NPT Pipe Thread Fitting: Everything You Need to Know

Introduction

NPT hydraulic fittings serve as crucial components across industries worldwide, offering reliable connections for fluid and gas systems. Their threaded design ensures secure sealing, making them indispensable in plumbing, manufacturing, oil and gas, and other sectors where precision and durability are paramount. Understanding NPT fittings is essential for ensuring efficient operations and maintaining safety standards in diverse industrial applications.

Understanding NPT Pipe Threads

NPT fittings are widely recognized for their tapered thread design, crucial for creating secure seals between connected components. This tapered feature plays a pivotal role in facilitating both assembly and disassembly processes, making NPT fittings highly suitable for applications requiring frequent adjustments or maintenance checks.

Characteristics of NPT Threads

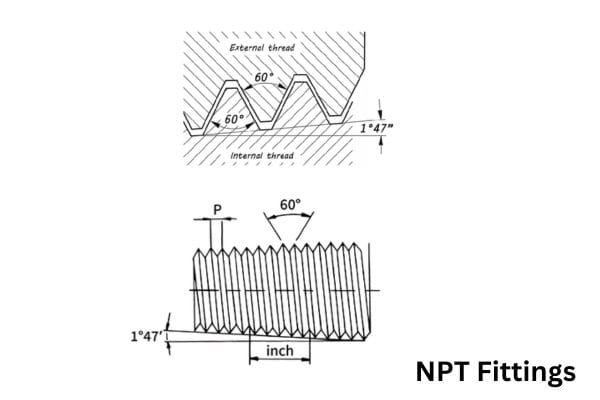

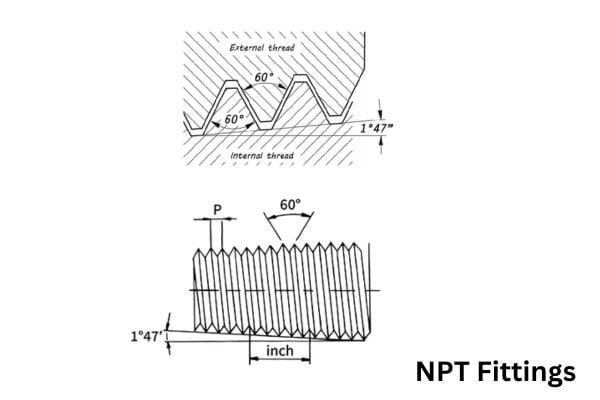

Tapered Design: NPT threads differ from straight threads by gradually tapering towards the end. This tapering creates a wedging effect as the fitting is tightened, enhancing the sealing capability.

Thread Angle: NPT threads have a standardized 60-degree included angle, ensuring a robust engagement that minimizes the risk of leakage under operational pressures.

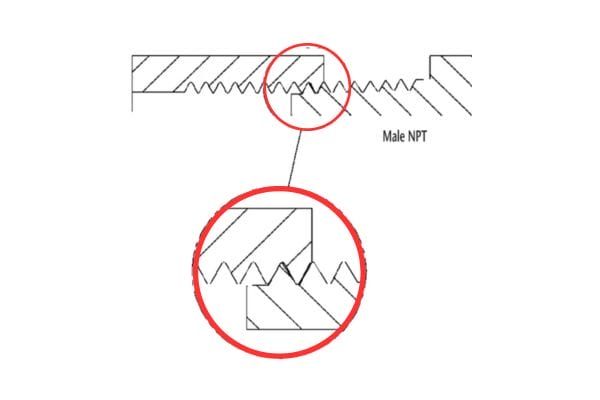

Sealing Mechanism: The sealing action of NPT threads relies on the deformation of the threads themselves when tightened against a mating surface. This design principle is often complemented by the use of sealing materials such as Teflon tape or pipe thread sealant, which further enhances the sealing effectiveness.

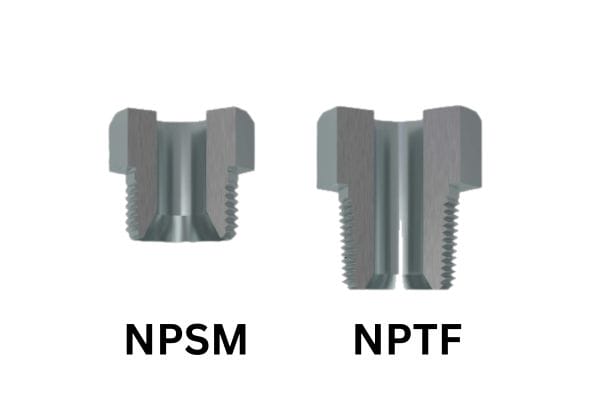

Comparison with Other Pipe Threads

BSP

Thread Type: BSP threads are parallel threads that do not feature a taper like NPT threads.

Sealing Method: BSP fittings typically rely on an O-ring or washer for sealing, rather than the thread deformation used in NPT fittings.

Applications: Commonly used in Europe and other regions, BSP fittings are prevalent in hydraulic systems where consistent, high-pressure sealing is crucial.

Advantages:

Uniformity: BSP threads offer standardized dimensions and specifications, ensuring compatibility across various applications.

Sealing Reliability: The use of O-rings or washers provides reliable sealing under high-pressure conditions.

Limitations:

Installation Complexity: Achieving proper sealing often requires careful alignment and tightening of components.

Compatibility Issues: BSP threads may not be directly interchangeable with NPT threads without adapters due to their different sealing mechanisms.

JIC

Thread Type: JIC threads feature a 37-degree flare angle, designed to create a metal-to-metal seal when engaged.

Sealing Method: Unlike NPT and BSP threads, JIC fittings rely on the flare of the male fitting against a cone seat within the female fitting to achieve a tight seal.

Applications: Widely used in hydraulic systems where vibration resistance and reliable sealing are critical, such as in the aerospace and automotive industries.

Advantages:

Sealing Integrity: Metal-to-metal contact provides robust sealing, resistant to vibration and thermal cycling.

Ease of Assembly: JIC fittings are relatively easy to assemble and disassemble, facilitating maintenance and repair operations.

Limitations:

Space Requirements: The flare design requires sufficient space for installation, which may limit their use in compact or confined spaces.

Specialized Tools: Proper assembly often requires specific tools to ensure correct flare angles and seating.

Types of NPT Pipe Fittings

NPT fittings encompass a diverse range of types, each designed to serve specific functions and accommodate various plumbing and industrial applications. Here’s a detailed exploration of the main types of NPT fittings:

NPT Pipe Elbows

NPT pipe elbows are angled fittings that facilitate directional changes in piping systems. They are available in various angles, typically 45 degrees or 90 degrees, allowing for efficient routing of fluid or gas flow without excessive stress on the piping. These fittings are essential for navigating around obstacles or achieving optimal alignment in complex plumbing layouts.

NPT Adapters

NPT adapters provide a means of transitioning between different thread sizes or types within a piping system. They feature NPT threads on one end and may have a different thread type or size on the other, such as NPT to BSP or NPT to metric threads. Adapters ensure compatibility between components that utilize different thread standards, enabling seamless integration and flexibility in system design.

NPT Couplings

NPT couplings are used to connect two pipes or fittings with NPT threads in a straight-line configuration. These fittings consist of two threaded ends that join together to form a continuous pipeline, providing a secure and leak-free connection. NPT couplings are available in various lengths to accommodate specific spacing requirements or to extend the length of a pipe run.

NPT Plugs and Caps

NPT plugs and caps serve as closure devices for unused openings in piping systems, protecting against debris ingress, leakage, and potential hazards. NPT plugs are internally threaded to fit into NPT threaded openings, sealing the end of a pipe or fitting. Caps, on the other hand, cover the external threads of NPT fittings, preventing contamination and ensuring safety during transportation or storage.

Others

Beyond the commonly used fittings mentioned above, NPT fittings include a wide array of specialized types to meet unique application requirements. These may include:

NPT Tees: Fittings that branch off from a main pipeline into two or more directions, often used to create multi-line systems or junctions.

NPT Crosses: Similar to tees but with additional outlets, allowing for more complex piping configurations.

NPT Reducers and Bushings: Fittings that facilitate transitions between different pipe diameters or thread sizes, ensuring compatibility in diverse plumbing installations.

Each type of NPT fitting plays a crucial role in optimizing fluid or gas handling systems, offering versatility, reliability, and ease of installation. Choosing the right type of NPT fitting depends on factors such as system design requirements, operational conditions, and compatibility with existing components within the plumbing or industrial setup.

Choosing the Right NPT Fitting

Selecting the appropriate NPT (National Pipe Thread) fitting is critical to ensuring compatibility, performance, and safety within plumbing or industrial applications. Consider the following factors when making your selection:

Size and Thread Compatibility

Size: Determine the nominal pipe size (NPS) and the corresponding NPT thread size required for your specific application. Ensure that the fitting matches the size of the pipes or components it will connect to, preventing compatibility issues and leaks.

Thread Compatibility: Verify that all threads—both internal and external—are of the same type (NPT) and size to achieve a proper fit. Misaligned or mismatched threads can lead to leaks and operational inefficiencies over time.

Pressure Rating and Temperature Considerations

Pressure Rating: Evaluate the maximum operating pressure of the NPT fitting under normal conditions. Ensure that the fitting’s pressure rating meets or exceeds the requirements of your system to avoid potential leaks or failures under pressure.

Temperature Range: Consider the temperature extremes that the fitting will encounter during operation. Choose materials and designs capable of withstanding these temperatures without compromising performance or integrity. For high-temperature applications, materials like stainless steel may be preferable due to their heat resistance.

Environmental Factors

Chemical Compatibility: Assess the compatibility of the fitting material with the fluids or gases it will handle. Different chemicals and environments may require specific materials (e.g., stainless steel, brass, PVC) to resist corrosion, degradation, or chemical reactions. Choose materials that offer optimal resistance to the substances present in your application.

Environmental Conditions: Evaluate factors such as exposure to UV radiation, humidity levels, and potential physical impacts. Select fittings that are durable and resistant to environmental stressors to ensure long-term reliability and safety. Materials with UV inhibitors or coatings may be suitable for outdoor or exposed applications where UV exposure is a concern.

Installation Techniques for NPT Fittings

Proper installation of NPT (National Pipe Thread) fittings is essential for ensuring leak-free connections and reliable performance. Follow these detailed steps to achieve correct installation:

Preparation and Inspection

Inspect Components: Before installation, thoroughly examine the NPT fitting, pipes, and mating surfaces. Look for defects, damage, or debris that could compromise the seal. Clean all components meticulously to remove dirt, grease, or remnants of old sealing materials.

Check Thread Condition: Ensure that the threads on both the fitting and the mating surface are clean, undamaged, and free of burrs. Smooth, intact threads are crucial for achieving a proper seal and preventing leaks.

Thread Sealing Methods

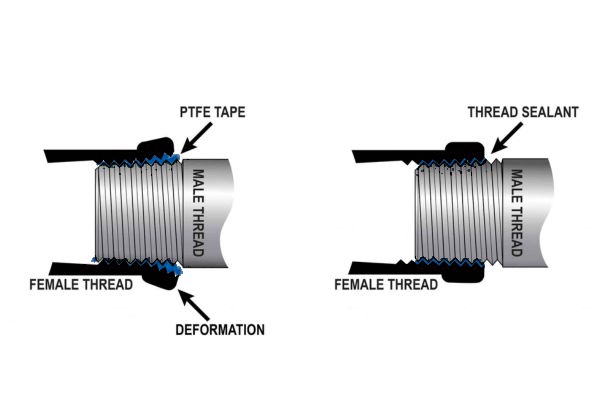

Teflon Tape:

Begin by wrapping Teflon tape around the male threads in a clockwise direction.

Overlap the tape by half on each wrap to ensure a tight seal and complete coverage of the thread surface.

Apply enough layers of Teflon tape to effectively seal the threads without excessive buildup, which could hinder proper tightening.

Pipe Dope (Thread Sealant):

Apply a thin, uniform layer of pipe dope to the male threads using a brush or applicator.

Ensure that the sealant covers the entire thread surface evenly without forming clumps or excess buildup.

Use a pipe dope that is compatible with the application environment and the type of fluid being conveyed through the fitting.

Assembly and Torque Requirements

Hand Tightening:

Begin threading the male fitting into the female fitting or pipe by hand until it is snug.

Avoid cross-threading, as this can damage the threads and compromise the integrity of the seal.

Final Tightening:

Once hand-tightened, use an appropriate wrench to turn the fitting an additional 1.5 to 2 turns.

This final tightening ensures a secure seal without over-torquing, which could potentially damage the threads or fittings.

Torque Requirements:

Consult manufacturer specifications or industry guidelines to determine the recommended torque values based on the size, material, and application of the fitting.

Use a torque wrench to achieve precise tightening within the specified limits, ensuring optimal performance and longevity of the installation.

Inspection and Testing

Leak Check:

After installation, conduct a comprehensive leak test to verify the integrity of the connection.

Perform visual inspections and pressure testing as necessary to detect any signs of leakage.

System Check:

Once the connection is confirmed leak-free, integrate the fitting into the system.

Test the system under operational conditions to ensure proper functionality and performance.

Maintenance and Care of NPT Fittings

Proper maintenance and regular inspection of NPT fittings are crucial to ensure longevity, reliability, and optimal performance within plumbing, industrial, and hydraulic systems. Here’s why maintenance is essential and how to troubleshoot common issues:

Importance of Regular Inspection and Maintenance

Preventative Maintenance: Regular inspections help identify potential issues early, preventing costly repairs or system failures. Routine maintenance extends the lifespan of NPT fittings and ensures uninterrupted operation.

Safety and Reliability: Well-maintained fittings reduce the risk of leaks, which can lead to environmental hazards, operational downtime, and safety concerns. Regular maintenance promotes system reliability and operational efficiency.

Compliance: Adherence to maintenance schedules ensures compliance with industry standards and regulations, maintaining system integrity and safety.

Troubleshooting Common Issues

Leaks: Inspect fittings for signs of leakage, such as moisture or puddles around connections. Ensure proper thread sealing using Teflon tape or pipe dope. Retighten fittings if necessary, following recommended torque specifications. Replace damaged or worn-out fittings promptly to prevent leaks.

Thread Damage: Check threads for wear, corrosion, or stripping. Damaged threads compromise sealing integrity and can lead to leaks. Use thread chasers or taps to repair minor damage. Replace fittings with severe thread damage to maintain system reliability.

Improper Installation: Review installation procedures if issues arise shortly after installation. Verify correct thread compatibility, sealing methods, and torque requirements. Reinstall fittings following manufacturer guidelines to rectify installation errors.

Maintenance Best Practices

Scheduled Inspections: Establish a routine inspection schedule based on operational demands and environmental factors. Inspect fittings during scheduled maintenance intervals or after significant system changes.

Cleaning and Lubrication: Clean fittings and threads regularly to remove debris and contaminants. Apply appropriate lubricants to threads to prevent galling and facilitate assembly.

Documentation: Maintain records of maintenance activities, including inspection dates, repairs, and replacements. Document findings to track fitting performance and identify recurring issues.

Conclusion

In summary, NPT fittings play a crucial role in plumbing and industrial applications due to their unique design and functionality. Key considerations such as size and thread compatibility, pressure rating, temperature capabilities, chemical resistance, and environmental factors are essential when selecting NPT fittings. The importance of NPT fittings lies in their versatility to accommodate various system requirements and operational conditions effectively. Choosing the right NPT fittings enhances system efficiency, longevity, and safety, contributing to overall operational success and reliability.

FAQ

NPT stands for National Pipe Thread. It is a standardized thread type used in the United States for joining pipes and fittings.

NPT fittings are sized based on their nominal pipe size (NPS) and the number of threads per inch (TPI). For example, a 1/2-inch NPT fitting has a nominal diameter of approximately 0.840 inches and 14 TPI.

NPT fittings feature a tapered thread design that provides a tight seal, making them ideal for applications requiring leak-free connections. They are also easy to assemble and disassemble, facilitating maintenance and adjustments.

NPT threads are not compatible with straight threads like BSP (British Standard Pipe) threads due to their tapered design. Adapters or conversion fittings may be required to transition between different thread types.

Common sealing methods for NPT fittings include using Teflon tape or pipe dope (thread sealant) applied to the male threads. Proper application ensures a secure seal and prevents leakage.

NPT fittings are available in various materials such as brass, stainless steel, and PVC. The choice of material depends on factors like compatibility with the fluid or gas being transported, environmental conditions, and durability requirements.