Brake Line Union vs Compression Fitting: Which to Choose?

Table of Contents

Introduction

Brake line fittings play a crucial role in the safety and performance of automotive brake systems. These small yet essential components ensure that the brake lines remain securely connected, preventing leaks and maintaining the hydraulic pressure needed for effective braking. This article aims to provide a comprehensive comparison between two common types of brake line fittings: brake line unions and compression fittings. We will delve into the definitions and functions of brake line unions and compression fittings, explore the various types and materials used, and discuss the key differences in design, installation, and performance.

Understanding Brake Line Unions

Definition and Function

A brake line union is a type of fitting used to connect two sections of brake line tubing. These fittings are designed to create a secure and leak-proof connection between the lines, ensuring that the hydraulic brake fluid can flow uninterrupted through the brake system. Brake line unions are essential components in any vehicle’s brake system, as they maintain the integrity and continuity of the brake lines, which is critical for effective braking performance.

Role in the brake system:

The primary role of brake line unions in the brake system is to join two separate pieces of brake line tubing. This connection is crucial for maintaining the hydraulic pressure needed for the brakes to function properly. Without a secure connection, the brake fluid could leak, leading to a loss of pressure and ultimately brake failure. Brake line unions are commonly used in repairs, modifications, or extensions of the brake lines, allowing mechanics to replace damaged sections or alter the layout of the brake system without replacing entire lines.

Types of Brake Line Unions

Different types:

Brake line unions come in various types, each designed to meet specific needs and standards:

- Standard Brake Line Unions: These are the most common type of unions, featuring a straightforward design that allows for easy connection of brake lines. They typically use a simple threaded connection to secure the brake lines together.

- Inverted Flare Brake Line Unions: These unions are designed with an inverted flare at the end of the fitting, which helps to create a more secure and leak-proof connection. The inverted flare design ensures that the brake line is tightly compressed against the union, providing a stronger seal.

- Bubble Flare Brake Line Unions: Similar to the inverted flare, bubble flare unions are designed to work with brake lines that have a bubble flare at the end. This type of union provides a secure connection by compressing the flare against the fitting.

Materials Used

Brake line unions are made from a variety of materials, each offering different benefits and drawbacks:

- Steel: Steel is a common material for brake line unions due to its strength and durability. It can withstand high pressures and is resistant to corrosion, making it ideal for use in harsh environments. However, steel fittings can be prone to rust if not properly treated or coated.

- Brass: Brass is another popular material for brake line unions. It is highly resistant to corrosion and is easier to work with than steel, as it does not require as much force to tighten. Brass fittings provide a good seal and are commonly used in automotive applications.

- Stainless Steel: Stainless steel unions offer the best of both worlds, combining the strength and durability of steel with the corrosion resistance of brass.

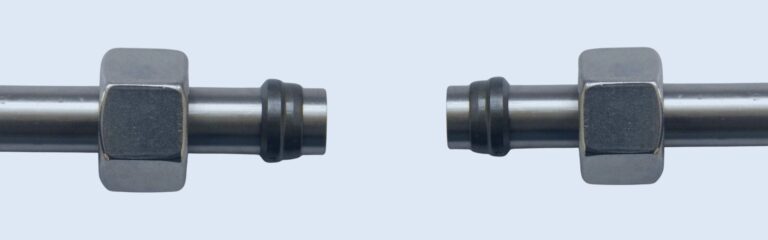

Understanding Compression Fittings

A compression fitting is a type of connector used to join two ends of tubing or pipe in a fluid or gas system. It consists of three main components: the compression nut, the compression ring (or ferrule), and the fitting body. When the compression nut is tightened, it compresses the ferrule onto the tubing, creating a secure and leak-proof seal.

Role in the brake system

In the brake system, compression fittings play a vital role in connecting sections of brake lines. They are used to ensure that the hydraulic brake fluid flows seamlessly without leaks, maintaining the necessary pressure for effective braking. Compression fittings are often employed in situations where the brake lines need to be joined or repaired, providing a reliable and strong connection that can withstand the high pressures found in brake systems.

Types of Compression Fittings

Compression fittings come in various types, each designed to meet specific requirements and provide different levels of sealing capability:

- Single Ferrule Compression Fittings: These fittings use a single ferrule to compress against the tubing. The ferrule acts as a seal and provides the mechanical grip needed to secure the connection.

- Double Ferrule Compression Fittings: These fittings use two ferrules, an inner and an outer ferrule, to create a more secure and robust connection. The inner ferrule grips the tubing, while the outer ferrule provides additional support and sealing capability.

Materials Used

Compression fittings are made from various materials, each offering distinct benefits and drawbacks:

- Brass: Brass is widely used for compression fittings due to its excellent corrosion resistance and ease of installation. It provides a good seal and is relatively soft, making it easy to work with. Brass fittings are common in automotive applications because they offer a balance of durability and cost-effectiveness.

- Stainless Steel: Stainless steel fittings are known for their strength and durability. They are highly resistant to corrosion and can withstand high pressures, making them ideal for performance and high-pressure brake systems. Stainless steel fittings are often used in applications where longevity and reliability are paramount.

Key Differences

Design and Construction

Structural differences:

- Brake Line Unions: Brake line unions consist of a simple cylindrical design that connects two brake lines directly. They often use threaded connections and are designed to match the flares on the ends of brake lines, such as standard flare or inverted flare fittings. The union provides a straightforward, mechanical connection that relies on the tightness of the threads and the mating flares to create a seal.

- Compression Fittings: Compression fittings have a more complex design, typically including a compression nut, a compression ring (ferrule), and a fitting body. When the compression nut is tightened, it compresses the ferrule around the brake line, which creates a secure and leak-proof seal. Compression fittings can come in single ferrule or double ferrule types, providing different levels of sealing capability and mechanical grip.

Installation Process

Brake Line Unions:

- Preparation: Cut and flare the brake line ends if necessary, ensuring they match the union type (e.g., inverted flare).

- Threading: Insert the brake line ends into the union and hand-tighten the union onto the brake lines.

- Tightening: Use a wrench to securely tighten the union, ensuring a snug fit without over-tightening, which could damage the threads or flare.

Compression Fittings:

- Preparation: Cut the brake line to the desired length, ensuring a clean, straight cut.

- Assembly: Slide the compression nut onto the brake line, followed by the compression ring (ferrule).

- Inserting: Insert the brake line end into the fitting body until it reaches the stop.

- Tightening: Slide the compression ring and nut towards the fitting body and hand-tighten the nut.

- Securing: Use a wrench to tighten the compression nut, which compresses the ferrule around the brake line, creating a seal. Avoid over-tightening to prevent damage.

Performance and Reliability

- Brake Line Unions: Provide a strong, reliable connection if installed correctly, maintaining the high hydraulic pressure necessary for effective braking. They are particularly suitable for high-pressure systems but require precision during installation to prevent leaks.

- Compression Fittings: Offer a versatile and strong connection that can also handle high pressures. They are slightly more forgiving in installation, as the ferrule compression provides a good seal even if the cut is not perfectly smooth. However, over-tightening can lead to damage and potential leaks.

Common failure points:

- Brake Line Unions: Leaks can occur if the flares are not properly formed or if the union is not adequately tightened. Thread damage from over-tightening is also a concern.

- Compression Fittings: Leaks may result from improper ferrule compression or over-tightening. In rare cases, the ferrule can crack under excessive pressure.

Factors to Consider When Choosing

Application and Specific Use Cases

Brake System Modifications:

When modifying a vehicle’s brake system, such as adding new brake lines or re-routing existing ones, the choice between unions and compression fittings can significantly impact the ease of the project. Compression fittings offer more flexibility and are often preferred in custom modifications because they can be installed without specialized flaring tools.

Emergency Repairs:

In emergencies where a quick fix is required, compression fittings may be more practical. They can be installed swiftly with basic tools, making them ideal for roadside repairs or in scenarios where immediate attention is needed.

Performance and Pressure Ratings

High-Performance Applications:

Vehicles that undergo high stress, such as racing cars or heavy-duty trucks, demand fittings that can withstand extreme pressures and vibrations. Double ferrule compression fittings are often chosen for their enhanced sealing and durability under high-pressure conditions, while brake line unions are preferred for their robustness in maintaining consistent hydraulic pressure.

Brake System Complexity:

For complex brake systems with multiple junctions and fittings, the reliability of the connections is paramount. Compression fittings can provide additional security due to their ability to create a strong seal through the compression of ferrules, making them suitable for intricate brake line networks.

Installation Environment

Space Constraints:

The physical space available for installation can influence the choice of fitting. Compression fittings, with their slightly bulkier design, might be more challenging to fit in tight spaces compared to the more compact brake line unions. Assessing the installation environment is crucial to ensure a proper and secure fit.

Accessibility:

In areas of the brake system that are hard to reach, compression fittings can offer an advantage due to their easier installation process. Since they do not require flaring tools, they can be installed with minimal movement and space, making them suitable for confined areas.

Durability and Longevity

Material Longevity:

The material of the fitting plays a critical role in its lifespan. Stainless steel and brass compression fittings are known for their long-lasting performance and resistance to corrosion, making them suitable for vehicles exposed to harsh environmental conditions. On the other hand, steel unions, if properly maintained and coated, can also offer long-term durability.

Resistance to Wear and Tear:

In applications where the brake lines are subject to frequent movement or stress, such as off-road vehicles, the wear resistance of the fittings becomes crucial. Compression fittings, particularly those made from high-strength materials, may offer better resistance to mechanical wear and tear compared to standard unions.

Compatibility with Fluids

Brake Fluid Type:

Different brake fluids, such as DOT 3, DOT 4, or DOT 5.1, have varying chemical properties that can affect the choice of fitting material. Compression fittings made from stainless steel or brass are typically more resistant to the corrosive effects of certain brake fluids, ensuring a longer-lasting seal and connection.

Chemical Resistance:

For vehicles that may encounter exposure to various chemicals or contaminants, selecting fittings with superior chemical resistance is essential. Stainless steel compression fittings are particularly advantageous in such environments due to their inert nature and ability to resist chemical degradation.

Environmental Factors

Corrosion Resistance:

In areas with high humidity, frequent rain, or use of road salt, stainless steel or brass compression fittings may offer better longevity due to their superior corrosion resistance compared to standard steel unions.

Temperature Extremes:

Both fitting types must withstand temperature fluctuations. Stainless steel and brass materials handle extreme temperatures better, making them ideal for regions with severe winters or hot summers.

Compatibility with Existing Brake Systems

Brake Line Unions:

Must match the flare type (e.g., inverted flare) and thread size of existing brake lines. Ensuring compatibility with the current brake system is crucial for a secure and leak-proof connection.

Compression Fittings:

Need to match the tubing size but offer more flexibility in connections due to the compression mechanism. This flexibility can simplify modifications and repairs.

Conclusion

In summary, brake line unions and compression fittings each offer distinct advantages and considerations. Both fitting types come in various materials, each with its benefits and drawbacks, affecting factors such as corrosion resistance, strength, and cost. When choosing between brake line unions and compression fittings, consider the specific requirements of your vehicle and brake system. If you have questions or need further guidance, feel free to ask.

FAQ

Brake line unions use threaded connections to join brake lines and require precise flaring of the brake lines, while compression fittings use a nut and ferrule system to create a seal by compressing the ferrule around the brake line.

Compression fittings are generally easier to install because they do not require flaring tools and offer a more forgiving installation process, making them suitable for DIY enthusiasts.

Both can be suitable for high-pressure applications, but compression fittings, especially double ferrule types, are often preferred for their enhanced sealing capability and durability in high-pressure and high-vibration environments.

Common materials for both include steel, brass, and stainless steel. Steel is strong but can corrode, brass is corrosion-resistant and easy to install, and stainless steel offers the best combination of strength and corrosion resistance.

Yes, compression fittings are ideal for emergency repairs because they can be installed quickly with basic tools, making them practical for roadside fixes or urgent situations.

Consider factors such as your vehicle type, the operating conditions, your installation skills, and the specific requirements of your brake system. For high-performance or heavy-duty applications, compression fittings are recommended, while brake line unions are suitable for standard passenger vehicles and cost-effective repairs.