How Are Hydraulic Fittings Made?

Table of Contents

Introduction

From agricultural machinery to aerospace engineering, these hydraulic fittings are vital for controlling flow and pressure in hydraulic systems. But have you ever wondered how these important fittings are made? In this comprehensive article, we’ll delve into the intricate process of their creation. From the selection of durable materials to the meticulous manufacturing process and rigorous testing and compliance standards, we’ll uncover every detailed manufacturing detail.

Materials Used to Make Hydraulic Fittings

In the realm of hydraulic fittings, the choice of material is pivotal, dictating both performance and longevity. The most commonly used materials include steel, brass, and stainless steel, each selected for their unique properties that make them ideal for this application.

Overview of Common Materials

Steel, known for its strength and durability, is a standard in hydraulic fittings. It is particularly favored in high-pressure environments. Brass, another popular choice, offers excellent corrosion resistance and is preferred for its malleability in more complex fittings. Stainless steel stands out for its combination of strength and resistance to corrosion and extreme temperatures, making it a go-to for harsh working conditions.

Properties That Make These Materials Suitable

Each of these materials brings essential properties to the table. Steel’s high tensile strength makes it capable of withstanding intense pressure without deforming. Brass, while not as strong as steel, resists corrosion exceptionally well, making it ideal for water-based systems. Stainless steel, a robust alloy, resists rust and maintains structural integrity even under extreme thermal conditions. These properties are critical in ensuring the safety and efficiency of hydraulic systems.

Environmental and Cost Considerations

When selecting materials for hydraulic fittings, environmental impact and cost are significant considerations. Steel and stainless steel, while durable, have a higher carbon footprint due to energy-intensive production processes. Brass, although more environmentally friendly to manufacture, often comes with a higher price tag. Recent advancements are focusing on more sustainable manufacturing practices, such as recycling scrap metal and improving energy efficiency in production. These innovations aim to reduce environmental impact while balancing cost-effectiveness, ensuring hydraulic fittings are both sustainable and economically viable for manufacturers and end-users.

Manufacturing Process

The manufacturing of hydraulic fittings is an intricate process, involving various techniques to meet the high standards required for their performance. The process begins with the design phase, where precise specifications are laid out, taking into consideration the application, pressure requirements, and environmental factors. This is followed by the selection of appropriate materials, which is crucial as the fittings must withstand high pressures and corrosive environments.

Design and Material Selection

Before the manufacturing process of hydraulic fittings commences, a critical step is the detailed design phase. This stage involves defining the precise dimensions, shape, and intended application of the fittings. Engineers and designers consider various factors such as the type of hydraulic system the fittings will be used in, the range of pressures they must withstand, and environmental conditions they may be exposed to.

The selection of materials is based on their performance characteristics to ensure the fittings can meet the specific demands of their application. Key properties considered include:

Strength: The material must possess enough strength to withstand high pressures without failure. This is crucial to prevent leaks or bursts in hydraulic systems, which can lead to equipment damage or safety hazards.

Corrosion Resistance: Since hydraulic systems often operate in environments that can be corrosive (such as outdoor settings or with certain hydraulic fluids), the material needs to resist corrosion to maintain integrity over time.

High-Pressure Tolerance: The ability to withstand the high-pressure environment of hydraulic systems is a must. This involves not just the immediate pressures but also the potential for pressure surges.

Raw material cutting process

The raw material cutting process in hydraulic fitting manufacturing is a crucial initial step. Once the appropriate material is selected, it undergoes precision cutting to shape it into the desired dimensions for the specific type of hydraulic fitting being produced.

Cutting techniques vary depending on the material and the required precision. Common methods include:

- CNC Machining: Computer Numerical Control (CNC) machining offers high precision and is ideal for complex shapes. It involves programming a computer to control the movement and operation of the cutting tools, ensuring exact dimensions and a high-quality finish.

- Laser Cutting: Laser cutting uses a high-powered laser to melt, burn, or vaporize the material, resulting in highly accurate and smooth cuts. This method is efficient for intricate designs and fine tolerances.

- Water Jet Cutting: This method uses high-pressure water, sometimes mixed with an abrasive substance, to cut through the material. It is particularly useful for materials that are sensitive to high temperatures generated by other cutting methods.

- Saw Cutting: Traditional but effective, saw cutting involves using various saw types to cut the material to length. While less precise than CNC machining or laser cutting, it is cost-effective for simpler cuts.

CNC machines

The machining process of hydraulic fittings is an intricate and precision-driven step in their production. It involves the utilization of various machine tools, including lathes, milling machines, and Computer Numerical Control (CNC) machines. These tools play a crucial role in shaping the raw materials into the desired form and specifications of the hydraulic fittings.

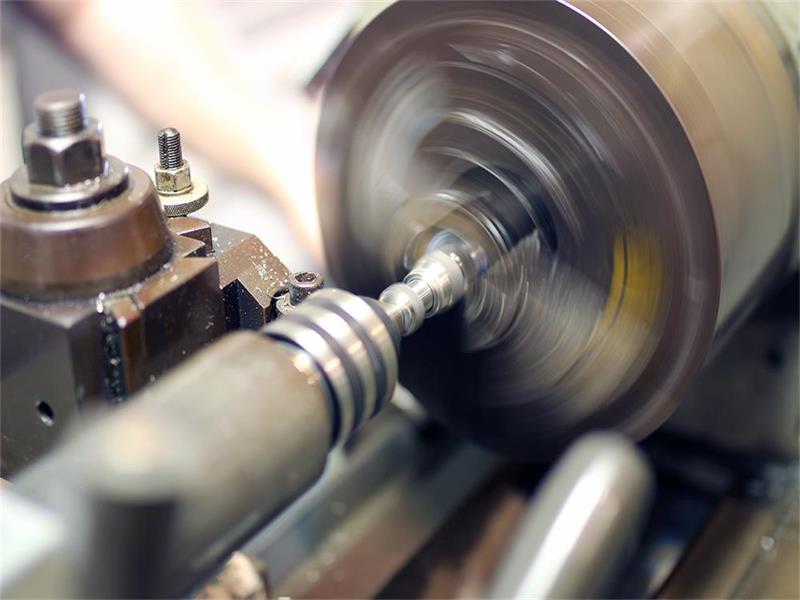

Turning and Lathe Operations

The lathe, a cornerstone in the manufacturing process, is primarily used for turning operations. In these operations, raw metal rods are rotated at high speeds while a stationary cutting tool shaves off unwanted material. This process is pivotal for crafting cylindrical components integral to hydraulic systems. It also plays a crucial role in refining the surface of the fittings, ensuring smoothness and precision. The lathe’s versatility allows for various operations, including facing, threading, and knurling, which are essential for creating specific features on the fittings.

Milling

Milling machines, equipped with sharp rotary cutters, are utilized for removing material from the workpiece’s surface. This step is crucial for creating not just flat surfaces but also complex shapes and intricate surface patterns. The precision of milling machines enables the creation of features like grooves and slots, which are often necessary for the interconnectivity and secure fitting of the hydraulic components.

Material and Construction

Drilling and Boring

Drilling and boring operations are vital for creating and refining holes within the hydraulic fittings. Drilling involves creating new holes using a rotating drill bit, while boring enlarges and refines these holes to precise diameters. This precision is essential as these holes play a crucial role in the fittings’ functionality, ensuring the proper flow and control of hydraulic fluids within the system.

CNC Machining

CNC (Computer Numerical Control) machining brings high-level precision and automation to the manufacturing process. CNC machines are programmed to perform a variety of tasks, including cutting, drilling, and milling, with exceptional accuracy. They are indispensable for producing fittings with complex shapes, intricate designs, or extremely tight tolerance requirements.

Grinding and Finishing

The final phase in the manufacturing process involves grinding and finishing. These operations are dedicated to fine-tuning the dimensions of the fittings and enhancing their surface finishes. Grinding uses abrasive wheels to remove minimal amounts of material, ensuring the fittings meet the exact size specifications. The finishing process then smooths the surface to achieve the desired texture and appearance. This step not only contributes to the aesthetic quality of the fittings but also enhances their performance by ensuring smooth surfaces that reduce friction and wear in hydraulic systems.

Heat treatment

In the manufacturing of hydraulic fittings, heat treatment plays a crucial role in enhancing the mechanical properties of the metal, primarily through processes like quenching and tempering. This stage is fundamental in achieving the desired durability and wear resistance of the fittings.

Quenching involves heating the metal to a high temperature and then rapidly cooling it, usually in water, oil, or air. This process alters the microstructure of the metal, increasing its hardness and strength. However, quenching can also make the metal brittle, which is why tempering is often necessary as a subsequent step.

Tempering, carried out after quenching, involves reheating the metal to a temperature below the critical point and then cooling it again at a controlled rate. This process reduces the brittleness imparted by quenching while retaining much of the increased hardness. It strikes a balance between the hardness and the elasticity of the metal, making the hydraulic fittings tough enough to withstand high-pressure applications without fracturing.

The precise temperatures and durations for both quenching and tempering vary based on the type of metal used and the specific requirements of the hydraulic fitting. For instance, fittings intended for high-pressure systems might undergo a different heat treatment process compared to those designed for lower pressure applications.

Thread Type

The thread type of a hydraulic fitting is another crucial factor affecting its reusability. Threads can be tapered or parallel, with each type presenting different considerations for reuse. Tapered threads, for instance, are more susceptible to wear due to their design, which requires them to form a seal by the metal-to-metal wedging. Repeated use can lead to thread deformation, which compromises the seal. In contrast, parallel threads rely on an additional sealing mechanism like an O-ring, which may be more amenable to reuse if the threads remain undamaged. The condition of the threads, their compatibility with mating components, and the presence of any thread damage are all vital considerations when assessing a fitting for reuse.

Surface treatment

Surface treatment processes play a crucial role in the manufacturing of hydraulic fittings, enhancing their durability, functionality, and aesthetic quality. Here’s an expanded overview of common surface treatment methods used for hydraulic fittings:

Galvanizing Process: Galvanization involves immersing the fitting into molten zinc to coat its surface. This process creates a corrosion-resistant layer, effectively protecting against moisture, salt, and chemical corrosion. Galvanization not only provides long-term corrosion protection but also improves the appearance and increases the lifespan of the fittings.

Nickel Plating: Nickel plating is another prevalent surface treatment, forming a layer of nickel on the surface of the fitting. This method offers superior corrosion resistance, making it particularly suitable for fittings used in harsh environments. The nickel layer not only resists corrosion but also enhances the overall strength and wear resistance of the fitting.

Anodizing: Used for aluminum alloy fittings, anodizing involves an electrochemical process that forms a thick oxide layer on the surface of the fitting. This treatment not only improves corrosion resistance but also increases surface hardness, reducing wear and tear. Anodized fittings are known for their enhanced durability and resistance to environmental factors.

Coating: Coating processes include the use of various paints and plastic coatings to provide an additional protective layer. This method can enhance the aesthetic appeal of the fittings and offers extra protection against corrosion and chemical erosion. Coatings can be customized in terms of color and finish, allowing for greater design flexibility and branding opportunities.

Heat Treatment: Some hydraulic fittings undergo heat treatment during their manufacturing process to alter their metal structure, thereby enhancing strength and toughness. This treatment helps ensure the fitting’s performance under extreme pressure and load conditions. Heat-treated fittings are typically more resilient and capable of withstanding rigorous operational demands.

Quality Check

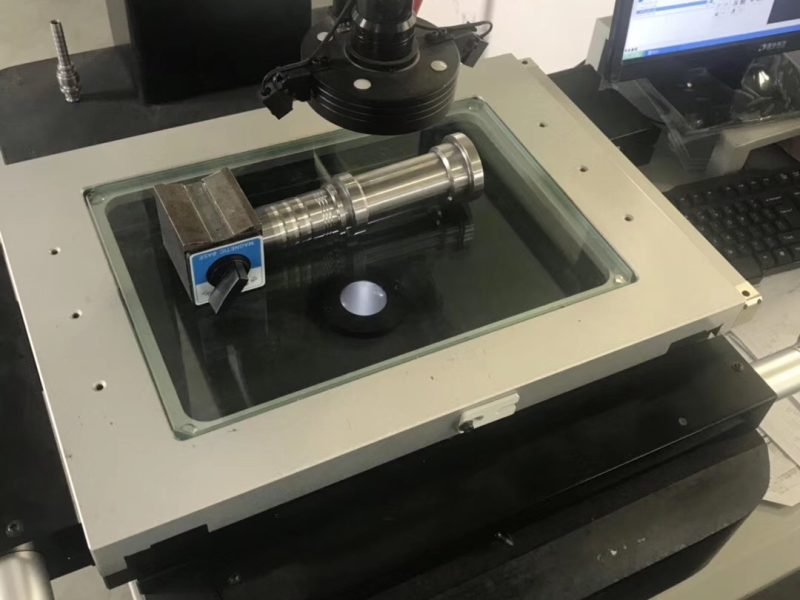

In the manufacturing process of hydraulic fittings, quality testing and control are essential steps to ensure each fitting meets the highest standards of performance and reliability. Here is an expanded overview of the key aspects of quality testing and control for hydraulic fittings:

Dimensional Accuracy Inspection: At the early stages of the manufacturing process, the dimensions of each fitting are precisely measured to ensure compliance with design specifications. High-precision measuring tools and metrology equipment are used to check critical dimensions such as diameter, length, and thread specifications. This step is crucial for ensuring that the fittings are compatible with other system components and can be installed correctly.

Material Testing: This involves assessing the quality of the materials used, including their strength, toughness, and corrosion resistance. This may involve tensile testing, hardness testing, and chemical analysis of material samples. High-quality materials are fundamental for ensuring the long-term reliability of the fittings.

Pressure Testing: Each fitting undergoes pressure testing to verify its performance under high-pressure conditions. This typically involves subjecting the fitting to pressures beyond its design limits to ensure there are no leaks or failures under actual application conditions.

Surface Inspection: A thorough examination of the fitting’s appearance and surface is conducted to identify any cracks, scratches, or other defects. Surface quality directly affects the fitting’s seal integrity and corrosion resistance.

Conclusion

In conclusion, the manufacturing and quality control processes of hydraulic fittings are intricate and highly specialized. They encompass a variety of techniques and stages, each critical to ensuring the reliability, durability, and functionality of the fittings. The integration of these processes and quality controls results in hydraulic fittings that are capable of performing under demanding conditions and in various applications, underscoring their importance in hydraulic systems.

FAQ

Hydraulic fittings are typically made from materials like stainless steel, brass, and carbon steel for their strength and resistance to corrosion.

Hydraulic fittings are manufactured through processes like machining, forging, and casting to shape and thread the components.

CNC machines are used to precisely machine hydraulic fittings, ensuring accurate dimensions, threading, and high-quality finishes.

Threads on hydraulic fittings are created using machines like lathes or thread mills, or by cutting the threads during the forging process.

Quality control includes inspection of dimensions, pressure testing, and material testing to ensure the fittings meet industry standards and perform reliably.

Seals are either inserted into grooves or attached during assembly, ensuring leak-free connections between fittings and hoses.

Topa Blog

Find out more about Topa Blog and learn more about specialized hydraulic fittings.