You need to make a sharp 90-degree turn in a tight space. Using a standard elbow plus a separate nipple fitting takes up too much room and adds another potential leak point to the system.

This fitting, a “street elbow,” has one male and one female end to solve this exact problem. It allows you to make a tight turn and connect directly to another fitting without needing an extra pipe nipple, saving space, parts, and labor.

In the world of piping and plumbing, every component has a purpose. Even a part as simple-looking as an elbow fitting comes in different variations designed to solve specific challenges.

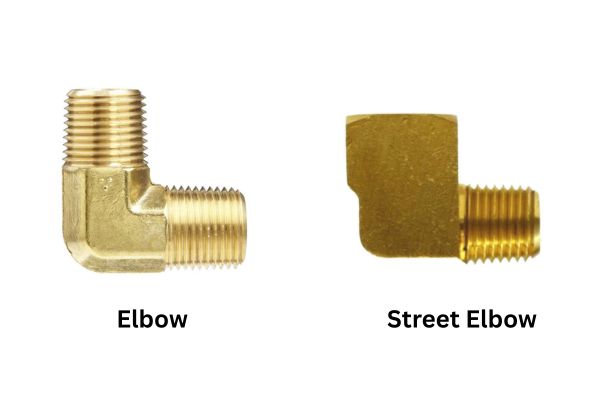

What Makes a Street Elbow Different from a Standard Elbow?

You’re planning a pipe run and a standard elbow requires another nipple fitting just to connect to a valve. This adds complexity, cost, and another point of failure you have to worry about.

The difference is the threading. A standard elbow has female threads on both ends (F x F). A street elbow has one female and one male end (F x M), acting as an elbow and a nipple in a single piece.

A Tale of Two Fittings

The fundamental purpose of any elbow is to change the direction of flow. The key difference between a standard elbow and a street elbow lies in how they connect to the rest of the system. This difference has significant implications for space, cost, and reliability.

A Standard Elbow: This fitting has two female (internal) threaded ports. To connect it to another fitting that also has a female port (like a valve or a pump outlet), you must use a short piece of pipe with male threads on both ends. This short connector is called a “close nipple” or a “pipe nipple.” So, the connection sequence is: Fitting -> Nipple -> Standard Elbow.

A Street Elbow: This fitting was intelligently designed to eliminate the need for that extra nipple. It has one female (internal) threaded port and one male (external) threaded port. This allows the male end to screw directly into another female-threaded fitting, creating a 90° or 45° turn in one compact step. The connection sequence is simply: Fitting -> Street Elbow.

This seemingly small change offers big advantages, which is why we see them used so frequently by experienced plumbers and technicians.

| Feature | Standard Elbow Assembly | Street Elbow Assembly |

| Component Count | 2 (Elbow + Nipple) | 1 |

| Threaded Connections | 3 | 2 |

| Potential Leak Points | 2 | 1 |

| Installation Length | Longer | Shorter |

| Inventory Requirement | Must stock elbows and nipples | Only stock street elbows |

Where Does a Street Elbow Save You Time and Money?

Your project budget is tight and labor isn’t cheap. Every extra part that has to be ordered, inventoried, and installed eats into your profit margin and extends your timeline.

A street elbow directly saves money by eliminating the need to buy a separate pipe nipple. More importantly, it reduces installation time and cuts the number of potential leak points in half for that connection.

The Compounding Value of Simplicity

The cost savings from using a street elbow go far beyond the price of a single pipe nipple. For a business owner or project manager, the savings compound across several areas, making it a strategically smart choice.

- Reduced Component Cost & Inventory: The most obvious saving. Instead of buying and stocking two separate parts (elbows and nipples), you only need one. For large projects or for distributors, this simplification of inventory can be a significant operational benefit, reducing carrying costs and freeing up capital.

- Lower Labor Costs: Time is money. Sealing and tightening a threaded connection takes time. By eliminating one full connection, a street elbow makes assembly faster. This might seem small, but over hundreds or thousands of connections in a large plumbing or OEM project, these saved minutes add up to many hours of saved labor costs.

- Increased System Reliability: This is perhaps the most critical financial benefit. Every threaded connection is a potential leak point. Leaks lead to system downtime, costly repairs, fluid loss, and potential damage to other equipment—not to mention damage to your reputation. By having only one connection to seal instead of two, a street elbow inherently creates a more robust and reliable joint.

Can a Street Elbow Restrict System Flow?

Your newly assembled pneumatic tool feels underpowered. You suspect a bottleneck somewhere in the air line, possibly from one of the new fittings you just installed.

Yes, like any elbow, a street elbow creates turbulence and a minor pressure drop. However, the effect is very similar to a standard elbow and is generally insignificant in most water, air, or low-pressure fluid systems.

A Look at the Inner Workings

Any time you force a fluid or gas to make a sharp 90-degree turn, you introduce turbulence. This turbulence creates resistance, which manifests as a small loss of pressure, known as a “pressure drop.” This is true for all elbow fittings, not just street elbows.

The design of a street elbow’s internal flow path is very similar to that of a standard elbow. While some designs might have a slightly smaller internal diameter, especially on the male-threaded side, the impact on overall system performance is typically negligible in the vast majority of applications.

Where this might become a consideration is in high-performance hydraulic systems or in systems where every bit of pressure is critical. In such cases, engineers might specify “sweep” or “long radius” elbows, which have a more gradual curve to minimize turbulence. However, for the most common uses of brass fittings—like residential and commercial plumbing, general industrial air lines, and low-pressure fluid transfer—the pressure drop from a street elbow is not a practical concern. The benefits of its compact design and reduced leak points far outweigh the minimal flow restriction.

Are All Brass Street Elbows Created Equal?

You ordered a batch of fittings for a project in Europe, but the threads won’t engage. You realize the supplier sent you North American standard threads, rendering the entire order useless.

Absolutely not. Quality is defined by the brass alloy used, the precision of the machined threads, and the thread standard itself. The most common are NPT for North America and BSP (BSPT/BSPP) for Europe, Asia, and many other regions.

The Buyer’s Technical Checklist

For a global buyer, understanding the technical specifications is non-negotiable. A low price is worthless if the product doesn’t fit. A reliable supplier like Topa must be an expert in these variations.

Brass Alloy:

- C36000 Free-Machining Brass: This is a common standard, excellent for creating clean, sharp threads.

- Lead-Free Brass: For any application involving potable (drinking) water, regulations in many parts of the world mandate the use of lead-free alloys (like C46400 or other proprietary blends). A quality supplier must be able to provide certification for these materials.

Thread Standards: This is the most common point of confusion for international buyers.

- NPT (National Pipe Taper): The American standard. The threads are tapered, meaning they get tighter as they are screwed in, creating the seal through thread deformation with the help of a sealant.

- BSPT (British Standard Pipe Taper): Similar to NPT in that the threads are tapered to create a seal. However, the thread angle and pitch are different, making them incompatible with NPT.

- BSPP (British Standard Pipe Parallel): The threads are parallel (straight). The seal is not made by the threads themselves, but by a bonded seal washer or O-ring compressed against the flat face of the fitting.

A professional supplier must be able to clearly identify and manufacture to the specific standard you require.

| Thread Standard | Thread Shape | Sealing Method | Common Regions |

| NPT | Tapered | Thread deformation + sealant | North America |

| BSPT | Tapered | Thread deformation + sealant | Europe, Asia, International |

| BSPP | Parallel | Gasket or O-ring | Europe, Asia, International |

When Is a Standard Elbow a Better Choice?

You have a street elbow, but the final connection is pointing in the wrong direction. You realize you don’t have enough adjustment to get the alignment right with just the one fitting.

A standard elbow and nipple combination is better when you need more rotational freedom for alignment, or when you need to bridge a specific distance that a street elbow’s fixed male end can’t accommodate.

A Case for a Two-Piece Solution

While the street elbow is a brilliant problem-solver, there are specific situations where the classic two-piece (elbow + nipple) approach offers more flexibility. A skilled technician knows when to use each.

The primary reason to choose a standard elbow is for **alignment**. When you tighten a tapered NPT or BSPT fitting, you have a limited window of rotation before it is fully sealed. With a street elbow, you only have one set of threads connecting to your component, giving you only one chance to get the orientation right. With a standard elbow and nipple, you have two sets of threads to play with (the nipple into the component, and the elbow onto the nipple). This extra joint provides more rotational leeway to ensure the final outlet is pointed in exactly the right direction without over-tightening or leaving the connection too loose.

Another reason is **custom spacing**. Pipe nipples come in various lengths. If you need to offset the elbow from the component by a specific distance—perhaps to clear an obstruction—you can select the exact nipple length required. A street elbow has a fixed, very short male end, offering no such flexibility. In these specific cases, the standard elbow provides a more customizable solution.

How Do You Identify a High-Quality Brass Street Elbow?

You get a quote that seems too good to be true. The fittings arrive and they feel light, the threads are rough, and the color looks off, confirming your suspicions about poor quality.

A quality fitting is easy to spot. Look for clean, sharp threads without burrs, a uniform, solid feel, a smooth surface finish, and clear markings from the manufacturer indicating size and material type.

A Visual and Tactile Inspection

As a buyer, you can learn to spot the signs of a well-made fitting, which often correlates directly with a reliable manufacturer. Before placing a large order, requesting samples and performing this quick inspection can save you from major headaches.

- Inspect the Threads: This is the most important part. The threads on a quality fitting will be sharp, clean, and precisely cut. Run your finger over them (carefully). They should feel smooth. Bad fittings will have rough or “gummy” threads with tiny metal burrs. These burrs can prevent a proper seal and even damage the threads of the component you’re connecting to.

- Check the Finish and Color: A good brass fitting should have a uniform, consistent golden color. Dark spots, discoloration, or a porous-looking surface can indicate a cheap alloy with impurities or poor casting. The surface should be smooth, not pitted.

- Feel the Weight: A well-made fitting will feel solid and substantial in your hand. If it feels unusually light, the manufacturer may have used a cheaper, weaker alloy or designed it with dangerously thin walls to save on material.

- Look for Markings: Reputable manufacturers are proud of their work. Look for clear, legible markings, often forged into the body of the fitting, that indicate the size, thread type, and sometimes a manufacturer’s logo. A fitting with no markings at all is a red flag.

Conclusion

The brass street elbow is a simple but effective component. Understanding its unique design and proper application allows for the creation of more compact, reliable, and cost-effective piping and plumbing systems.

At Topa, we specialize in manufacturing high-quality brass fittings, including a full range of street elbows in NPT, BSP, and other standards. We provide the certified materials and precision machining your projects demand. Contact our team today to source the reliable components that will make your systems better.