Unlike tapered threads, which rely on the angle of the threads to form a seal, parallel threads utilize a flat surface and an O-ring to create a reliable connection. This design not only enhances the sealing capabilities but also allows for easier reusability and maintenance. With various types of materials and specifications available, understanding the characteristics of parallel threaded fittings can help users optimize their systems effectively.

Understanding Parallel Threaded Fittings

A. Definition and Characteristics

Parallel threaded fittings are designed with threads that run parallel to the fitting’s axis, providing a distinct sealing mechanism compared to tapered threads. These fittings typically incorporate an O-ring or other sealing materials to ensure a leak-proof connection. The characteristics of parallel threaded fittings include:

Thread Geometry: The threads are uniform and maintain a consistent diameter throughout their length, which allows for precise alignment during assembly.

Sealing Mechanism: The use of O-rings or flat sealing surfaces creates a robust seal, making these fittings ideal for applications where fluid retention is crucial.

Reusability: Many parallel threaded fittings can be disassembled and reassembled without loss of sealing integrity, making them suitable for applications requiring frequent maintenance.

B. Types of Parallel Threads

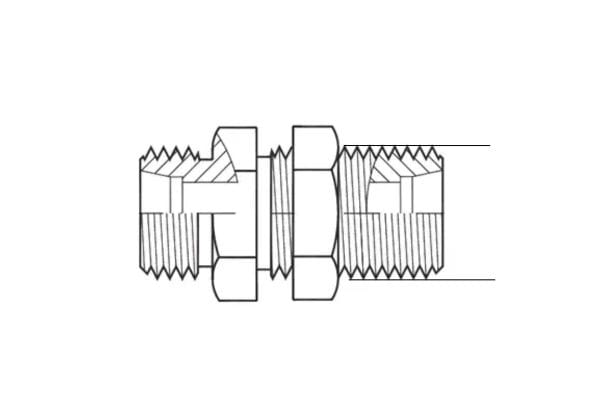

Straight Threads:

Straight threaded fittings feature a uniform diameter without a taper. They rely on the compression of the O-ring to create a seal when the fitting is tightened. This type is prevalent in hydraulic and pneumatic systems where consistent performance is required.

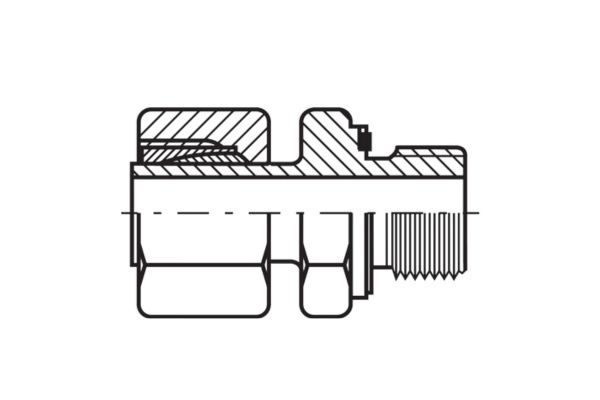

O-Ring Boss Threads:

O-ring boss threads are a specific type of straight thread fitting that includes an O-ring groove. This design allows for a tighter seal by compressing the O-ring against a flat surface as the fitting is tightened. These fittings are particularly beneficial in high-vibration applications due to their enhanced sealing capabilities.

C. Comparison with Tapered Thread Fittings

Parallel threaded fittings differ significantly from tapered thread fittings, which have threads that gradually decrease in diameter towards the end. The primary differences include:

Sealing Method: Tapered threads form a seal through the physical interlocking of the threads, while parallel threads rely on an O-ring or flat surface for sealing.

Installation Flexibility: Parallel threads allow for adjustments during installation, as the position can be altered without compromising the seal. In contrast, tapered threads are fixed once installed.

Reusability: While tapered threads can wear out with repeated use, parallel threaded fittings can be disassembled and reused effectively, making them a more sustainable choice for many applications.

D. Benefits of Parallel Threaded Fittings

Versatility in Applications

Parallel threaded fittings are used across various industries, including automotive, aerospace, and manufacturing. Their design allows them to function effectively in both hydraulic and pneumatic systems, making them suitable for diverse applications. This versatility is attributed to their ability to handle different fluids and gases under varying pressures and temperatures.

Ease of Installation and Reusability

One of the standout features of parallel threaded fittings is their ease of installation. The straightforward design allows for quick assembly without requiring special tools, significantly reducing downtime during maintenance. Moreover, because they can be reused multiple times without significant wear, parallel threaded fittings are not only cost-effective but also environmentally friendly. Users can simply replace the O-ring during maintenance to maintain the integrity of the fitting.

Enhanced Sealing Capabilities

The sealing mechanism of parallel threaded fittings is another significant advantage. The O-ring compression provides a more effective seal compared to traditional tapered threads, minimizing the risk of leaks. This characteristic is particularly crucial in applications involving high-pressure environments, where any leakage could lead to severe safety hazards or system failures. Additionally, their performance in high-vibration scenarios makes them ideal for dynamic applications where movement could compromise other types of fittings.

E. Common Applications of Parallel Threaded Fittings

A. Hydraulic Systems

In hydraulic systems, parallel threaded fittings are essential for connecting hoses, pipes, and components that transport hydraulic fluid under high pressure. Their design allows for a secure, leak-proof connection, which is critical for maintaining system integrity. These fittings are used in various applications, including:

Heavy Machinery: Equipment such as excavators, bulldozers, and forklifts utilize hydraulic systems that require robust and reliable fittings.

Manufacturing Equipment: Hydraulic presses and conveyors often depend on these fittings to ensure efficient fluid transfer and system performance.

Agricultural Equipment: Tractors and other farm machinery leverage hydraulic systems for operations such as lifting and steering.

B. Pneumatic Systems

In pneumatic systems, which rely on compressed air to operate tools and machinery, parallel threaded fittings provide efficient connections that withstand high pressure. Their ability to create airtight seals is essential for maintaining system pressure and performance. Common applications include:

Air Tools: Pneumatic tools such as drills, wrenches, and hammers use parallel threaded fittings to connect to air hoses and compressors.

Automation Equipment: Many manufacturing processes use pneumatic systems for automation, requiring reliable fittings to maintain consistent airflow.

Transportation: Pneumatic systems in trains and buses often use these fittings to connect braking systems and door mechanisms.

C. Plumbing and HVAC

In plumbing and HVAC (Heating, Ventilation, and Air Conditioning) applications, parallel threaded fittings are frequently employed to connect pipes and valves, ensuring a leak-free operation. Key uses include:

Water Supply Lines: These fittings are used in residential and commercial plumbing to connect pipes supplying water to fixtures and appliances.

Heating Systems: In hydronic heating systems, parallel threaded fittings connect radiators, boilers, and piping, facilitating efficient heat distribution.

Air Conditioning Units: HVAC systems use these fittings to connect refrigerant lines, ensuring proper flow and system efficiency.

D. Industrial Machinery

Industrial machinery across various sectors relies on parallel threaded fittings for their durability and performance under challenging conditions. Applications in this category include:

Manufacturing Plants: Machinery used for cutting, milling, and fabricating materials often requires parallel threaded fittings for hydraulic and pneumatic connections.

Assembly Lines: Automated assembly lines depend on pneumatic systems to operate tools and convey materials, necessitating reliable fittings to maintain pressure and efficiency.

Material Handling: Equipment such as conveyors and lifts utilize parallel threaded fittings to ensure smooth operation and effective material transfer.

E. Automotive Applications

In the automotive industry, parallel threaded fittings play a vital role in ensuring the safety and functionality of vehicles. Their applications include:

Brake Systems: Parallel threaded fittings are used to connect brake lines and components, providing a secure and leak-proof seal necessary for safe braking performance.

Fuel Systems: These fittings are utilized in fuel lines to connect tanks, pumps, and injectors, ensuring efficient fuel delivery and minimizing the risk of leaks.

Cooling Systems: In engine cooling systems, parallel threaded fittings connect hoses and radiators, facilitating the effective transfer of coolant to maintain optimal engine temperatures.

Key Considerations When Choosing Parallel Threaded Fittings

A. Material Selection

Choosing the right material for parallel threaded fittings is crucial as it directly impacts durability, performance, and compatibility with the fluids being transported. The most common materials include:

Stainless Steel:

Advantages: Known for its strength and corrosion resistance, stainless steel is ideal for high-pressure and high-temperature applications. It is particularly suitable for environments exposed to moisture or corrosive chemicals.

Considerations: While it offers superior durability, stainless steel fittings can be more expensive and heavier than other materials.

Brass:

Advantages: Brass is a popular choice due to its good corrosion resistance and ease of machining. It is effective for a variety of applications, including water, gas, and air lines.

Considerations: Brass fittings may not be suitable for high-temperature applications, as they can deform under extreme heat. Additionally, some brass alloys may contain lead, which can be a health concern in potable water applications.

Plastic:

Advantages: Plastic fittings are lightweight, cost-effective, and resistant to corrosion. They are commonly used in low-pressure applications and for transporting non-aggressive fluids.

Considerations: Plastic fittings may not withstand high temperatures or pressures, limiting their application range. They are also less durable compared to metal fittings.

B. Size and Dimensions

Understanding thread sizes and standards is essential for ensuring a proper fit between components. Key considerations include:

Thread Standards: Familiarize yourself with international standards such as ISO, NPT (National Pipe Thread), and BSP (British Standard Pipe) to ensure compatibility. Different standards can have varying thread angles and profiles, which can impact sealing performance.

Measurement: Accurately measuring the diameter and pitch of threads is vital. Using calipers or thread gauges can help in determining the exact specifications needed for a proper fit.

Sizing Up: When in doubt, consider the application requirements. Selecting a slightly larger fitting can provide more flexibility in terms of flow rates and pressure handling.

C. Pressure and Temperature Ratings

Each fitting comes with specific pressure and temperature ratings that must be adhered to for safe operation. Consider the following:

Pressure Rating: Verify the maximum working pressure of the fitting. Using a fitting beyond its rated pressure can lead to failure, causing leaks or catastrophic system breakdowns.

Temperature Rating: Different materials have varying temperature tolerances. Ensure that the selected fittings can operate effectively within the temperature range of your system. For instance, stainless steel generally offers higher temperature resistance compared to plastic.

Environmental Factors: Consider environmental conditions such as humidity, exposure to chemicals, and temperature fluctuations that might affect the fitting’s performance over time.

D. Compatibility with Existing Systems

Ensuring compatibility with existing systems is critical for seamless operation. Key aspects to consider include:

Existing Fittings: Check the type and material of fittings currently in use. Mixing materials (e.g., metal and plastic) can lead to compatibility issues and potential failures.

Fluid Type: Consider the type of fluid or gas being transported. Certain materials may react adversely with specific substances, leading to degradation or leakage. For example, some plastics may not be suitable for solvents or oils.

System Configuration: Assess the overall configuration of your system, including space limitations and accessibility for installation and maintenance. The fitting’s design should complement the existing layout without causing obstructions.

E. Cost vs. Quality Considerations

When selecting parallel threaded fittings, balancing cost with quality is essential for long-term satisfaction:

Initial Cost: While cheaper fittings may be attractive initially, they can lead to higher maintenance and replacement costs down the line. Investing in quality fittings can reduce the frequency of replacements and associated labor costs.

Quality Indicators: Look for reputable manufacturers who provide certifications or quality assurance. Fittings that meet industry standards are generally more reliable and durable.

Total Cost of Ownership: Consider the total cost over the fitting’s lifecycle, including installation, maintenance, and potential downtime. Sometimes, a higher upfront cost can lead to greater savings in the long run.

Installation and Maintenance Tips

Proper installation and ongoing maintenance of parallel threaded fittings are critical to ensuring their performance and longevity. Below are essential techniques and practices to help achieve optimal results.

A. Proper Installation Techniques

Tools and Equipment Needed:

Wrenches: Use adjustable or torque wrenches to ensure that fittings are tightened to the correct specifications. Avoid using pliers, as they can damage the fitting.

Pipe Sealants: Depending on the application, consider using appropriate thread sealants or Teflon tape to enhance the seal and prevent leaks. Make sure the sealant is compatible with the fluids involved.

Cleaning Tools: Clean the threads of both the fitting and the mating surface to remove any debris or old sealant that could compromise the seal.

Torque Specifications:

Always refer to the manufacturer’s guidelines for torque specifications, as over-tightening can lead to fitting damage or deformation. Proper torque ensures a secure connection without risking the integrity of the threads.

Use a torque wrench to achieve the specified torque evenly, ensuring that the fitting is snug but not overly tight. If available, follow a star pattern for tightening to distribute pressure evenly.

B. Maintenance Practices for Longevity

Regular Inspections:

Periodically inspect fittings for signs of wear, corrosion, or leaks. Early detection of issues can prevent more significant problems down the line.

Check for any discoloration or cracking in plastic fittings, and for rust or pitting in metal fittings, as these can indicate deterioration.

Cleaning:

Keep fittings clean to avoid buildup of contaminants that can impair functionality. Use appropriate cleaning solutions compatible with the materials of the fittings.

After cleaning, ensure that the surfaces are completely dry before reassembling, as moisture can lead to rust or corrosion.

O-ring Replacement:

In parallel threaded fittings that utilize O-rings, regularly check the O-ring condition and replace them as necessary. Signs of wear include cracking, hardening, or loss of flexibility.

Always use O-rings that meet the specifications for the fitting and the fluids being transported to ensure compatibility and effective sealing.

C. Troubleshooting Common Issues

Leaks:

If a fitting is leaking, first check to see if it is adequately tightened. If not, use a torque wrench to adjust to the proper specifications.

If the fitting continues to leak, inspect the O-ring and mating surfaces for damage or contamination. Clean or replace components as necessary.

Difficulty in Disassembly:

If fittings are difficult to disassemble, apply penetrating oil to help loosen any corrosion or buildup that may have formed. Allow it to sit for a while before attempting to disassemble again.

Use appropriate tools to avoid damaging the fitting during removal.

Pressure Loss:

Pressure loss in a system using parallel threaded fittings may indicate a poor seal or a blockage in the line. Check all fittings for tightness and inspect hoses or pipes for any obstructions.

Consider testing the system with a pressure gauge to determine where the loss is occurring, allowing for targeted troubleshooting.

Conclusion

As we explored, the versatility of parallel threaded fittings makes them suitable for a wide array of applications. Their ease of installation, enhanced sealing capabilities, and ability to be reused further establish their importance in ensuring system efficiency and safety. However, users must remain vigilant in evaluating compatibility with existing systems, understanding size, and pressure ratings, and balancing cost with quality to ensure optimal performance.

FAQ

What are parallel threaded fittings?

Parallel threaded fittings have threads that run parallel to the fitting’s axis and typically use an O-ring or flat surface for sealing, making them ideal for high-pressure applications.

What materials are commonly used for these fittings?

Common materials include stainless steel, brass, and plastic, each offering different advantages in terms of durability, corrosion resistance, and cost.

How do I know the correct size and thread type for my fittings?

Measure the diameter and thread pitch accurately, and refer to international standards such as ISO, NPT, or BSP to ensure compatibility.

What are the benefits of using parallel threaded fittings?

Benefits include enhanced sealing capabilities, ease of installation and reusability, and versatility in various applications across industries.

How should I maintain parallel threaded fittings?

Regularly inspect for wear or leaks, clean fittings to remove contaminants, and replace O-rings as needed to ensure optimal performance.

What should I do if my fitting is leaking?

Check the tightness of the fitting, inspect the O-ring and surfaces for damage, and replace any worn components as necessary to stop the leak.