Category | Details |

Design | No-skive, bite-the-wire crimp profile |

Compatible Hose Types | 4-spiral hoses |

Hose Sizes | From 3/8″ (-6) up to 2″ (-32) |

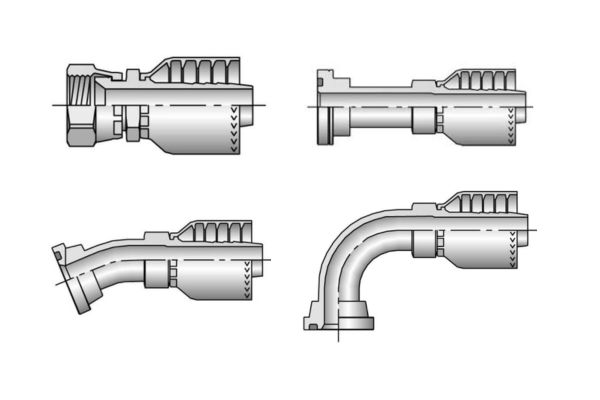

End Configurations | Straight, 45°, 60°, 90°, and 110° elbows; SAE and ISO flanges; male/female threaded ends; ORFS and JIC connections |

Working Pressure | Up to 6000 psi (depending on hose type and size) |

Temperature Range | –40 °C to +100 °C (–40 °F to +212 °F) for standard hoses |

The one-piece, no-skive construction reduces both production and assembly time. This efficiency translates into lower overall costs, making the fittings highly competitive in price-sensitive markets while maintaining reliable performance.

By combining the ferrule and fitting body into a single unit, the 71 Series minimizes part numbers and reduces SKU complexity. This streamlined inventory management helps distributors and end-users lower storage costs and simplify logistics.

The versatility of the 71 Series allows it to serve a wide range of industries, including agriculture, construction, mining, and automation. Its broad compatibility ensures that Topa can meet the demands of different customers with a single product line.

Easy installation and dependable sealing make the fittings attractive to both equipment manufacturers and maintenance professionals. This reliability strengthens customer trust and encourages repeat business.