Metric thread ports are specialized fittings designed for fluid transfer in hydraulic and pneumatic systems. These ports utilize metric threading, which is essential for ensuring a secure connection between components. Unlike imperial systems, metric thread ports are standardized according to internationally recognized specifications, facilitating compatibility and interoperability across various applications. The use of metric threads helps to streamline manufacturing processes and reduce the likelihood of assembly errors.

Understanding ISO 6149-1

A. History and Development of ISO 6149-1

The ISO 6149-1 standard was developed to address the growing need for a unified approach to metric thread ports in hydraulic systems. Established by the International Organization for Standardization (ISO), this standard emerged in response to the industrial push for greater compatibility and efficiency in hydraulic machinery. Initially published in the early 2000s, ISO 6149-1 aimed to provide clear specifications that would facilitate the interchangeability of hydraulic components across different manufacturers and applications.

The standard was developed through collaboration among various stakeholders, including engineers, manufacturers, and industry experts. This collective effort ensured that the standard would meet the practical needs of the industry while also adhering to stringent safety and performance criteria. As hydraulic technology advanced, ISO 6149-1 underwent revisions to keep pace with innovations in design and materials, ensuring its ongoing relevance in a rapidly evolving field.

B. Key Features of ISO 6149-1

Thread Specifications

ISO 6149-1 defines a specific set of thread dimensions and tolerances for metric threaded ports. The standard primarily focuses on the following aspects:

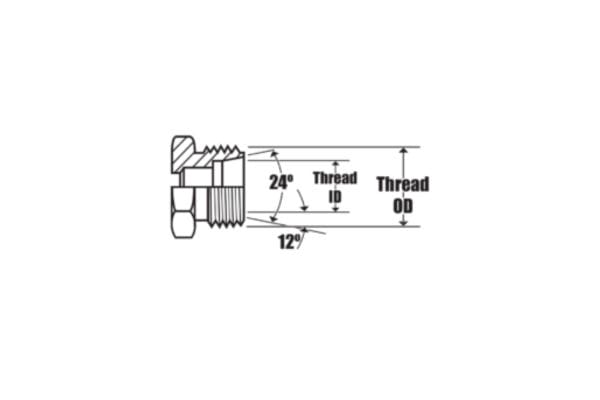

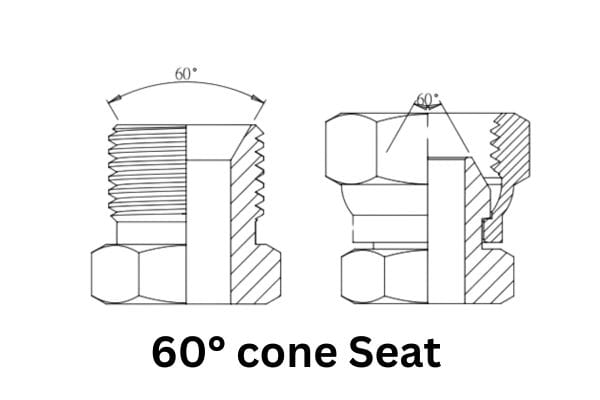

Thread Form: ISO 6149-1 specifies a metric thread form (M profile) characterized by a 60-degree thread angle. This form is designed to provide effective sealing and high tensile strength, crucial for high-pressure applications.

Thread Size: The standard details various thread sizes, ensuring that components can be matched accurately. Common sizes include M10, M12, M14, and larger diameters, with each size defined by its nominal diameter and pitch.

Tolerances: The standard establishes specific tolerances for thread dimensions to ensure proper fit and function. These tolerances are critical for preventing leaks and ensuring reliable connections between components.

Design Characteristics

ISO 6149-1 also outlines several design characteristics that enhance the functionality and performance of metric thread ports:

Sealing Mechanisms: The standard emphasizes the importance of effective sealing to prevent fluid leakage. It specifies design features that accommodate O-rings and other sealing solutions, ensuring robust connections.

Material Compatibility: ISO 6149-1 encourages the use of materials that can withstand harsh operating conditions, including high pressure and temperature variations. Common materials include steel, stainless steel, and various alloys, which provide the necessary strength and corrosion resistance.

Surface Finish: The standard specifies acceptable surface finishes for threaded ports, contributing to the overall sealing integrity and reducing wear over time.

C. Applications and Industry Relevance

ISO 6149-1 finds widespread application across various industries, particularly those that rely on hydraulic systems. Key sectors include:

Construction and Heavy Equipment: Hydraulic machinery used in construction—such as excavators and bulldozers—often employs ISO 6149-1 ports to facilitate efficient fluid transfer and control.

Agriculture: Modern agricultural equipment, including tractors and harvesters, utilizes these standards to ensure reliable performance in demanding environments.

Manufacturing: Hydraulic systems in manufacturing processes, such as presses and conveyors, benefit from the compatibility and efficiency provided by ISO 6149-1 specifications.

Automotive: The automotive industry employs ISO 6149-1 for various hydraulic applications, including braking systems and power steering, where reliable fluid connections are paramount.

The relevance of ISO 6149-1 extends beyond mere compatibility; it enhances the safety and reliability of hydraulic systems, reducing the risk of catastrophic failures and improving overall operational efficiency.

D. Comparison with Other Standards

ISO 6149-1 is often compared with other standards governing metric thread ports, such as DIN 3852-1 and SAE J514. While each standard has its unique features and specifications, there are notable differences:

Thread Form and Dimensions: DIN 3852-1, for instance, also specifies metric threads but may differ in certain dimensions and tolerances. ISO 6149-1 focuses more on sealing capabilities, whereas DIN 3852-1 emphasizes general thread compatibility.

Application Focus: ISO standards generally have a broader international application, while DIN standards may be more specific to certain European contexts. This can affect the choice of standards based on regional regulations and industry practices.

Sealing Methods: ISO 6149-1 is particularly recognized for its emphasis on effective sealing mechanisms, often incorporating features like O-rings. In contrast, other standards may have varying approaches to sealing, influencing the design of hydraulic components.

Understanding DIN 3852-1

A. History and Development of DIN 3852-1

DIN 3852-1 is a standard that addresses the specifications for metric thread ports used in hydraulic applications, developed by the German Institute for Standardization (Deutsches Institut für Normung, DIN). Established in the late 20th century, DIN 3852-1 emerged as a response to the need for uniformity in hydraulic fittings, particularly in the context of the European market. The standard was formulated to enhance compatibility among manufacturers and promote safety in hydraulic systems.

The development process involved extensive collaboration with industry stakeholders, including engineers, manufacturers, and technical experts. This collaboration ensured that the standard would effectively address the practical needs of the industry while adhering to safety and performance benchmarks. As hydraulic technologies advanced, DIN 3852-1 was periodically revised to incorporate new materials, design innovations, and best practices, maintaining its relevance in a dynamic engineering landscape.

B. Key Features of DIN 3852-1

Thread Specifications

DIN 3852-1 specifies various dimensions and tolerances for metric threaded ports, focusing on several critical aspects:

Thread Form: The standard employs a metric thread form (M profile) with a 60-degree thread angle, which is similar to ISO 6149-1. This design promotes effective sealing and high tensile strength, making it suitable for high-pressure applications.

Thread Sizes: DIN 3852-1 outlines a range of thread sizes, including M10, M12, and larger diameters. Each size is defined by its nominal diameter and pitch, ensuring that components can be correctly matched.

Tolerances: Specific tolerances are established for thread dimensions to ensure proper fit and functionality. These tolerances are vital for preventing leaks and ensuring reliable connections between hydraulic components.

Design Characteristics

In addition to thread specifications, DIN 3852-1 outlines essential design characteristics that enhance the performance of metric thread ports:

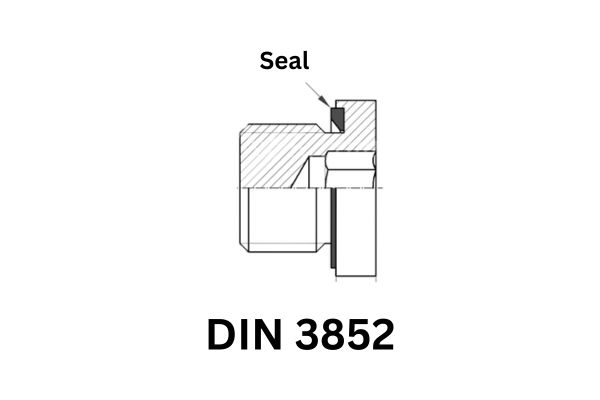

Sealing Solutions: The standard emphasizes effective sealing to prevent fluid leaks. DIN 3852-1 typically incorporates features that accommodate O-rings and other sealing methods, ensuring a robust connection.

Material Selection: DIN 3852-1 encourages the use of materials that can endure demanding operating conditions, including variations in pressure and temperature. Common materials include carbon steel, stainless steel, and various alloys, which provide the necessary strength and corrosion resistance.

Surface Finish: The standard specifies acceptable surface finishes for threaded ports, which are crucial for maintaining sealing integrity and minimizing wear over time.

C. Applications and Industry Relevance

DIN 3852-1 is widely utilized across various industries that rely on hydraulic systems. Its key applications include:

Construction and Heavy Machinery: Hydraulic equipment used in construction, such as cranes and excavators, frequently employs DIN 3852-1 ports for efficient fluid transfer and control.

Agricultural Machinery: Modern agricultural implements, including tractors and sprayers, benefit from the compatibility and reliability offered by DIN 3852-1 specifications.

Manufacturing Equipment: Hydraulic systems in manufacturing, such as automated presses and robotic arms, utilize DIN 3852-1 for dependable performance in high-stress environments.

Automotive Industry: Hydraulic applications in vehicles, including braking systems and power steering, often incorporate DIN 3852-1 standards to ensure safe and reliable operation.

The relevance of DIN 3852-1 extends beyond compatibility; it enhances the overall safety and reliability of hydraulic systems, reducing the risk of failures and improving operational efficiency.

D. Comparison with Other Standards

When comparing DIN 3852-1 with other standards, such as ISO 6149-1 and SAE J514, several differences and similarities emerge:

Thread Specifications: Both DIN 3852-1 and ISO 6149-1 utilize a metric thread form, but there may be variations in specific dimensions and tolerances. These differences can impact the choice of standard based on the required application.

Sealing Mechanisms: While both standards emphasize effective sealing, DIN 3852-1 may offer different design approaches. ISO 6149-1 is particularly noted for its detailed sealing requirements, while DIN 3852-1 focuses on general compatibility with sealing solutions.

Regional Focus: DIN standards are often more prevalent in Europe, whereas ISO standards have a broader international application. This can influence the choice of standards based on regional regulations and industry practices.

Applications: Both standards are applicable in hydraulic systems, but the choice may depend on specific industry requirements, manufacturing practices, and regional preferences.

Comparing ISO 6149-1 and DIN 3852-1

A. Similarities Between the Two Standards

ISO 6149-1 and DIN 3852-1 share several key similarities, making them both critical standards in the realm of hydraulic systems:

Metric Thread Form: Both standards utilize a metric thread form with a 60-degree thread angle. This commonality ensures compatibility in threaded connections, facilitating the interchangeability of components across different manufacturers.

Emphasis on Sealing: Each standard prioritizes effective sealing mechanisms to prevent fluid leakage. They specify features that accommodate O-rings and other sealing solutions, enhancing the overall integrity of hydraulic connections.

Applications in Hydraulics: ISO 6149-1 and DIN 3852-1 are specifically designed for hydraulic applications, making them essential references for engineers and manufacturers in the hydraulic industry. Both standards support similar applications across sectors like construction, agriculture, and manufacturing.

Focus on Material Compatibility: Both standards recommend materials capable of withstanding high pressures and temperature variations. Common materials, such as carbon steel and stainless steel, are endorsed to ensure durability and reliability in hydraulic systems.

These similarities help create a foundation for compatibility and performance in hydraulic fittings, streamlining manufacturing and assembly processes.

B. Differences in Specifications

Despite their similarities, ISO 6149-1 and DIN 3852-1 have notable differences that can influence the choice of the standard:

Thread Dimensions and Tolerances: While both standards define thread sizes and tolerances, they may differ slightly in their specific dimensions. For example, the pitch and tolerances for certain thread sizes may vary, which can affect the fit between components.

Sealing Approaches: ISO 6149-1 provides a more detailed focus on sealing requirements compared to DIN 3852-1. This includes specifications for specific sealing methods and the performance of O-rings, ensuring a more rigorous sealing standard in various applications.

Design Characteristics: Each standard has unique design characteristics that cater to different aspects of hydraulic applications. DIN 3852-1 might prioritize certain features that are more relevant to specific European applications, while ISO 6149-1 may include broader specifications suited for international use.

Regional Usage: ISO 6149-1 is more widely recognized and adopted internationally, while DIN 3852-1 is primarily used in Europe. This geographical distinction can influence the choice of standard based on the location of manufacturing and end-use applications.

These differences can significantly impact the selection of components for specific applications, affecting assembly and overall system performance.

C. Choosing Between ISO 6149-1 and DIN 3852-1

When deciding between ISO 6149-1 and DIN 3852-1, several factors should be considered:

Application Requirements: Evaluate the specific needs of the hydraulic system in question. If the application requires stringent sealing performance, ISO 6149-1 may be preferable due to its detailed sealing specifications.

Manufacturer Compatibility: Consider the existing components and systems in use. If a system is already designed around one standard, it may be more efficient to continue using that standard for new components to maintain compatibility.

Geographic Considerations: If operating primarily in Europe, DIN 3852-1 might be more advantageous due to its regional familiarity among manufacturers. Conversely, if the system is intended for international use, ISO 6149-1 is likely to offer broader compatibility.

Industry Standards: Certain industries may have preferred standards based on historical use or regulatory requirements. It is crucial to understand any industry-specific standards that may dictate the choice between ISO and DIN.

By carefully evaluating these factors, engineers and manufacturers can make informed decisions that enhance the performance and reliability of their hydraulic systems.

D. Impact on Product Compatibility

The compatibility of products based on ISO 6149-1 and DIN 3852-1 is a critical consideration in the hydraulic industry. The differences and similarities between the two standards can influence how well components fit and function together:

Interchangeability: Components designed to ISO 6149-1 may not always fit seamlessly with those made to DIN 3852-1 due to differences in tolerances and dimensions. This can result in issues such as leaks or compromised performance if not carefully managed.

Supply Chain Implications: Manufacturers must consider their supply chain when selecting standards. Sourcing components from different suppliers adhering to different standards may complicate assembly and increase the risk of compatibility issues.

Safety and Reliability: In hydraulic applications, ensuring that components are compatible is vital for maintaining system integrity and safety. Mismatched fittings can lead to catastrophic failures, emphasizing the need for careful standard selection and adherence.

Future-Proofing: As technology evolves, understanding the implications of standard choice on compatibility becomes increasingly important. Selecting a widely adopted standard like ISO 6149-1 may provide greater flexibility and compatibility with future innovations in hydraulic technology.

Conclusion

The importance of understanding metric thread ports extends beyond mere technical specifications; it encompasses the overall functionality and efficiency of hydraulic systems. These ports are integral components that influence fluid flow, pressure management, and the longevity of hydraulic equipment. As industries evolve and the demand for innovative hydraulic solutions increases, knowledge of these standards will become even more essential. It not only ensures the proper selection of components but also enhances the safety and reliability of hydraulic systems, ultimately contributing to smoother operations and reduced downtime.

FAQ

What are metric thread ports?

Metric thread ports are specialized fittings used in hydraulic and pneumatic systems, designed with metric threads to ensure compatibility and secure connections between components.

What is the significance of ISO 6149-1 and DIN 3852-1?

ISO 6149-1 and DIN 3852-1 are standards that define the specifications for metric thread ports, ensuring compatibility, safety, and performance in hydraulic applications.

How do ISO 6149-1 and DIN 3852-1 differ?

While both standards focus on metric thread ports, they differ in specific dimensions, tolerances, sealing approaches, and regional applicability.

Which standard should I choose for my hydraulic system?

The choice between ISO 6149-1 and DIN 3852-1 depends on your specific application requirements, existing components, and geographic considerations.

Why is sealing important in metric thread ports?

Effective sealing is crucial to prevent fluid leaks, which can compromise the performance and safety of hydraulic systems.

How can I ensure compatibility between components?

To ensure compatibility, carefully select components that adhere to the same standard (ISO 6149-1 or DIN 3852-1) and verify thread sizes and tolerances.