In the demanding world of chemical processing and industrial hydraulics, the integrity and longevity of hydraulic hose systems are paramount. A critical, yet often overlooked, component is the inner tube of the hydraulic hose. This seemingly simple layer is the primary barrier between the conveyed fluid and the rest of the hose assembly, making its material selection a decisive factor in operational safety, efficiency, and cost-effectiveness. This comprehensive guide is tailored for chemical industry engineers and material selection experts, aiming to demystify the complexities of inner tube material compatibility. We will explore how choosing the right material can prevent catastrophic failures, mitigate media corrosion, combat material aging, resolve compatibility issues, and eliminate fluid contamination, ultimately safeguarding your investments and operational continuity.

Understanding Hydraulic Hose Inner Tubes: The Unsung Hero of Fluid Conveyance

The Fundamental Role of the Inner Tube

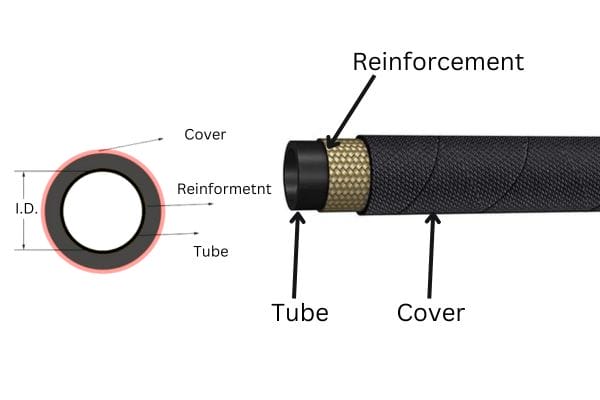

The inner tube, also known as the core tube or liner, is the innermost layer of a hydraulic hose. Its primary function is to contain the conveyed fluid and prevent its permeation into the reinforcement layers or outer cover of the hose. This layer is in direct contact with the hydraulic fluid or chemical medium, making its material composition the most critical determinant of the hose’s chemical resistance and overall performance.

Anatomy of a Hydraulic Hose

While the inner tube is central to media compatibility, it’s essential to understand its place within the complete hydraulic hose assembly. A typical hydraulic hose comprises several layers, each serving a distinct purpose:

- Inner Tube: The fluid-contacting layer, responsible for chemical compatibility and fluid containment.

- Reinforcement Layer(s): Typically made of braided or spiraled wire (steel or textile) or synthetic fibers, these layers provide the hose with its pressure-bearing capability and structural integrity.

- Outer Cover: The outermost layer, designed to protect the reinforcement and inner tube from external environmental factors such as abrasion, ozone, UV radiation, and weather.

Key Inner Tube Materials: Properties and Applications

Selecting the appropriate inner tube material requires a detailed understanding of the properties of various elastomers and thermoplastics. Here, we delve into the characteristics of commonly used materials, highlighting their strengths, limitations, and typical applications.

NBR (Nitrile Butadiene Rubber): The Workhorse of Hydraulic Systems

Nitrile Butadiene Rubber, commonly known as NBR or Buna-N, is one of the most widely used elastomers for hydraulic hose inner tubes. Its popularity stems from its excellent balance of properties, particularly its resistance to petroleum-based fluids.

Characteristics of NBR:

- Oil Resistance: NBR exhibits superior resistance to petroleum-based hydraulic fluids, mineral oils, greases, and fuels. This makes it an ideal choice for a vast majority of industrial hydraulic applications.

- Temperature Range: It generally performs well across a broad temperature range, typically from -40°C to +100°C (-40°F to +212°F), with some formulations extending to higher temperatures.

- Abrasion Resistance: NBR offers good abrasion resistance, contributing to the longevity of the inner tube.

- Mechanical Properties: It possesses good tensile strength, elongation, and compression set characteristics.

Limitations of NBR:

- Poor Resistance to Polar Solvents: NBR is generally not recommended for use with polar solvents such as ketones, esters, and chlorinated hydrocarbons.

- Limited Ozone and Weather Resistance: Without special compounding, NBR has poor resistance to ozone, UV radiation, and weathering, which primarily affects the outer cover but can be a consideration for the inner tube if exposed.

- Limited High-Temperature Performance: While good for many applications, its high-temperature limit can be a constraint in extreme heat environments.

Typical Applications of NBR:

- General industrial hydraulic systems

- Automotive fuel and oil lines

- Pneumatic systems

- Agricultural equipment

- Construction machinery

FKM (Fluoroelastomer/Viton): The High-Performance Champion

Fluoroelastomers, commonly known as FKM or by the brand name Viton (a registered trademark of Chemours), are a class of synthetic rubbers renowned for their exceptional chemical and heat resistance. FKM is the material of choice for demanding applications where conventional elastomers fall short.

Characteristics of FKM:

- Superior Chemical Resistance: FKM offers outstanding resistance to a wide range of aggressive chemicals, including hydrocarbons, acids, alkalis, fuels, oils, and many solvents. It is particularly effective against petroleum-based fluids at elevated temperatures.

- High-Temperature Performance: FKM can withstand continuous operating temperatures up to +200°C (+392°F) and even higher for intermittent exposure, making it suitable for extreme heat environments.

- Excellent Ozone and Weather Resistance: It exhibits excellent resistance to ozone, UV radiation, and weathering, ensuring long-term durability in harsh outdoor conditions.

- Low Permeation: FKM has very low gas permeability, which is crucial in applications where fluid loss or gas diffusion is a concern.

- Good Mechanical Properties: It maintains good mechanical properties, including tensile strength and compression set, even at high temperatures.

Limitations of FKM:

- Poor Resistance to Certain Media: While highly resistant to many chemicals, FKM has poor resistance to ketones, low molecular weight esters, hot water, steam, and some brake fluids.

- Low-Temperature Flexibility: Standard FKM grades can become stiff at very low temperatures (below -15°C or 5°F), though special low-temperature grades are available.

Typical Applications of FKM:

- Aerospace and aviation hydraulic systems

- Chemical processing and transfer

- Oil and gas exploration (e.g., downhole applications)

- High-temperature industrial applications

- Automotive fuel injection and emission control systems

EPDM (Ethylene Propylene Diene Monomer): The Water and Steam Specialist

EPDM is a synthetic rubber known for its excellent resistance to water, steam, ozone, and a variety of polar fluids. It is a versatile material, particularly suited for applications where petroleum-based fluids are not present.

Characteristics of EPDM:

- Excellent Water and Steam Resistance: EPDM is highly resistant to hot water, steam, and polar fluids such as alcohols, ketones, and some acids and bases.

- Outstanding Ozone and Weather Resistance: It offers superior resistance to ozone, UV radiation, and weathering, making it ideal for outdoor and automotive applications.

- Good Temperature Range: EPDM performs well in a wide temperature range, typically from -50°C to +150°C (-58°F to +302°F), with some grades extending to higher temperatures.

- Good Electrical Insulation Properties: EPDM is an excellent electrical insulator.

- Resistance to Brake Fluids: It is commonly used in brake fluid systems (glycol-based).

Limitations of EPDM:

- Poor Oil Resistance: EPDM has very poor resistance to petroleum-based oils, greases, and fuels. It will swell and degrade rapidly when exposed to these substances.

- Limited Resistance to Hydrocarbons: It is not recommended for use with aliphatic or aromatic hydrocarbons.

Typical Applications of EPDM:

- Brake fluid systems

- Hot water and steam lines

- HVAC systems

- Outdoor weather sealing

- Automotive cooling systems

Other Inner Tube Materials: Expanding the Horizon

While NBR, FKM, and EPDM are the most common, other materials are used for specialized hydraulic hose inner tubes, each offering unique advantages:

- PTFE (Polytetrafluoroethylene): Known for its almost universal chemical resistance and wide temperature range (-73°C to +260°C / -100°F to +500°F). PTFE hoses are often used in highly corrosive chemical transfer applications and high-purity systems due to their non-stick surface and minimal fluid absorption. However, PTFE is less flexible and has a lower fatigue life than rubber hoses, and typically requires external reinforcement for pressure applications.

- Thermoplastics (e.g., Nylon, Polyurethane): These materials offer good flexibility, abrasion resistance, and can be used in specific hydraulic applications, particularly for lower pressure systems or where weight is a concern. Their chemical resistance varies widely depending on the specific thermoplastic.

Navigating Chemical Compatibility: A Strategic Approach

The Importance of a Comprehensive Compatibility Chart

Selecting the correct inner tube material is a meticulous process that requires more than just a general understanding of material properties. It demands a detailed assessment of the specific chemical media involved, including their concentration, temperature, and pressure. A comprehensive chemical compatibility chart is an indispensable tool in this process, providing a quick reference for the suitability of various elastomers with different chemicals.

Factors Influencing Compatibility

Beyond the primary chemical composition, several other factors can significantly influence the compatibility between the inner tube material and the conveyed fluid:

- Temperature: Elevated temperatures generally accelerate chemical reactions and material degradation. A material that is compatible at room temperature may not be at higher temperatures.

- Concentration: The concentration of a chemical in a solution can drastically alter its corrosiveness. A dilute solution might be harmless, while a concentrated one could be highly aggressive.

- Pressure: High pressure can force fluids into the material’s pores, potentially accelerating degradation or permeation.

- Mixtures: When a hose conveys a mixture of chemicals, the compatibility must be assessed against all components, as synergistic effects can occur, making the mixture more aggressive than individual components.

- Pulsation and Vibration: Dynamic conditions can introduce mechanical stresses that, combined with chemical exposure, can accelerate material fatigue and failure.

- Fluid Purity: Impurities in the fluid can sometimes react with the inner tube material, leading to unexpected degradation.

Practical Considerations for Material Selection

While chemical compatibility is paramount, a holistic approach to material selection considers all operating conditions. This includes:

- Temperature Range: Both ambient and fluid temperatures must be within the material’s continuous operating range.

- Pressure Rating: The hose assembly must be rated for the maximum system pressure, and the inner tube material must withstand this pressure without permeation or rupture.

- Flow Rate and Velocity: High flow rates or abrasive fluids can lead to erosion of the inner tube, necessitating materials with good abrasion resistance.

- Flexibility Requirements: The application may demand a certain degree of flexibility from the hose. Some materials are inherently more flexible than others.

- Environmental Factors: Exposure to ozone, UV radiation, extreme temperatures, or corrosive external environments can impact the outer cover and indirectly affect the inner tube’s longevity.

Mitigating Common Pain Points: Strategies for Success

Addressing the customer pain points identified earlier requires a strategic approach to material selection and system management.

Addressing Media Corrosion and Material Aging

- Rigorous Compatibility Assessment: Always perform a detailed compatibility assessment for all fluids, including cleaning agents and additives. Consult multiple compatibility charts and, if possible, conduct in-house testing for critical applications.

- Temperature Management: Ensure that operating temperatures remain within the recommended range for the chosen inner tube material. Implement cooling systems if necessary.

- Regular Inspection: Implement a routine inspection program to detect early signs of material degradation, such as cracking, swelling, hardening, or discoloration of the inner tube (if visible) or outer cover.

Resolving Compatibility Issues and Preventing Media Contamination

- Specify Clearly: When ordering hoses, provide detailed information about the conveyed media, including chemical name, concentration, temperature, and any potential mixtures. This allows manufacturers to recommend the most suitable inner tube material.

- Dedicated Hoses: For systems handling highly aggressive or sensitive media, consider using dedicated hoses for each fluid to prevent cross-contamination and ensure optimal compatibility.

- Material Certification: Request material certifications from hose manufacturers to verify the composition and quality of the inner tube material.

- Proactive Testing: For new or unusual media, consider sending samples to a reputable laboratory for compatibility testing with various inner tube materials. This can prevent costly failures in the field.

No matter what material of hydraulic hose is needed, contact Topa and we can customize the most suitable product for your needs, send your request now!

FAQ

What is the most important factor in selecting a hydraulic hose inner tube material?

The most important factor is the chemical compatibility of the inner tube material with the conveyed fluid.

Can I use NBR with brake fluid?

No, NBR is generally not recommended for use with glycol-based brake fluids; EPDM is typically preferred.

Why is FKM more expensive than NBR or EPDM?

FKM is more expensive due to its superior chemical and high-temperature resistance, requiring specialized manufacturing processes.

What happens if I use an incompatible inner tube material?

Using an incompatible material can lead to media corrosion, material aging, leaks, and fluid contamination, causing system failure.

Are chemical compatibility charts always 100% accurate?

Chemical compatibility charts are general guides; actual performance can vary based on temperature, concentration, pressure, and fluid mixtures.

Should I conduct my own compatibility testing?

Yes, for critical or unique applications, conducting custom compatibility testing is highly recommended to ensure absolute confidence.

References

- Trelleborg Fluid Handling Solutions. (n.d.). EPDM or NBR.

- Marco Rubber & Plastics. (n.d.). O-Ring Chemical Compatibility Guide.

- WARCO. (n.d.). Understanding Fluoroelastomers (FKM).

- Minor Rubber. (n.d.). Rubber Chemical Compatibility Chart & Resistance Guide.

- Graco Inc. (n.d.). Chemical Compatibility Guide.