As a procurement manager, you face a global puzzle. A new machine arrives from Europe with metric DIN fittings, but your entire stock is American SAE. The parts don’t connect, production halts, and you’re left scrambling for answers.

You can differentiate hydraulic standards by their unique thread types and sealing surfaces. SAE (American) uses imperial threads and a 37° flare. DIN (German) uses metric threads and a 24° cone. ISO aims to harmonize these, but they remain distinct and are not interchangeable.

What Defines the American SAE JIC Standard?

When dealing with equipment from North America, you will almost certainly encounter this familiar fitting. It is the workhorse of American heavy machinery.

The SAE J514 standard defines the JIC 37° flare fitting. It is the most common hydraulic connection in the United States. It creates a robust, all-metal seal by pressing a flared tube or hose end onto a conical seat, making it reliable for high-pressure applications.

Key Identification Features of JIC

When you have a fitting in your hand, you need to look for two things to confirm it’s JIC. First, the 37° angle on the sealing surface. This is a specific angle, different from other standards. Second, the threads are UN/UNF (Unified National Fine), which are imperial threads measured in inches. We use a thread gauge and calipers to confirm these details precisely. A JIC fitting is a mechanical seal with no O-rings involved in the connection itself.

Where is JIC Most Common?

You will find JIC fittings predominantly on machinery designed and manufactured in North America. Companies like Caterpillar, John Deere, and many others have used it extensively for decades. Its an extremely common standard in:

- Construction equipment (excavators, loaders)

- Agricultural machinery (tractors, combines)

- Industrial power units

- Material handling equipment (forklifts)

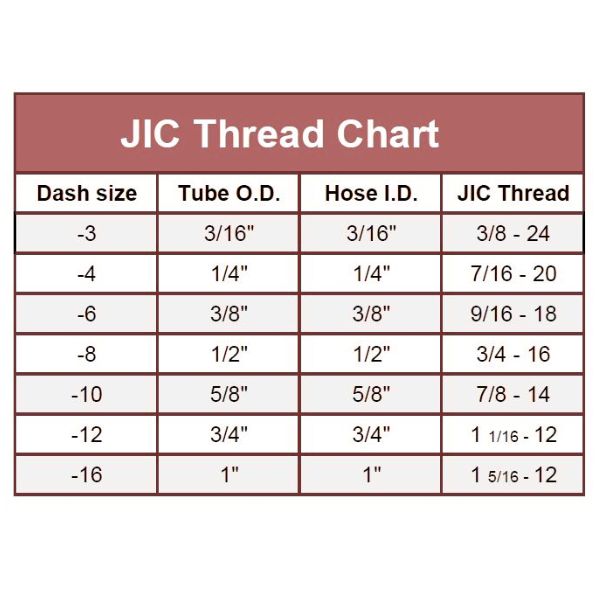

Understanding JIC Dash Sizes

JIC fittings use the standard “dash size” system, where the number represents the outer diameter of the tube in sixteenths of an inch.

How Does the German DIN Standard Differ?

You’ve just unboxed a new press from Germany and see a fitting that looks similar to JIC, but it won’t connect. The angle seems sharper, and the threads are different.

This is likely a DIN fitting. The German DIN 2353 standard (now harmonized into ISO 8434-1) uses metric threads and a distinct 24° cone. It is the dominant standard in Germany and across Europe, known for its high-pressure capability and excellent sealing.

Unlike the single-piece flare seal of JIC, the DIN system is more complex and versatile. It is a “compression” style fitting. A hardened “cutting ring” or “ferrule” bites into the steel tube as the nut is tightened, creating an incredibly strong and leak-proof seal. The 24° cone is the mating surface for this connection. Understanding this “bite-type” principle is the key to identifying and working with European machinery.

The 24° Cone System Explained

The DIN system is a family of fittings. They all share the 24° cone angle, but can seal in different ways. The most common is the “bite-type” for rigid tubes, where the ferrule creates the seal. When used with a hose, a special male fitting with a soft seal (like an O-ring) on the 24° cone is often used to ensure a leak-free connection, especially in high-vibration environments. This versatility is a major strength of the DIN standard.

Light (LL) vs. Extra-Light (LL) vs. Heavy (S) Series

A critical feature of DIN fittings is that they come in different pressure series for the same tube diameter. This allows designers to choose the most cost-effective part that meets the pressure requirements.

- LL Series (Extra Light): For very low-pressure applications.

- L Series (Light): For medium-pressure systems.

- S Series (Heavy): For high-pressure, demanding applications.

The S series fittings have thicker walls and a more robust design to handle higher pressures safely. As a procurement manager, you must ensure you are ordering the correct series (L or S), as they are **not interchangeable**.

| Tube OD (mm) | Series | Max Working Pressure (bar) |

| 10 mm | L Series | 315 bar |

| 10 mm | S Series | 630 bar |

| 16 mm | L Series | 250 bar |

| 16 mm | S Series | 400 bar |

What About British (BSP) and Japanese (JIS) Fittings?

To make your job even more interesting, equipment from the UK, Japan, and other parts of Asia introduces even more standards that are easily confused.

British Standard Pipe (BSP) and Japanese Industrial Standard (JIS) are two other major fitting families. BSP, common in the UK and Commonwealth countries, uses Whitworth threads and often has a 60° cone. JIS is visually similar to BSP but uses a 30° cone, a frequent point of confusion.

These standards are particularly common on mobile equipment from manufacturers like JCB (British) or Komatsu (Japanese). The threads on BSP and JIS fittings are very similar and can sometimes be threaded together, but they will never seal correctly due to the different cone angles. This is a dangerous mismatch that can lead to catastrophic leaks under pressure. Correctly identifying the cone angle is absolutely essential.

Understanding British Standard Pipe (BSP)

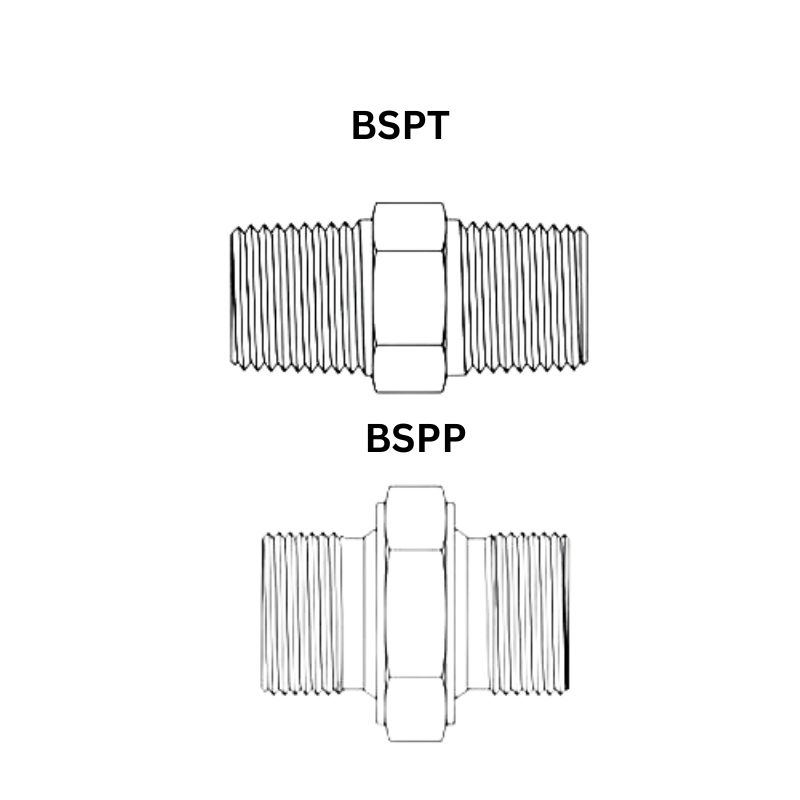

BSP comes in two main flavors:

- BSPP (Parallel): The threads are straight (parallel). The sealing does not happen on the threads. Instead, it happens at the top of the male fitting, usually with a “bonded seal” (a metal washer with a rubber ring) or an O-ring being crushed against a smooth female port. Sometimes, a 60° cone is used for a metal-to-metal seal.

- BSPT (Tapered): The threads are tapered. The sealing action happens as the male and female threads are crushed together. This type of connection always requires a thread sealant (like PTFE tape or liquid sealant) to ensure a leak-free joint.

The Japanese Industrial Standard (JIS) Confusion

JIS fittings (specified in JIS B8363) are visually very similar to BSPP fittings with a 60° cone. They both use parallel BSPP threads. The critical difference is the angle of the sealing cone. JIS uses a 30° cone. Trying to mate a 30° JIS fitting with a 60° BSP fitting creates a seal on a very small line of contact, which is extremely unreliable and unsafe. You must use an angle gauge to be certain.

| Standard | Thread Type | Male Sealing Angle | Sealing Method |

| BSPP | Parallel (G) | 60° Cone | Metal-to-metal cone or Bonded Seal |

| BSPT | Tapered (R/Rc) | N/A | Thread interference + sealant |

| JIS | Parallel (G) | 30° Cone | Metal-to-metal cone |

How Does ISO Bring These Standards Together?

With all these competing standards, it’s natural to hope for a single, unified global system. This is the goal of the International Organization for Standardization (ISO).

ISO’s role is not to replace existing standards but to harmonize and document them to promote global interchangeability. It creates “master standards,” like ISO 8434, that officially define the specifications for hydraulic fittings like DIN, JIC, and ORFS, ensuring a manufacturer in any country can produce a part to the same precise dimensions.

For a procurement manager, this is both helpful and confusing. When a drawing calls for a fitting “per ISO 8434-1,” you know it refers to the 24° DIN-style fitting. However, it’s crucial to understand that ISO does not make different standards physically compatible. An ISO 8434-1 (DIN) fitting will still not connect to an ISO 8434-2 (JIC) fitting. ISO provides a common language, but you still need to know which language you are speaking.

ISO 8434: The Master Standard

The ISO 8434 standard for “Metallic tube connections for fluid power” is a perfect example of this harmonization work. It is published in several parts, with each part corresponding to a major existing standard. This provides a single, authoritative reference for global manufacturers.

- ISO 8434-1: Defines 24° cone connectors (harmonizing with DIN 2353).

- ISO 8434-2: Defines 37° flared connectors (harmonizing with SAE J514/JIC).

- ISO 8434-3: Defines O-ring face seal (ORFS) connectors (harmonizing with SAE J1453).

- ISO 8434-4: Defines 24° cone connectors with an O-ring seal for high-pressure stud ends.

- ISO 8434-6: Defines 60° cone connectors (harmonizing BSPP).

Does ISO Guarantee Interchangeability?

No, not between different parts of the standard. It only guarantees that two fittings made to the same part of the standard (e.g., two fittings made to ISO 8434-1) are fully interchangeable, regardless of who made them. The ISO designation is a mark of quality and dimensional accuracy, but it does not magically make a metric fitting work with an imperial one.

How Do You Correctly Identify an Unknown Fitting?

You have a fitting on your desk. It’s not labeled. You need to order a replacement, but you don’t know what it is. What do you do?

The key is a systematic process of measurement using four simple tools: calipers, a thread pitch gauge, an angle gauge, and your eyes. By measuring the thread diameter, thread pitch, and sealing angle in a specific order, you can confidently identify almost any hydraulic fitting.

A Step-by-Step Identification Process

Follow these steps in order:

- Look at the Seal: Is it a tapered thread (like NPT or BSPT)? Or is the sealing surface a cone, or flat with an O-ring (ORFS)? This is your first clue.

- Measure the Cone Angle: If there is a cone, use an angle gauge. Is it 24°, 30°, 37°, or 60°? This one measurement narrows down the possibilities dramatically.

- Measure the Thread Diameter: Use your calipers to measure the outside diameter (OD) of the male thread.

- Determine the Thread Pitch: Use your thread pitch gauge. Is it metric (millimeters between threads) or imperial (threads per inch)?

- Cross-Reference Your Findings: With these four pieces of information, you can use a standard identification chart to find the exact fitting type.

Common Points of Confusion

| If You See This… | It could be… | Check This to Confirm: |

| Similar Metric Threads | DIN 24° Cone | Check the cone angle. Also check for light (L) or heavy (S) series markings. |

| A 37° Flare Cone | JIC (SAE J514) | Confirm the threads are Imperial (UN/UNF). If they are different, it could be a specialized fitting. |

| A Cone & BSP Threads | BSPP or JIS | Check the cone angle precisely. 60° = BSPP. 30° = JIS. This is a critical check! |

| Tapered Threads | NPT or BSPT | The thread angles are slightly different (NPT=60°, BSPT=55°). An NPT will seem tight in a BSPT fitting but won’t seal. |

How Can You Solve an Incompatible Fitting Problem?

You have successfully identified that you need to connect a German DIN hose to an American JIC port. They are incompatible. What is the solution?

The most common solution is to use an inter-series adapter. These adapters are purpose-built fittings with one standard on one end and a different standard on the other. For complex situations, a custom-made fitting may be more efficient. The key is to partner with a supplier who stocks all standards and can provide these solutions.

The Essential World of Adapters

Adapters are the universal translators of the hydraulic world. They are the fastest and most cost-effective way to connect two different fitting standards. Common adapters we supply include:

- DIN Male to JIC Female

- BSPP Male to NPT Female

- ORFS Male to DIN Female

- JIC Male to BSPP Male

By keeping a small inventory of the most common adapters for your equipment, you can dramatically reduce downtime when a mismatch occurs.

When to Choose a Custom Fitting

Sometimes, a single adapter isn’t enough. You may find yourself needing to connect two or three adapters together to make a connection. This is inefficient, costly, and creates multiple potential leak points. In these situations, a single custom-made fitting that combines the two required ends into one solid part is a far superior solution. It is cleaner, more reliable, and ultimately more professional.

Conclusion

Understanding the differences between SAE, DIN, and BSP standards is key to managing a global supply chain. A knowledgeable supplier who stocks all standards and can provide adapters or custom solutions is your most valuable asset in solving incompatibility problems.

At Topa, we provide high-quality hydraulic fittings, hoses, and adapters that meet global standards like SAE, DIN, BSP, and ISO. Whether you need reliable stock parts or custom solutions, our team ensures fast delivery, strict quality control, and competitive pricing. Partner with Topa today to reduce downtime and keep your business running smoothly—contact us now to place your order.

FAQ

What is the difference between SAE JIC and DIN fittings?

SAE JIC fittings use imperial UN/UNF threads and a 37° flare for sealing. DIN fittings use metric threads and a 24° cone with a cutting ring or O-ring for sealing. They are not interchangeable.

How can I identify if a fitting is JIC?

Look for a 37° flare sealing surface and imperial UN/UNF threads. A thread gauge and angle gauge will confirm the dimensions. JIC fittings do not use O-rings in the seal.

What does the DIN 24° cone system include?

DIN fittings (ISO 8434-1) use metric threads and a 24° cone. They may seal with a cutting ring (bite-type) on rigid tubes or with an O-ring on hoses. They are available in LL, L, and S series for different pressure ratings.

How are BSP and JIS fittings different?

Both use parallel BSPP threads, but BSP fittings seal with a 60° cone, while JIS fittings seal with a 30° cone. They may thread together, but they will not seal safely.

Does ISO make different standards interchangeable?

No. ISO 8434 harmonizes definitions but does not allow physical interchange between standards. An ISO 8434-1 fitting (DIN) will not connect to an ISO 8434-2 fitting (JIC).

What can I do if two fittings are incompatible?

The best solution is to use an inter-series adapter, such as DIN-to-JIC or BSP-to-NPT. For complex cases, custom fittings are available to reduce leak points and improve reliability.