The role of high-temperature hoses in hydraulic systems goes beyond simply transferring fluids. They ensure safe and reliable performance, even when subjected to high-pressure and high-temperature environments. This capability is vital because hydraulic systems often operate in harsh conditions where maintaining system integrity is paramount to avoiding catastrophic failures, downtime, and costly repairs. The materials used in these hoses—ranging from specialized rubber compounds to PTFE and other advanced polymers—are designed to resist degradation, cracking, and leaks under intense heat.

Understanding High-Temperature Hoses

High-temperature hoses are specialized hoses designed to transport hydraulic fluids under high-pressure conditions while enduring elevated temperatures. Unlike standard hoses, these hoses can handle continuous exposure to high temperatures without compromising their structural integrity or functionality. Typically, they are constructed from advanced materials that resist heat degradation, ensuring long-term reliability and safety in demanding environments.

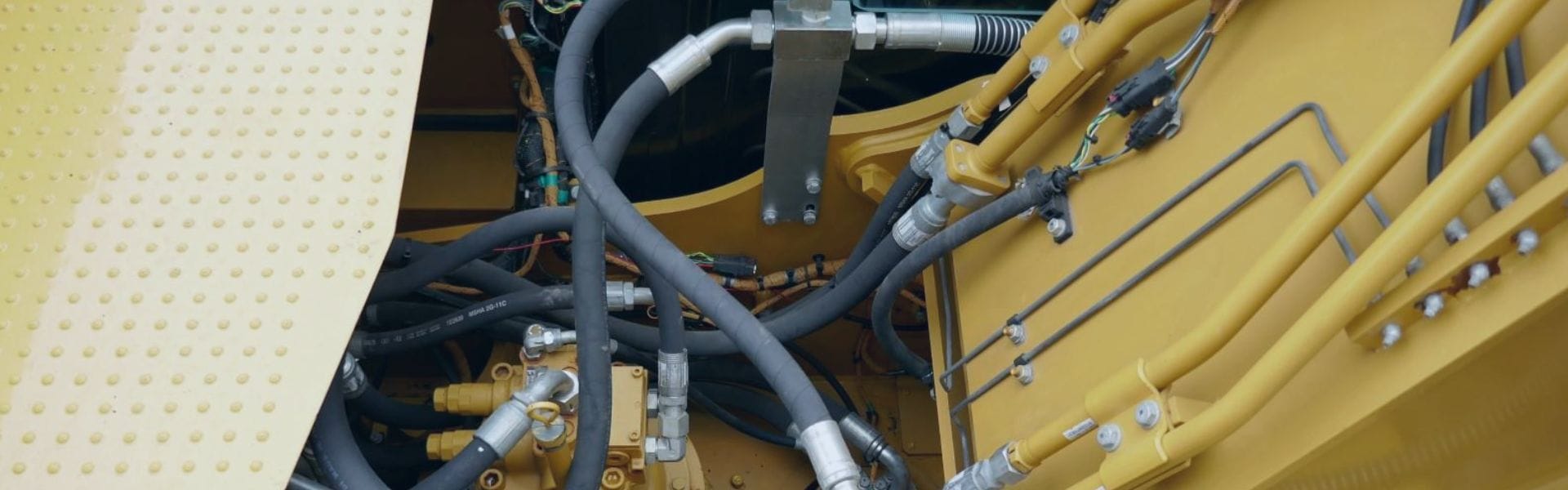

High-temperature hoses are engineered to withstand both the internal pressure of the hydraulic fluid and the external high-temperature environment. These hoses are built with multiple layers:

Inner Tube: Often made from heat-resistant materials like PTFE (polytetrafluoroethylene), synthetic rubber, or thermoplastic elastomers. The inner tube must prevent leaks and resist fluid-induced wear.

Reinforcement Layer: Usually composed of braided or spiral-wrapped steel wires or textile fibers, providing the necessary strength to withstand high-pressure conditions. This layer helps the hose maintain its structural integrity despite significant stress and thermal expansion.

Outer Cover: Constructed from specialized compounds like chlorinated polyethylene or EPDM rubber, this layer provides additional protection against heat, abrasion, chemicals, and other environmental factors. Some hoses may have additional heat shields or insulating layers to improve thermal resistance.

Temperature Ratings

High-temperature hoses can typically withstand temperatures ranging from 150°C (302°F) to over 260°C (500°F), depending on the materials used. The specific temperature rating is determined by the type of fluid, hose construction, and intended operating environment. For instance, PTFE hoses often have higher temperature ratings compared to those made from synthetic rubber.

Applications of High-Temperature Hoses

High temperature hydraulic hoses are essential across several industries that require efficient fluid power transmission under extreme thermal conditions:

Automotive Industry: These hoses are widely used in vehicle power steering systems, brake systems, and transmissions, where hydraulic fluids are subject to intense heat generated by engines and braking systems. High-temperature hoses ensure that fluid systems operate safely even during prolonged driving or heavy loads.

Aerospace Industry: In aerospace applications, hydraulic systems control critical functions like landing gear, flight control surfaces, and brakes. High-temperature hoses are essential here, as the systems often experience rapid temperature fluctuations, particularly during take-off, landing, and rapid altitude changes.

Manufacturing: In industrial machinery, high temperature hydraulic hoses are used in equipment like hydraulic presses, injection molding machines, and robotic systems. These hoses maintain high-pressure fluid flow while withstanding the heat generated by continuous operations and high-speed processes.

Oil & Gas Industry: The oil and gas sector involves exploration and drilling processes that expose hydraulic systems to extreme heat and pressure. High-temperature hoses are critical for ensuring the safe and efficient operation of drilling rigs, extraction machinery, and hydraulic control systems.

Importance of Standards in High-Temperature Hoses

Standards are formal guidelines that outline the minimum requirements for the design, manufacturing, testing, and performance of high-temperature hoses. These standards are established by international organizations such as ISO (International Organization for Standardization), SAE (Society of Automotive Engineers), EN (European Norms), and other regulatory bodies. They set clear criteria for quality, safety, and compatibility, providing a benchmark that ensures the reliability and consistency of hydraulic hoses across various industries.

Why Standards Matter

High-temperature hoses are often used in critical applications where failure can lead to significant safety risks, downtime, or costly repairs. As such, adhering to recognized standards is not merely an option but a necessity for manufacturers, engineers, and users. Standards ensure that hoses meet essential safety and performance requirements, making them suitable for their intended applications under extreme conditions. Here’s why they matter:

Safety Assurance:

Standards specify the materials, construction methods, and testing procedures to ensure that the hoses can withstand the pressure, temperature, and environmental stresses they are designed for.

Compliance with these standards minimizes the risk of sudden hose failures, leaks, or ruptures, which could lead to hazardous situations like fires, fluid spills, or equipment damage.

For instance, ISO 18752 and SAE J517 specify pressure classes, temperature ratings, and endurance tests to ensure that the hoses can sustain prolonged exposure to high temperatures without compromising safety.

Performance Reliability:

High-temperature hoses need to perform consistently under varying pressures and thermal loads. Standards define performance criteria such as burst pressure, flexibility, and resistance to thermal degradation, ensuring that hoses can maintain efficient fluid transfer throughout their lifespan.

By adhering to these standards, manufacturers can offer products that meet predictable performance levels, which in turn helps engineers design hydraulic systems with confidence, knowing that they are using components with proven capabilities.

Tests such as impulse testing, abrasion resistance, and compatibility with different fluids ensure that hoses can sustain performance even in challenging environments.

Compatibility and Interchangeability:

Standards also facilitate compatibility between hoses and hydraulic systems. By following standardized dimensions, fittings, and pressure classes, hoses can be easily integrated into existing systems, reducing the need for extensive modifications.

Interchangeability is especially important in industries like manufacturing and aerospace, where components often come from different suppliers. Adherence to standards ensures that hoses from one manufacturer can replace or work alongside those from another without compatibility issues.

Benefits of Adhering to Established Standards

For manufacturers, engineers, and end-users, there are several tangible benefits to ensuring that high-temperature hoses meet industry standards:

For Manufacturers:

Enhanced Product Quality: By aligning with recognized standards, manufacturers can maintain consistent product quality, build trust with customers, and reduce the risk of product recalls or failures.

Market Access: Many industries require compliance with specific standards before accepting products for use. Meeting these requirements enables manufacturers to access broader markets and comply with regulatory mandates across regions.

Reduced Liability: Producing hoses that meet safety and performance standards helps manufacturers limit potential legal liabilities resulting from hose failures.

For Engineers:

Streamlined Design Process: Engineers can confidently design systems using hoses that comply with standards, knowing that they are working with products tested for specific performance criteria. This reduces the need for extensive trial-and-error testing.

Improved System Reliability: Using standardized hoses ensures compatibility with other components and allows engineers to predict system performance accurately, enhancing overall system reliability.

For End-Users:

Increased Safety: When end-users select hoses that meet established standards, they reduce the risk of accidents, equipment damage, and operational failures, ensuring a safer working environment.

Lower Maintenance Costs: Standard-compliant hoses tend to have longer lifespans, require fewer replacements, and maintain better performance, ultimately reducing maintenance costs.

Greater Operational Efficiency: High-quality hoses that adhere to standards enhance system efficiency, minimizing energy losses, fluid leaks, and downtime.

Key Standards for High-Temperature Hydraulic Hoses

ISO 18752: High-Pressure Hose Applications and Classes

ISO 18752 is an international standard that provides classification criteria and requirements for high-pressure hydraulic hoses. It categorizes hoses based on their pressure capability rather than construction, making it easier to select the appropriate hose for specific applications.

Application: This standard is used across a range of industries, including construction, mining, and manufacturing, where hoses are subjected to high pressures and extreme temperatures.

Classification:

Hoses are classified into eight pressure levels, ranging from 500 psi (3.5 MPa) to 8000 psi (56 MPa).

These pressure levels are further divided into two performance classes:

Class A: Hoses with standard performance requirements.

Class B: Hoses with more rigorous performance criteria, particularly suited for pulsating pressure applications.

Performance Tests:

Impulse Testing: Hoses are subjected to cycles of high-pressure pulses at elevated temperatures to simulate real-world operating conditions. Class A hoses undergo 400,000 cycles, while Class B hoses must withstand 1,000,000 cycles.

Temperature Resistance: Hoses are tested to maintain integrity under temperatures up to 125°C (257°F) for standard applications and up to 150°C (302°F) for more demanding environments.

Leakage Tests: These ensure that the hoses do not leak fluid under high pressure, maintaining system safety and efficiency.

SAE J517: General Guidelines for Hydraulic Hoses

SAE J517, established by the Society of Automotive Engineers (SAE), provides guidelines for hydraulic hose specifications, construction, and performance. It covers a broad range of hydraulic hoses, including those designed for high-temperature applications.

Application: Widely used in industries like automotive, agriculture, and industrial machinery, SAE J517 defines various hose series based on pressure capacity and application type.

Hose Series:

SAE 100R1 to R9: Each series corresponds to specific pressure capabilities, construction (e.g., single or double braiding), and applications (e.g., general or high-pressure use).

SAE 100R12 and R13: These series are specifically designed for higher-pressure applications and are often used in systems operating under extreme temperatures.

Performance Tests:

Burst Pressure Testing: Hoses must withstand burst pressures four times their designated working pressure without rupturing, ensuring safety margins for high-stress conditions.

Cold Flexibility Testing: Hoses are tested for flexibility and kink resistance at low temperatures (as low as -40°C), ensuring versatility in various climates.

Ozone Resistance: Since hydraulic hoses may be exposed to ozone in industrial environments, they undergo ozone resistance testing to ensure longevity and prevent premature degradation.

EN 853 & EN 857: Reinforced Hoses for Medium and High-Pressure Applications

EN 853 and EN 857 are European standards that define requirements for reinforced hydraulic hoses used in medium to high-pressure applications. These standards are commonly adopted in manufacturing, construction, and other industries across Europe.

EN 853:

Focuses on reinforced hoses with textile or wire braiding for medium-pressure hydraulic systems.

Hoses under this standard must exhibit good flexibility, pressure resistance, and durability in high-temperature environments.

Performance Tests:

Burst Pressure: Must be four times the working pressure.

Impulse Testing: Hoses are tested for 200,000 to 400,000 cycles at high pressure, simulating demanding operating conditions.

Heat Resistance: Maintains integrity at temperatures up to 100°C (212°F) for prolonged durations.

EN 857:

Applies to hoses designed for even higher pressures than those covered by EN 853.

Hoses under EN 857 typically have tighter bending radii and are constructed with stronger reinforcement layers to handle extreme pressure and heat.

Performance Tests:

Impulse Testing: Hoses must withstand 500,000 cycles at high pressures and temperatures up to 120°C (248°F).

Abrasion Resistance: The outer cover is tested for abrasion resistance, ensuring the hose’s durability in harsh operating conditions.

API Spec 7K: Oilfield High-Temperature Applications

API Spec 7K, established by the American Petroleum Institute (API), sets requirements for hoses used in oilfield applications, including high-temperature conditions. It is one of the most stringent standards due to the challenging environments associated with drilling and extraction processes.

Application: This standard is vital in the oil and gas industry, where hoses are exposed to extreme pressures, temperatures, and chemical substances.

Performance Requirements:

Hoses must handle temperatures up to 130°C (266°F) and maintain their structural integrity under severe pressure fluctuations typical of drilling operations.

Performance Tests:

Fire Resistance Testing: Hoses are subjected to fire resistance tests to ensure they can withstand potential fire exposure without rupturing, a critical safety measure in oilfield environments.

Pressure Pulsation Tests: Hoses must endure repeated pressure pulsations, simulating the dynamic loads experienced during drilling and hydraulic fracturing.

Chemical Resistance: Hoses are tested for resistance to oil, drilling fluids, and other chemicals, ensuring compatibility and preventing degradation.

Certifications for High-Temperature Hoses

UL (Underwriters Laboratories) Certification

UL certification is one of the most respected safety certifications in the industry, especially in the North American market. It ensures that hydraulic hoses, including those designed for high-temperature use, meet specific safety and performance requirements.

Application: UL certification is crucial in sectors like manufacturing, oil & gas, and aerospace, where safety is critical. It covers not just the hose’s resistance to high temperatures but also its ability to withstand various other stress factors, including pressure surges, fluid compatibility, and chemical resistance.

Certification Requirements:

Safety Tests: Hoses undergo rigorous fire resistance and flame-retardant tests to ensure they can maintain their integrity in fire-prone environments. This is particularly important in high-risk industries such as oil and gas, where fire exposure is a potential hazard.

Pressure and Temperature Testing: Hoses are tested to sustain high pressures at elevated temperatures for prolonged periods. They must demonstrate that they can maintain performance without failure, leakage, or significant degradation.

Material Compliance: The materials used in hose construction, such as inner tubes, reinforcements, and outer covers, must meet UL’s criteria for heat resistance and chemical compatibility.

Impact on Product Credibility:

Safety Assurance: UL certification is widely recognized as a mark of safety, giving end-users confidence that the hose can handle extreme conditions without compromising system safety.

Market Acceptance: In many industries, UL certification is a prerequisite for equipment approval, making it an essential credential for manufacturers looking to enter or expand in the North American market.

CE Marking

The CE (Conformité Européenne) marking is a certification that indicates compliance with European health, safety, and environmental protection standards. It is mandatory for products sold within the European Economic Area (EEA), ensuring that they meet EU directives.

Application: The CE marking is critical for manufacturers exporting high-temperature hoses to Europe, where stringent regulations govern industrial products, including hydraulic components.

Certification Requirements:

Conformity to EU Directives: High-temperature hoses must comply with several EU directives, including the Pressure Equipment Directive (PED), which governs the safety of pressure-related components, and the Restriction of Hazardous Substances (RoHS) Directive, which restricts the use of hazardous materials in manufacturing.

Performance Testing: CE-marked hoses undergo tests for pressure resistance, temperature endurance, and durability under various operating conditions. Hoses must meet specific burst pressure requirements and demonstrate consistent performance across a range of temperatures, including high-temperature extremes.

Environmental Compliance: The materials used in hose construction must comply with EU environmental guidelines, ensuring that they do not pose risks to human health or the environment.

Impact on Product Credibility:

European Market Access: The CE marking is a gateway for manufacturers seeking to enter or compete in the European market, as it is legally required for many industrial products.

Customer Confidence: CE marking indicates that the product meets stringent safety and performance standards, making it more attractive to European buyers and enhancing the manufacturer’s credibility in the market.

CSA (Canadian Standards Association) Certification

CSA certification is a highly regarded credential for industrial products in Canada, ensuring compliance with safety and performance standards. It covers a broad range of safety aspects, including pressure, temperature resistance, and chemical compatibility for high-temperature hoses.

Application: CSA certification is crucial for products used in Canadian industries, particularly in oil and gas, mining, and manufacturing sectors where safety and regulatory compliance are essential.

Certification Requirements:

High-Temperature and Pressure Testing: Hoses are subjected to extreme pressure and temperature tests to ensure they can operate safely under demanding conditions typical of Canadian industrial environments.

Fire and Chemical Resistance: Hoses must demonstrate resistance to fire exposure, toxic chemicals, and other hazardous substances. This is vital for industries like mining and oil extraction, where chemical exposure is common.

Material Evaluation: The materials used in manufacturing high-temperature hoses must comply with CSA’s standards for durability and resistance to environmental factors like moisture, cold, and chemical exposure.

Impact on Product Credibility:

Canadian Market Compliance: CSA certification is often mandatory for products sold in Canada, making it a critical credential for manufacturers targeting the Canadian market.

Trust and Reliability: Products with CSA certification are viewed as safer and more reliable, boosting customer confidence and improving the chances of market acceptance.

Performance Factors and Testing for High-Temperature Hoses

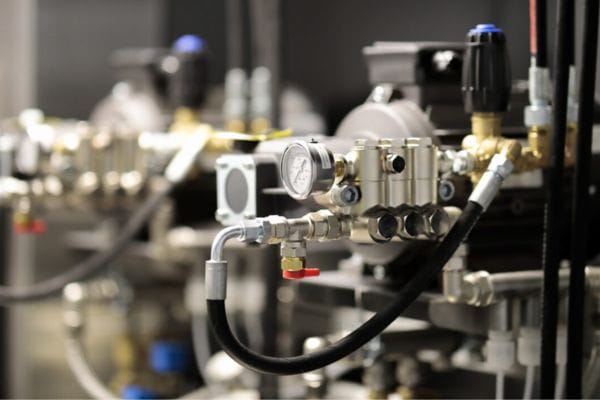

Pressure Testing

Pressure testing is one of the most critical evaluations for hydraulic hoses, especially those designed for high-temperature environments. It ensures that the hoses can handle both burst and operating pressures without failure.

Burst Pressure Testing:

Burst pressure testing involves subjecting the hose to pressure levels significantly higher than its maximum operating pressure to ensure it can withstand extreme conditions.

Hoses are connected to a pressurization system and filled with either water or hydraulic fluid, gradually increasing the pressure until the hose bursts. This test verifies the maximum pressure the hose can handle before failure.

Standards such as SAE J517, ISO 18752, and EN 853 require hoses to withstand burst pressures at least four times their designated working pressure. For example, a hose rated for 3,000 psi operating pressure should withstand burst pressures up to 12,000 psi.

Importance: Burst pressure testing confirms the hose’s safety margin, reducing the risk of unexpected ruptures in high-pressure applications, thus protecting equipment and personnel.

Operating Pressure Testing:

This test simulates the hose’s regular operating conditions, ensuring it maintains integrity and performance under expected pressure levels.

Hoses are tested at their working pressure for extended periods to verify that they don’t exhibit leaks, deformation, or other signs of failure. This helps ensure reliability during continuous use in high-pressure hydraulic systems.

Temperature Testing

High-temperature hoses must endure prolonged exposure to elevated temperatures while maintaining their structural integrity and performance.

High-Temperature Endurance Testing:

In this test, hoses are exposed to high temperatures that simulate their actual working environment. Temperatures range from 150°C (302°F) to over 260°C (500°F), depending on the hose’s specific rating.

Hoses are often tested for thermal endurance while under pressure to simulate real-world conditions, ensuring that they can maintain performance without leaking, cracking, or deforming.

Standards like ISO 18752 and API Spec 7K outline specific temperature endurance requirements for hoses used in industries such as oil & gas, manufacturing, and aerospace.

Importance: Ensuring that hoses maintain functionality at high temperatures is essential, as it prevents fluid degradation, hose material breakdown, and pressure loss, all of which could compromise system performance and safety.

Thermal Shock Testing:

Thermal shock testing evaluates how well hoses respond to sudden and extreme temperature changes. This is crucial for applications where hoses may transition rapidly from low to high temperatures.

In this test, hoses are rapidly exposed to alternating hot and cold environments to check for cracks, leaks, or structural degradation.

Importance: Thermal shock resistance is vital in applications like aerospace and automotive, where temperature fluctuations are frequent and can compromise hose integrity.

Material Testing

Material testing is designed to verify that the materials used in hose construction meet durability, chemical compatibility, and safety criteria.

Material Composition Testing:

Materials used in high-temperature hoses, such as inner tubes, reinforcement layers, and outer covers, must be evaluated for compliance with specific material standards.

Tests assess the resistance of materials to heat, chemical exposure, and mechanical wear, ensuring that they maintain structural integrity under stress.

Rubber, PTFE, and thermoplastic compounds are commonly used for high-temperature hoses, each undergoing tests for flexibility, tensile strength, and abrasion resistance.

Importance: Material testing helps prevent hose failure due to chemical reactions, abrasion, or thermal degradation, ensuring safety and reliability in harsh environments.

Fire Resistance Testing:

For hoses used in fire-prone environments, materials are tested for fire resistance to ensure they can maintain performance even during direct exposure to flames.

These tests are critical in sectors like oil & gas, where hoses may be exposed to fire risks during drilling or extraction processes.

The Role of Regular Inspection and Maintenance

While rigorous testing ensures that hoses meet performance standards, regular inspection and maintenance are equally important to sustain long-term functionality.

Regular Inspection:

Visual inspections should be conducted periodically to identify signs of wear, such as cracks, leaks, or abrasions, which can compromise hose performance.

Inspections also involve checking hose fittings, connections, and clamps to prevent leaks and pressure losses.

Importance: Early detection of potential issues through regular inspections can prevent system failures, reduce downtime, and enhance overall safety.

Routine Maintenance:

Maintenance includes cleaning hoses to prevent fluid contamination, replacing worn-out components, and ensuring proper hose routing to avoid bending or kinking.

Replacing hoses based on service life recommendations, even if no visible wear is present, helps maintain system reliability.

Conclusion

When selecting hoses, prioritize those that are quality-compliant and certified for high-temperature use. This approach not only secures operational safety but also contributes to the overall reliability and efficiency of hydraulic systems. Investing in certified, high-quality hoses is a proactive step toward safer, more resilient operations.

FAQ

What are high-temperature hoses?

High-temperature hoses are designed to withstand elevated temperatures while maintaining performance and pressure in hydraulic systems.

Why are standards important for high-temperature hoses?

Standards ensure safety, performance, and compatibility, reducing risks of failures and improving reliability in extreme conditions.

What certifications should I look for in high-temperature hoses?

Look for certifications like UL, CE Marking, and CSA, which verify compliance with safety and performance requirements.

How often should high-temperature hoses be inspected?

Regular inspections should be conducted every 3 to 6 months, depending on usage, to check for wear, leaks, or damage.

Can high-temperature hoses handle sudden temperature changes?

Yes, hoses designed for high-temperature applications typically undergo thermal shock testing to ensure they can handle rapid temperature shifts.

What materials are used in high-temperature hydraulic hoses?

Common materials include PTFE, rubber, and thermoplastics, selected for their heat resistance, flexibility, and durability.