Are you an engineer struggling with hydraulic system leaks or failures? Choosing the wrong hydraulic fitting leads to costly downtime, safety hazards, and wasted resources, a problem that frustrates even the most experienced professionals.

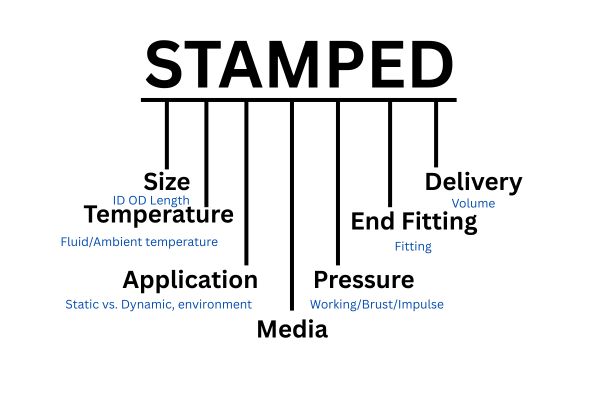

You can prevent over 90% of selection errors by following the five-step STAMP method: Size, Temperature, Application, Media, and Pressure. This systematic approach ensures every aspect of your system is considered, leading to a secure and reliable connection.

Step 1: How Do You Define Your System’s Needs with S.T.A.M.P.?

Are you jumping straight to thread types without first understanding your operating conditions? This common mistake is like building a house without checking the foundation; it’s destined to cause problems later.

S.T.A.M.P. is the industry-standard acronym that forces you to define the fundamentals. It stands for Size, Temperature, Application, Media, and Pressure. Answering these five questions first provides the essential data needed to select a compatible and safe fitting.

S for Size

Size is more than just the thread dimension. It primarily refers to the inside diameter (I.D.) of the hose, which determines the flow rate. fittings are sized using “dash numbers” which represent the I.D. in sixteenths of an inch. For example, a -08 fitting is for a hose with an 8/16″ or 1/2″ I.D. Selecting the wrong size can starve the system of fluid or cause excessive velocity, leading to heat and damage. You must match the fitting size to the hose size and the system’s flow requirements.

T for Temperature

You must consider two temperatures: the ambient temperature of the environment outside the hose and the media temperature of the fluid running through it. Extreme cold can make fitting materials brittle, while extreme heat can degrade seals and hose materials. Most standard carbon steel fittings with Buna-N (Nitrile) seals are rated for -40°F to +212°F (-40°C to +100°C). For more extreme temperatures, you may need stainless steel fittings and specialized seals like Viton or Teflon.

A for Application, M for Media, P for Pressure

These three are closely related. Application covers the physical routing, potential for abrasion, and vibration levels. Media refers to the type of fluid being conveyed. Is it a standard petroleum-based hydraulic oil, or a synthetic fluid, water, or chemical that might require special materials like stainless steel? Finally, Pressure is critical. You must know the system’s maximum working pressure, including any potential spikes or surges. The fitting’s pressure rating must always exceed the system’s maximum working pressure.

| S.T.A.M.P. | What to Ask | Why It Matters |

| Size | What is the hose I.D. and required flow rate? | Affects fluid velocity and system efficiency. |

| Temperature | What are the ambient and fluid temperatures? | Determines the correct fitting and seal material. |

| Application | Will there be vibration, abrasion, or complex routing? | Influences fitting style (e.g., ORFS) and shape (e.g., elbow). |

| Media | What fluid is in the system? | Crucial for chemical compatibility with the fitting and seals. |

| Pressure | What is the maximum system working pressure? | Safety is paramount; the fitting rating must exceed system pressure. |

Step 2: How Do You Accurately Identify the Thread Type?

Have you ever tried to connect a metric fitting to an inch-based port? The threads might seem to catch, but they will never seal correctly, guaranteeing a leak and damaging both components.

You must accurately identify both the type and size of the thread. Use a pair of calipers to measure the thread diameter and a thread pitch gauge to determine the spacing. This is the only way to ensure you are selecting a mating part that will create a perfect seal.

Tapered vs. Straight Threads

This is the first major division. Tapered threads (like NPT and BSPT) are designed to seal by deforming and creating an interference fit along the threads. They always require a sealant like PTFE tape. Straight threads (like JIC, ORFS, and BSPP) do not seal with the threads. Their function is purely mechanical, providing the clamping force to press two separate sealing surfaces together. This could be a metal cone (JIC) or a soft O-ring (ORFS, BSPP). Mixing these two types is a guaranteed failure.

Identifying Common Thread Standards

Once you know if it’s tapered or straight, you need to identify the specific standard.

- JIC (SAE J514): A very common straight thread with a 37° flared cone seating surface.

- ORFS (SAE J1453): A straight thread with a flat face that seals via an O-ring. Excellent for high vibration.

- NPT (ANSI B1.20.1): The most common tapered thread in North America.

- BSPP (BS 2779): A straight thread popular worldwide, seals with a bonded seal washer or O-ring.

- BSPT (BS 21): A tapered thread similar to NPT but with a different thread angle (55° vs. NPT’s 60°).

- DIN (German Metric): Uses metric threads and a 24° cone. There are light (L) and heavy (S) series.

The Identification Process

- Visually Inspect: Is it tapered or straight? Can you see an O-ring, a bonded seal, or a flared cone?

- Measure Diameter: Use calipers to measure the outside diameter (O.D.) of a male thread or the inside diameter (I.D.) of a female thread.

- Measure Pitch: Use a thread pitch gauge to find the number of threads per inch or the distance between threads for metric fittings.

- Consult a Chart: Compare your measurements and visual inspection against a thread identification chart to confirm the standard.

Step 3: Which Material is Right For Your Application?

Are you using standard carbon steel fittings in a saltwater environment? Choosing a material that isn’t compatible with your application can lead to rapid corrosion, contamination of the hydraulic fluid, and sudden failure.

The material choice depends directly on your STAMP analysis. For most standard hydraulic systems, zinc-plated carbon steel is the cost-effective workhorse. For corrosive environments or specific media, you must upgrade to stainless steel or brass.

Carbon Steel – The Industry Standard

Carbon steel is the most common material for hydraulic fittings due to its excellent strength and relatively low cost. To protect it from rust, it is almost always coated, typically with an electroplated zinc or a zinc-nickel alloy. This coating provides good resistance to corrosion in most general-purpose applications. It’s the go-to choice for construction, agriculture, and manufacturing machinery where the fittings aren’t exposed to extreme chemicals or saltwater. Its high pressure-holding capability makes it suitable for the vast majority of hydraulic systems.

Stainless Steel – For Corrosion and Purity

When corrosion resistance is the primary concern, stainless steel is the answer. There are two common grades used for fittings:

- 304 Stainless Steel: Offers good corrosion resistance for many environments but can be susceptible to attack from chlorides (like salt).

- 316 Stainless Steel: Contains molybdenum, which provides significantly superior resistance to corrosion, especially from saltwater, de-icing salts, and harsh chemicals. It is the standard for marine, chemical processing, and food-grade applications where purity is a must. While more expensive, its longevity in these applications is well worth the investment.

Brass – For Specific Applications

Brass is an alloy of copper and zinc. It offers very good corrosion resistance and is softer than steel, which allows it to seal well in some low-pressure applications. However, its primary use in hydraulics is where there is a risk of sparking. Because it’s a non-sparking material, it’s often specified for use in explosive environments like underground mines or certain gas facilities. It has a lower pressure rating than steel, so it is typically limited to lower-pressure pneumatic or hydraulic lines.

| Material | Strength/Pressure Rating | Corrosion Resistance | Cost | Best Use Case |

| Carbon Steel | Very High | Good (with plating) | Low | General machinery, construction, agriculture |

| 304 Stainless | High | Very Good | Medium | Food processing, chemical plants |

| 316 Stainless | High | Excellent | High | Marine environments, saltwater, harsh chemicals |

| Brass | Lower | Very Good | Medium | Low pressure, non-sparking environments |

Step 4: What Fitting Shape Do You Need for Routing?

Are you using multiple straight fittings and adapters to make a 90-degree turn? Every additional connection point you create is another potential leak path and adds unnecessary cost and complexity to your system.

Select a fitting shape that routes the hose directly from port to port with a gentle bend and minimal stress. Use straight fittings for straight runs, and use 45° or 90° elbow fittings to navigate corners and obstacles cleanly.

Straight Fittings

Straight fittings are the most common shape. They are used when the hose runs directly away from the port without any immediate turns. They connect a hose to a port, or they can be used to connect two hoses together (as a union). While they are the simplest configuration, you must ensure that there is enough room for the hose to make a natural bend without kinking near the fitting. A kink not only restricts flow but also puts immense stress on the hose’s reinforcement, leading to premature failure.

Angled Fittings (Elbows)

Elbow fittings are essential for efficient plumbing. They are most commonly available in 90° and 45° angles. Using an elbow allows the hose to exit the port at an angle, eliminating the need for a sharp bend. This is critical in tight spaces found on mobile equipment. It reduces the total length of hose required and, most importantly, prevents stress and potential abrasion points that occur when a hose is forced into a tight radius. Always choose an elbow over a straight fitting if the hose needs to make an immediate turn.

Branch Fittings (Tees and Crosses)

Tees and crosses are used to split a single hydraulic line into two or more lines or to combine multiple lines into one. A tee fitting has one inlet and two outlets (or vice-versa), while a cross has one inlet and three outlets. These are vital for creating more complex circuits where you need to send fluid to multiple actuators from a single pump, or where you need to install gauges and sensors into a line. Using a single tee is far more reliable and professional than trying to stack multiple adapters to achieve the same result.

Step 5: How Do You Verify the Supplier and Standards?

You’ve found a fitting that looks right online for a very low price. But how do you know if it meets international quality standards, or if the supplier will still be there to support you tomorrow?

Always choose a supplier who can prove their products conform to international standards like SAE, ISO, and DIN. Furthermore, evaluate the supplier on their service, responsiveness, and technical support, not just the price. A reliable partner is worth more than a cheap part.

Why International Standards (SAE, ISO, DIN) Matter

International standards are a guarantee of interchangeability and performance. When a fitting is made to an SAE J514 (JIC) or ISO 8434-2 standard, you can be confident that it will properly connect with any other fitting made to that same standard, anywhere in the world. These standards dictate everything from thread dimensions and tolerances to burst pressure requirements and material composition. A fitting without a clear standard is a complete gamble. Always demand that your supplier specify the standards their products meet.

Evaluating a Supplier’s True Value

A low price is tempting, but it can hide many costs. A truly valuable supplier offers more.

- Responsiveness: How quickly do they answer your technical questions and provide quotations? A fast response from a knowledgeable team saves you time.

- One-Stop Sourcing: Can they provide all the fittings you need, both standard and custom? This simplifies your purchasing and logistics.

- Guaranteed Quality: Do they have a clear quality control process? Do they stand behind their product with a warranty?

- After-Sales Support: What happens if there is a problem? A good supplier works with you to solve the issue, they don’t disappear after the sale.

The Hidden Costs of a Bad Supplier

Choosing a poor supplier can be disastrous. You may receive parts that fail prematurely, causing expensive equipment damage and dangerous situations. You could face production delays because of late shipments or incorrect parts. If a part fails in your customer’s machine, it damages your own reputation. The money you saved on a cheap fitting is quickly lost to rework, downtime, and lost business. Investing in a quality part from a reputable supplier is an investment in peace of mind.

Conclusion

Selecting the right hydraulic fitting is easy with the 5-step method: use S.T.A.M.P., identify threads, choose your material and shape, and verify your supplier. This secures a leak-free, reliable system.

At Topa, we provide reliable hydraulic fittings, hoses, and adapters that meet SAE, ISO, and DIN standards. With fast response, wide product range, and strict quality control, we ensure leak-free and durable connections for your systems. Contact us today to request a quote!

FAQ

What is the STAMP method in hydraulic fitting selection?

STAMP (Size, Temperature, Application, Media, Pressure) is a systematic approach that ensures fittings are chosen based on actual system conditions for safe and reliable performance.

Why does thread identification matter in hydraulic fittings?

Correctly identifying thread type and size prevents mismatches like BSP vs NPT, which can cause leaks, damage components, and compromise system safety.

Which material is best for hydraulic fittings?

Carbon steel suits general use, stainless steel is ideal for corrosion environments like marine or chemical, and brass is used in low-pressure or spark-free conditions.

How do I select the correct fitting shape?

Choose straight fittings for direct runs, elbows for bends, and tees or crosses for branching lines; reducing adapters lowers leak risks and simplifies routing.

Why should I only buy fittings that meet ISO, SAE, or DIN standards?

Certified standards guarantee proper dimensions, sealing, and pressure ratings, ensuring fittings are interchangeable, durable, and globally compatible.

What are the risks of choosing a low-cost, uncertified supplier?

Cheap suppliers may deliver fittings with poor tolerance or weak materials, leading to leaks, downtime, safety hazards, and higher long-term costs.