Hydraulic Hose Fitting Repair: Expert Tips for Quick Fixes

Table of Contents

Introduction

Hydraulic hose fittings are crucial components in various industrial applications, ensuring the efficient transfer of fluids under high pressure. When these fittings fail, the consequences can be severe, leading to costly downtime and potential safety hazards. Understanding how to quickly and effectively repair hydraulic hose fittings is essential for maintaining productivity and safety. This post aims to provide expert tips for both immediate on-site fixes and long-term repair solutions, helping you minimize downtime and maintain optimal performance in your hydraulic systems.

Understanding Hydraulic Hose Fittings

Hydraulic hose fittings are integral components in hydraulic systems, designed to connect hoses to various system parts such as pumps, valves, and cylinders. These fittings ensure the seamless flow of hydraulic fluid under high pressure, enabling the system to function effectively and efficiently. Given their critical role, understanding the different types of fittings and the common causes of their failures is essential for maintaining the reliability of hydraulic systems.

Common Causes of Hose Fitting Failures

Understanding the common causes of hose fitting failures can help in preventing issues and ensuring the longevity of hydraulic systems:

Wear and Tear:

Over time, hydraulic hose fittings are subjected to repeated use and exposure to harsh conditions, leading to gradual degradation. Factors such as friction, pressure cycles, and environmental exposure contribute to wear and tear, eventually causing fittings to weaken and fail.

Improper Installation:

Incorrect installation practices are a significant cause of premature fitting failure. This includes using the wrong type of fitting, not following manufacturer guidelines, or not ensuring a secure and tight connection. Improper installation can lead to leaks, reduced system efficiency, and increased risk of fitting blowouts.

Environmental Factors:

Hydraulic hose fittings are often exposed to extreme environmental conditions, including temperature fluctuations, chemicals, and physical abrasion. High temperatures can cause fittings to expand and contract, leading to material fatigue. Exposure to chemicals can cause corrosion, while physical abrasion can wear down the surface of the fittings, compromising their integrity.

Signs of Failing Hose Fittings

Recognizing the signs of failing hose fittings is essential for timely maintenance and repair, preventing more severe system failures:

Leaks:

Visible fluid leakage around the fitting area is a clear indicator of fitting failure. Leaks can occur due to cracks, loose connections, or damaged sealing surfaces. Regular inspection for leaks can help identify problems early and prevent fluid loss and contamination.

Pressure Drops:

A sudden drop in system pressure suggests a problem with the hydraulic hose fittings. Pressure drops can occur when there is a partial blockage, a significant leak, or a fitting that is not securely connected. Monitoring system pressure can help detect issues before they lead to complete system failure.

Visible Damage:

Cracks, corrosion, or other visible damage to the fittings indicate the need for repair or replacement. Regular visual inspections of the fittings and hoses can help identify signs of damage early. Look for any signs of wear, rust, or deformation that could compromise the fitting’s performance.

Quick Fixes for On-Site Hydraulic Hose Fitting Repair

In many situations, the ability to perform quick fixes on hydraulic hose fittings can be the difference between significant downtime and continued operation. These temporary repairs are essential to keep operations running smoothly until a more permanent solution can be implemented.

Temporary Repairs

Temporary repairs are critical for immediate issues that arise unexpectedly. Here are two effective methods for quick on-site repairs:

Using Hose Clamps:

Hose clamps are a reliable and straightforward solution for temporarily stopping leaks in hydraulic hoses. When a leak is detected, placing a hose clamp over the affected area can help contain the fluid and prevent further leakage. Here’s how to use hose clamps effectively:

Selection: Choose a clamp that fits the diameter of the hose snugly.

Placement: Position the clamp directly over the leak.

Tightening: Use a screwdriver or wrench to tighten the clamp until the leak is stopped. Be careful not to over-tighten, as this can damage the hose further.

Applying Sealants and Tapes:

Hydraulic sealants and self-fusing silicone tapes are excellent for quickly patching minor leaks. These materials are designed to withstand high pressure and create a temporary seal that prevents fluid from escaping.

Sealants: Apply hydraulic sealant around the leaking area, ensuring it covers the entire circumference of the hose. Allow the sealant to set as per the manufacturer’s instructions before testing the repair.

Silicone Tapes: Wrap self-fusing silicone tape tightly around the leak, overlapping each layer to ensure a secure seal. The tape bonds to itself, forming a durable, waterproof barrier.

Step-by-Step Guide for On-Site Quick Fixes

Implementing a quick fix requires careful attention to detail and adherence to safety protocols. Here’s a step-by-step guide to ensure effective and safe repairs:

Identifying the Problem:

- Inspection: Begin by thoroughly inspecting the hose and fittings to locate the source of the issue. Look for visible signs of wear, damage, or fluid leakage.

- Pressure Testing: If the leak is not immediately apparent, use a pressure testing kit to identify pressure drops that indicate a leak.

Preparing the Site and Equipment:

- Depressurizing the System: Before starting any repair, ensure the hydraulic system is fully depressurized to prevent accidents. Turn off the hydraulic pump and bleed the pressure from the system using the appropriate valves.

- Gathering Tools: Collect all necessary tools and materials for the repair, including hose clamps, sealants, silicone tape, wrenches, screwdrivers, and safety gear.

Implementing the Temporary Fix:

- Safety First: Wear safety goggles, gloves, and protective clothing to safeguard against fluid exposure and potential injuries.

- Applying the Fix: Depending on the chosen method, use hose clamps, sealant, or silicone tape to the damaged area. Ensure the application is thorough and secure.

- Hose Clamps: Position the clamp over the leak and tighten it until the leak stops.

- Sealants: Apply the sealant evenly around the leak and allow it to cure.

- Silicone Tapes: Wrap the tape tightly around the hose, covering the leak completely.

Testing the Repair:

- Repressurizing the System: Slowly repressurize the hydraulic system, monitoring the repaired area for any signs of leakage. Gradually increase the pressure to the operating level.

- Checking for Leaks: Observe the repaired area closely to ensure the temporary fix is holding. If leaks persist, reapply the temporary fix or consider a different method.

Practical Tips for On-Site Repairs

- Keep a Repair Kit Ready: Always have a well-stocked repair kit on hand that includes various sizes of hose clamps, sealants, tapes, and basic tools. This preparedness ensures you can address issues promptly.

- Routine Inspections: Regularly inspect your hydraulic systems for early signs of wear and damage. Early detection can prevent minor issues from escalating into major failures.

Detailed Repair Procedures for Long-Term Solutions

For a more permanent solution to hydraulic hose fitting issues, it’s essential to follow detailed and precise repair procedures. These steps ensure the longevity and reliability of the repaired fittings, preventing future failures and maintaining system efficiency.

Removing and Replacing Damaged Hose Fittings

Proper Disconnection Techniques:

- Depressurize the System: Before starting any repair, ensure the hydraulic system is completely depressurized to prevent accidents. Turn off the hydraulic pump and open the appropriate valves to release any residual pressure.

- Clean the Area: Clean the area around the damaged fitting to remove dirt and debris. This ensures that no contaminants enter the hydraulic system during the repair process.

- Use the Correct Tools: Gather the necessary tools, such as wrenches, pliers, and hose cutters. Use these tools to carefully disconnect the damaged fitting from the hose and the hydraulic system. Ensure you follow the manufacturer’s guidelines to avoid damaging the hose or other components.

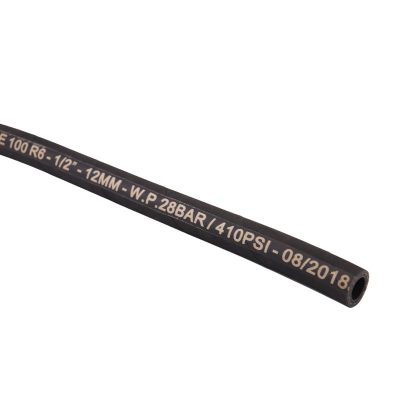

Selecting the Right Replacement Fittings:

- Match Specifications: Choose replacement fittings that match the exact specifications of your system, including size, thread type, and material. Using the correct fittings is crucial for ensuring a secure and leak-proof connection.

- Quality Components: Invest in high-quality fittings from reputable manufacturers to ensure durability and reliability. Avoid cheap or substandard fittings that may fail prematurely.

Techniques for Permanent Hose Fitting Repairs

Crimping and Swaging:

- Hydraulic Crimping Machine: Use a hydraulic crimping machine to securely attach new fittings to the hose. Follow these steps:

- Cut the Hose: Use a hose cutter to make a clean, straight cut at the end of the hose where the new fitting will be attached.

- Insert the Fitting: Insert the hose end into the fitting until it reaches the fitting’s stop.

- Crimping Process: Place the hose and fitting assembly into the crimping machine and select the appropriate die set. Activate the crimping machine to compress the fitting onto the hose, ensuring a tight and secure connection.

- Inspect the Crimp: After crimping, inspect the fitting to ensure it is properly seated and there are no visible gaps or misalignments.

Welding and Soldering:

- When Necessary: In some cases, especially with metal fittings, welding or soldering may be required to repair or reinforce fittings. This is typically done when fittings are part of a larger metal assembly or when high-pressure applications demand additional strength.

- Welding Process: Use appropriate welding techniques (such as TIG or MIG welding) to fuse the fitting to the hose or assembly. Ensure the weld is strong and free from defects.

- Soldering Process: For smaller repairs, soldering may be used to join fittings. Heat the fitting and apply solder to create a secure bond. Allow the solder to cool and solidify before testing.

Reassembly and Testing

Ensuring a Secure Fit:

- Reassemble Components: Carefully reassemble the new fittings onto the hose and reconnect them to the hydraulic system. Ensure all connections are tight and secure, following the manufacturer’s specifications.

- Check Alignment: Verify that all components are properly aligned and that there is no strain on the hose or fittings. Misalignment can lead to premature wear and potential failures.

Pressure Testing for Leaks:

- Conduct a Thorough Test: After reassembly, conduct a pressure test to confirm the integrity of the repair. Gradually increase the system pressure to the operating level while closely monitoring the repaired area for any signs of leaks.

- Use a Pressure Gauge: Attach a pressure gauge to monitor the system pressure accurately. Ensure the pressure remains stable and within the specified range.

- Inspect for Leaks: Visually inspect all connections and fittings for any signs of fluid leakage. If leaks are detected, depressurize the system and re-tighten the fittings or apply additional repairs as needed.

- Final Verification: Once the system has been pressurized and no leaks are found, verify the overall performance of the hydraulic system. Ensure that it operates smoothly and efficiently, with no unusual noises or pressure fluctuations.

Conclusion

Hydraulic hose fitting repairs are an essential skill for maintaining the efficiency and safety of hydraulic systems. By understanding the causes of failures, having the right tools, and following expert tips for quick and permanent repairs, you can minimize downtime and ensure the longevity of your equipment. Implement these strategies to keep your operations running smoothly and effectively.

FAQ

How often should I inspect my hydraulic hose fittings?

It’s recommended to perform brief daily inspections, more thorough weekly inspections, and comprehensive monthly inspections to ensure early detection of wear, leaks, or other potential issues.

What are the signs of a failing hydraulic hose fitting?

Common signs include visible fluid leaks, sudden drops in system pressure, and visible damage such as cracks or corrosion on the fittings.

Can I perform hydraulic hose fitting repairs myself?

Yes, with the right tools and knowledge, you can perform temporary and even permanent repairs. However, for complex issues or if you’re unsure, it’s best to consult a professional.

What tools do I need for on-site hydraulic hose fitting repairs?

Basic tools include wrenches, screwdrivers, pliers, and a utility knife. Specialized equipment like a hydraulic crimping machine, hose cutters, and a pressure testing kit are also essential for more complex repairs.

How can I prevent hydraulic hose fitting failures?

Regular inspections, proper installation practices, using high-quality materials, and ensuring your team is well-trained in handling and maintenance procedures are key steps in preventing failures.

What should I do if I detect a leak in a hydraulic hose fitting?

Immediately depressurize the system, inspect the area to locate the leak, and apply a temporary fix such as a hose clamp or hydraulic sealant. Follow up with a permanent repair as soon as possible to ensure the system’s reliability.