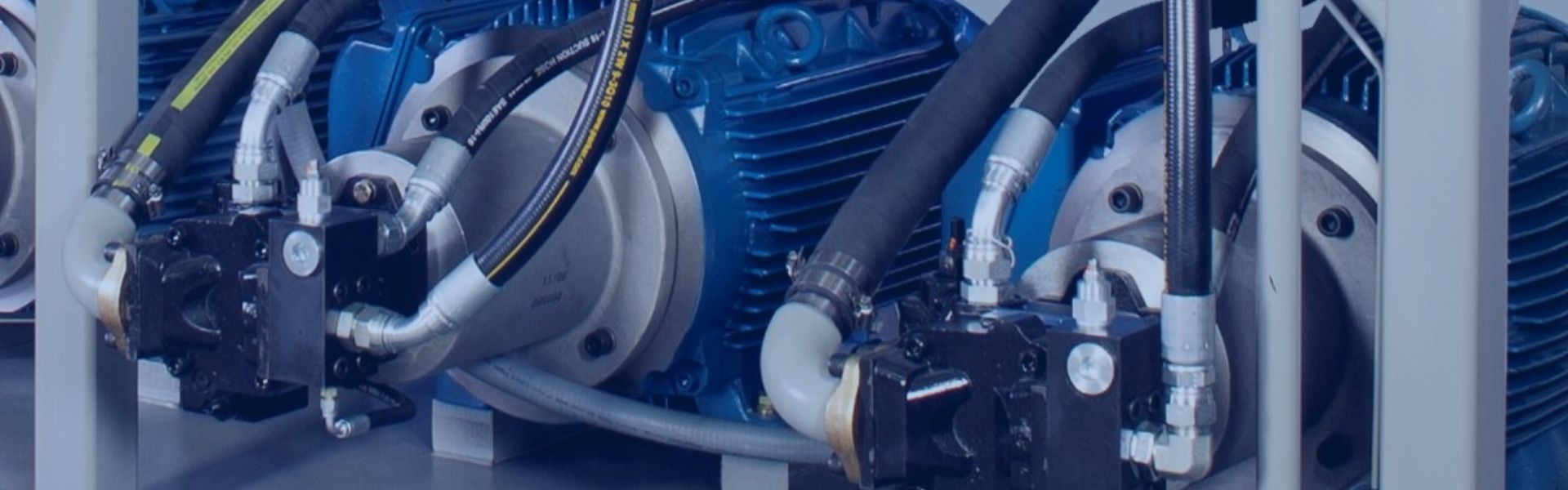

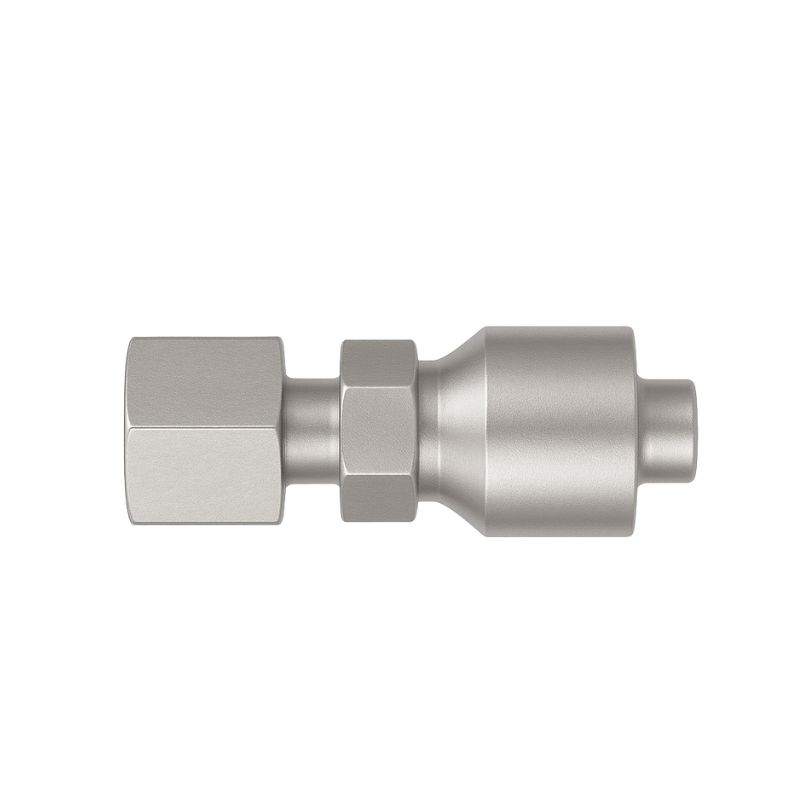

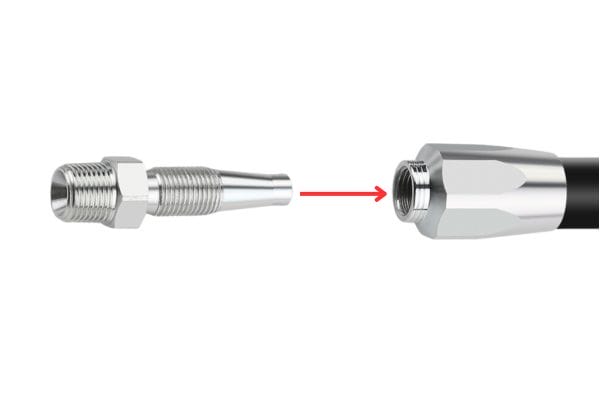

Female straight ORFS hydraulic crimp fitting. Compatible with CAT/Caterpillar hydraulic couplings.

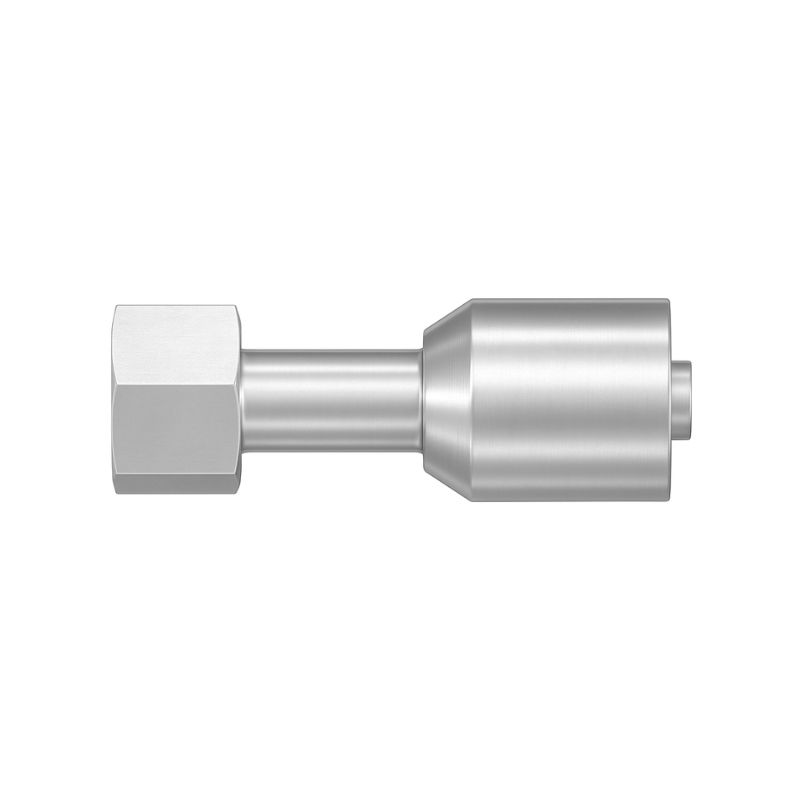

Female 45° elbow ORFS hydraulic crimp fitting. Compatible with CAT/Caterpillar hydraulic couplings.

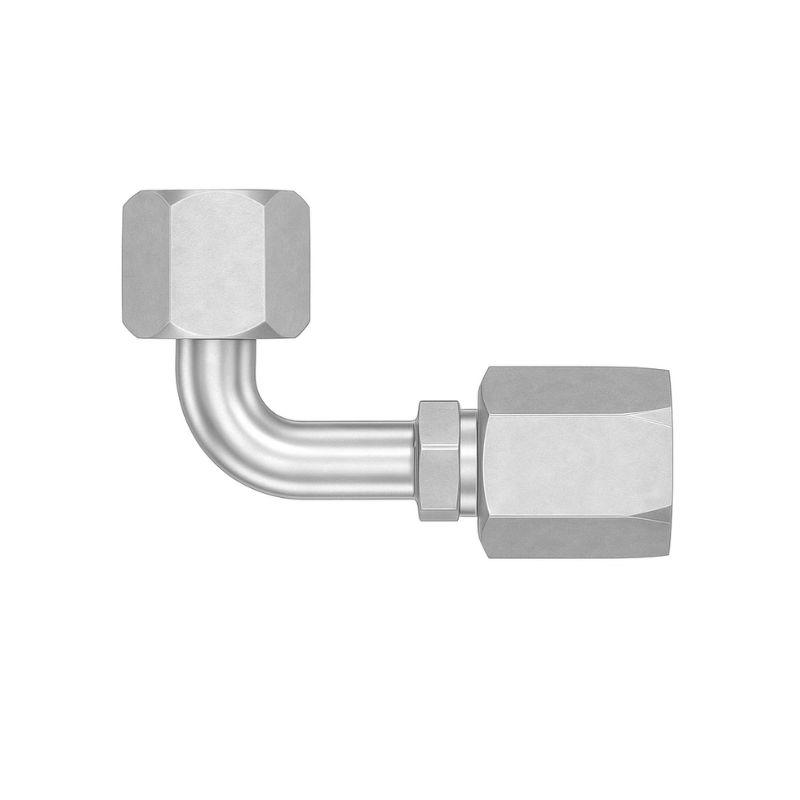

Female 90° elbow ORFS hydraulic crimp fitting. Compatible with CAT/Caterpillar hydraulic couplings.

Straight Code 61 flange hydraulic crimp fitting. Compatible with CAT/Caterpillar hydraulic couplings.

45° Code 61 flange hydraulic crimp fitting. Compatible with CAT/Caterpillar hydraulic couplings.

90° elbow Code 61 flange hydraulic crimp fitting. Compatible with CAT/Caterpillar hydraulic couplings.

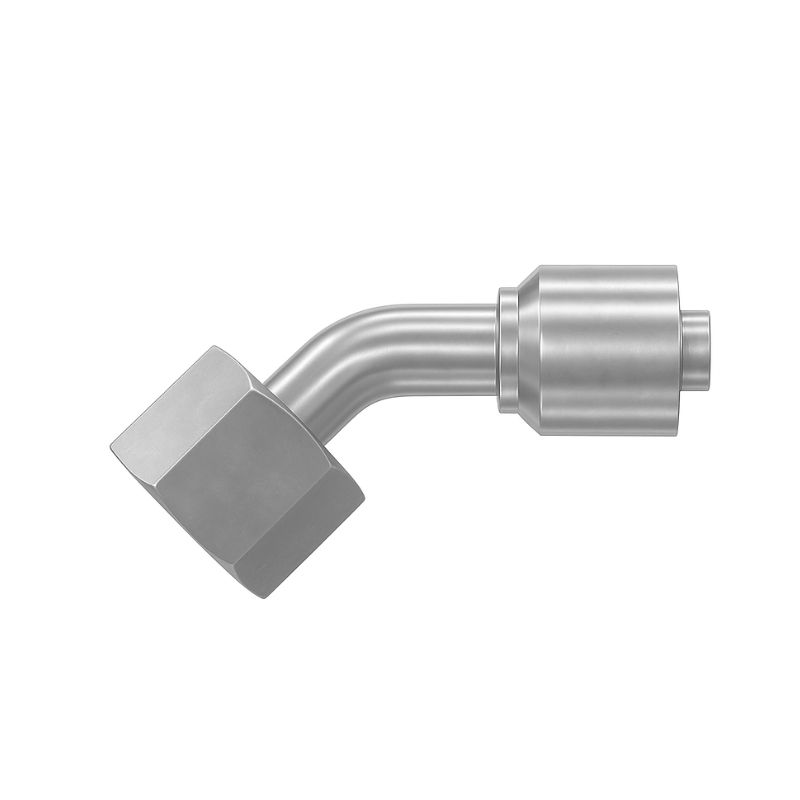

SAE 45° straight hydraulic crimp fitting. Compatible with CAT/Caterpillar hydraulic couplings.

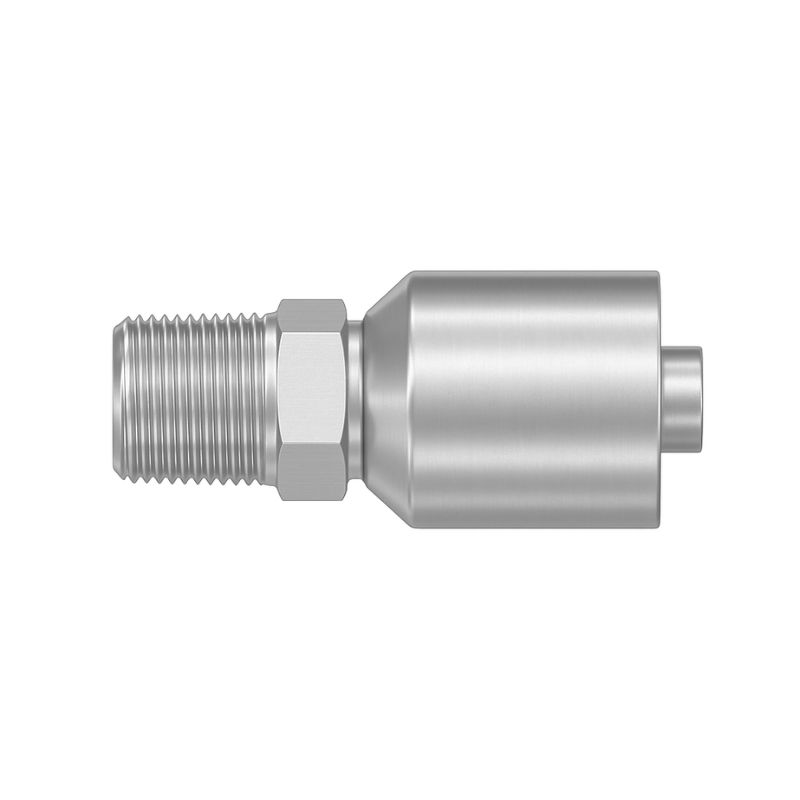

Komatsu straight hydraulic crimp fitting. Compatible with CAT/Caterpillar hydraulic couplings.

Female JIC straight hydraulic crimp fitting. Compatible with CAT/Caterpillar hydraulic couplings.

Female JIC 45° hydraulic crimp fitting. Compatible with CAT/Caterpillar hydraulic couplings.

Female JIC 90° hydraulic crimp fitting. Compatible with CAT/Caterpillar hydraulic couplings.

Female BSPP 45° elbow hydraulic crimp fitting. Compatible with CAT/Caterpillar hydraulic couplings.

Male BSPP 45° elbow hydraulic crimp fitting. Compatible with CAT/Caterpillar hydraulic couplings.

Female JIC 45° elbow hydraulic reusable fitting. Compatible with CAT/Caterpillar hydraulic couplings.

Female ORFS 45° elbow hydraulic reusable fitting. Compatible with CAT/Caterpillar hydraulic couplings.

Female JIC 90° elbow hydraulic reusable fitting. Compatible with CAT/Caterpillar hydraulic couplings.

Discover the versatility and precision of Topa’s crimped hydraulic fittings in this comprehensive video presentation. We will highlight our wide range of expertly designed hydraulic fittings, demonstrating their robust construction and ability to be used in a wide range of demanding hydraulic applications.

From standard configurations to specialized designs, every detail has been meticulously considered to ensure optimal performance and leak-free connections. We believe this intuitive insight will be invaluable in your selection process.

We invite you to click and watch a video that gives you a comprehensive overview of Topa’s crimping hydraulic couplings. Witness how our solutions can improve the reliability and efficiency of your hydraulic system. If you have any specific questions or detailed specifications, our team is ready to assist you further after your viewing.

Hydraulic hose fittings play a pivotal role in a myriad of applications, underpinning the performance and reliability of hydraulic systems across diverse industries.

Excavators, loaders, bulldozers, and other construction equipment are frequently operated in harsh, demanding environments and often run for extended periods. These applications place extremely high demands on the reliability of hydraulic systems. Our high-strength hydraulic fittings are manufactured using advanced heat treatment processes, providing exceptional impact resistance. They are designed to withstand intense vibrations and shocks caused by challenging terrain.

Modern agricultural equipment, such as tractors, harvesters, and seeders, relies heavily on hydraulic systems for precise control. TOPA’s specialized hydraulic fitting series for agricultural machinery features outstanding vibration resistance and excellent temperature adaptability. These fittings maintain reliable operation in bumpy field conditions and in environments with large seasonal temperature fluctuations. Our quick-connect technology also allows for fast, efficient implement changes, making equipment swaps simple and boosting the flexibility and efficiency of agricultural production.

In logistics centers, warehouses, and manufacturing plants, equipment like forklifts, pallet stackers, and automated guided vehicles (AGVs) depend on robust hydraulic systems for reliable operation. Topa hydraulic fittings offer precise dimensional tolerances and superior sealing, ensuring leak-free connections even with frequent movement and high cycle counts. The corrosion-resistant construction stands up to the presence of oils, chemicals, and moisture often found in these environments.

Fitting body

As the main structure of the whole fitting, it is usually made of high-strength carbon steel or stainless steel precision processing, and the surface is specially treated to enhance corrosion resistance.

Sealing element

Anti-loosening devices

Protective Components

The working principle of hydraulic fittings is rooted in both precision mechanical connection and fluid dynamics, ensuring secure and efficient hydraulic transmission through several core mechanisms:

Mechanical Connection Principle

Sealing Principle

Topa hydraulic fittings feature a unique sealing design and precision machining process, with surface roughness controlled to Ra0.4 or below. Even under working pressures up to 35 MPa, they maintain a flawless seal. This outstanding sealing capability effectively prevents hydraulic oil leaks that can cause environmental pollution and safety risks, while also significantly reducing system pressure losses.

Our hydraulic fittings are manufactured from special alloy materials and undergo advanced surface treatment, delivering excellent corrosion resistance and a wide operating temperature range from -40°C to +120°C. This exceptional adaptability enables TOPA fittings to perform reliably in harsh environments such as marine, mining, and chemical applications. They resist acids, alkalis, salt spray, and chemical solvents, ensuring solid connections even under the toughest conditions.

Topa hydraulic fittings are engineered and manufactured strictly according to international standards, ensuring perfect interchangeability with leading global brands such as CAT. Certified to ISO and other international benchmarks, our fittings offer dimensional accuracy within ±0.02mm, guaranteeing seamless integration with your existing systems.

With an innovative quick-connect design, Topa hydraulic fittings cut installation time by more than 50% compared to traditional fittings, and require no specialized tools. Special anti-error features ensure correct and reliable connections, even under challenging field conditions. For your day-to-day operations, this means faster maintenance and system upgrades, reduced downtime, and higher efficiency.

Topa not only provides high quality hydraulic couplings, but is also committed to providing customers with a full range of professional service support. We know that high quality products need to be matched with equally high quality services in order to maximize the value. Based on the in-depth understanding of customer needs, Topa has built a comprehensive service system, covering the entire life cycle of product selection, technical support, customized development and after-sales protection. Whether you are a large OEM or an end-user, Topa can provide you with professional, efficient, and caring one-stop services, allowing you to maintain a leading edge in the fierce competition in the market.

We offer tailored hydraulic fitting solutions based on your specific application requirements. Our engineering team can provide custom sizes, thread types, materials, and branding.

Topa’s sales team is committed to fast and accurate quoting. Most inquiries receive a detailed quotation within 12 hours, helping you move quickly on your procurement decisions.

Our technical experts are available to assist with product selection, troubleshooting, installation guidance, and system optimization. We provide both pre and after-sales technical support.

We provide samples for quality verification and pre-production testing. This allows you to evaluate fit, function, and quality before committing to bulk orders.

Every batch of products undergoes thorough inspection, including material verification, dimensional checks, sealing tests, and surface treatment evaluation, to guarantee defect-free shipments.

We offer multiple shipping options including air, sea, and express delivery. We can work with your preferred logistics partners or arrange end-to-end transport to your destination.

Our after-sales support includes timely resolution of product issues, technical guidance, and warranty services. Your satisfaction and continuous operation are our top priorities.

Topa maintains a strong inventory of standard products and can reserve production slots for regular customers. This ensures stable supply, helping you avoid stockouts and delays.

Topa’s one-piece hydraulic fittings are manufactured using advanced integrated precision forging or CNC machining processes, combining the fitting body, nut, and ferrule/flared components into a single, solid structure.

Choosing Topa as your hydraulic fitting supplier means partnering with a company that is truly customer-focused and dedicated to quality and innovation. Our manufacturing processes represent the industry’s leading standards and directly translate into tangible benefits for our customers:

Topa utilizes high-precision CNC machining centers, automated production lines, and advanced testing equipment to achieve full digital management of the entire process—from raw materials to finished products. Our large-scale production capacity and localized supply chain give you a significant pricing advantage, helping you control procurement costs and enhance your market competitiveness.

Our R&D team continuously develops new materials, processes, and designs, launching multiple patented technologies and innovative products each year. These innovations result in better equipment performance, longer service life, and lower maintenance costs for our customers. Our products are also compatible with many internationally renowned hydraulic brands.

When you choose Topa , you benefit from our comprehensive quality assurance system. Our factory holds ISO and other international certifications. Every batch of products undergoes strict performance testing and reliability verification to ensure that it meets or exceeds industry standards. This rigorous quality management provides peace of mind for our customers and greatly reduces equipment failures and downtime caused by product issues.

Another key advantage of Topa is our flexible customization capabilities and rapid response system. Our engineering team can quickly develop customized products based on your unique requirements. At the same time, our service ensures that customers in any region can receive prompt technical support and after-sales service, minimizing problem resolution time.

Our hydraulic fittings are available in carbon steel, stainless steel (304/316L), brass, and special alloys to suit different application environments.

Yes, Topa fittings are manufactured to international standards and are fully compatible with many leading brands such as CAT, Parker, and Eaton.

Our standard fittings typically support up to 35 MPa, with custom solutions available for higher-pressure applications.

Absolutely. We offer custom designs, including special threads, sizes, materials, and branding to meet your unique requirements.

All products undergo strict material inspection, CNC precision machining, 100% pressure and leak testing, and comply with ISO and other international certifications.

We use O-ring, metal-to-metal, conical, and flat face seals, with options in NBR, HNBR, PTFE, and more to ensure leak-free performance under various conditions.

Our stainless steel and special alloy fittings offer superior corrosion resistance, while advanced surface treatments provide long-lasting protection.

Topa hydraulic fittings are designed to work reliably from -40°C to +120°C, making them suitable for a wide range of environments.

We use precision-machined surfaces and high-quality sealing elements, with all fittings undergoing strict leak and pressure testing before shipment.

We offer zinc plating, nickel plating, chrome plating, black oxide, and advanced nano-coating to enhance corrosion resistance and appearance.