Dealing with hydraulic maintenance on American equipment and getting frustrated by mismatched threads? This incompatibility leads to leaks, costly downtime, and a shelf full of useless fittings.

JIC fittings are the solution. Defined by the SAE J514 standard, their 37° flare design ensures perfect interchangeability across most North American machinery, making them the default choice for reliable, leak-free connections.

What Exactly Defines a JIC Fitting?

You hear the term “JIC” all the time, but what does it actually mean? Ordering the wrong part because of a misunderstanding about the design can stop a project cold.

A JIC fitting is defined by its two key features: a 37-degree flared seating surface for a metal-to-metal seal and a straight thread for mechanical clamping force. It is governed by the SAE J514 standard.

The 37° Flare Sealing Surface

The heart of the JIC fitting is the cone. The male half of the fitting has a 37° cone on its sealing face. The female half has a matching 37° flared seat. When you tighten the nut, these two metal surfaces are forced together. This creates a small, circular line of contact where the metal deforms slightly, creating a positive seal that can hold extremely high pressures. This metal-to-metal design means it can be disconnected and reconnected multiple times without losing its sealing ability, a key feature for reusable fittings.

The Role of Straight Threads

Unlike NPT (National Pipe Taper) fittings, JIC threads are straight, or parallel. They do not form a seal themselves. Their sole purpose is to provide the mechanical strength to connect the male and female halves. Because the threads aren’t being deformed to create a seal, they are less prone to wear and damage from repeated assembly and disassembly. This is a critical distinction that makes JIC hydraulic fittings inherently more reusable and reliable for service and maintenance compared to tapered thread designs.

SAE J514: The Standard of Trust

The Society of Automotive Engineers (SAE) J514 standard is the rulebook for hydraulic JIC fittings. This standard dictates the precise dimensions, tolerances, thread specifications, and performance requirements for every JIC fitting. When we at Topa manufacture our JIC hydraulic fittings, we do so in strict compliance with SAE J514. This guarantees that our fitting will be perfectly interchangeable with any other fitting made to the same standard, regardless of the manufacturer. This global standard is your assurance of compatibility and quality.

| Feature | Description |

| 37° Flare Sealing Surface | Male cone (37°) mates with female flared seat for a metal-to-metal seal. |

| Straight Threads | Parallel threads provide clamping force, not sealing. |

| SAE J514 Standard | Defines dimensions, tolerances, and performance requirements. |

Why Is the JIC Standard So Dominant in the USA?

Ever wondered why almost every piece of American-made mobile equipment seems to use JIC? It’s not a coincidence; it’s a legacy of performance and practicality that has made it the default choice.

JIC became the dominant standard in the US due to its military origins, its simplicity, and its widespread availability. This makes it incredibly reliable and easy for technicians to work with in the field.

From Military AN to Industrial JIC

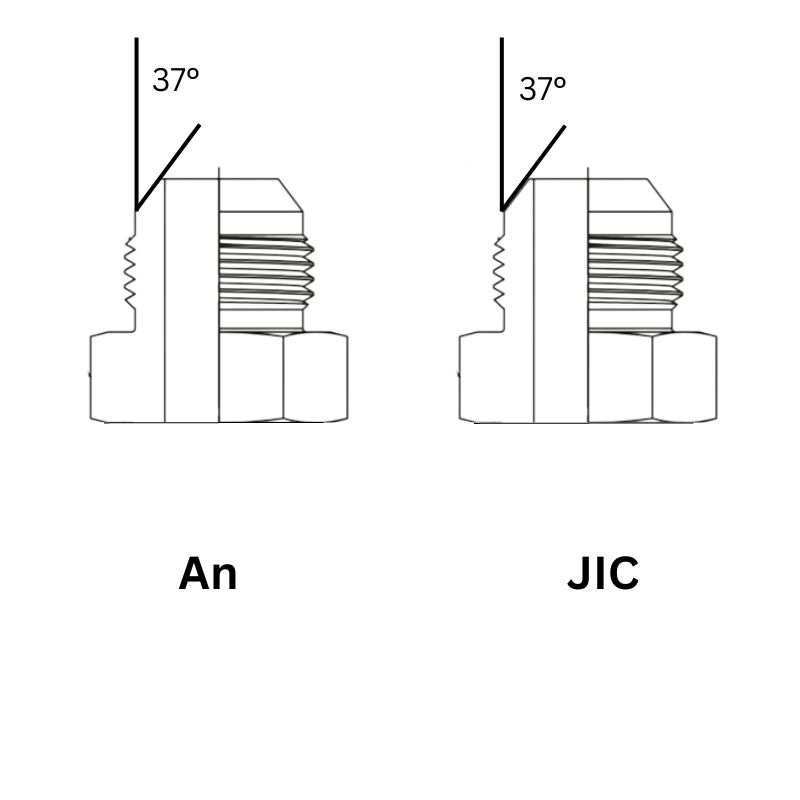

The JIC fitting is a direct descendant of the AN (Army-Navy) fitting standard developed during World War II. The AN standard used the same 37° flare but had a higher thread class for military aviation. The industrial version, JIC (Joint Industry Council), adopted the same reliable flare design but with a slightly looser thread tolerance, making it easier and more cost-effective to manufacture for industrial and mobile equipment. This heritage gives it a decades-long track record of performance in the most demanding environments.

Simplicity and Field Serviceability

The main reason for its continued dominance is its simplicity. You don’t need sealant or special tools. Identifying it is straightforward with a caliper and a good eye. Assembling it is easy. Disconnecting and reconnecting it is simple. For a mechanic working on a construction site or a farmer in a field, this simplicity is invaluable. You can make reliable, high-pressure connections quickly with just a couple of wrenches, which is a huge advantage over more complex or single-use fitting types.

Unmatched Availability in North America

Because it is the de-facto standard for most American manufacturers, the JIC fitting is everywhere in the US, Canada, and Mexico. This North American ubiquity means that finding replacement parts, hoses, and adapters is never a problem. For procurement managers and business owners, this simplifies inventory management and reduces the risk of having a machine down while waiting for a rare part to be shipped. It’s the safe, reliable, and accessible choice for any operation using US-built equipment.

How Do You Correctly Identify JIC Threads?

You have a fitting in your hand. Is it JIC, or is it a similar-looking but incompatible 45° flare? Guessing wrong will cause leaks and damaged threads, a costly mistake.

To identify a JIC fitting, you perform a three-step check. First, visually confirm the 37° flare. Second, use calipers to measure the outer diameter of the male thread. Finally, match this measurement against a JIC thread chart.

Step 1: Visual Inspection for the 37° Flare

The first and most obvious feature to look for is the flared seating surface. A JIC fitting has a distinct 37° cone. This is different from the much steeper 45° flare found on some automotive and refrigeration fittings. If you try to connect a 37° fitting to a 45° fitting, they will only connect on a single, thin line and will never seal properly under pressure. Visually confirming the flare angle is a critical first check.

Step 2: Measure the Thread Outer Diameter (O.D.)

Take your digital or dial calipers and measure the outside diameter of the threads on the male fitting. Be as precise as possible. This measurement is the main piece of data you will use to identify the fitting’s dash size. For example, a male thread that measures approximately 9/16 of an inch (or .5625 inches) corresponds to a -06 JIC fitting. Always measure the male thread, as it is a more reliable reference than measuring the inner diameter of the female nut.

Step 3: Match Your Measurement to a Thread Chart

Once you have your measurement, compare it to a standard JIC / SAE J514 thread identification chart. This chart will directly link your thread O.D. measurement to a specific dash size. This removes all guesswork. At Topa, we provide these charts to all our clients to empower them to check their own thread compatibility. It’s an essential tool for any hydraulic professional.

JIC (SAE J514) Identification Chart:

| JIC Dash Size | Hose Size | Male Thread O.D. (inches) | Standard Thread Size |

| -04 | 1/4″ | 7/16″ | 7/16-20 |

| -06 | 3/8″ | 9/16″ | 9/16-18 |

| -08 | 1/2″ | 3/4″ | 3/4-16 |

| -10 | 5/8″ | 7/8″ | 7/8-14 |

| -12 | 3/4″ | 1-1/16″ | 1 1/16-12 |

| -16 | 1″ | 1-5/16″ | 1 5/16-12 |

| -20 | 1-1/4″ | 1-5/8″ | 1 5/8-12 |

How Do You Assemble a Reusable JIC Fitting?

Your crimper is back at the shop, but you need to make a new hose assembly now. This is precisely what reusable JIC hydraulic fittings were designed for, but how do you do it correctly?

To assemble a reusable JIC fitting, you cleanly cut the hose, screw the outer socket onto the hose, then lubricate and screw the inner nipple into the socket. This simple mechanical process requires only hand tools.

Steps to Install Reusable JIC Hydraulic Fittings

1. Prepare the Hose and Components

- Cut the hose squarely using a hose saw or fine-toothed hacksaw.

- Skiving is usually not required, but check manufacturer instructions.

- Secure the fitting socket in a vise.

- Lubricate the hose interior and socket threads with hydraulic oil.

2. Install the Socket and Nipple

- Screw the hose into the socket counter-clockwise until it bottoms out.

- Back off the hose about ¼ turn.

- Lubricate the nipple threads.

- Insert the nipple into the socket and screw in clockwise by hand until finger-tight.

3. Final Tightening with Wrenches

- Hold the socket steady with one wrench.

- Tighten the nipple with another wrench.

- After firm seating, rotate about two flats (⅓ turn) of the hex nut.

- Avoid overtightening to protect the 37° flare seal.

What Are the Most Common JIC Fitting Mistakes?

You’ve used a JIC fitting, but it’s still leaking. Before you blame the product, it’s crucial to check for common user errors that can easily cause a perfect fitting to fail.

The most common mistakes are mismatching flare angles (37° vs. 45°), overtightening the nut which cracks the flare, and using tubes with poorly formed flares, all of which will guarantee a leak.

Mismatched Flare Angles

This is mistake number one. JIC is 37°. Many other systems, especially in HVAC and plumbing, use a 45° flare. They look similar to the untrained eye, and the threads may even be the same. However, the sealing surfaces will not mate correctly. The connection will only touch on a single edge instead of the whole face of the cone. This creates a high-stress point that will not seal under hydraulic pressure and can easily crack the female flare. Always verify both sides of the connection are 37°.

Overtightening and Under-tightening

More is not always better. The torque on a JIC fitting is only meant to press the two metal faces together. If you overtighten it, you can physically crack the cone on the male fitting or the flare on the female fitting, causing a permanent failure. Conversely, if you under-tighten it, there won’t be enough clamping force to maintain the seal against system pressure and vibration. Using the “flats from wrench resistance” method is the best way to get the torque just right without a torque wrench.

Poor Quality Flares on Tubing

When connecting a JIC nut and sleeve to a hard tube, the quality of the flare you create on the tube is everything. Using a low-quality flaring tool can create flares that are off-center, too thin, or have small cracks in them. Any imperfection on this sealing surface is a potential leak path. Always use a high-quality 37° flaring tool, inspect your flares for a smooth, uniform finish before assembly, and never try to flare a tube that has already been hardened or work-hardened.

| Mistake | What Happens | How to Avoid |

| Mismatched Flare Angles | 37° JIC vs 45° flare look similar but won’t seal; may crack. | Always confirm both sides are 37° before tightening. |

| Overtightening / Under-tightening | Over-torque cracks cone/flare; under-torque causes leaks. | Use the “flats from wrench resistance” method or torque specs. |

| Poor Quality Flares on Tubing | Off-center, thin, or cracked flares create leak paths. | Use a high-quality 37° flaring tool, check finish, and avoid hardened tubes. |

Conclusion

JIC fittings are the ideal, reliable standard for US hydraulic systems. By ensuring correct identification, proper assembly, and partnership with a quality supplier, you guarantee perfect compatibility and leak-free performance.

At Topa, we specialize in manufacturing high-quality hydraulic fittings, hoses, quick couplings, and adapters fully compliant with international standards like SAE J514, ISO 8434, and DIN 2353.

Whether you need standard JIC, BSP, NPT, ORFS, or customized solutions, Topa provides fast delivery and competitive prices.

Send us your inquiry today and get a tailored quotation within 24 hours.

FAQ

What makes reusable JIC hydraulic fittings different from other fittings?

Reusable JIC hydraulic fittings use a 37° flare metal-to-metal seal and straight threads, allowing multiple reuses without losing sealing performance.

How do I identify a JIC fitting correctly in the field?

Check for a 37° flare, measure the male thread O.D. with calipers, and match it against a JIC SAE J514 thread chart to confirm compatibility.

Can I connect a 37° JIC fitting to a 45° flare fitting?

No, JIC hydraulic fittings must only connect with 37° flares. Mixing 37° and 45° fittings causes leaks, damaged threads, and potential hydraulic failure.

What are the common mistakes when installing reusable JIC hydraulic fittings?

The main mistakes are mismatched flare angles, overtightening or under-tightening, and using poor-quality tube flares that cannot seal properly.

What tools do I need to assemble a reusable JIC hydraulic fitting?

You only need a hose saw or hacksaw, a vise, hydraulic oil for lubrication, and two wrenches for final tightening—no crimping machine required.

Why are hydraulic JIC fittings so widely used in American hydraulic equipment?

JIC fittings dominate in the US due to their military origins, simplicity, reusability, and wide availability, ensuring reliable leak-free connections.