Did you know that banjo bolts, despite their unassuming appearance, play a crucial role in ensuring the safety and efficiency of high-performance vehicles? A banjo bolt is a specialized type of fastener that features a hollow, cylindrical design with a cross-drilled hole, allowing fluid to pass through it. This bolt is paired with a banjo fitting, which is a hollow, ring-shaped component with a single or double barb. The banjo bolt and fitting work together to create a secure and leak-proof connection in fluid systems. The unique design allows the banjo fitting to rotate around the bolt, providing flexibility and ease of alignment in various applications.

The design of a banjo bolt is ingeniously simple yet highly effective. At its core, a banjo bolt consists of a hollow, cylindrical bolt that is cross-drilled, allowing fluid to flow through its center and out through the side holes. This unique structure enables the bolt to serve as a conduit for fluids, making it a vital component in systems where secure and efficient fluid transfer is essential.

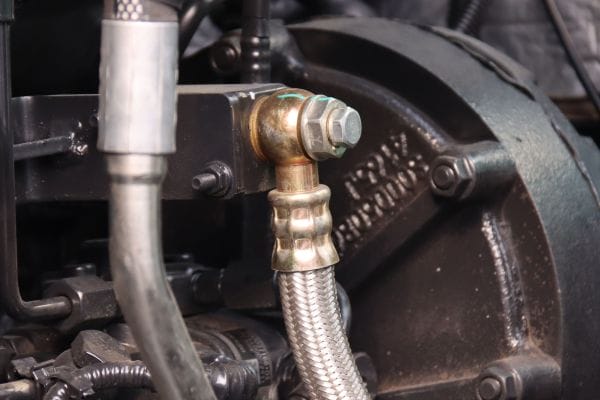

The banjo bolt pairs with a banjo fitting, which is a ring-shaped, hollow component that resembles the shape of a banjo—hence the name. The banjo fitting typically has one or two barbs that connect to hoses or pipes, creating a seamless pathway for fluid to travel. When the banjo fitting is placed around the bolt and secured with a nut, the assembly forms a tight, leak-proof connection that can withstand high pressures.

To better visualize, imagine a bolt with a hole drilled through its shaft. This hole intersects with another hole drilled perpendicular to it, forming a passageway for fluid. The banjo fitting, which resembles a flattened ring with a hose attached to its side, fits over the bolt. When fluid enters the banjo fitting, it flows through the bolt’s hollow shaft and exits through the side holes, continuing its journey through the connected hose or pipe.

Stainless Steel: Known for its exceptional strength, corrosion resistance, and durability, stainless steel is a popular choice for banjo bolts used in harsh environments or where the risk of corrosion is high. This makes stainless steel banjo bolts ideal for automotive brake systems, marine applications, and industrial machinery where exposure to moisture and chemicals is common.

Brass: Brass is prized for its excellent machinability, corrosion resistance, and aesthetic appeal. Banjo bolts made from brass are often used in fuel systems and low-pressure hydraulic applications. The material’s natural resistance to corrosion by fuel and its ability to form a tight seal make it a reliable choice for these systems.

Aluminum: Lightweight yet strong, aluminum banjo bolts are used in applications where weight savings are crucial, such as in aerospace and high-performance automotive systems. Despite being lighter, aluminum can still provide the necessary strength and durability for many fluid transfer applications.

The choice of material for a banjo bolt depends largely on the specific requirements of the application, including factors like operating pressure, environmental conditions, and compatibility with the fluids being transferred. For instance, in an automotive braking system, the ability to withstand high pressures and resist corrosion from brake fluids is paramount, making stainless steel the material of choice. In contrast, a fuel system might prioritize corrosion resistance and ease of manufacturing, leading to the selection of brass.

By understanding the basic structure and materials used in banjo bolts, one can appreciate the versatility and critical role these components play in a wide range of industries. Whether ensuring the safety of a vehicle’s braking system or facilitating the smooth operation of hydraulic machinery, banjo bolts are indispensable in their applications.

In the automotive industry, banjo bolts play a pivotal role in brake systems, ensuring safe and efficient operation. Brake systems rely on hydraulic pressure to activate the brake calipers, which in turn press the brake pads against the rotors to slow down or stop the vehicle. Banjo bolts are essential in creating a secure and leak-proof connection between the brake lines and the calipers.

The banjo bolt is used to attach the brake line to the caliper through a banjo fitting. When the brake pedal is pressed, brake fluid travels through the brake lines and enters the banjo fitting via the hollow banjo bolt. The fluid then flows through the bolt’s drilled holes and into the caliper, creating the hydraulic pressure needed to push the brake pads against the rotors. This mechanism ensures that the braking force is evenly distributed and effective, providing reliable stopping power.

Use in Fuel Systems, Including Fuel Lines and Filters

Banjo bolts are also widely used in automotive fuel systems. They are instrumental in connecting fuel lines to various components such as fuel pumps, filters, and injectors. In fuel systems, the banjo bolt ensures a secure and tight connection, preventing fuel leaks and maintaining system integrity.

For instance, in a fuel injection system, banjo bolts connect the fuel lines to the injectors. Fuel from the tank is pumped through the lines and passes through the banjo fitting attached by the banjo bolt. This connection allows the fuel to flow smoothly into the injectors, where it is atomized and delivered into the engine cylinders. The precision and reliability of banjo bolts in these connections are crucial for optimal engine performance and fuel efficiency.

Application in Hydraulic Lines for Fluid Transfer

In hydraulic systems, banjo bolts are essential for facilitating fluid transfer in high-pressure environments. Hydraulic systems rely on pressurized fluid to transmit power and perform various functions, such as lifting, pressing, and moving heavy loads. Banjo bolts are used to connect hydraulic hoses and components, ensuring a secure and leak-proof fluid transfer.

For example, in construction equipment like excavators and bulldozers, hydraulic systems power the movement of the arms, buckets, and other attachments. Banjo bolts connect the hydraulic hoses to the cylinders and control valves, allowing pressurized hydraulic fluid to flow through the system and activate the desired movements. The robustness and reliability of banjo bolts ensure that these machines can operate efficiently under demanding conditions.

Examples of Machinery and Equipment Utilizing Banjo Bolts

Beyond construction equipment, banjo bolts are used in a wide range of machinery and equipment that rely on hydraulic systems. This includes agricultural machinery like tractors and harvesters, industrial machines such as presses and lifts, and even in aircraft landing gear systems. In each of these applications, banjo bolts facilitate the secure and efficient transfer of hydraulic fluid, enabling the machinery to perform its intended functions.

Use in Oil and Gas Industries

In the oil and gas industry, banjo bolts are used in various applications involving fluid transfer and pressure management. They are employed in systems that transport oil, gas, and other fluids through pipelines and processing equipment. The ability of banjo bolts to provide leak-proof connections under high pressure and harsh environmental conditions makes them indispensable in this sector.

For instance, banjo bolts are used in the connection of pipelines to pumps and valves in oil refineries and drilling rigs. These connections need to withstand extreme pressures and temperatures, and banjo bolts provide the necessary durability and reliability to ensure safe and efficient operation.

Application in Marine and Aerospace Industries

In the marine industry, banjo bolts are used in hydraulic systems that control various functions on ships and boats, such as steering, propulsion, and deck machinery. The corrosive marine environment requires components that can resist rust and deterioration, and banjo bolts made from materials like stainless steel are ideal for these conditions.

In the aerospace industry, banjo bolts are used in hydraulic systems that operate the aircraft’s control surfaces, landing gear, and other critical systems. The high-performance requirements of aerospace applications demand components that are lightweight, durable, and capable of withstanding extreme pressures and temperatures. Banjo bolts meet these criteria, ensuring reliable operation in the demanding conditions of flight.

Stainless Steel: Known for its excellent corrosion resistance and high strength, stainless steel is often chosen for applications exposed to harsh environments or corrosive substances. For instance, in marine applications where components are frequently in contact with salt water, stainless steel banjo bolts provide long-lasting performance without rusting. Additionally, in automotive brake systems, stainless steel bolts ensure durability and safety under high-pressure conditions.

Brass: Brass is valued for its good corrosion resistance, ease of machining, and suitability for lower-pressure applications. It is commonly used in fuel systems and lower-pressure hydraulic applications where its ability to resist fuel corrosion and form tight seals is beneficial. Brass banjo bolts are also aesthetically pleasing and often used where appearance matters.

Aluminum: Lightweight yet strong, aluminum is ideal for applications where reducing weight is a priority, such as in aerospace and high-performance automotive systems. Although aluminum does not have the same strength as stainless steel, its lightweight and resistance to oxidation make it suitable for components that need to minimize overall weight without compromising on performance.

The size and thread specifications of a banjo bolt are vital for ensuring a proper fit and secure connection. Selecting the correct size involves matching the bolt to the diameter of the hose or pipe it will connect to, as well as ensuring it fits the banjo fitting properly.

Diameter: The diameter of the banjo bolt must match the inner diameter of the hose or pipe to ensure a secure fit and effective fluid transfer. Using the correct diameter prevents leaks and maintains system pressure.

Thread Type and Pitch: The thread type (e.g., metric, SAE) and pitch (the distance between threads) must match the receiving component’s specifications. Using mismatched threads can lead to cross-threading, leaks, and potential system failure. It’s essential to verify the thread specifications and ensure compatibility with the components being used.

Length: The length of the banjo bolt should be sufficient to pass through the banjo fitting and secure with a nut while allowing enough thread engagement for a tight seal. Insufficient length can result in a weak connection, while excessive length can cause interference with other components.

Industry Standards and Certifications to Look For

To ensure the reliability and safety of banjo bolts, it’s important to adhere to industry standards and certifications. These standards guarantee that the components meet specific criteria for quality, performance, and safety.

ISO Standards: The International Organization for Standardization (ISO) provides globally recognized standards for various components, including banjo bolts. ISO standards ensure that the bolts meet rigorous quality and performance criteria, making them suitable for international use.

SAE Standards: The Society of Automotive Engineers (SAE) sets standards for automotive components, including banjo bolts. SAE standards ensure that the bolts are compatible with automotive systems and meet safety and performance requirements.

Certifications: Look for certifications such as ISO 9001, which indicates that the manufacturer adheres to a quality management system and consistently produces high-quality products. Other relevant certifications might include those for specific industries, such as aerospace or marine.

By considering these factors and prioritizing quality standards and reputable sources, you can select the right banjo bolt for your specific application, ensuring optimal performance, safety, and longevity.

Banjo bolts are indispensable components in various industries, providing secure and efficient fluid transfer in automotive, hydraulic, oil and gas, marine, and aerospace applications. Their unique design, material versatility, and ability to withstand high pressures make them critical for safety and performance. Reflecting on their widespread use, it’s clear that banjo bolts play a vital role in ensuring the reliability of complex systems. We invite you to share your experiences with banjo bolts or reach out for more information on selecting the right one for your needs.

A banjo bolt is a hollow bolt used to connect fluid lines in hydraulic and fuel systems, allowing fluid to pass through its center and into a connected fitting.

Banjo bolts are commonly used in automotive brake and fuel systems, hydraulic machinery, and various industrial applications including oil and gas, marine, and aerospace industries.

Banjo bolts are typically made from stainless steel, brass, or aluminum, each chosen for its specific properties such as corrosion resistance, strength, and weight.

Consider factors such as material compatibility, size, thread type, and the specific requirements of your application, including pressure and environmental conditions.

Banjo bolts offer secure and leak-proof connections, ease of installation, flexibility in alignment, and reliable performance under high-pressure conditions.

Sourcing from reputable manufacturers ensures high-quality materials, adherence to industry standards, rigorous quality control, and reliable performance of the banjo bolts in critical applications.