A hydraulic hose operates under immense pressure, unseen and often forgotten. But inside, it can degrade and weaken, waiting for the one moment to burst with explosive, life-altering force.

A hydraulic hose can become a ticking time bomb due to five main factors: abrasion, exposure to pressures above its rating, aging, improper installation, and chemical incompatibility. Proactive inspection and correct selection are the only ways to defuse this threat and ensure workplace safety.

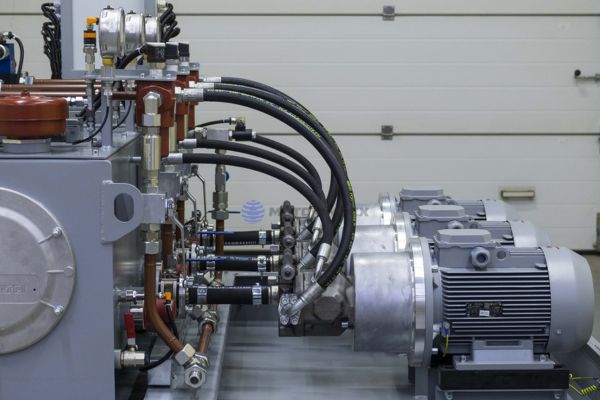

In any operation that relies on hydraulic power, the humble hydraulic hose is the critical artery that channels immense force. Yet, it is often the most neglected and misunderstood component. A single hose failure can unleash a high-pressure blast of hot oil, causing severe burns, injection injuries, equipment damage, and catastrophic downtime. This isn’t just a maintenance issue; it’s a fundamental safety crisis waiting to happen. Understanding the anatomy of hose failure is the first step toward creating a safer, more reliable, and more productive work environment.

What is the #1 Invisible Killer of Hydraulic Hoses?

That hose is tucked away, doing its job day after day. But unseen, constant friction is silently grinding away its protective layers, bringing it closer to a violent rupture.

The number one cause of hydraulic hose failure is abrasion. Relentless rubbing against machine parts or other hoses wears down the outer cover, exposing the steel reinforcement to moisture, corrosion, and eventual collapse.

A War of Attrition

Abrasion is such an insidious threat because it happens slowly and often out of sight. By the time the damage is noticeable, the hose’s integrity is already severely compromised. As a manufacturer and supplier, we see this more than any other failure mode. Abrasion can be categorized into three main types, each requiring a specific preventative approach.

- Hose-to-Component Abrasion: This is the most common type, where a hose rubs against a metal bracket, frame, or other machine surface. Vibration causes a constant grinding effect, like sandpaper on the hose’s cover. The solution is proper routing—ensuring the hose has adequate clearance from all surfaces—and the use of clamps and stand-offs to secure it in place.

- Hose-to-Hose Abrasion: When two hoses run parallel and touch, their movement against each other can wear away their covers. The best practice is to use clamps or separators to maintain a gap between them.

- Hose-to-Fluid Abrasion: This is an internal issue where high-velocity, abrasive particles within the hydraulic fluid itself (like sand or metal shavings from wear) scour the inner tube of the hose, thinning it from the inside out. This highlights the critical importance of a robust fluid filtration program.

For external protection, a variety of guards and sleeves offer an effective line of defense. Selecting the right one depends on the severity of the application.

| Protective Guard Type | Best Use Case | Material | Abrasion Resistance |

| Nylon Sleeve | General-purpose, bundling hoses | Woven Nylon Fabric | Good |

| Plastic Coil Guard | High-abrasion zones, tight bends | HDPE Plastic | Excellent |

| Metal Spring Guard | Extreme abrasion, impact protection | Plated Spring Steel | Superior |

| Fire Sleeve | High heat and welding spatter | Silicone-coated fiberglass | Excellent (Heat) |

Are You Ignoring Your Hose’s Maximum Pressure Limit?

Your system pressure is set to 3,000 PSI, and you used a 3,000 PSI hose. This seems safe, but it fails to account for the invisible, powerful pressure spikes that hammer your system.

Using a hose with a working pressure equal to the system pressure is a dangerous mistake. You must select a hose whose maximum working pressure exceeds the total system pressure, including routine pressure spikes (impulses) to maintain a safe operational margin.

The Difference Between Working Pressure and Burst Pressure

Understanding pressure ratings is fundamental to hose safety. Every hydraulic hose has two key pressure ratings, and they mean very different things.

Maximum Working Pressure

This is the most important number. It is the maximum pressure that the hose is designed to safely handle on a continuous basis throughout its service life. All system design should be based on this figure. Reputable manufacturers, like Topa, clearly print the maximum working pressure directly on the hose layline.

Minimum Burst Pressure

This is a factory-testing value. It is the pressure at which a new hose will rupture during a one-time, destructive test. It is NOT a working value. The industry standard, governed by organizations like the SAE (Society of Automotive Engineers), typically requires a 4:1 safety factor. This means a hose with a 3,000 PSI maximum working pressure must have a minimum burst pressure of at least 12,000 PSI. This safety margin is there to account for degradation over time and, critically, to handle pressure spikes.

Pressure spikes, or impulses, are momentary, high-intensity pressure surges that occur when a valve closes suddenly or a cylinder hits the end of its stroke. These spikes can be two to three times higher than the normal system pressure. If your system runs at 3,000 PSI but experiences spikes up to 4,000 PSI, a 3,000 PSI hose is being pushed beyond its safe limit with every cycle. This constant flexing at over-pressure fatigues the reinforcement wires, leading to a sudden, explosive burst. Always select a hose with a working pressure rating higher than the highest anticipated pressure in the system.

Could a Simple Installation Error Condemn Your Hose?

You installed a brand-new, high-quality hose. A few weeks later, it fails catastrophically. The cause isn’t the hose, but a simple, avoidable mistake made during its installation.

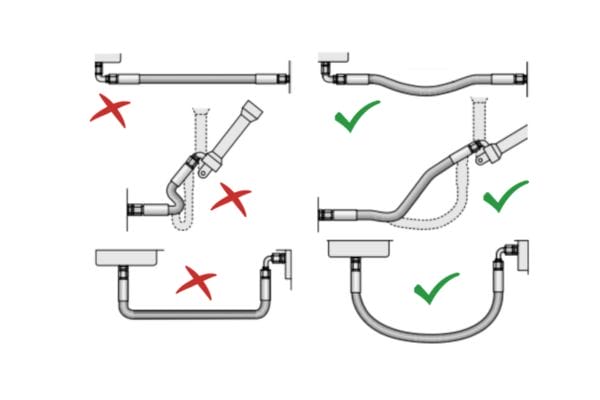

Yes, improper installation is a primary cause of premature hose failure. A twisted hose, or one bent tighter than its minimum bend radius, creates immense stress on the reinforcement, guaranteeing a short and dangerous service life.

A Foundation of Failure

A hydraulic hose assembly is only as good as its installation. You can select the highest quality hose and fittings in the world, but if they are installed incorrectly, they are destined to fail.

The Sin of Twisting

A hydraulic hose is designed to flex in one plane only. It is not designed to twist. The steel wire reinforcement layers are braided at a specific, neutral angle. When you twist a hose during installation—even by just a few degrees—you are misaligning these reinforcement braids. This puts them under constant, unnatural tension. The hose will try to untwist itself under pressure, causing fittings to loosen and creating massive stress points that lead to a burst. The layline printed on the hose is your guide; if that line is spiraling like a candy cane, the hose is twisted and must be reinstalled.

Respecting the Minimum Bend Radius

Every hose has a specified minimum bend radius, which is the tightest it can be bent without causing damage. Bending it sharper than this limit has two negative effects. First, it can flatten the hose, creating a flow restriction. Second, it puts extreme stress on the reinforcement wires on the outside of the bend while compressing the wires on the inside. This can cause the wires to fatigue and break, or it can lead to the inner tube kinking and failing. Always leave enough slack to accommodate the full range of motion without violating the minimum bend radius. A simple rule is that if the hose looks “strained” at the fitting, the bend is likely too sharp.

Does a Hydraulic Hose Have a Hidden Expiration Date?

That hose has been sitting on the warehouse shelf for years. It looks brand new, but its chemical makeup is silently breaking down, making it a brittle and unsafe component.

Yes, a hydraulic hose absolutely has an expiration date. The rubber compounds in the hose degrade over time due to exposure to oxygen, UV light, and temperature fluctuations, even when in storage. Using an old hose is a significant safety risk.

The Aging Process

A hydraulic hose is not a stable, inert object like a block of steel. It is made of complex synthetic rubber compounds that are in a constant, slow state of degradation from the moment they are manufactured. This process is called thermo-oxidative degradation.

Oxygen in the air attacks the long polymer chains that give the rubber its flexibility, making them brittle. Ozone, even in small atmospheric concentrations, is extremely aggressive and causes microscopic cracks. UV light from the sun or even fluorescent lighting accelerates this process dramatically. The result is an inner tube that can crack and flake apart, sending debris through the hydraulic system, and an outer cover that becomes hard, cracked, and loses its ability to protect the reinforcement layers.

Shelf Life vs. Service Life

- Shelf Life: Most manufacturers recommend that a hose should not be put into service if it is more than 10 years old from its date of manufacture. As a supplier, we manage our inventory on a strict First-In, First-Out (FIFO) basis to ensure our customers always receive fresh, reliable hoses.

- Service Life: This is highly variable and depends entirely on the application’s severity (pressure, impulses, temperature, abrasion). For a critical application, a hose might have a mandated replacement schedule of just one or two years, regardless of its visual condition.

Always check the manufacturing date printed on the layline before installing a hose. It is typically shown as a quarter and a year (e.g., “3Q23” for the third quarter of 2023). If the hose is old, or if the date code is unreadable, it should be discarded.

Is the Wrong Hydraulic Fluid Eating Your Hose from the Inside?

You switched to a new, “better” hydraulic fluid. Shortly after, your hoses start to fail, feeling mushy and swollen. The fluid itself is the culprit, chemically attacking the hose’s inner lining.

Yes, chemical incompatibility between the hydraulic fluid and the hose’s inner tube material is a major cause of failure. An incompatible fluid will cause the inner tube to swell, crack, or delaminate (“wash out”), leading to a blockage or burst.

An Internal Chemical Attack

The inner tube of a hydraulic hose is its most chemically sensitive part. It must contain the fluid without being degraded by it. The term “hydraulic oil” is very broad; fluids can range from standard petroleum-based oils to synthetic esters, water-glycol mixtures, and phosphate esters. Each of these chemical families interacts differently with rubber compounds.

A common mistake is assuming that any hose will work with any fluid. For example, a standard Nitrile (NBR) inner tube, which is excellent for petroleum-based oils, will be quickly damaged by a synthetic fluid like Skydrol. The fluid will leach the plasticizing agents out of the rubber, making it shrink and crack, or it can cause the rubber to swell up to twice its normal size, delaminating from the reinforcement and shedding particles that clog the system.

This is why we, as your supplier, always ask about the fluid type. It is a critical piece of the selection puzzle, known as the “S.T.A.M.P.E.D.” method (Size, Temperature, Application, Media, Pressure, Ends, Delivery). The “Media” is the fluid. Ensuring the inner tube material is compatible with the media is just as important as getting the pressure rating right. Always consult a chemical compatibility chart.

| Inner Tube Material | Good Compatibility | Poor Compatibility |

| Nitrile (NBR) | Petroleum-based oils, water-glycol | Synthetic fluids, ozone, weather |

| Neoprene (CR) | Petroleum-based oils, refrigerants, weather | Aromatic fuels, phosphate esters |

| EPDM | Phosphate esters, water-glycol, steam | Petroleum-based oils, diesel fuel |

| Viton (FKM) | Most petroleum oils, synthetic fluids, fuels | Skydrol, ketones |

How Can You Spot a Failing Hose Before Disaster Strikes?

A catastrophic hose failure often seems to happen without warning. But in reality, a failing hose almost always provides clear visual clues that it is under stress and approaching its breaking point.

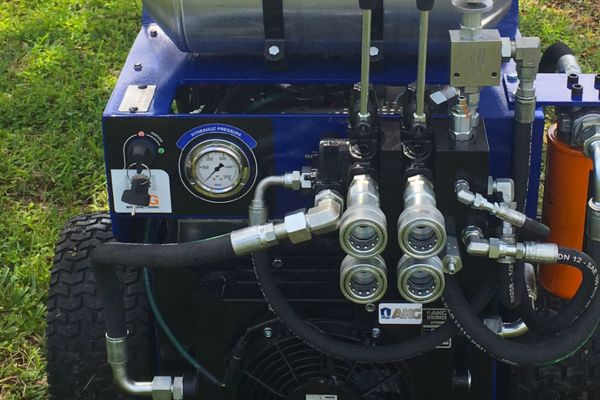

You can spot a failing hose by conducting regular, detailed visual inspections. Look for cracks, blisters, leaks around the fitting, signs of abrasion, and kinks. A proactive maintenance schedule is the best defense against a sudden burst.

A Program of Preventative Maintenance

The most effective way to prevent hose-related accidents is to move from a reactive (“fix it when it breaks”) mindset to a proactive (“find it before it fails”) one. This means implementing a regular and thorough hose inspection program. Operators and maintenance staff should be trained to look for these specific warning signs.

The Visual Inspection Checklist:

- Cracked, Hard, or Charred Cover: This indicates the hose is aging and becoming brittle due to heat or chemical exposure.

- Blisters or Soft Spots: This is a sign that the inner tube has likely failed, allowing high-pressure fluid to seep into the reinforcement layers. A blistered hose is on the verge of bursting and must be replaced immediately.

- Abrasion Damage: Look for any area where the outer cover is worn thin or completely worn through, exposing the wire reinforcement. An exposed braid is a direct path for moisture and corrosion.

- Leaks at the Fitting: Check for weeping or dripping at the point where the hose enters the metal fitting. This can indicate an improper crimp or that the hose has begun to slip out of the fitting.

- Kinks or Crushed Sections: Any visible deformation of the hose’s natural shape is a major weak point and flow restriction.

- Corroded or Damaged Fittings: Rusted or cracked fittings can fail under pressure.

These inspections should not be a random occurrence. They should be scheduled and documented, especially for equipment operating in severe conditions. Finding and replacing a single damaged hose before it fails can save tens of thousands of dollars in downtime and, more importantly, can prevent a life-changing injury.

Conclusion

A safe workplace is one where the inherent dangers of hydraulic power are respected and managed proactively. This begins with understanding that a hydraulic hose is a dynamic component with a finite life, not a “fit-and-forget” part.

At Topa, we believe in empowering our customers with both high-quality products and the knowledge to use them safely. We provide a comprehensive range of hydraulic hoses and fittings that meet and exceed international safety standards. Our expert team can help you select the exact hose for your application—considering pressure, temperature, media, and more—to ensure you are building a system that is not only powerful but fundamentally safe. Contact us today to make your workplace safer with better hoses.