How to Remove a Compression Fitting

Table of Contents

Introduction

Understanding how to remove them correctly can prevent damage to pipes and ensure the longevity and efficiency of the system. Compression fittings, consisting of a nut, a ferrule, and a fitting body, are commonly used to join two pipes or a pipe to a fixture without the need for soldering. They offer a reliable and leak-free connection, making them a popular choice in various applications, from household plumbing to hydraulic machinery. This guide aims to provide you with a comprehensive, step-by-step process for safely and effectively removing compression fittings, ensuring you can handle this task with confidence and precision.

Understanding Compression Fittings

What is a Compression Fitting?

A compression fitting is a type of coupling used to connect two pipes or a pipe to a fixture. This connection method involves compressing a ring (the ferrule) onto the pipe by tightening a nut, creating a secure and leak-free joint. Compression fittings are commonly used because they provide a robust and reliable connection without the need for soldering, making them ideal for both temporary and permanent installations.

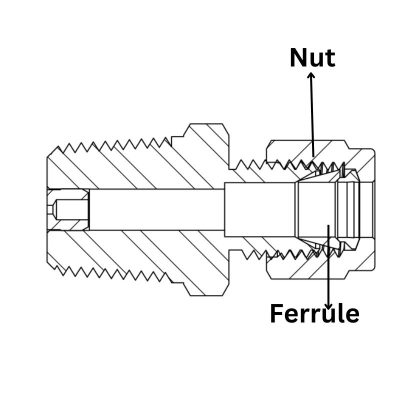

Components

Compression Nut: This is the outermost component that threads onto the fitting body. When tightened, it compresses the ferrule onto the pipe, creating a seal.

Ferrule (or Olive): A ring, typically made of brass or copper, that fits around the pipe. The ferrule is compressed between the nut and the fitting body, forming a tight seal around the pipe.

Fitting Body: The central part of the fitting, connects to the pipe or fixture. It has a threaded section where the compression nut is screwed onto and a seat where the ferrule is compressed against, ensuring a secure connection.

Applications

Compression fittings are widely used in various applications due to their versatility and ease of installation:

Plumbing: They are commonly used in household water supply lines, such as connecting faucets, toilet supply lines, and other fixtures.

Hydraulic Systems: In industrial settings, compression fittings are used in hydraulic lines to join pipes and components that carry fluids under pressure.

Gas Lines: Compression fittings are also used for connecting gas lines, provided they are made of materials that are compatible with the gas type and meet safety standards.

Refrigeration and Air Conditioning: These fittings are utilized in refrigeration and HVAC systems for their ability to withstand high pressure and provide a secure seal.

Advantages and Disadvantages

Advantages:

Ease of Installation: Compression fittings do not require specialized tools or soldering, making them easy to install, even for DIY enthusiasts.

Versatility: They can be used with a variety of pipe materials, including copper, plastic, and steel.

Reliability: When properly installed, compression fittings provide a leak-free connection that can withstand significant pressure.

Reusability: These fittings can be disassembled and reused, making them ideal for temporary installations or situations where changes may be necessary.

Disadvantages:

Risk of Leaks: If not installed correctly, compression fittings can leak. Proper tightening and alignment are crucial to ensure a secure seal.

Limited Vibration Resistance: Compression fittings may loosen over time in systems that experience significant vibrations, requiring periodic inspection and maintenance.

Pressure Limitations: While suitable for many applications, compression fittings may not be ideal for extremely high-pressure systems, where welded or brazed connections are more appropriate.

Material Compatibility: The materials of the fitting and the pipe must be compatible to avoid galvanic corrosion, which can lead to leaks and system failures over time.

Understanding the fundamentals of compression fittings, including their components, applications, and the pros and cons of their use, is essential for anyone involved in plumbing or hydraulic systems. This knowledge ensures that these fittings are used effectively and safely, providing reliable connections in a variety of settings.

Step-by-Step Guide to Removing a Compression Fitting

Preparation Steps

Safety Precautions

Before starting any work on removing a compression fitting, it is crucial to ensure safety. The most important step is to turn off the water supply or depressurize the hydraulic system. This prevents any accidental release of water or fluid, which can cause damage or injury. In plumbing systems, locate the main water shutoff valve and turn it off. For hydraulic systems, follow the manufacturer’s instructions to safely release pressure from the system.

Workspace Setup

A well-prepared workspace is essential for efficient and safe removal of compression fittings. Clear the area around the fitting to ensure you have enough space to work comfortably. Cover nearby surfaces with protective materials to prevent damage from any spilled water or fluid. Ensure proper lighting in the workspace to see the fitting and the tools you are using. Having a clean and organized workspace reduces the risk of accidents and makes the task easier.

Inspect the Fitting

Before proceeding with the removal, inspect the compression fitting for any signs of damage or corrosion. Look for cracks, rust, or any deformation in the fitting, nut, or pipe. Identifying these issues early can help you take necessary precautions and avoid further damage during the removal process. If the fitting is severely corroded or damaged, it may require additional steps or tools to remove it safely.

Turn off the Water Supply or Depressurize the System

Plumbing Systems:

Locate the Main Water Shutoff Valve: The main water shutoff valve is usually found near the water meter or where the main water line enters your house. It could be in a basement, crawlspace, or utility room. Knowing the location of this valve is crucial in case of emergencies and for routine maintenance tasks like removing compression fittings.

Shut Off the Water Supply: Turn the valve clockwise to close it. This action stops the flow of water into your home, ensuring no water will escape when you start working on the compression fitting.

Drain Remaining Water: Open a faucet at the lowest point in your house to drain any remaining water in the system. This step helps to relieve pressure and prevents water from spilling out when you disconnect the compression fitting. It’s also advisable to open a faucet at a higher level to allow air to enter the system and ensure all water drains out completely.

Hydraulic Systems:

Turn Off the Power to the Pump: Begin by turning off the power supply to the hydraulic pump. This prevents any unintentional operation of the pump while you are working on the system.

Open a Pressure Release Valve: Locate and open the pressure release valve to depressurize the system. This step is crucial to avoid any sudden release of pressurized fluid, which can be dangerous.

Drain the Fluid: Allow the hydraulic fluid to drain into a suitable container. Ensure the container is large enough to hold all the fluid and is made of a material that is compatible with the fluid to avoid any chemical reactions. Follow the manufacturer’s instructions for safe disposal of the hydraulic fluid.

Loosen the Compression Nut

Using a Wrench:

Select the Appropriate Size Wrench: Use a wrench that fits snugly around the compression nut to avoid slipping and rounding off the edges of the nut.

Position the Wrench on the Nut: Place the wrench on the compression nut and make sure it is securely in place.

Turn Counterclockwise to Loosen: Apply steady pressure to turn the wrench counterclockwise. It may require some effort, especially if the fitting has been in place for a long time.

Prevent the Fitting Body from Turning: Use a second wrench to hold the fitting body steady. This prevents the entire fitting from turning, which could twist and damage the connected pipes.

Dealing with Stubborn Nuts:

Apply Penetrating Oil: If the nut is difficult to loosen, apply a penetrating oil around the threads. Allow the oil to sit for a few minutes to penetrate and break down any corrosion or debris.

Use Gentle but Firm Pressure: When reattempting to loosen the nut, apply gentle but firm pressure. Avoid using excessive force, which could strip the nut or damage the fitting.

Tapping the Wrench: Lightly tap the wrench with a hammer to help break the nut free. This technique can be useful for loosening stubborn nuts without applying too much force.

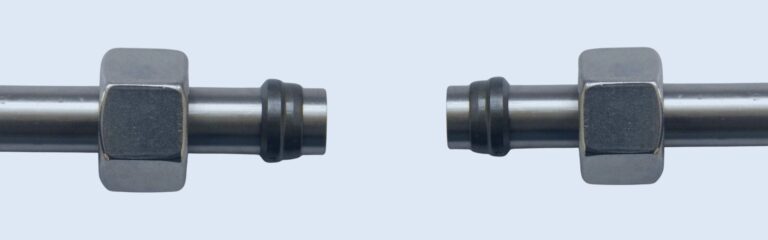

Remove the Compression Nut and Ferrule

Continue Turning the Nut by Hand: Once the nut is loosened, continue turning it by hand to remove it completely. This allows you to control the process and prevent damage.

Slide the Nut and Ferrule Off the Pipe: Carefully slide the compression nut and ferrule off the pipe. If the ferrule is stuck, gently twist it back and forth while pulling it off the pipe. Be patient to avoid damaging the pipe.

Use Pliers if Necessary: If the ferrule is particularly stubborn, you can use a pair of pliers to gently grip and twist it off. Be cautious not to apply too much pressure, which could deform the pipe.

Remove the Pipe from the Fitting

Detaching the Pipe:

Gently Pull the Pipe Out: With the nut and ferrule removed, carefully pull the pipe out of the fitting body.

Use a Twisting Motion: If the pipe is difficult to remove, use a gentle twisting motion while pulling. This can help break any remaining seal and make the removal easier.

Check for Obstructions: Ensure no obstructions or debris inside the fitting could be causing difficulty in removing the pipe.

Inspect the Removed Components

Inspecting for Damage or Wear:

Examine the Compression Nut: Look for any signs of damage, such as cracks or stripped threads. A damaged nut should be replaced to ensure a secure connection when reassembling.

Inspect the Ferrule: Check the Ferrule for any signs of wear, deformation, or corrosion. A worn or damaged ferrule will not create a proper seal and should be replaced.

Check the Fitting Body: Inspect the fitting body for any signs of damage or corrosion. Ensure the seating area where the ferrule sits is clean and smooth.

Examine the Pipe: Look for any cracks, deformities, or signs of wear on the pipe. If the pipe is damaged, it may need to be cut back or replaced before reassembly.

Troubleshooting Common Issues

Stuck Compression Nuts

Apply Penetrating Oil: One of the most effective methods for loosening a stuck compression nut is to use a penetrating oil. Apply the oil generously around the threads of the nut and let it sit for at least 10-15 minutes. This helps to break down any rust or debris that might be causing the nut to stick.

Use Heat: Applying heat can expand the metal and help break the bond. Use a heat gun or a propane torch to heat the nut gently. Be cautious not to overheat and damage surrounding materials. Heat the nut for a few minutes and then try loosening it again with a wrench.

Tapping the Nut: Lightly tapping the nut with a hammer can help to loosen it. This can break the rust or debris holding it in place. Tap around the nut and then try to turn it with a wrench.

Using a Cheater Bar: A cheater bar is an extension added to a wrench to increase leverage. Attach the cheater bar to your wrench and apply steady pressure to turn the nut. This additional leverage can often provide the extra force needed to loosen a stuck nut.

Cutting the Nut: As a last resort, you can use a hacksaw or a rotary tool with a cutting disc to carefully cut through the nut. Make sure to avoid damaging the pipe. Once the nut is cut, it should come off easily.

Damaged Pipes

Assess the Damage: Inspect the pipe thoroughly to determine the extent of the damage. Look for cracks, dents, or bends that could affect the pipe’s integrity.

Cutting the Pipe: If the damage is localized, use a pipe cutter to remove the damaged section. Ensure the cut is clean and straight. Measure and mark the pipe before cutting to avoid removing more than necessary.

Smoothing Edges: After cutting the pipe, use a deburring tool or sandpaper to smooth the edges. This prevents rough edges from damaging the new fitting and ensures a proper seal.

Using Repair Sleeves: For small cracks or holes, you can use a pipe repair sleeve or clamp. These are designed to provide a temporary or permanent fix by clamping over the damaged area and sealing it.

Replacing the Pipe: In cases of extensive damage, it might be necessary to replace the entire section of the pipe. Measure and cut a new piece of pipe to the required length and install it using appropriate fittings.

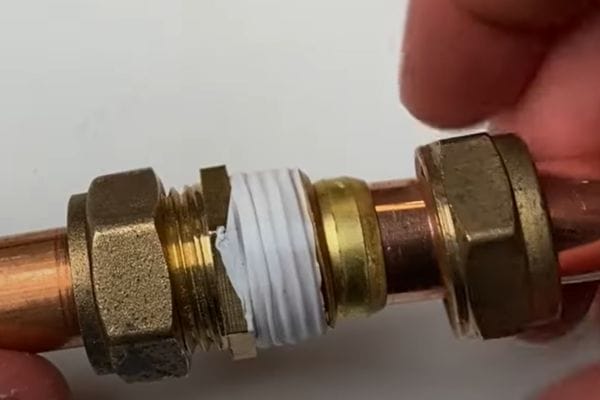

Corroded Fittings

Cleaning Corroded Fittings: For minor corrosion, use a wire brush to clean the fitting. Scrub away the rust and debris until the metal surface is clean. For more stubborn corrosion, use a rust remover or soak the fitting in a vinegar solution.

Applying Anti-Seize Compound: After cleaning, apply an anti-seize compound to the threads of the fitting. This helps to prevent future corrosion and makes it easier to remove the fitting in the future.

Using Corrosion-Resistant Materials: Consider replacing corroded fittings with ones made of corrosion-resistant materials, such as brass or stainless steel. These materials are more durable and less likely to corrode.

Protective Coatings: Apply a protective coating or sealant to the fitting to prevent moisture and air from reaching the metal surface. Products like pipe sealant or plumber’s tape can help protect the fitting from corrosion.

Regular Maintenance: Inspect your fittings regularly for signs of corrosion. Clean and apply anti-seize compound periodically to maintain their condition. Regular maintenance helps to catch and address corrosion issues early before they become significant problems.

By addressing these common issues with compression fittings, you can ensure that your plumbing or hydraulic system remains reliable and efficient. Taking the time to properly troubleshoot and maintain your fittings helps to prevent leaks, reduce downtime, and extend the lifespan of your system.

Conclusion

In summary, this guide has provided detailed steps on safely and effectively removing compression fittings, including turning off the water supply or depressurizing the system, loosening the compression nut, removing the nut and ferrule, detaching the pipe, and inspecting the removed components. Proper removal techniques are crucial to avoid damage to your pipes and fittings, ensuring the integrity and longevity of your system. We encourage you to share your experiences, ask any questions you may have, or seek professional help if needed to ensure the best results in your plumbing or hydraulic projects.

FAQ

A compression fitting is a type of coupling used to connect two pipes or a pipe to a fixture without the need for soldering, consisting of a nut, ferrule, and fitting body.

Signs that a compression fitting may need to be removed include leaks, visible corrosion, or damage to the fitting or connected pipes.

Essential tools include two wrenches (one for the nut and one for the fitting body), penetrating oil, a pipe cutter, and safety gear such as gloves and safety glasses.

While the compression nut and fitting body can often be reused if undamaged, the ferrule is typically not reusable and should be replaced to ensure a proper seal.

Apply penetrating oil and let it sit for a few minutes, use heat to expand the metal, or gently tap the nut with a hammer. As a last resort, you can carefully cut the nut.

Regularly inspect and clean fittings, apply anti-seize compound, use corrosion-resistant materials like brass or stainless steel, and apply protective coatings to prevent moisture and air from reaching the metal surface.