Can You Reuse Brass Compression Fittings?

Table of Contents

Introduction

Brass compression fittings are a crucial component in plumbing and various industrial applications. They provide a secure and leak-free connection between pipes or tubes, typically used in water supply systems, gas lines, and hydraulic systems. Understanding whether these fittings can be reused is essential for both economic and environmental reasons.

Understanding Brass Compression Fittings

Composition and Structure

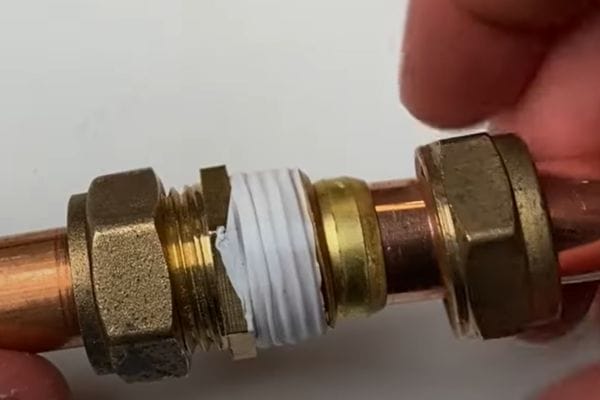

Brass compression fittings are an integral part of plumbing systems, known for their reliable and secure connections. These fittings consist of three primary components:

Compression Nut: The compression nut is a threaded component that, when tightened, forces the ferrule into the compression seat. This tightening action ensures that the ferrule is compressed against the pipe, creating a secure seal. The nut is usually hexagonal for easy tightening with a wrench.

Compression Ring (Ferrule): The ferrule is a small ring, often made from brass or copper, placed between the nut and the compression seat. As the nut is tightened, the ferrule is compressed against the pipe, deforming slightly to create a tight seal that prevents leaks. This deformation allows the ferrule to grip the pipe securely.

Compression Seat (Body): The compression seat, or body, is the main part of the fitting into which the pipe is inserted. It provides a stable base for the ferrule to compress against. The seat often has internal threads that engage with the threads on the compression nut, allowing the ferrule to be compressed when the nut is tightened.

Material Composition

Brass, an alloy of copper and zinc, is used for these fittings due to its advantageous properties. Brass is durable, corrosion-resistant, and malleable, making it ideal for creating secure, long-lasting connections. Its corrosion resistance ensures that the fittings can withstand various environmental conditions, including exposure to water and different chemicals.

Sealing Mechanism:

The sealing mechanism of brass compression fittings relies on the deformation of the ferrule. When the compression nut is tightened, it pushes the ferrule against the compression seat, causing the ferrule to deform and grip the pipe tightly. This deformation creates a metal-to-metal seal that is highly effective in preventing leaks, even under high pressure. The design of the fitting allows for easy disassembly and reassembly, making it a versatile choice for plumbing applications.

Types of Brass Compression Fittings

Properly connecting brass pipe fittings involves several crucial steps to ensure a secure, leak-free joint. This step-by-step guide will help you navigate the process with precision and confidence.

Standard Fittings

Standard brass compression fittings are widely used in residential and commercial plumbing due to their versatility and ease of installation. They come in various shapes and sizes to accommodate different piping configurations. Common types of standard fittings include:

Straight Connectors: These are used to join two pipes in a straight line. They are the simplest type of compression fitting and are commonly used in both residential and commercial applications.

Elbows: Elbow fittings are used to change the direction of the piping system, typically at a 90-degree angle. They are essential for navigating around obstacles and fitting pipes into tight spaces.

Tees: Tee fittings allow for the branching of a pipe into two directions, forming a T-shaped connection. This is useful for distributing fluids to different areas or for creating multiple outlets from a single source.

Couplings: Couplings are used to join two pipes together. They can be straight or reduced, allowing for the connection of pipes with different diameters.

Specialized Fittings

Specialized brass compression fittings are designed for specific applications and requirements. They offer additional functionality beyond standard fittings and are used in more complex plumbing and industrial systems. Common types of specialized fittings include:

Reducing Fittings: These fittings are used to connect pipes of different diameters. They are essential in systems where pipe size needs to be adjusted, such as reducing the size of a main supply line to smaller branch lines.

Flare Fittings: Flare fittings are used in high-pressure applications, such as gas lines and hydraulic systems. They require the pipe end to be flared using a special tool, creating a conical shape that fits into the flare fitting. This provides a strong, leak-proof connection capable of withstanding high pressures.

Swivel Fittings: Swivel fittings allow for easy disconnection and reconnection of pipes. They are commonly used in applications where pipes need to be frequently disassembled and reassembled, such as in maintenance or repair operations. The swivel action prevents the need to rotate the entire pipe, simplifying the process.

Factors to Consider Before Reusing

Condition of the Fitting

Before deciding to reuse a brass compression fitting, it is crucial to thoroughly assess its current condition. This involves both external and internal inspections to ensure that the fitting is still capable of providing a secure and leak-free connection.

Visual Inspection:

Damage: Examine the fitting for any visible signs of damage, such as cracks, dents, or deformities. Even minor damage can compromise the integrity of the fitting, leading to leaks or failures.

Corrosion: Look for any signs of corrosion, especially around the threads and the ferrule. Brass is resistant to corrosion, but prolonged exposure to moisture or harsh chemicals can still cause oxidation or pitting, which weakens the fitting.

Wear: Check for general wear and tear, such as worn threads on the compression nut or flattened surfaces on the ferrule. These signs indicate that the fitting has been subjected to repeated use and may not perform as effectively in a new application.

Threads: Ensure that the threads on the compression nut are not stripped or damaged. Stripped threads can prevent the nut from tightening properly, leading to a poor seal.

Ferrule Deformation: Inspect the ferrule for any deformations. A deformed ferrule may not create a proper seal when reused, increasing the risk of leaks.

Internal Condition:

Corrosion or Buildup: Check for internal corrosion or buildup that might compromise the seal. Use a flashlight to inspect the interior surfaces of the fitting. Buildup from minerals or other contaminants can prevent a tight seal and lead to leaks.

Cleanliness: Ensure that the interior of the fitting is clean and free from any debris or residues. Clean the fitting thoroughly if necessary to remove any obstructions that could affect its performance.

Previous Usage and Environment

The history of the fitting’s usage and the environment it has been exposed to can significantly impact its suitability for reuse. Consider the following factors:

Exposure to Corrosive Substances:

Chemical Exposure: Fittings that have been exposed to harsh chemicals, such as acids, alkalis, or solvents, may have compromised integrity. Chemical exposure can weaken the brass, causing it to become brittle or corroded.

Environmental Conditions: Evaluate the environmental conditions the fitting has been subjected to. Fittings used in environments with high humidity, saltwater, or extreme temperatures may have experienced accelerated wear and corrosion.

Stress and Pressure Levels:

High-Pressure Applications: Consider the pressure and stress the fitting has been subjected to. High-pressure applications, such as hydraulic systems or high-pressure gas lines, place additional stress on fittings. Over time, this stress can cause metal fatigue, making the fitting more prone to failure.

Mechanical Stress: Evaluate any mechanical stress the fitting has experienced, such as vibration, bending, or impact. Repeated mechanical stress can weaken the fitting, reducing its ability to maintain a secure seal.

Compatibility with New Application

When reusing a brass compression fitting, it is essential to ensure that it is compatible with the new application. This involves matching specifications and verifying that the fitting can still create a proper seal.

Matching Specifications:

Pipe Size: Ensure that the reused fitting matches the size of the pipes in the new application. Using a fitting that is too large or too small can result in poor connections and leaks.

Material Compatibility: Verify that the materials of the fitting and the pipes are compatible. Some materials may react with each other, leading to corrosion or weakening of the connection. For example, brass is generally compatible with copper and plastic pipes, but it may not be suitable for use with certain stainless steel or galvanized steel pipes.

Proper Sealing and Fit:

Ferrule Condition: Verify that the ferrule can still create a proper seal. A worn or damaged ferrule may not provide an adequate seal, leading to leaks. If the ferrule shows signs of wear or deformation, it may need to be replaced before reuse.

Connection Tightness: Ensure that the fitting can be tightened securely without over-tightening. Over-tightening can cause damage to the fitting and the pipe while under-tightening can result in leaks. Test the connection to confirm that it can maintain a secure seal under the required pressure.

Best Practices for Reusing Brass Compression Fittings

Reusing brass compression fittings can be beneficial if done correctly. Following best practices ensures that the fittings remain reliable and leak-free in their new application.

Proper Removal Techniques

To ensure the integrity of brass compression fittings during removal, follow these guidelines:

Tools and Methods:

Appropriate Wrenches: Use the correct size wrenches to avoid damaging the fitting. An adjustable wrench or a pair of slip-joint pliers can provide the necessary grip without causing damage.

Avoid Over-Tightening: When removing the fitting, avoid over-tightening the wrench. Over-tightening can strip the threads or deform the components, rendering the fitting unusable.

Gentle Handling: Do not force components apart. If the fitting is difficult to remove, apply penetrating oil to loosen any corrosion or buildup that may be causing resistance.

Avoiding Damage:

Careful Loosening: Slowly and carefully loosen the compression nut. Once the nut is loose, gently remove it along with the ferrule.

Minimize Bending or Distortion: Take care not to bend or distort the ferrule and the compression nut during removal. Use steady, even pressure to prevent damage.

Preserve Threads: Ensure that the threads on the compression nut and fitting remain intact and undamaged. Stripped or damaged threads can compromise the fitting’s ability to create a seal when reused.

Cleaning and Inspection Process

Thorough cleaning and inspection are critical steps in preparing a brass compression fitting for reuse:

Cleaning Methods:

Mild Detergent and Brush: Clean the fitting thoroughly using a mild detergent and a soft brush. This helps remove any debris, corrosion, or buildup that may have accumulated.

Rinse and Dry: After cleaning, rinse the fitting with clean water and dry it completely to prevent any residual moisture from causing corrosion.

Penetrating Oil: For fittings with stubborn buildup or corrosion, use a penetrating oil to help loosen and remove the deposits.

Thorough Inspection:

Visual Examination: Inspect all parts of the fitting, including the compression nut, ferrule, and body, for any signs of wear or damage.

Ferrule and Nut Condition: Check the ferrule for deformations or wear. Inspect the threads on the compression nut to ensure they are not stripped or damaged.

Replace Damaged Components: If any part of the fitting shows significant wear or damage, replace it. Using damaged components can lead to leaks and unreliable connections.

Reassembly and Testing

Proper reassembly and testing are essential to ensure the reused fitting functions correctly:

Proper Installation:

Alignment: Ensure all parts are correctly aligned during reassembly. Misalignment can cause leaks and compromise the fitting’s integrity.

Tightening to Specifications: Tighten the compression nut to the manufacturer’s specifications. Avoid over-tightening, which can deform the ferrule and the pipe, leading to leaks.

Use of Sealants: If recommended by the manufacturer, apply a suitable thread sealant to enhance the connection’s reliability. Be cautious with the amount and type of sealant used, as excessive sealant can cause blockages.

Pressure Testing:

Initial Test: After reassembly, conduct an initial pressure test to ensure the fitting is leak-free. Apply the required pressure and check for any signs of leaks around the fitting.

Gradual Increase in Pressure: Gradually increase the pressure during testing to the required levels for the application. Monitor the fitting for any leaks or failures.

Final Inspection: Once the fitting passes the pressure test, perform a final inspection to ensure everything is secure and there are no leaks. Document the test results for future reference.

Conclusion

Reusing brass compression fittings can reduce costs and protect the environment, but must be done with caution. Key points to consider include assessing when and why reuse is appropriate, and balancing the risk of potential leakage and impaired performance against the benefits of cost savings and reduced waste. Thoroughly inspect, clean, and test fittings before reuse, prioritizing safety and performance. Always make informed decisions based on the specific needs of the application and the current condition of the fittings.

FAQ

Not all fittings are suitable for reuse. Each fitting should be inspected for damage, wear, and corrosion before deciding to reuse it.

Conduct a thorough visual and internal inspection. Look for signs of damage, corrosion, and ensure that the threads and ferrule are in good condition.

The main risks include potential leaks, compromised performance, and reduced lifespan compared to new fittings.

Use appropriate wrenches that fit the compression nut and avoid over-tightening to prevent damage during disassembly.

Clean the fitting with a brush and mild detergent, rinse thoroughly, and ensure it is completely dry before reassembling.

Replace any components that show significant wear or damage to ensure a reliable and leak-free connection when reusing the fitting.