Rapid Sample Development

Our rapid prototype development service allows you to test and refine hydraulic systems before committing to full-scale production. This service significantly reduces development time and helps you bring your products to market faster.

Personalized Consultation

At Topa, we provide personalized consultation services to understand your specific needs and challenges. Our expert team collaborates closely with you to develop solutions tailored to your system's requirements, ensuring optimal integration and performance of our hydraulic fittings.

24/7 Support

Our team of skilled technicians is always ready to provide assistance, advice, and troubleshooting to keep your operations running smoothly, minimizing downtime and enhancing productivity.

What We Do

Why Choose Topa

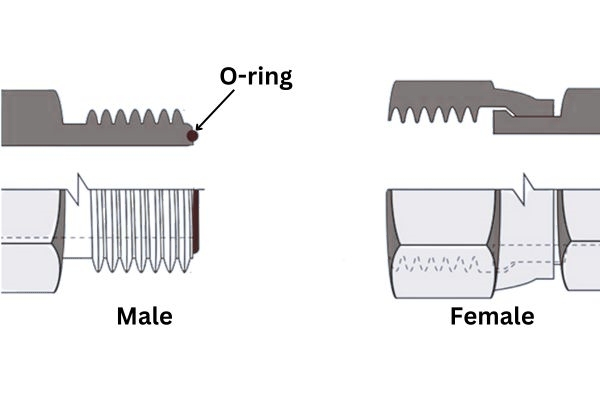

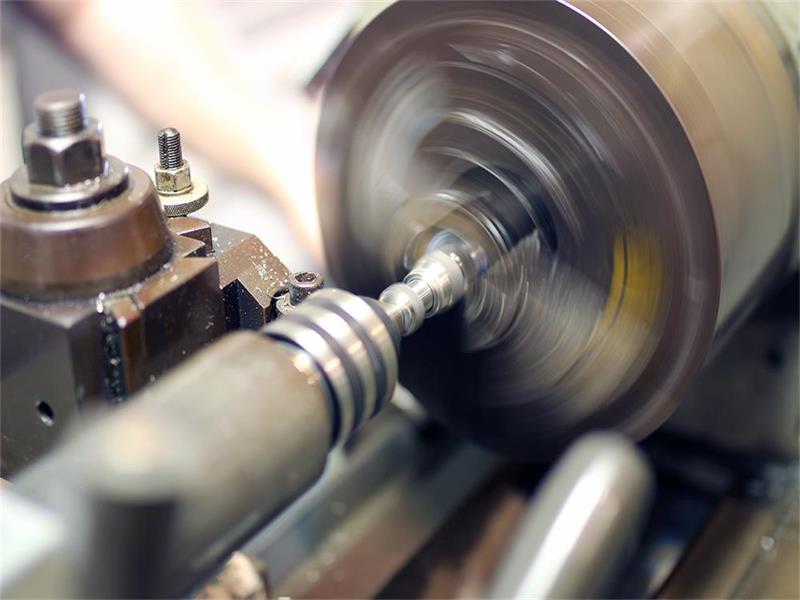

Topa leverages advanced manufacturing techniques and rigorous quality control processes to ensure that each ORFS fitting meets and exceeds modern hydraulic systems’ stringent demands. With Topa, clients gain a reliable partner dedicated to providing solutions that enhance system efficiency, reduce maintenance costs, and extend the lifespan of hydraulic assemblies.