You’re holding a hydraulic fitting with “UNF” threads and need to connect it to a port marked “G”. They look similar, but they won’t go together. Using the wrong thread can cause leaks, damage expensive equipment, and lead to critical failures.

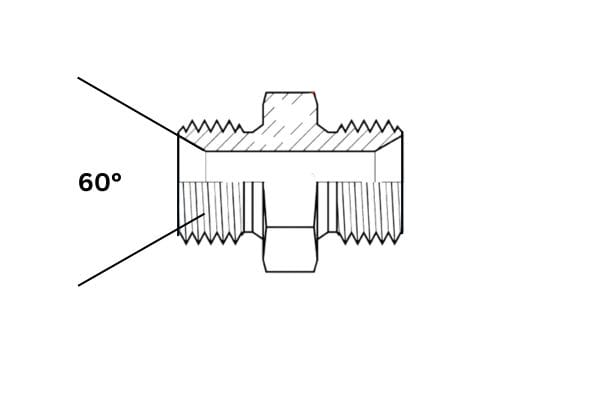

You can identify any thread by checking two key features: its thread angle (usually 60° or 55°) and its shape (parallel or tapered). This guide and our cheat sheet at the end will teach you how to spot these differences instantly.

Why Do Thread Standards Even Matter?

You might think a thread is just a thread. But using the wrong tap in a machine shop or forcing two different thread types together can lead to a low-level mistake with irreversible and costly consequences.

Threads are the foundation of the mechanical world, holding everything from watches to spacecraft together. Using the correct, standardized thread ensures a strong, reliable, and leak-proof connection. Getting it wrong is a direct path to system failure.

The Foundation of Safe Mechanical Assembly

Standardization ensures that components are interchangeable, strong, and predictable. When you use an M8 bolt, you know its exact dimensions, its strength characteristics, and how it will behave under load. This predictability is the basis of all safe and reliable mechanical design. Without it, every single component would have to be a custom one-off part.

The High Cost of a Thread Mismatch

Forcing incompatible threads together is called “cross-threading.” It permanently damages both the male and female threads, a process known as galling. This often makes the parts unusable. In a plumbing or hydraulic system, even a slight mismatch will create a leak path. This can lead to fluid loss, equipment damage, environmental contamination, and serious safety hazards.

What Are the Metric Thread Standards?

You see an “M8” bolt. You know it’s metric, but what does that really tell you? Not knowing the difference between a standard coarse thread and a fine thread can lead you to choose the wrong fastener for a critical application.

The “M” stands for Metric, the most common thread system in the world. The number indicates the nominal diameter in millimeters. Metric threads have a 60° thread angle and are the default choice for general mechanical connections globally, outside of North America.

The metric system is wonderfully logical. Its design is based on simple, easy-to-understand units. When you are sourcing parts for machinery made in Europe or Asia, you will almost certainly be dealing with metric threads.

The Global Standard: M Threads

The ‘M’ profile thread is the international standard for general-purpose screw threads. Its 60° symmetrical V-shape is excellent for fastening and provides good strength. The specification is simple: the nominal diameter followed by the pitch (the distance between threads). For example, “M8 x 1.25” means an 8mm diameter with a 1.25mm pitch.

Coarse vs. Fine Threads

- Coarse Threads (e.g., M8): This is the most common type. The pitch is often omitted from the description because it is the standard. Coarse threads are more tolerant of nicks and damage, and they are faster to assemble.

- Fine Threads (e.g., M8 x 1.0): These have a smaller pitch. They offer better resistance to loosening from vibration and allow for finer adjustment. They are also stronger because of their larger stress area. This makes them ideal for automotive engines, precision instruments, and aerospace.

Special Metric Threads: MJ for Aerospace

The MJ thread is a modification of the standard metric thread, designed for the extreme safety requirements of the aerospace industry. It features a larger root radius in the thread profile. This rounded root distributes stress more effectively, dramatically increasing fatigue strength and reducing the risk of a crack forming under a heavy load.

How Do You Read Unified (American) Threads?

Your hardware is from the USA, and the bolts are marked UNC and UNF. They look very similar, but they serve very different purposes. Using a UNC bolt where a UNF is specified could lead to disaster in a high-vibration environment.

This is the Unified Thread Standard (UTS), the American counterpart to the metric system. It also uses a 60° thread angle but sizes are based on inches. UNC means “Unified Coarse,” and UNF means “Unified Fine.” They offer different strengths and weaknesses.

The UTS system dominates in North America. Learning to read these standards is essential for anyone working with American-made equipment. The core concept is the same as metric threads: coarse threads for general use and fast assembly, and fine threads for precision, strength, and vibration resistance. The choice between UNC and UNF is a critical engineering decision based on the application’s specific demands.

Unified Thread Series (UNS)

The Unified Thread Series, commonly used in the United States and many international industries, includes three major families: UNC, UNF, and UNEF. Each type has unique characteristics tailored to different performance requirements.

UNC – Unified National Coarse Thread

Characteristics: Coarse-pitch design with larger thread spacing and deeper thread depth.

Advantages:

- Provides faster assembly and disassembly.

- Offers higher resistance to wear, dirt, and damage during repeated use.

- Performs well under impact and vibration, reducing the risk of thread stripping.

Applications: The most common general-purpose thread form, widely used in structural steelwork, construction fasteners, and standard bolts and nuts.

UNF – Unified National Fine Thread

Characteristics: Fine-pitch design with smaller thread spacing and shallower thread depth.

Advantages:

- Provides better resistance to loosening under vibration.

- Offers superior sealing capabilities in applications where fluid leakage must be minimized.

- Allows for more precise adjustment and tighter clamping force.

Applications: Commonly used in aerospace components, automotive engines, and precision instruments where reliability and accuracy are critical.

UNEF – Unified National Extra Fine Thread

Characteristics: Even finer pitch than UNF, with extremely close thread spacing.

Advantages:

- Ideal for very thin-walled parts, as the shallow depth reduces the risk of cracking.

- Allows for extremely precise adjustments in applications requiring delicate control.

Applications: Specialized uses such as instrumentation, electronic equipment, and applications requiring fine mechanical alignment.

| Thread Type | Standard | Thread Angle | Profile | Connection Type | Seal Method | Common Applications |

| UNC | Unified National Coarse | 60° | Straight | Mechanical joint | None (with gasket/washer if needed) | Steel structures, general bolts, common fasteners |

| UNF | Unified National Fine | 60° | Straight | Mechanical joint | None (better resistance to loosening) | Aerospace, automotive engines, precision instruments |

What’s the Difference Between All the Pipe Threads?

This is a major source of confusion. You have an NPT fitting, a G fitting, and an R fitting. They are all pipe threads, but none of them will seal with each other. This mistake can cause persistent, damaging leaks.

The key differences are the thread angle and the **shape**. American NPT threads are tapered with a 60° angle. British/ISO pipe threads (G, R, Rc, Rp) are based on a 55° angle. Furthermore, G is parallel, while NPT and R are tapered.

Pipe threads are designed to create a pressure-tight seal for carrying fluids or gases. Unlike mechanical threads that just fasten, these must prevent leaks. The world is divided into two main camps for pipe threads, and they are completely incompatible. Knowing which camp you are in is the first and most important step to creating a leak-free system.

American Standard: NPT & NPTF (60° Taper)

NPT (National Pipe Taper): This is the North American standard. It has a 60° thread angle and a 1:16 taper. The seal is created by the threads deforming into each other as they are tightened. A sealant (like PTFE tape or pipe dope) is required to fill any gaps.

NPTF (National Pipe Taper Fuel): Also called “Dryseal,” this thread is dimensionally similar to NPT but has controlled crests and roots. This ensures a metal-on-metal seal without the need for sealant, making it ideal for fuel and hydraulic systems where sealant could contaminate the fluid.

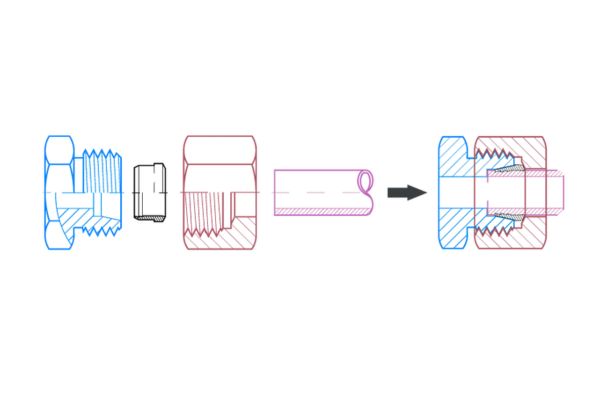

British/ISO Standard: G (55° Parallel)

G (BSPP – British StandardPipe Parallel): This thread has a 55° angle and is parallel (straight). The threads themselves do not form a seal. The seal is made by a gasket, O-ring, or bonded washer that is compressed against the face of the fitting. This is the common standard in Europe, Asia, and most of the world for hydraulics and plumbing.

British/ISO Standard: R, Rp, Rc (55° Taper)

R/Rc/Rp (BSPT – British StandardPipe Taper): This is the tapered counterpart to the G thread. It also has a 55° angle.

R refers to the external tapered thread.

Rc (Tapered) and Rp (Parallel) refer to the internal threads.

A male R thread can seal with a female Rc or Rp thread. Like NPT, a sealant is required.

| Standard / Type | Thread Angle | Form | Seal Method | Typical Use Cases |

| NPT (National Pipe Taper) | 60° | Tapered 1:16 | Thread deformation + sealant (PTFE, pipe dope) | General plumbing, hydraulics (North America) |

| NPTF (National Pipe Taper Fuel / Dryseal) | 60° | Tapered 1:16 | Metal-to-metal seal (no sealant) | Fuel systems, hydraulics, contamination-sensitive systems |

| G / BSPP (British Standard Pipe Parallel) | 55° | Parallel | Gasket, O-ring, or bonded washer | Hydraulics, plumbing (Europe/Asia/global) |

| R / BSPT (British Standard Pipe Taper) | 55° | Tapered | Thread deformation + sealant | Plumbing and hydraulics (Europe/Asia/global) |

How Do I Choose the Right Thread?

You have a port to fill. How do you decide between NPT, G, or UNF? Making the wrong choice means you will be ordering parts all over again, wasting time and money.

First, determine the application: are you fastening or sealing? Then, identify the system’s origin to choose the right standard (American vs. European/ISO). Finally, focus on key identifiers like the 55° vs. 60° thread angle to confirm your choice.

Choosing the right thread is a process of elimination. As a manufacturer, we use this same logic when helping our customers. By asking these simple questions, you can quickly narrow down the possibilities from dozens to just one or two. To make it even easier, we’ve compiled all the essential information into one simple chart.

Step 1: Connecting vs. Sealing

- For Mechanical Connection (fastening): You will most likely use a parallel thread like Metric (M) or Unified (UNC/UNF). The choice depends on the origin of the equipment and the strength requirements.

- For Fluid Power (sealing pipes/hoses): You will use a pipe thread. The choice is primarily between the American NPT system and the British/ISO G or R systems.

Step 2: Use the Ultimate Litmus Test: 55° vs. 60°

This is the most critical check. Get a thread gauge.

- If the thread angle is **60°**, you are dealing with a Metric (M) or an American thread (UNC, UNF, NPT).

- If the thread angle is **55°**, it is a British/ISO pipe thread (G, R, Rc, Rp).

These two systems are never compatible. This single test can prevent the most common and damaging mistakes.

Your Ultimate Thread Identification Chart

Use this table as your quick reference guide. It contains all the core information you need to identify almost any thread you will encounter in the field.

| Thread Code | System | Angle | Shape | Primary Function | Sealing Method | Typical Application |

| M | Metric | 60° | Parallel | Mechanical Connection | None (relies on washer) | General Manufacturing, Automotive |

| UNC | Unified (US) | 60° | Parallel | Mechanical Connection | None (relies on washer) | General Fasteners, Steel Structures |

| UNF | Unified (US) | 60° | Parallel | Mechanical Connection | None (good vibration resistance) | Aerospace, Precision Instruments |

| NPT | US Pipe | 60° | Tapered | Sealing & Connection | Taper + Sealant | North American Pipe Systems (Gas, Water) |

| NPTF | US Pipe | 60° | Tapered | Sealing & Connection | Dryseal (no sealant needed) | Fuel Lines, Hydraulic Systems |

| G | British/ISO Pipe | 55° | Parallel | Connection (Not Sealing) | Gasket / O-Ring | Global Hydraulic & Plumbing Fittings |

| R / Rc | British/ISO Pipe | 55° | Tapered | Sealing & Connection | Taper + Sealant | European & Chinese Pipe Systems |

| Tr / Acme | Translation | 30° / 29° | Parallel | Power Transmission | None | Machine Tool Lead Screws, Vices |

| MJ | Aerospace Metric | 60° | Parallel | High-Strength Connection | None | Critical Aerospace Components |

Conclusion

The world of threads is vast, but it is not complicated. By understanding the core families and their key features like thread angle and shape, you can confidently identify and select the correct thread for any job, ensuring a safe and reliable system.

Choose Topa’s precision-engineered hydraulic fittings for your business needs. Our products are built to international standards, ensuring reliable performance, long service life, and cost savings. Contact us today to place your order and keep your equipment running safely and efficiently.

FAQ

Can I use thread sealant on fittings that are designed for metal-to-metal sealing (like NPTF)?

While not required, adding sealant on NPTF can actually prevent proper sealing by interfering with the controlled crest and root engagement..

How can I quickly tell if a thread is parallel or tapered without special tools?

Place the fitting against a straight ruler or caliper. If the thread flanks gradually narrow, it’s tapered (NPT, BSPT). If they remain constant, it’s parallel (UNF, G/BSPP, Metric).

Are metric and UNF threads interchangeable since both have a 60° angle?

No. Even though both use a 60° angle, the pitch, diameter, and tolerances differ. Attempting to mix them causes cross-threading and damage.

Why do British threads use a 55° angle instead of 60°?

The 55° Whitworth form is an older British standard. It provides slightly more thread engagement but is not compatible with 60° metric or unified forms.

What’s the safest way to identify an unknown thread in the field?

Use a thread gauge and caliper to measure pitch, diameter, and angle. Then compare results with a reference chart. This avoids costly assumptions.

Can pipe threads (like NPT and BSPT) ever be safely joined with adapters?

Yes, but only with specialized conversion adapters that correctly match the sealing method. Directly mating NPT with BSPT will almost always leak.