Hydraulic fitting leak repair is crucial for maintaining system efficiency because even small leaks can lead to significant operational problems. A leak in your hydraulic system reduces the overall performance and wastes valuable hydraulic fluid, increases energy consumption, and causes unnecessary wear on components. Ignoring hydraulic leaks can result in severe consequences such as decreased productivity, system failures, environmental damage due to fluid spillage, and increased maintenance costs.

Common Hydraulic Fitting Issues That Lead to Leaks

Hydraulic fittings play a vital role in ensuring the proper functioning of hydraulic systems. However, over time, several common issues can cause these fittings to leak, leading to system inefficiencies and costly repairs. Understanding these issues is crucial to maintaining the integrity of your hydraulic system and preventing further damage. Let’s take a look at some of the most common causes of hydraulic fitting leaks.

Worn Out Seals and O-Rings

One of the primary culprits of hydraulic fitting leaks is the deterioration of seals and O-rings. These components are responsible for creating a tight seal between fittings, preventing fluid from escaping. Over time, seals can wear out due to constant pressure, heat, and friction, resulting in leaks that can compromise the system’s performance.

Incorrect Fitting Installation or Tightening

Improper installation or insufficient tightening of hydraulic fittings can lead to leaks at the connection points. If the fittings are not aligned correctly or tightened to the appropriate torque specifications, the seal can fail, allowing fluid to escape. It’s important to follow manufacturer guidelines to avoid these installation errors.

Corrosion and Damage to Hydraulic Fittings

Corrosion is a significant issue for hydraulic fittings, especially in environments exposed to moisture, chemicals, or extreme temperatures. Over time, corrosion can weaken the material of the fittings, creating cracks or holes where fluid can leak out. Regular inspection and maintenance are key to identifying and replacing corroded fittings before they cause major system problems.

Misalignment and Vibration-Induced Leaks

Misalignment of hydraulic fittings, whether due to improper installation or system movement, can cause undue stress on the connections, leading to leaks. Additionally, vibration from the machinery can loosen fittings or cause micro-cracks to form over time. Ensuring that fittings are properly aligned and secured can prevent these types of leaks.

How to Detect a Hydraulic Fitting Leak Early

Early detection of hydraulic fitting leaks is essential for maintaining the performance and longevity of your hydraulic system. By identifying leaks early, you can prevent costly repairs and avoid system failures. There are several signs and methods to detect hydraulic leaks before they become a major issue. Let’s explore how to spot hydraulic fitting leaks early.

Symptoms of Hydraulic Fitting Leaks

The most obvious symptom of a hydraulic fitting leak is visible fluid loss. However, other subtle signs can indicate a leak before it becomes visible:

Drop in System Pressure: A decrease in hydraulic pressure often signals a leak, as the system struggles to maintain the required pressure due to fluid loss.

Unusual Noises: A hissing or whistling sound from the fitting area could indicate escaping hydraulic fluid.

Fluid Stains: Look for oil stains or puddles near fittings or joints. Over time, even small leaks can accumulate and create noticeable marks on the surface.

Excessive Heat: Leaks can cause the hydraulic system to overheat, as the system works harder to compensate for lost fluid.

Increased System Wear: A loss of fluid can lead to less lubrication, causing components to wear down faster than usual.

Tools and Techniques for Leak Detection

Detecting hydraulic fitting leaks requires the right tools and techniques. Here are some common methods for identifying leaks in your system:

Visual Inspection: Regularly inspect hydraulic fittings for visible signs of leakage or wear. This is the simplest method but can miss smaller leaks that are harder to detect.

Ultrasonic Leak Detectors: These devices can pick up high-frequency sounds emitted by small leaks, even if the fluid isn’t visible to the naked eye.

Dye Injection: Introducing a colored dye into the system allows you to trace the leak’s source by observing where the dye escapes.

Soap Solution Method: Applying a soap solution to fittings and connections can create bubbles when there is a leak. This method is effective for pinpointing small leaks.

Using Hydraulic Pressure Testing to Spot Leaks

Hydraulic pressure testing is one of the most reliable ways to detect leaks, especially for those hidden in hard-to-see areas. Here’s how it works:

Applying Pressure: The system is pressurized beyond its normal operating range (within safe limits) to reveal any leaks that wouldn’t normally show up at standard pressures.

Monitoring Pressure Drops: A drop in system pressure during testing is a clear indication of a leak. This method helps locate leaks that may not be visible or audible during regular operations.

Leak Isolation: Pressure testing allows you to isolate specific sections of the hydraulic system, making it easier to identify the exact location of the leak and take targeted action.

Step-by-Step Guide to Hydraulic Fitting Leak Repair

Repairing hydraulic fitting leaks efficiently requires a systematic approach to ensure that the root cause is addressed and the system is restored to its optimal performance.

Assessing the Problem: Visual Inspection and Pressure Testing

The first step in repairing a hydraulic fitting leak is identifying the source of the issue. Here’s how to assess the problem effectively:

Visual Inspection: Start by visually inspecting all hydraulic fittings, hoses, and connections. Look for obvious signs of fluid leakage, corrosion, damage, or wear around the fittings. Check for any pooling fluid or stains, which are common indicators of a leak.

Pressure Testing: After a visual inspection, perform a pressure test on the hydraulic system to check for leaks that may not be visible during normal operation. Apply pressure to the system (within safe limits) and monitor the pressure gauge. A significant drop in pressure indicates a leak, allowing you to isolate the problematic area.

Listen for Sound: Use a stethoscope or ultrasonic leak detector to listen for any hissing or high-frequency sounds emitted by small leaks. This technique can be especially helpful in finding hard-to-spot leaks.

By combining these methods, you can effectively locate the general area where the leak is occurring.

Identifying the Type of Leak: Pinpointing the Exact Location

Once you’ve identified that a leak exists, it’s crucial to pinpoint its exact location to proceed with the repair. Here’s how to go about it:

Check the Fittings and Connections: Focus on the connections where hoses meet fittings, as these are common areas for leaks. Look for damaged seals, O-rings, or threads that might not be properly sealed.

Use a Leak Detection Dye: Injecting a leak detection dye into the hydraulic system can help you pinpoint the exact location of the leak. The dye will escape with the fluid, allowing you to visually track the leak with a UV light.

Soap Solution: For minor leaks, applying a soap solution to fittings can help identify the precise location. If bubbles form, it indicates a leak at that specific point.

Pressure Hold Test: Perform a pressure hold test, where you apply pressure to the system and hold it for a set amount of time. If the pressure drops, the area where the leak occurs can be found by isolating sections of the system.

Once you’ve accurately identified the exact location of the leak, you can decide on the appropriate repair method.

Choosing the Right Sealing Method for Your Fitting

After pinpointing the leak, the next step is choosing the right sealing method. The best approach depends on the type of fitting and the severity of the leak. Here are a few options:

O-Ring Replacement: If the leak is caused by a damaged or worn-out O-ring, replacing the O-ring with a new, compatible one is often the best solution. Ensure that the new O-ring is the right size and made of the appropriate material for the system’s operating conditions.

Sealant Application: For minor leaks, a hydraulic system sealant may be sufficient. Choose a high-quality sealant that’s designed for the specific material and pressure of your hydraulic fittings. Apply the sealant carefully to prevent excess from contaminating the system.

Thread Sealing Tape or Paste: For threaded hydraulic fittings, using a thread sealant or PTFE tape can help prevent leaks. Make sure to apply the right amount of sealant to the threads, and avoid over-tightening, which can damage the fitting.

Fitting Replacement: If the fitting is severely corroded or damaged, the best option may be to replace it entirely. Over time, some fittings lose their integrity and can’t be repaired effectively. In these cases, replacing the fitting ensures a longer-lasting solution.

Fixing Hydraulic Hose Leaks: Quick and Effective Solutions

Hydraulic hose leaks can cause serious disruptions to your system’s performance, leading to fluid loss, pressure drops, and potential damage to other components. Addressing hose leaks promptly is essential for maintaining system efficiency and minimizing downtime.

Identifying Hose Failures That Lead to Leaks

The first step in fixing hydraulic hose leaks is identifying the specific cause of failure. Some common reasons for hose leaks include:

Abrasion and Wear: Hoses can wear out due to constant movement, friction, or contact with sharp edges, leading to punctures or cuts.

Hydraulic Fluid Contamination: Contaminants, such as dirt or moisture, can damage the hose material and cause leaks.

Excessive Pressure or Temperature: Over-pressurization or exposure to extreme temperatures can weaken the hose, causing it to rupture or crack.

Improper Installation: Incorrect fitting or hose routing can result in kinks, bends, or stress points that lead to leaks.

By carefully inspecting hoses for these issues, you can quickly identify which hoses need to be repaired or replaced.

Tools for Hydraulic Hose Repair

Having the right tools for hydraulic hose repair makes the job faster, safer, and more effective. Some essential tools include:

Hose Cutter: A clean, straight cut is essential for proper fitting and sealing, so a quality hose cutter is a must-have tool.

Crimping Tool: Used to attach hydraulic hose fittings securely, ensuring there are no leaks at the connections.

Hose Fitting Inserts: Inserts help prevent the hose from collapsing under pressure, providing a better seal.

Pressure Testing Kit: A pressure testing kit helps verify whether the hose repair is successful by confirming that the system is holding pressure properly.

Cleaning Tools: Brushes, cleaning solvents, and cloths to remove contaminants from hoses and fittings before reassembly.

These tools ensure that hydraulic hose repairs are carried out effectively and safely.

When to Replace vs. Repair a Hydraulic Hose

In some cases, repairing the hose might not be enough, and replacing it is the better solution. Here’s how to decide:

Repair: If the leak is minor (such as a small puncture or small crack in the outer layer), and the hose material is still intact, you can repair it by replacing the fittings or patching the affected area.

Replace: If the hose is excessively worn, cracked, or corroded, or if the leak is in an area that cannot be easily repaired, it’s best to replace the entire hose. Always replace hoses that show significant signs of wear, as continuing to use them can result in catastrophic system failure.

Sealing Hydraulic Fittings: The Ultimate Leak Prevention Strategy

Sealing hydraulic fittings properly is key to preventing leaks and ensuring the hydraulic system operates at peak efficiency. Whether you’re installing new fittings or repairing existing ones, the right sealing method will keep your system leak-free.

Choosing the Right Sealant for Hydraulic Fittings

Choosing the right sealant is critical for ensuring a secure and long-lasting seal. Here are some things to consider when selecting a sealant for hydraulic fittings:

Compatibility: Ensure that the sealant you choose is compatible with the hydraulic fluid and the material of the fitting. For example, certain sealants may not work well with petroleum-based oils or may degrade when exposed to specific chemicals.

Pressure Rating: The sealant must be able to withstand the system’s pressure without breaking down or leaking. Check the pressure rating of the sealant to ensure it can handle the conditions of your hydraulic system.

Temperature Tolerance: The sealant should also be able to tolerate high temperatures, especially in systems that operate in extreme conditions or that involve high heat generation.

Some commonly used sealants for hydraulic fittings include PTFE thread sealant tape, anaerobic sealants, and thread sealant pastes that are designed specifically for hydraulic systems.

How to Properly Seal Hydraulic Fittings to Prevent Leaks

Properly sealing hydraulic fittings requires the following steps:

Clean the Surface: Before applying sealant, clean the threads and surfaces of the hydraulic fitting and hose to remove any debris, dirt, or old sealant. This ensures a proper bond and prevents contamination.

Apply the Sealant: For thread fittings, apply a thin, even layer of sealant to the male threads. For O-rings and other seals, lightly lubricate the seal to ensure a proper fit without over-applying.

Tighten the Fittings: Tighten the fittings according to manufacturer specifications. Avoid over-tightening, as this can damage the fitting or cause excess strain on the seal.

Check for Leaks: After tightening, perform a pressure test to ensure the system holds pressure and there are no signs of leaks around the fittings.

By carefully following these steps, you can prevent leaks and maintain a reliable hydraulic system.

Common Sealant Mistakes and How to Avoid Them

Even the best sealant won’t work if it’s not applied properly. Here are some common mistakes to avoid when sealing hydraulic fittings:

Overuse of Sealant: Applying too much sealant can lead to excess material that can contaminate the hydraulic fluid or cause clogs in the system. Always use the recommended amount for a clean and effective seal.

Using the Wrong Sealant Type: Not all sealants are designed for high-pressure or high-temperature environments. Make sure the sealant is suitable for your system’s specific conditions.

Not Cleaning the Fittings First: Applying sealant to a dirty or corroded surface will prevent the sealant from bonding properly, leading to leaks. Always clean and inspect the fitting before sealing.

Under-Tightening Fittings: Even with the right sealant, a loose fitting won’t create a proper seal. Be sure to tighten the fittings according to the manufacturer’s torque specifications.

Hydraulic Coupling Leak Repair: Specialized Techniques

Hydraulic couplings are integral components in hydraulic systems, used to connect hoses and pipes to allow the flow of fluid. When a leak occurs at a coupling, it can cause significant performance issues and pose safety risks. Repairing hydraulic coupling leaks requires specific knowledge and techniques to ensure that the issue is resolved effectively.

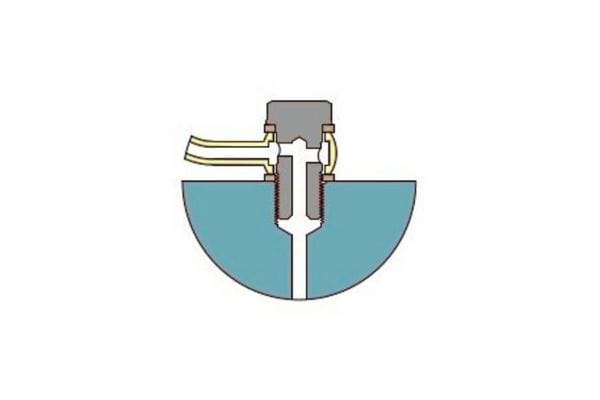

What Are Hydraulic Couplings and Why They Leak

Hydraulic couplings are mechanical devices used to join two hydraulic lines or components, ensuring a secure and leak-free connection. They are typically made of materials such as steel, stainless steel, or brass, and come in various types, including threaded, quick-connect, and flanged couplings. While these components are designed to withstand high pressure and stress, several factors can cause leaks:

Worn Seals or O-Rings: Seals and O-rings inside the coupling may degrade over time due to wear, chemical exposure, or high temperature, leading to fluid leaks.

Improper Installation: Incorrectly installed couplings, whether overtightened or cross-threaded, can cause leaks at the connection points.

Corrosion and Wear: Exposure to harsh environmental conditions, including moisture, salt, or chemicals, can cause couplings to corrode and weaken, leading to leakage.

Over-Pressurization: Excessive pressure in the hydraulic system can exceed the coupling’s capacity, causing deformation or rupture, which leads to leaks.

By understanding these common causes, you can more easily diagnose and address hydraulic coupling leaks in your system.

How to Repair Hydraulic Coupling Leaks Quickly

Repairing a hydraulic coupling leak requires a quick and effective approach to minimize system downtime. Here are the steps to follow for a speedy repair:

Shut Down the System: Before attempting any repairs, ensure that the hydraulic system is shut off and pressure is released from the lines to avoid accidental fluid spillage or injury.

Identify the Leak Source: Perform a thorough inspection to locate the exact point of the leak. Look for visible signs of fluid escaping from the coupling, check for damaged seals or O-rings, and assess whether there is any corrosion or physical damage.

Disassemble the Coupling: If the leak is due to worn seals or O-rings, carefully disassemble the coupling. Use appropriate tools, such as wrenches or pliers, to remove the coupling without damaging it. Take note of the coupling’s orientation to ensure proper reinstallation.

Replace Seals or O-Rings: If the leak is caused by a damaged seal, replace it with a new, compatible one. Ensure that the new O-ring or seal is correctly sized and made of material suitable for the hydraulic fluid and system pressure.

Clean and Inspect the Components: Clean the internal and external surfaces of the coupling and any other components that are part of the connection. Inspect the coupling for cracks, wear, or corrosion, and replace any parts that appear damaged beyond repair.

Reassemble the Coupling: Reassemble the coupling, ensuring that all parts are aligned correctly and tightened to the recommended torque specification. Use a thread sealant or O-ring lubricant to prevent future leaks.

Pressure Test the System: After reassembly, perform a pressure test to check for leaks. If the pressure holds and no fluid escapes from the repaired area, the repair has been successful.

Common Mistakes in Hydraulic Coupling Leak Repair

When repairing hydraulic coupling leaks, there are a few common mistakes that can hinder the repair process or lead to further damage. Here’s what to avoid:

Over-tightening the Coupling: One of the most common mistakes is over-tightening the coupling during reassembly. This can damage the coupling threads, O-rings, or seals, causing future leaks or even breakage. Always follow the manufacturer’s recommended torque settings.

Using Incompatible Seals or O-Rings: Using the wrong type or size of seal or O-ring can prevent the coupling from sealing properly, leading to continued leaks. Always use the manufacturer-recommended parts for replacements.

Neglecting to Inspect for Other Issues: Sometimes, a coupling leak may be a symptom of a larger issue, such as excessive system pressure or poor alignment. Failing to check the entire system could result in the same problem recurring shortly after repair.

Not Cleaning the Components Thoroughly: Dirt, debris, or old sealant left in the coupling can compromise the new seal, leading to leaks. Ensure that all parts are thoroughly cleaned before reassembly.

Conclusion

Maintaining a leak-free hydraulic system is vital for productivity, safety, and cost-efficiency. By taking a proactive approach to leak prevention and repair, and staying on top of regular inspections and maintenance, you ensure that your system performs at its best, with minimal downtime.

FAQ

What causes hydraulic fitting leaks?

Hydraulic fitting leaks are usually caused by worn-out seals or O-rings, incorrect installation, over-tightening, corrosion, or excessive pressure. Proper maintenance and using high-quality components can help prevent leaks.

How can I detect a hydraulic fitting leak early?

Early detection can be done through visual inspection, a pressure test, applying a leak detection dye, or listening for leaks using ultrasonic tools. These methods can help identify leaks before they cause major damage.

What are the best tools for repairing hydraulic fitting leaks?

Essential tools include a hose cutter, crimping tool, pressure testing kit, wrenches, and cleaning supplies. These tools help ensure a quick and efficient repair process.

Can I repair a hydraulic fitting leak myself?

Yes, many hydraulic fitting leaks can be repaired with the right tools and knowledge. However, for major leaks or system-wide issues, it’s advisable to consult a professional to ensure proper repairs and avoid further damage.

When should I replace a hydraulic hose instead of repairing it?

If the hose is severely worn, cracked, or damaged beyond repair, it’s best to replace it. A minor puncture or leak can be repaired, but extensive wear or corrosion typically requires full hose replacement to maintain system safety.

How can I prevent hydraulic fitting leaks in the future?

To prevent future leaks, regularly inspect fittings, hoses, and seals. Proper installation, correct torque settings, and routine maintenance checks will help avoid leaks and ensure a reliable hydraulic system.