If you don’t follow the right steps to remove a compression fitting, you risk damaging the pipe itself. Applying excessive force, using the wrong tools, or rushing the process can lead to cracked or bent pipes, misaligned fittings, and leaks.

When to Remove a Compression Fitting

Compression fittings play an important role in securing your plumbing system, but over time, they may need to be removed for various reasons. Understanding when and why it’s necessary to remove a compression fitting can save you from headaches and costly repairs in the future.

Signs It’s Time to Remove the Compression Fitting

There are a few telltale signs that indicate your compression fitting needs to be removed. These include:

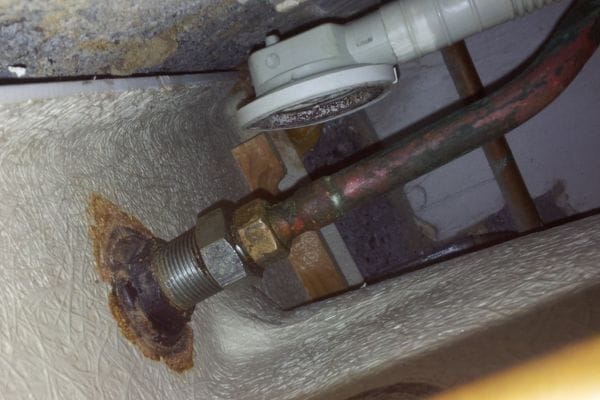

Leaks or Drips: If you notice water leaking around the fitting, it could be a sign that the compression nut or ferrule is no longer creating a proper seal. This is often a primary indicator that removal is needed to replace or repair the fitting.

Corrosion or Rust: Over time, compression fittings may corrode due to exposure to moisture, which can weaken the fitting’s integrity. Corrosion can lead to leaks and other issues, so it’s best to remove the fitting for inspection and replacement.

Wear and Tear: If the fitting has been in place for years, it may have suffered from general wear and tear. Fittings can become cracked, bent, or otherwise damaged, making it necessary to replace them with a new one.

Difficulties Tightening or Loosening: If you’re finding it difficult to tighten or loosen the compression fitting, it may be a sign that the fitting has become stripped, warped, or misaligned. Removal may be necessary to ensure everything is working smoothly.

Why Removal Might Be Necessary: Leaks, Replacements, and Maintenance

There are several reasons you might need to remove a compression fitting:

Leaks: A common reason to remove a compression fitting is to fix a leak. If the fitting isn’t sealing properly, it can result in water leakage that damages pipes and surrounding materials. Removing the fitting will allow you to inspect and replace any damaged components, ensuring your pipes are secure again.

Replacements: Compression fittings often need to be replaced due to age, wear, or malfunction. Regular maintenance can help prevent problems, but eventually, the fitting may need to be replaced to maintain the system’s efficiency. Removal is the first step in replacing the old fitting with a new one.

Routine Maintenance: Compression fittings, like any other part of your plumbing system, benefit from regular maintenance. If you’re inspecting your pipes or doing a routine check-up on your plumbing system, you might need to remove compression fittings to check for corrosion, blockages, or potential future issues. Re-tightening, cleaning, or replacing them as part of regular maintenance ensures that your plumbing system remains reliable and leak-free.

Step-by-Step Guide to Remove Compression Fitting Without Damaging Your Pipes

Removing a compression fitting doesn’t have to be a daunting task. By following these simple steps, you can ensure that the process goes smoothly without causing any harm to your pipes. Whether you’re replacing a fitting, repairing a leak, or performing routine maintenance, this guide will walk you through the entire process.

Step 1: Turn Off Water Supply

Before you start any plumbing work, safety comes first. Always turn off the water supply to the affected area to avoid unnecessary water leaks or damage. This ensures that you won’t face a burst pipe or flooding while working.

Locate the Shutoff Valve: Find the water shutoff valve near the area where you’re working. This is usually located under sinks or near the main water supply.

Turn Off the Valve: Rotate the valve clockwise to stop the flow of water. If the area is connected to a larger system, ensure that the main water supply is turned off.

Step 2: Clear the Area and Gather Tools

Creating a safe and organized workspace is essential for a smooth removal process. Make sure you have everything you need to avoid interruptions during the task.

Clear the Area: Remove any items or obstructions around the fitting to give yourself plenty of room to work. This includes moving away any towels, tools, or other materials that could get in your way.

Gather Your Tools: You’ll need a few basic tools to remove the compression fitting:

Compression Fitting Wrench (or adjustable wrench)

Pipe Cutter (if you need to cut the pipe)

Penetrating Oil (for stubborn fittings)

Towel or Bucket (to catch any residual water)

Step 3: Loosen the Compression Nut with a Wrench

Once the area is clear and your tools are ready, it’s time to begin loosening the compression nut, which is the main component that holds the fitting in place.

Position the Wrench: Use a compression fitting wrench or adjustable wrench to grip the compression nut. Make sure it’s positioned tightly around the nut, without slipping or damaging the threads.

Turn Counterclockwise: Slowly and carefully turn the wrench counterclockwise to loosen the nut. Applying too much force can damage the fitting or the pipe, so take your time.

Use Penetrating Oil if Stuck: If the nut feels stuck, apply a small amount of penetrating oil around the threads and let it sit for a few minutes. This will help loosen any rust or corrosion that might be causing resistance.

Step 4: Remove the Ferrule Carefully

After the compression nut has been removed, you will need to remove the ferrule (also known as the compression ring). This piece is responsible for sealing the fitting to the pipe.

Check the Ferrule Position: Once the nut is off, you should be able to see the ferrule on the pipe. In some cases, the ferrule may stay attached to the fitting or the pipe.

Use a Ferrule Remover or Pipe Cutter: If the ferrule is stuck, you can use a specialized ferrule remover or carefully cut it off with a pipe cutter. Be gentle, as too much force can damage the pipe.

Step 5: Inspect the Pipe and Fitting for Damage

Before proceeding with any further work, it’s important to inspect both the pipe and the fitting for any signs of damage that could affect your next steps.

Look for Cracks or Bends in the Pipe: Check the area where the compression fitting was connected to the pipe for any visible cracks, dents, or damage. If the pipe is compromised, it may need to be replaced.

Inspect the Fitting for Wear: Examine the compression fitting for any signs of wear, corrosion, or cracks. If the fitting is damaged, it will need to be replaced.

Clean the Pipe and Fitting: If both the pipe and fitting are in good condition, clean them to remove any debris, old sealant, or corrosion. This will make the reinstallation process easier.

Step 6: Clean and Prepare the Pipe for Reinstallation

Once you’ve removed the compression fitting and inspected both the fitting and pipe for damage, it’s time to prepare the pipe for reinstallation.

Clean the Pipe Surface: Use a wire brush or a rag to wipe down the pipe, removing any dirt, corrosion, or old sealant from the area where the compression fitting was attached.

Check Pipe Alignment: Make sure the pipe is properly aligned and free from any bends or irregularities that could affect the new fitting’s installation.

Apply Pipe Sealing (Optional): If necessary, apply a light layer of pipe joint compound or Teflon tape to the pipe threads to ensure a secure, leak-proof seal when you reinstall the fitting.

How to Loosen Stubborn Compression Fittings

Stubborn compression fittings can be one of the most frustrating aspects of plumbing work. Over time, corrosion, wear, or improper installation can cause these fittings to become stuck, making removal seem nearly impossible.

Common Issues: Stuck or Corroded Compression Fittings

There are several reasons why compression fittings can become stuck or difficult to remove. Understanding these issues can help you take the right approach to solving them.

Corrosion: Exposure to water and air over time can cause compression fittings to corrode. Rust and mineral buildup around the threads can cause the nut to seize and make it hard to loosen.

Excessive Tightening: If the fitting was tightened too much when it was installed, it can become over-tightened, making it difficult to turn without applying excessive force.

Mineral Buildup: In hard water areas, mineral deposits can build up around the fitting and nut, creating resistance when attempting to loosen the fitting.

Old or Worn Fittings: Over time, the material of the fitting itself may degrade, causing it to become brittle or cracked, which makes removal even trickier.

Effective Techniques for Loosening Tight Fittings

When you’re faced with a stubborn compression fitting, there are several techniques that can help you loosen it without causing damage to the pipe or fitting.

Apply Steady Pressure: When attempting to loosen a tight compression fitting, it’s important to apply steady, even pressure. Sudden jerks or forceful attempts can break or strip the fitting. Use a compression fitting wrench or adjustable wrench to grip the nut securely and turn it counterclockwise slowly.

Use Leverage for Extra Force: If the fitting still won’t budge, extend the handle of your wrench with a pipe or another tool to increase leverage. This extra force can help break the fitting free without damaging the surrounding pipes.

Tapping the Wrench: Sometimes, a little shock can help loosen a stubborn fitting. Using a hammer, gently tap the handle of the wrench while turning. This can help break up rust or debris stuck in the threads and make the nut easier to remove.

Heat It Up: Applying heat can help expand the metal and break the bond between the fitting and the pipe. Use a heat gun or a propane torch to heat the area around the compression fitting for 1–2 minutes. Be sure not to overheat, as too much heat can damage the pipe, especially if it’s plastic.

Using Penetrating Oil to Aid Removal

One of the most effective ways to loosen a stuck compression fitting is by using penetrating oil. This oil helps break down rust, mineral buildup, and corrosion, making it easier to loosen the fitting.

Apply the Penetrating Oil: Spray the penetrating oil (such as WD-40, PB Blaster, or Liquid Wrench) around the threads of the compression nut. Make sure the oil reaches all the way around the nut and fitting. Let the oil sit for about 5–10 minutes to allow it to penetrate and break down any rust or debris.

Wiggle and Loosen: After applying the penetrating oil, try loosening the compression nut again using the wrench. The oil will reduce friction, making it easier to turn the nut. If it’s still stubborn, reapply the oil and let it sit for a little longer.

Repeat as Needed: Sometimes it may take multiple applications of penetrating oil, especially if the fitting has been in place for years or has significant corrosion. Be patient, and allow the oil to do its job before attempting to turn the nut again.

Preventing Damage to Pipes During Compression Fitting Removal

Removing compression fittings can be a delicate task, and if not done properly, it can lead to unintended damage to your pipes. Whether you’re dealing with a stuck fitting or simply performing routine maintenance, it’s crucial to handle your pipes with care to avoid cracks, scratches, or misalignments that can result in leaks or more serious plumbing issues.

Why Pipe Damage Happens During Fitting Removal

Pipe damage often occurs during compression fitting removal for several reasons, most of which are related to forceful or improper handling. Understanding these causes can help you avoid mistakes and protect your pipes:

Over-Tightening: If a compression fitting is over-tightened when it was first installed or during the removal process, applying too much force to loosen it can cause the pipe to bend or crack. Tight fittings can create extra stress on the pipe, especially if it’s made of softer materials like copper or PVC.

Excessive Force: Using the wrong tools or improper techniques when loosening a compression fitting can lead to uneven force being applied. If you use an ill-fitting wrench or twist too aggressively, the pipe itself might be damaged in the process.

Corrosion or Mineral Build-Up: In areas with hard water, mineral deposits and corrosion can accumulate around the fitting and the pipe. Trying to remove the fitting without addressing this buildup can result in scratches or small cracks as you force the fitting off.

Weak Pipe Material: Older pipes or pipes made from softer materials are more prone to damage. When you apply pressure to a weak or corroded pipe, it’s easier to accidentally bend, crack, or scratch the surface, which can lead to leaks down the line.

Tips for Protecting Pipes from Scratches and Cracks

To protect your pipes from damage during compression fitting removal, consider these helpful tips:

Use the Right Tools: Always use the proper tools for the job, such as a compression fitting wrench or adjustable wrench, which provide a secure grip without slipping or damaging the fitting. Ensure the wrench is the correct size for the nut to avoid excessive force.

Apply Even Pressure: When loosening a compression fitting, apply slow, steady pressure. Jerking the wrench or forcing it too quickly can lead to pipe damage. Patience is key, especially when dealing with tight or corroded fittings.

Use a Pipe Protector: Wrap a cloth or a protective rubber sleeve around the pipe where you’re working. This helps prevent scratches or dents while you apply force to the fitting. You can also use a wood block or other soft material to cushion the area if you’re using a hammer or mallet for extra force.

Heat the Fitting, Not the Pipe: If you’re using heat to loosen a stubborn compression fitting, make sure to focus the heat directly on the fitting and not on the pipe itself. Excessive heat on the pipe can weaken it, especially if it’s made of PVC or other temperature-sensitive materials.

Use a Pipe Clamp or Holder: For added stability, clamp the pipe down (near the fitting) using a pipe clamp or holder. This helps minimize movement while you work, reducing the chances of applying unintentional force that could crack the pipe.

The Role of Pipe Sealing in Preventing Future Leaks

Proper sealing plays an important role in preventing leaks after removing and reinstalling compression fittings. Even if you’ve removed a fitting without damaging the pipe, a poor seal can still cause future issues. Here’s how sealing helps:

Prevents Water Leaks: After you remove a compression fitting and reinstall a new one, it’s essential to ensure the connection is sealed properly. Compression fittings rely on a tight seal between the nut, ferrule, and pipe to prevent water leaks. If the seal is compromised, you may experience leakage around the fitting, which can damage your property and lead to expensive repairs.

Protects the Pipe Threads: Using pipe joint compound or Teflon tape on the threads of the pipe can provide an extra layer of protection, ensuring that water doesn’t leak through small gaps. This is especially helpful when you’re working with threaded fittings or pipes that have been used for a while.

Reduces Pressure on the Fitting: Proper sealing also helps reduce the strain on the fitting itself, which can extend its lifespan. If the seal is too tight or improperly installed, it can create additional stress on the fitting and pipe, leading to potential leaks in the future.

Conclusion

Successfully removing and reinstalling compression fittings is an essential skill for maintaining a well-functioning plumbing system. By following the right steps, using the correct tools, and ensuring proper sealing, you can prevent damage to your pipes and avoid costly leaks. Whether you’re performing routine maintenance, replacing a worn fitting, or making repairs, mastering the process will keep your plumbing system running smoothly for years to come.

FAQ

Can You Remove a Compression Fitting Without a Wrench?

It’s possible, but not recommended. A wrench provides the leverage needed to loosen the compression nut without damaging the fitting or pipe. Using the proper tool ensures a safer and more efficient removal.

What Happens If You Damage the Pipe During Removal?

Damaging the pipe during compression fitting removal can lead to leaks, reduced water pressure, or even complete pipe failure. It’s important to handle the pipe carefully and use the correct tools to avoid this.

How Do I Know If a Compression Fitting Needs Replacing?

If the fitting is corroded, cracked, or you notice persistent leaks even after tightening, it’s time to replace the compression fitting. Also, if the ferrule or nut is damaged, it’s best to install a new fitting.

Can I Reuse a Compression Fitting After Removal?

In most cases, you can reuse a compression fitting if it’s in good condition. However, always inspect the ferrule and nut for wear. If they are damaged, replace them before reinstalling.

Why Is My Compression Fitting Leaking After Reinstallation?

A leaking compression fitting after reinstallation could be due to improper tightening, a worn-out ferrule, or a damaged seal. Check that the fitting is tightly secured and ensure the ferrule is properly seated.

How Do I Prevent Future Leaks After Removing a Compression Fitting?

To prevent future leaks, ensure you clean the pipe thoroughly, use the correct sealing methods (such as thread sealant or Teflon tape), and properly tighten the compression fitting during reinstallation.