A hydraulic hose fails in the field, far from a workshop. Your machine is down, and every second of downtime is costing you money, creating immense pressure to find a solution.

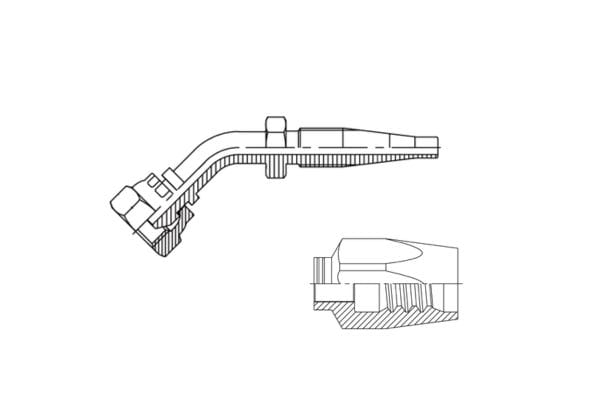

A field-attachable (reusable) fitting works in two steps. First, a socket with internal threads grips the hose’s exterior. Then, a threaded nipple is inserted, expanding the hose’s inner tube to create a high-pressure seal against the socket—no specialized crimper is needed.

What Are the Core Components of the Fitting?

You have a fitting in your hand, but it’s just two pieces of metal. Without knowing what each part does, you risk assembling it incorrectly, leading to a dangerous and costly failure.

A field-attachable fitting consists of two main parts: the **Socket**, which is the female-threaded outer shell that grips the hose, and the **Nipple**, the male-threaded inner component that creates the seal and connects to the system.

A Partnership in Metal

The entire principle of a field-attachable fitting relies on the precise interaction between its two core components. They are designed as a matched set, and understanding their individual roles is the first step to a successful assembly. Think of it as a partnership where each component has a distinct and critical job. At Topa, we machine these components to incredibly tight tolerances because we know that any deviation can compromise the final seal.

The Socket: The Outer Fortress

The socket is the female-threaded body of the fitting. Its primary job is to provide the mechanical grip on the outside of the hydraulic hose.

- External Features: On the outside, it typically has a hex-shaped area so it can be held securely in a vise during assembly.

- Internal Features: The inside is where the critical engineering lies. It features a set of sharp, specially designed threads. These are not standard pipe threads; they are designed specifically to bite into and grip the tough outer cover and wire reinforcement of a hydraulic hose. In many designs, these are left-hand threads, meaning you screw the hose in counter-clockwise. This is a deliberate design choice to prevent the fitting from loosening if the hose twists during operation.

The Nipple: The Inner Seal

The nipple is the male-threaded component that completes the assembly. It has two jobs: create the fluid seal and provide the connection point to the rest of the hydraulic system.

- Hose-End Features: The end of the nipple that goes into the hose is typically tapered or has a “pilot” section. This end is physically forced into the hose’s inner tube during assembly.

- System-End Features: The other end of the nipple contains the standard connection interface, such as JIC 37° flare, NPT pipe thread, ORFS (O-Ring Face Seal), or BSPP. This is the part that connects your newly created hose assembly to a valve, pump, or cylinder.

Separately, they are just machined parts. Together, they form a powerful system that contains hydraulic pressure through pure mechanical force.

How Does the Socket Create the Primary Grip?

You assemble a hose, but under pressure, the hose blows right out of the fitting. The connection failed catastrophically because the fitting never achieved a secure mechanical grip on the hose reinforcement.

The socket’s internal threads are specifically engineered to bite through the hose’s outer rubber cover and firmly embed into the steel wire braid beneath, creating a powerful mechanical lock that resists blowout forces.

More Than Just a Thread

The genius of a modern reusable fitting lies in its “non-skive” design, a feature centered entirely on the socket’s threads. In older fitting designs, a technician first had to “skive” the hose—a time-consuming process of removing the outer rubber cover with a special tool to expose the wire braid. This was a common point of error; skiving too much or too little would result in a bad connection.

The non-skive socket eliminates this step. Its internal threads are machined to be sharp and aggressive enough to cut through the outer cover during assembly. As you rotate the hose into the socket (again, typically counter-clockwise), these threads peel away the rubber and make direct contact with the steel wire reinforcement layers. This achieves two things:

- A Tenacious Grip: The threads embed themselves directly into the woven steel braid, creating an incredibly strong mechanical interlock. This is what provides the primary resistance against the immense hydrostatic forces that are trying to push the hose out of the fitting.

- A Simpler, Faster Process: By eliminating the skiving step, the assembly becomes much faster and far less prone to operator error. This is a massive advantage for field repairs where specialized skiving tools may not be available.

While non-skive is the modern standard for most 1-wire and 2-wire hoses, skive-type fittings still exist, particularly for multi-spiral, extreme high-pressure hoses (like 4SH/6SH). A quality supplier must be able to provide both types and, more importantly, provide clear instructions on which hose requires which type of fitting.

| Fitting Design | Hose Preparation | Assembly Speed | Risk of Error |

| Non-Skive | Just a clean, square cut | Fast | Low |

| Skive | Must remove outer cover | Slower | High (improper skive depth) |

What is the Nipple’s Role in Sealing?

The hose is securely attached, but hydraulic fluid is weeping from the fitting. The mechanical grip is holding, but the fluid seal itself has failed, rendering the assembly useless.

The nipple’s job is to create the fluid-tight seal. As it’s screwed into the socket, its tapered end forces the hose’s inner tube to expand outwards, violently compressing it against the inner wall of the socket.

The Science of Compression

While the socket provides the brute force grip, the nipple performs the fine, surgical task of sealing. The seal isn’t created by the threads; it’s created by an act of controlled compression. Picture the cross-section of the hose inside the socket. You have the socket wall on the outside and the hose’s inner rubber tube on the inside.

When you begin to thread the lubricated nipple into the socket, its leading edge enters the hose’s inner tube. As you continue to tighten, the diameter of the nipple increases. This forces the soft rubber of the inner tube to expand outwards. It has nowhere to go but to press against the unyielding steel inner wall of the socket. This intense compression creates a 360-degree, high-pressure seal that is completely free of leak paths.

The final tightening position is also critical. Technicians are trained not to tighten the nipple until its hex bottoms out against the socket. A small, specified gap (often around 1mm) should remain. This gap is the visual confirmation that the nipple has advanced far enough to create the seal but not so far that it has over-compressed the hose or damaged the threads. Overtightening can be just as bad as under-tightening, as it can crack the socket or strip the threads.

Why Are Thread Types So Important?

You order fittings for a repair on a European machine, but they won’t connect. The threads look similar, but they are incompatible, bringing your entire repair operation to a standstill.

The fitting’s anatomy includes its connection threads, and these must match the system. The most common are NPT (American), BSP (British/International), and Metric, and they are not interchangeable. Using the wrong one guarantees a leak.

A Global Language of Connection

For an international buyer or a technician working on diverse equipment, understanding thread standards is as important as knowing how the fitting works. A fitting’s core anatomy is useless if its “system-end” cannot communicate with the machine. At Topa, a huge part of our business is manufacturing these fittings with the precise thread standard our global customers require.

The Main Families of Threads

- NPT/NPTF (National Pipe Taper / Fuel): This is the dominant standard in North America. The threads are tapered. As the male and female are tightened, the threads deform and wedge together to create the seal. A sealant (like PTFE tape or paste) is required to fill any microscopic gaps.

- BSP (British Standard Pipe): This is the most common standard in Europe, Asia, Australia, and many other parts of the world. It comes in two variants:

- BSPT (Tapered): Similar in concept to NPT where the tapered threads form the seal. However, the thread angle and pitch are different, making it incompatible with NPT.

- BSPP (Parallel): The threads are parallel (straight) and do not form the seal. The seal is made by a bonded seal washer or O-ring that is compressed between the male fitting and a flat surface on the female port.

- Metric Taper & Parallel: Similar in concept to BSP threads but with metric dimensions. Common on equipment from Germany and other parts of continental Europe.

Ordering the wrong thread type is one of the most common and costly mistakes in global sourcing. A reliable supplier must have the expertise to identify and provide the exact standard needed for a customer’s specific region and equipment.

| Thread Standard | Sealing Method | Thread Shape | Common Regions |

| NPT | Thread interference + sealant | Tapered | North America |

| BSPT | Thread interference + sealant | Tapered | UK, Europe, Asia, International |

| BSPP | Bonded seal or O-ring | Parallel | UK, Europe, Asia, International |

| JIC 37° Flare | Metal-to-metal cone seal | Parallel | Universal (SAE Standard) |

| ORFS | O-ring in fitting face | Parallel | Universal (High-Pressure, No-Leak) |

What Material Is a Quality Fitting Made From?

You saved a little money on cheaper fittings, but they started to rust within weeks. Now, you have to replace them all, costing more in labor and downtime than you ever saved.

Quality fittings are made from specific materials for strength and corrosion resistance. The most common are plated carbon steel for high pressure, brass for corrosion resistance, and stainless steel for harsh environments.

The Substance Behind the Shape

Carbon Steel

This is the workhorse of the high-pressure hydraulic world.

- Why: It offers superior strength and fatigue resistance, making it ideal for the high pressures found in construction, agriculture, and industrial machinery.

- The Catch: Carbon steel rusts easily. To combat this, it must be plated. Standard zinc plating is common, but for better corrosion resistance (crucial for surviving salt spray or harsh weather), superior platings like Zinc-Nickel are used. The quality of this plating is a key differentiator between a low-cost supplier and a quality manufacturer like Topa.

Brass

Brass is an alloy of copper and zinc.

- Why: Its primary advantage is excellent natural resistance to corrosion from water and many chemicals, without needing any plating. It is also easy to machine, allowing for the creation of very precise threads and sealing surfaces.

- The Use Case: It’s the standard for air brake systems, plumbing, and lower-pressure pneumatic and fluid transfer lines where rust contamination is a major concern.

Stainless Steel

This is the premium material for fittings.

- Why: It offers both high strength and superior corrosion resistance, far beyond what plated steel or brass can offer. Grades like 304 and 316 are common. 316 stainless steel, with its added molybdenum, is the gold standard for marine, chemical, and food-grade applications.

How Does Its Design Enable Reusability?

The fitting is called “reusable,” but you’re not sure if that’s safe. A failed crimp fitting is thrown away, so what makes this one different and trustworthy enough to use again?

Its reusability comes from its design as a mechanical assembly, not a permanent deformation. Unlike a crimped fitting, which is permanently crushed, a reusable fitting can be disassembled, inspected, and reinstalled on a new hose.

A Contrast with Permanent Crimping

To understand why a field-attachable fitting is reusable, you must first understand its counterpart: the crimped fitting. A crimped fitting is made by placing a hose and a fitting “ferrule” into a hydraulic crimping machine. The machine then uses immense force to squeeze and permanently deform the metal ferrule, crushing it onto the hose to create the grip and seal. This is a one-time event. The metal is permanently deformed and cannot be uncrimped or reused.

A reusable fitting, by contrast, achieves its grip and seal through threaded mechanical force. No part of the fitting itself is designed to be permanently deformed. You can unscrew the nipple from the socket, and then unscrew the socket from the hose. The fitting components return to their original state, ready for inspection.

The Rules of Reusability

While the fitting is reusable, there are strict rules:

- The Hose is Never Reusable: The end of the hose that was inside the fitting has been compressed and deformed. It must be cut off and discarded. The fitting can only be reused on a brand-new, freshly cut section of hose.

- Inspection is Mandatory: Reusability is conditional upon the fitting passing a rigorous inspection. You must clean the components thoroughly and check for any damage. Look for stripped threads in the socket, debris embedded in the threads, and critically, any nicks, scratches, or corrosion on the sealing surfaces of the nipple. If any damage is found, the component must be discarded.

The ability to reuse the fitting is a major cost-saving and logistical advantage, but it carries the responsibility of careful inspection. This empowers the field technician but also demands a high level of professionalism and attention to detail.

Conclusion

The field-attachable fitting is an elegant solution to a common problem. Its two-part anatomy—a gripping socket and a sealing nipple—creates a secure, high-pressure connection through pure mechanical force, empowering repairs anywhere.

At Topa, we manufacture a complete range of field-attachable fittings that embody this smart design. We provide the precision components and expert knowledge you need to keep your equipment running. Contact us today for reliable fittings that perform in the field.

FAQ

What makes field-attachable fittings useful for on-site repairs?

Field-attachable fittings can be assembled with simple hand tools, allowing quick and reliable hose repairs without needing a crimping machine—ideal for remote or emergency situations.

Can reusable fittings handle high-pressure hydraulic systems?

Yes, when properly assembled and used with the right hose type, reusable fittings can safely handle high-pressure applications, though always within the manufacturer’s rated limits.

How many times can a field-attachable fitting be reused?

There’s no fixed limit, but fittings should only be reused if they pass visual inspection for thread wear, corrosion, or damage after each disassembly and cleaning.

What types of hoses are compatible with reusable fittings?

Reusable fittings are generally designed for 1-wire and 2-wire braided hoses. They are not recommended for spiral hoses unless specifically rated for that purpose.

Do field-attachable fittings require special training to assemble?

Basic knowledge of hose construction and correct tightening methods is enough. Following manufacturer instructions ensures proper sealing and long-term reliability.

Why choose field-attachable fittings over crimped fittings?

They offer flexibility, fast field repair, and cost savings on equipment and labor, making them perfect for maintenance teams and operations in remote areas.