Hydraulic systems are integral to modern industrial and mobile machinery, relying heavily on the integrity and performance of their hoses. The strength and durability of these hoses are significantly influenced by their reinforcement, particularly through wire braiding. This article delves into the intricacies of advanced wire braiding techniques, exploring how they enhance hose strength by up to 60%, and examines critical quality control measures.

The Foundation: Understanding Hydraulic Hoses

Hydraulic hoses are flexible conduits designed to carry hydraulic fluid between components in a hydraulic system. They are engineered to withstand high pressures, temperatures, and various environmental conditions, making their construction critical for system reliability and safety.

Components of a Hydraulic Hose

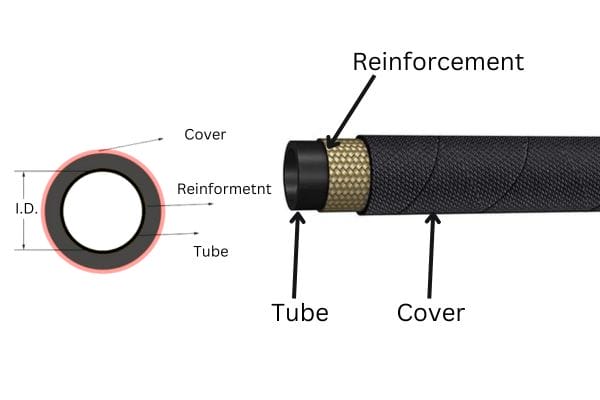

A typical hydraulic hose is composed of several distinct layers, each serving a specific function:

- Inner Tube (Core Tube): This innermost layer is responsible for carrying the hydraulic fluid. It must be compatible with the fluid to prevent degradation and contamination. Common materials include synthetic rubber (e.g., Nitrile, Neoprene) or thermoplastic, chosen for their chemical resistance and flexibility.

- Reinforcement Layer(s): This is the most crucial component for the hose’s pressure-bearing capability. It typically consists of one or more layers of braided or spiraled high-tensile steel wire, or sometimes textile fibers. The reinforcement provides the strength to withstand internal pressure and external forces.

- Outer Cover: The outermost layer protects the reinforcement and inner tube from abrasion, ozone, weather, and other environmental factors. It is usually made of synthetic rubber or thermoplastic, formulated for durability and resistance to specific operating conditions.

The Role of Reinforcement in Hydraulic Hoses

The reinforcement layer is the backbone of a hydraulic hose, directly determining its working pressure, burst pressure, and overall structural integrity. Without adequate reinforcement, the hose would simply expand and rupture under the immense pressures generated in hydraulic systems. The primary functions of the reinforcement include:

- Pressure Containment: The reinforcement counteracts the outward force exerted by the hydraulic fluid, preventing the hose from expanding or bursting.

- Tensile Strength: It provides resistance to stretching or pulling forces, which is important during installation and operation.

- Bend Radius Control: The reinforcement contributes to the hose’s ability to bend without kinking or collapsing, allowing for flexible routing in complex machinery.

- Impulse Resistance: In dynamic hydraulic systems, hoses are subjected to rapid pressure fluctuations (impulse cycles). The reinforcement must be robust enough to withstand these repetitive stresses without fatigue.

The Art and Science of Wire Braiding

Wire braiding is a sophisticated manufacturing process that transforms high-tensile steel wire into a robust reinforcement layer for hydraulic hoses. This process is critical for imparting the necessary strength and flexibility to the hose, enabling it to perform reliably under demanding conditions.

Principles of Wire Braiding Technology

The fundamental principle behind wire braiding involves interweaving strands of wire around the inner tube of the hose. This creates a crisscrossing pattern that effectively distributes pressure and stress across the hose wall. The wires are typically made of high-carbon steel, chosen for its exceptional tensile strength and fatigue resistance.

The braiding machine, often a highly automated and program-controlled device, precisely controls the tension, angle, and density of the wire application. The wires are fed from bobbins, which rotate around the hose core, laying down the wire in a helical pattern. Subsequent layers are braided in opposing directions to create a balanced and stable structure. This counter-directional braiding is crucial for preventing the hose from twisting or elongating under pressure.

Key parameters in wire braiding technology include:

- Wire Material: High-tensile steel is standard, but variations in carbon content and surface treatment can influence strength and corrosion resistance.

- Wire Diameter: Thicker wires generally provide greater strength but can reduce flexibility.

- Number of Wires per Carrier: This refers to how many individual wires are grouped together to form a single strand in the braid.

- Number of Carriers: The total number of wire strands actively braiding around the hose.

- Braiding Angle: The angle at which the wires cross relative to the longitudinal axis of the hose. This is a critical parameter influencing hose performance, as discussed in a later section.

- Braiding Density: The tightness of the weave, determined by the number of wire crossings per unit length. Higher density generally means greater strength.

The Braiding Process: From Spool to Hose

The wire braiding process is a multi-step operation that requires precision and control to ensure the final product meets stringent performance standards. The general steps include:

- Inner Tube Extrusion: The first step involves extruding the inner tube, which forms the fluid-carrying core of the hose. This tube is then typically cooled and cut to length.

- Adhesive Application: A bonding agent or adhesive layer is applied to the outer surface of the inner tube. This ensures proper adhesion between the inner tube and the first reinforcement layer, preventing delamination under pressure.

- Wire Winding/Spooling: High-tensile steel wires are wound onto bobbins, which are then loaded onto the braiding machine. Proper tensioning of these bobbins is crucial for consistent braiding.

- Braiding: The braiding machine then interweaves the wires around the inner tube. For multi-layer hoses, this process is repeated, often with an intermediate rubber layer applied between wire layers to enhance adhesion and provide cushioning.

- Outer Cover Extrusion: Once all reinforcement layers are applied, the outer cover is extruded over the reinforced hose. This provides protection against environmental factors and abrasion.

- Curing/Vulcanization: The entire hose assembly is then subjected to a curing process (vulcanization for rubber hoses) under heat and pressure. This process cross-links the rubber compounds, giving the hose its final mechanical properties, flexibility, and durability.

- Finishing and Testing: After curing, the hose is cooled, cut to specified lengths, and may undergo various finishing processes such as branding or marking. Finally, each hose or a sample batch undergoes rigorous testing to ensure it meets performance specifications, including pressure testing, impulse testing, and dimensional checks.

Enhancing Strength: Advanced Braiding Techniques

The quest for higher performance in hydraulic systems necessitates continuous innovation in hose design and manufacturing. Advanced wire braiding techniques are at the forefront of this evolution, offering significant improvements in pressure resistance, impulse life, and overall hose durability. These techniques primarily focus on optimizing the geometry and material application within the reinforcement layers.

Braiding Density: A Critical Factor

Braiding density refers to the compactness of the wire weave within the reinforcement layer. It is a direct measure of how closely the individual wires are packed together. A higher braiding density means more wire material per unit area, leading to a stronger and more robust hose structure. This increased material concentration directly translates to enhanced pressure containment capabilities and improved resistance to external forces.

Increasing braiding density can be achieved through several methods:

- Using Finer Wires with More Carriers: Employing a greater number of thinner wires, each carried by a separate bobbin, allows for a tighter weave. While individual wires are smaller, their collective density significantly boosts strength.

- Optimizing Machine Settings: Adjusting the take-up speed of the hose relative to the braiding machine’s rotation speed can control the wire lay-down, resulting in a denser braid.

- Pre-tensioning Wires: Applying precise tension to the wires during the braiding process ensures they are laid down tightly against the inner tube and subsequent layers, minimizing gaps and maximizing density.

The impact of braiding density on hose performance is substantial. A denser braid provides superior support to the inner tube, preventing its expansion under pressure and thus increasing the hose’s burst pressure. It also enhances the hose’s resistance to kinking and abrasion, contributing to a longer service life. However, excessively high density can sometimes reduce flexibility, so a balance must be struck based on the hose’s intended application.

The Impact of Braiding Angle on Performance

The braiding angle, defined as the angle at which the reinforcement wires cross relative to the longitudinal axis of the hose, is perhaps the most critical parameter influencing hydraulic hose performance. This angle dictates how the hose deforms under pressure and affects its length change, volumetric expansion, and torsional stability.

Ideally, a hydraulic hose should exhibit minimal change in length and volume when pressurized. Research and empirical data have shown that a braiding angle close to 54 degrees 44 minutes (approximately 54.7 degrees), often referred to as the

neutral angle” or “zero-length change angle,” is optimal for minimizing length change under pressure. At this angle, the forces exerted by the internal pressure are balanced, leading to minimal axial contraction or elongation.

| Braiding Angle (Approx.) | Effect on Hose Performance |

| < 54.7 degrees | Hose tends to elongate under pressure, reducing burst strength. |

| = 54.7 degrees | Optimal for minimal length change and maximum burst pressure. |

| > 54.7 degrees | Hose tends to contract under pressure, increasing torsional stress. |

Deviations from this optimal angle can lead to several issues:

- Angles less than 54.7 degrees: The hose tends to elongate under pressure. This can lead to reduced burst strength and increased stress on fittings.

- Angles greater than 54.7 degrees: The hose tends to contract axially under pressure. This can induce torsional stresses, potentially leading to hose failure or loosening of fittings.

Precise control over the braiding angle during manufacturing is therefore paramount for achieving high-performance hydraulic hoses. Modern braiding machines utilize advanced control systems to maintain this angle within tight tolerances, even at high production speeds.

Multi-Layer Braiding and Hybrid Reinforcements

To meet the demands of increasingly high-pressure applications, manufacturers often employ multi-layer braiding and hybrid reinforcement designs. These techniques involve combining multiple layers of wire braid, sometimes with intermediate rubber layers, or integrating different types of reinforcement materials.

- Multi-Layer Braiding: This involves applying two or more distinct layers of wire braid, often separated by a thin rubber layer. Each braid layer contributes to the overall pressure rating of the hose. For example, SAE 100R2 hoses feature a double-wire braid for higher pressure applications compared to SAE 100R1 hoses with a single-wire braid [8]. The intermediate rubber layer helps to bond the reinforcement layers together, preventing friction between them and enhancing impulse life.

- Hybrid Reinforcements: This approach combines different types of reinforcement materials within the same hose structure. For instance, a hose might feature an inner layer of wire braid for high pressure resistance and an outer layer of textile braid for increased flexibility and abrasion resistance. Another example could involve combining steel wire with synthetic fibers like aramid for specific performance characteristics, such as lighter weight or improved chemical resistance.

These advanced braiding techniques, coupled with precise control over braiding density and angle, enable the production of hydraulic hoses capable of withstanding extreme pressures and harsh operating conditions, significantly improving their strength and longevity. The continuous innovation in this area is crucial for the advancement of hydraulic systems across various industries.

Quality Control in Wire Braiding Manufacturing

Maintaining high quality standards in the wire braiding process is essential for ensuring the safety, reliability, and performance of hydraulic hoses. Stringent quality control (QC) measures must be implemented at every stage of manufacturing, from raw material inspection to final product testing. This focus on quality helps to prevent common issues such as insufficient strength, uneven braiding, and overall quality instability.

Key Quality Control Parameters

Effective quality control in wire braiding involves monitoring and controlling a range of parameters that directly impact the final hose characteristics. These include:

Raw Material Inspection:

- Wire: Verification of wire diameter, tensile strength, material composition (e.g., high-carbon steel), and surface condition (free from defects, rust, or contaminants). Consistent wire quality is fundamental to consistent hose performance.

- Inner Tube and Cover Compounds: Checking the chemical composition, durometer (hardness), and physical properties of the rubber or thermoplastic compounds to ensure they meet specifications for fluid compatibility, temperature resistance, and durability.

Braiding Process Control:

- Wire Tension: Maintaining consistent and correct tension on each wire spool during braiding is critical. Insufficient tension can lead to loose braids and reduced strength, while excessive tension can damage the wire or the inner tube.

- Braiding Angle: Continuous monitoring and adjustment of the braiding angle to ensure it remains within the specified tolerance (typically around 54.7 degrees for optimal performance). Laser or optical measurement systems are often used for real-time monitoring.

- Braiding Density/Coverage: Ensuring the wires are laid down with the correct density and achieve full coverage of the underlying layer. Gaps or unevenness in the braid can create stress concentration points and reduce burst pressure.

- Concentricity: Maintaining the concentricity of the reinforcement layers with the inner tube. Off-center braiding can lead to uneven stress distribution and premature failure.

- Machine Calibration and Maintenance: Regular calibration of braiding machines and routine maintenance are crucial to ensure consistent and accurate operation.

Dimensional Checks:

- Inner Diameter (ID) and Outer Diameter (OD): Verifying that the hose dimensions are within specified tolerances after each stage (inner tube, after braiding, final cover). This is important for proper fitting compatibility and pressure rating.

- Wall Thickness: Ensuring uniform wall thickness of the inner tube and outer cover.

Adhesion Testing:

Testing the adhesion strength between the inner tube and the first reinforcement layer, between reinforcement layers (if applicable), and between the final reinforcement layer and the outer cover. Poor adhesion can lead to delamination and hose failure.

Testing and Validation of Braided Hoses

After manufacturing, hydraulic hoses undergo a series of rigorous tests to validate their performance and ensure they meet or exceed industry standards (e.g., SAE, ISO, DIN, EN). These tests simulate the demanding conditions the hoses will experience in service.

| Test Type | Purpose | Typical Standard Reference |

| Proof Pressure Test | Each hose or a statistical sample is subjected to a pressure (typically 2x working pressure) for a set duration to check for leaks or defects. | SAE J343, ISO 1402 |

| Burst Pressure Test | Samples are pressurized until they burst to determine the ultimate strength. Must exceed a minimum burst pressure (typically 4x working pressure). | SAE J343, ISO 1402 |

| Impulse Test | Simulates dynamic pressure cycling. Hoses are subjected to repeated pressure pulses at elevated temperatures to assess fatigue resistance. | SAE J343, ISO 6803 |

| Change in Length Test | Measures the elongation or contraction of the hose under working pressure. | ISO 1402 |

| Bend Radius Test | Verifies the hose can be bent to its specified minimum bend radius without kinking or damage. | SAE J343, ISO 10619-1 |

| Abrasion Resistance Test | Evaluates the outer cover’s ability to withstand wear and abrasion. | ISO 6945 |

| Ozone Resistance Test | Assesses the outer cover’s resistance to cracking when exposed to ozone, a common cause of rubber degradation. | ISO 1431-1 |

| Fluid Compatibility Test | Ensures the inner tube material does not degrade when exposed to specific hydraulic fluids. | ISO 1817 |

Comprehensive quality control, encompassing both in-process monitoring and final product testing, is indispensable for producing high-strength, reliable wire braided hydraulic hoses. By addressing potential issues like insufficient strength, uneven braiding, and quality instability proactively, manufacturers can deliver products that meet the stringent demands of modern hydraulic applications and ensure the safety and efficiency of the machinery they power.

Troubleshooting and Common Issues

Despite advancements in manufacturing and quality control, hydraulic hoses, particularly those with wire braiding, can still experience issues. Understanding common failure modes and implementing proper maintenance practices are crucial for maximizing hose lifespan and ensuring system reliability.

Identifying Braiding-Related Failures

Failures in wire braided hydraulic hoses can often be traced back to issues related to the braiding process or the inherent stresses on the reinforcement layer. Recognizing these failure patterns is key to effective troubleshooting and preventative maintenance.

- Hose Swelling or Blistering: This often indicates a breakdown of the inner tube material, possibly due to incompatibility with the hydraulic fluid or excessive temperature. As the inner tube degrades, fluid can permeate through to the reinforcement layer, causing the outer cover to swell or blister. While not directly a braiding failure, it compromises the integrity of the entire hose structure, including the braid.

- Hose Kinking or Collapse: Kinking occurs when the hose is bent beyond its minimum bend radius, leading to a permanent deformation that restricts fluid flow and can damage the reinforcement. Collapse, often seen in suction lines, happens when external pressure exceeds internal pressure, causing the hose to flatten. While kinking is often an installation error, repeated kinking can stress the braid, leading to wire fatigue and failure.

- Wire Protrusion (Wicking): This is a direct indication of a braiding-related issue, where individual wires or strands of the reinforcement protrude through the outer cover. This can be caused by insufficient adhesion between layers, damage to the outer cover, or excessive pressure cycles leading to wire fatigue and breakage. Protruding wires can cause abrasion to surrounding components and indicate a loss of structural integrity.

- Hose Burst (Catastrophic Failure): A sudden rupture of the hose, often accompanied by a loud noise and rapid fluid release. While a burst can be due to exceeding the hose’s maximum working pressure, it can also result from localized weaknesses in the braiding, such as uneven tension, missing wires, or a compromised braiding angle. Fatigue from impulse cycles is a common cause of burst, especially if the braid was not optimally constructed.

- Hardening or Cracking of Outer Cover: While the outer cover protects the braid, its degradation can expose the reinforcement to environmental elements, leading to corrosion of the steel wires. Hardening and cracking are often due to exposure to ozone, UV radiation, or extreme temperatures, indicating a need for better environmental protection or a more suitable cover material.

- Fitting Blow-Off: This occurs when the hose separates from the fitting. While often related to improper crimping or fitting selection, it can also be exacerbated by axial forces on the hose, particularly if the braiding angle is significantly off the neutral angle, causing excessive length change under pressure.

Maintenance and Longevity of Braided Hoses

Proactive maintenance and proper handling are essential for extending the lifespan of wire braided hydraulic hoses and preventing premature failures. A comprehensive approach includes regular inspection, correct installation, and adherence to operational guidelines.

Regular Visual Inspection: Routinely check hoses for signs of wear, abrasion, cuts, cracks, bulges, kinks, or wire protrusion. Pay close attention to areas near fittings and points of contact with other components. Any visible damage warrants immediate investigation and potential replacement.

Pressure and Temperature Monitoring: Ensure that the hydraulic system operates within the specified working pressure and temperature limits of the hose. Over-pressurization and excessive heat are major contributors to hose degradation and failure.

Proper Installation:

- Minimum Bend Radius: Always adhere to the manufacturer’s specified minimum bend radius. Bending a hose too tightly will damage the reinforcement and significantly reduce its lifespan.

- Avoid Twisting: Hoses should be installed without any twist. Twisting a hose under pressure can severely stress the reinforcement wires and lead to premature failure. Use proper routing techniques and, if necessary, swivel fittings to prevent twisting.

- Proper Length: Ensure the hose is neither too short (leading to tension) nor too long (leading to excessive slack and potential kinking). Allow for slight length changes under pressure.

Protection from Abrasion: Use hose guards, sleeves, or clamps to protect hoses from rubbing against other components or abrasive surfaces.

Fluid Compatibility: Always use hydraulic fluids that are compatible with the hose’s inner tube and seal materials. Incompatible fluids can cause rapid degradation of internal components.

Cleanliness: Maintain system cleanliness to prevent contamination of the hydraulic fluid. Particulates can abrade the inner tube and seals, leading to internal damage and leakage.

Scheduled Replacement: Even with proper maintenance, hoses have a finite lifespan. Consider scheduled replacement based on manufacturer recommendations, operating hours, or environmental severity, especially in critical applications. This proactive approach can prevent costly downtime and safety hazards.

Conclusion

Wire braiding technology is fundamental to the performance and reliability of hydraulic hoses, with advancements in braiding density, angle optimization, and multi-layer designs significantly enhancing strength and durability. Coupled with rigorous quality control throughout the manufacturing process, these innovations ensure hoses can withstand extreme pressures and demanding conditions. The critical role of hydraulic joint seals, selected based on fluid compatibility, temperature, and pressure, further underscores the importance of a holistic approach to hydraulic system integrity. By understanding these elements, engineers can optimize system performance and longevity.

FAQ

What is the primary purpose of wire braiding in hydraulic hoses?

Wire braiding reinforces the hose, enabling it to withstand high internal pressures and external forces.

Why is the 54.7-degree braiding angle considered optimal?

This angle minimizes length change under pressure, balancing forces for optimal hose performance.

How does braiding density affect hose strength?

Higher braiding density means more wire material per unit area, leading to increased pressure containment and robustness.

What are the consequences of exceeding a hose’s minimum bend radius?

Exceeding the minimum bend radius can cause kinking, damaging the reinforcement and restricting fluid flow.

Why is fluid compatibility important for hydraulic seals?

Incompatible fluids can degrade seal materials, leading to leakage and premature seal failure.

How often should hydraulic hoses be inspected?

Hydraulic hoses should be visually inspected regularly for signs of wear, damage, or leaks.

References

[1] The Effect of Braid Angle on Hydraulic Hose Geometry – MDPI.

[2] Braid Angle and its Influence on the Hydraulic Hoses Behaviour – MATEC Web of Conferences.

[3] How to Make Hydraulic Hoses? – StrongFlex.

[4] The behaviour of braided hydraulic hose reinforced with steel wires – ScienceDirect.