How to Measure Hydraulic Quick Connect Fitting?

Table of Contents

Introduction

Imagine this: you’re in the middle of an important project, and suddenly, your hydraulics break down. The culprit? A seemingly minor mismatch in the measurement of a hydraulic quick coupling. This situation underscores the critical importance of accurate measurements to keep your hydraulic system efficient and safe. In this comprehensive guide, we embark on a journey through the world of hydraulic quick couplings – unraveling the intricacies of their measurements, understanding the nuances of the different types, and offering expert tips for avoiding common pitfalls.

Understanding Hydraulic Quick Connect Fittings

Definition and Function

Hydraulic quick connect fittings are the unsung heroes of hydraulic systems. They are specialized connectors that allow for the rapid connection and disconnection of hydraulic hoses to different components within a system. Think of them as the critical links that keep the lifeblood of hydraulic machinery – the hydraulic fluid – flowing seamlessly. These fittings are ingeniously designed to prevent fluid leakage during connection and disconnection, ensuring the integrity of the hydraulic system. Their role extends beyond just connecting parts; they contribute significantly to the overall efficiency, safety, and maintenance convenience of hydraulic systems.

Types of Hydraulic Quick Couplings

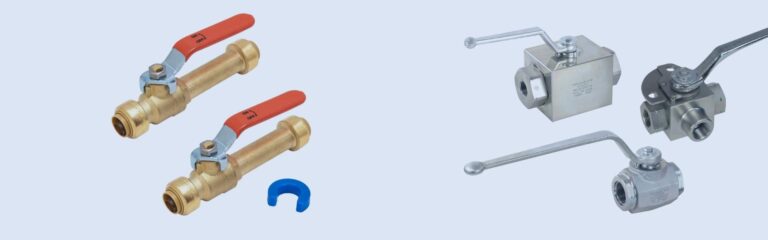

The world of hydraulic quick connect fittings is diverse, each type crafted to meet specific requirements. Here are some common ones:

ISO A: Known for its poppet valve design, ISO A fittings are widely used and are recognized for their ability to prevent fluid loss and air inclusion.

ISO B: These fittings, with their ball-locking mechanism, are another popular choice, known for their robustness in high-pressure applications.

Flat Face: True to their name, these fittings have a flat mating surface and are prized in environments where minimal spillage is critical.

Threaded Flat Face: A variation of the flat face, these fittings are used where additional security in connection is needed.

Each type has its unique characteristics, applications, and benefits, making the selection process a crucial one.

Importance of Selecting the Right Fitting

Choosing the right hydraulic quick connect fitting is not just a matter of convenience; it’s a necessity for the optimal performance of a hydraulic system. The wrong fitting can lead to leaks, pressure drops, and even system failures. It’s essential to consider factors like the type of hydraulic fluid, operating pressure, temperature range, and environmental conditions when selecting a fitting. The right fitting ensures a seamless flow of hydraulic fluid, maintains system integrity, and enhances the lifespan of the hydraulic machinery. In essence, the right fitting choice is pivotal in harnessing the full potential of a hydraulic system.

Understanding Quick Connect Fitting Thread Standards and Sizes

Quick connect fittings in hydraulic systems rely heavily on the thread standards and sizes for a secure and leak-free connection. Understanding these standards is essential for selecting the right fittings for your hydraulic systems.

Different Thread Standards

National Pipe Thread (NPT): Common in North America, NPT threads are tapered and create a seal through thread interference, requiring thread sealant or tape.

British Standard Pipe (BSP): Popular in Europe and other parts of the world, BSP threads come in two types – parallel (BSPP) and tapered (BSPT). BSPP threads usually require a bonded seal, while BSPT threads are similar to NPT in forming a seal.

Metric Threads: Used globally, these threads follow the metric measurement system and are commonly found in ISO standard fittings.

SAE Threads: Predominantly used in mobile hydraulic applications, SAE threads are based on dimensions defined by the Society of Automotive Engineers.

Identifying Thread Sizes

Thread size for NPT and BSP is often denoted by the nominal pipe size, which doesn’t match the actual dimensions. For example, a 1/2″ NPT thread does not measure 1/2″ anywhere on the thread.

Metric threads are measured in millimeters and are typically easier to identify since their designation corresponds to the actual dimension in millimeters.

SAE thread sizes are usually denoted in inches and are often accompanied by a dash number (e.g., -4, -6, -8, etc.), indicating the size.

Tools Required for Measurement

Introduction to Necessary Tools

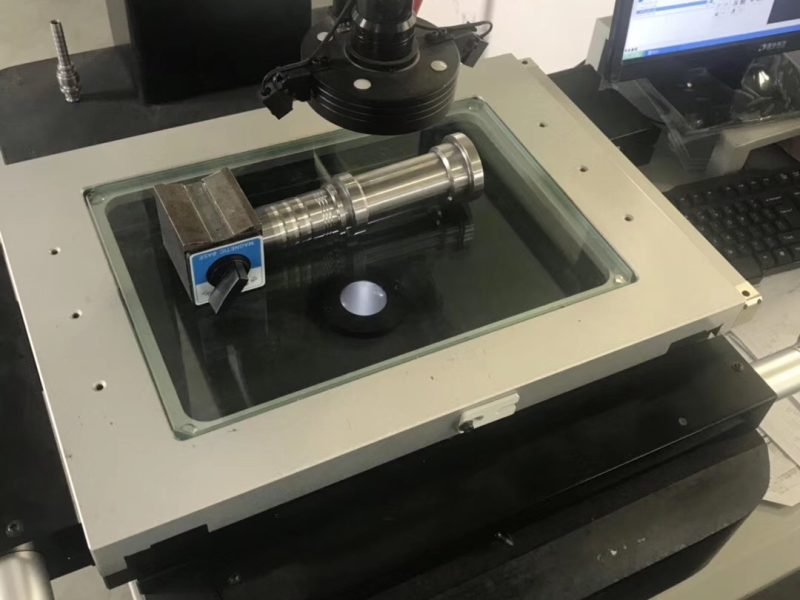

The precision measurement of hydraulic quick connect fittings demands specialized tools, each serving a unique purpose. Essential in this toolkit are calipers and thread gauges, instruments that bring accuracy and reliability to your measurements.

Calipers: A cornerstone tool in measuring hydraulic fittings, calipers come in various forms – digital, dial, or vernier. They are used to measure the outer and inner diameters of fittings, crucial for ensuring the correct fit.

Thread Gauges: These are used to determine the thread pitch and size of the fittings. Accurate identification of thread type is critical as mismatched threads can lead to leaks or fitting failures.

Ruler or Tape Measure: For quick, general measurements, a standard ruler or tape measure is useful, especially for measuring the length of hoses or the overall dimensions of fittings.

Effective Usage of These Tools

Using Calipers:

- For External Diameter: Place the fitting between the jaws of the caliper, close the jaws gently until they make contact with the fitting, and read the measurement.

- For Internal Diameter: Use the upper smaller jaws of the caliper for this measurement. Insert them into the fitting and expand until they fit snugly against the internal walls, then read the size.

Using Thread Gauges:

- Start by visually inspecting the thread profile against a thread gauge.

- Place the gauge on the threads and try different sizes until you find a perfect match. The correct gauge should fit snugly with no wiggle room.

Using a Ruler or Tape Measure:

- For straightforward measurements like the length of a hose, lay it flat and measure from end to end.

Step-by-Step Guide to Measuring Quick Coupler

Measuring the Diameter

Measuring the External Diameter:

- Select the Right Caliper: Choose a caliper that’s appropriate for the size of the fitting. Digital calipers are recommended for their ease of reading and precision.

- Positioning the Fitting: Carefully place the fitting between the jaws of the caliper. It’s crucial to ensure that the fitting is perpendicular to the jaws. This positioning is essential for an accurate measurement.

- Taking the Measurement: Gently close the caliper until it makes firm contact with the external surface of the fitting. Avoid applying excessive force to prevent any damage to the fitting or the caliper.

- Recording the Measurement: Once the caliper is snug against the fitting, lock the caliper jaws (if applicable) and record the measurement. Note the measurement down to the appropriate decimal place for precision.

Measuring the Internal Diameter:

- Caliper Selection: Use a caliper that has a range suitable for the expected internal diameter of the fitting.

- Using the Upper Jaws: The upper jaws of the caliper are designed for measuring internal diameters. Carefully insert these jaws into the opening of the fitting.

- Expanding the Jaws: Gently expand the caliper jaws until they reach the internal walls of the fitting. Be cautious not to over-expand as it may distort the measurement or damage the fitting.

- Snug Fit and Measurement: Expand the jaws until they fit snugly against the internal walls. The fit should be firm but not forced. Once a snug fit is achieved, lock the caliper and record the measurement.

Identifying Thread Types and Sizes

Visual Inspection:

- Initial Observation: Start by closely examining the thread pattern on the fitting. Observe whether the threads appear tapered (conical shape) or parallel (cylindrical shape). This visual distinction is vital as it helps in identifying the thread type.

- Thread Appearance: Note any unique characteristics of the threads, such as the number of threads per inch, thread pitch, and the angle of the threads. These observations can provide initial clues about the thread type.

Using Thread Gauges:

- Selection of Thread Gauge: Choose a thread gauge that matches your initial visual estimate. It’s beneficial to have a set of thread gauges that includes various standards like NPT (National Pipe Thread), BSP (British Standard Pipe), Metric, etc.

- Aligning Gauge with Thread: Carefully place the thread gauge against the fitting’s threads. Begin with the gauge size you estimated visually to be closest.

- Finding the Perfect Match: Slide the gauge along the threads. The correct size gauge will align seamlessly with the threads without any gap or play. It should sit flush against both the peaks (crests) and valleys (roots) of the threads.

- Recording Thread Type and Size: Once you find the matching gauge, record the thread type and size. For example, you might identify a fitting as 1/2″ NPT or 3/4″ BSP.

Determining the Body Size of the Fitting

Measuring Body Diameter:

- Using a Caliper for Measurement: Position the caliper around the largest part of the fitting body. This is typically the section with the maximum diameter.

- Recording the Measurement: Measure and record the diameter, ensuring the caliper is perpendicular to the fitting for an accurate reading. This diameter is essential in understanding the fitting’s flow capacity.

Referencing Manufacturer Specifications:

- Comparing with Standards: Once you have the measurements, compare them with the manufacturer’s specifications or standard size charts. This comparison ensures that the fitting aligns with industry standards and can correctly match with complementary components.

Special Considerations for Different Fitting Styles

- ISO A vs ISO B Fittings: Recognize that ISO A and ISO B fittings have different locking mechanisms. For ISO B, it is crucial to measure across the locking balls as this dimension impacts the interlocking capability of the fittings.

- Flat Face Fittings: The sealing surface diameter is critical in flat face fittings. Ensure accurate measurement of this surface as it directly affects the fitting’s ability to seal and prevent leaks.

- Threaded Fittings: When dealing with threaded fittings, both the thread size and the body size are important. Accurate measurement of these dimensions ensures proper fitting functionality and compatibility within the hydraulic system.

Common Mistakes and How to Avoid Them

Overview of Typical Errors Made During Measurement

- Incorrect Tool Use: A frequent error is the improper use of measurement tools, like using a caliper incorrectly. This leads to inaccurate readings.

- Ignoring Calibration: Failing to calibrate tools, especially digital ones, can result in measurements that are off.

- Misreading Thread Types: Mixing up thread types, such as confusing NPT with BSP, is a common mistake due to their subtle differences.

- Overlooking Wear and Tear: Measuring worn-out fittings without considering their degraded state can lead to inaccurate size determination.

- Assuming Standard Sizes: Assuming that all fittings adhere to standard sizes and not measuring each fitting individually can lead to mismatches.

- Neglecting Environmental Factors: Not accounting for temperature or pressure conditions that could affect the fitting dimensions.

Tips for Ensuring Accuracy in Measurements

- Proper Tool Handling: Always use measurement tools as intended. For calipers, ensure they are perpendicular to the object being measured and that the jaws are gently closed on the item.

- Regular Calibration: Regularly calibrate your tools, especially if they are digital, to ensure ongoing accuracy.

- Educate on Thread Types: Familiarize yourself with different thread types and their characteristics. Use a thread identification chart if necessary.

- Consider Condition of Fittings: When measuring used fittings, consider their wear and tear. Compare with new fittings if possible to understand how wear has affected the size.

- Measure Each Fitting Individually: Don’t assume all fittings of the same type are identical. Variations can occur, so measure each fitting individually.

- Mind the Environment: Consider the environmental factors where the fittings will be used. Temperature and pressure can affect both the fitting material and the measurements.

- Double-Check Measurements: Always double-check measurements, especially when they seem off or do not align with standard sizes.

- Use Quality Tools: Invest in high-quality, reliable measuring tools. Good tools reduce the chance of error.

- Keep Tools Clean and Protected: Ensure your tools are clean and stored properly. Dirt and damage can affect accuracy.

- Continuous Learning: Stay informed about new fittings, tools, and measurement techniques. The field of hydraulics is constantly evolving, and keeping up-to-date can help avoid mistakes.

Advanced Considerations

When selecting hydraulic quick connect fittings, it’s not just about size and compatibility; advanced considerations like pressure ratings, flow rates, and material selection play a critical role in the performance and durability of the hydraulic system.

Pressure Ratings

Understanding Pressure Ratings: Each hydraulic fitting is rated for a maximum operating pressure. It’s essential to choose fittings that can withstand the system’s maximum pressure, including pressure surges.

Consequences of Incorrect Ratings: Using a fitting with a lower pressure rating than the system can lead to catastrophic failures, posing safety risks and potential system damage.

Matching with System Requirements: Ensure that the fittings’ pressure ratings either match or exceed the requirements of the hydraulic system to maintain integrity under all operating conditions.

Flow Rates

Importance of Flow Rate: The flow rate, typically measured in gallons per minute (GPM), determines the speed at which fluid travels through the system. Fitting size and internal design impact this rate.

Selection Based on Flow Requirements: Select fittings that can accommodate the system’s required flow rate without causing excessive turbulence or pressure drop.

Impact on System Efficiency: Inadequate flow rates can lead to inefficiencies, such as slow operation of hydraulic actuators or overheating of the fluid.

Material Selection

Types of Materials: Common materials for hydraulic fittings include steel, stainless steel, brass, and thermoplastics. Each material has its advantages and limitations.

Steel and Stainless Steel: These materials are known for their strength and durability. Stainless steel offers additional corrosion resistance, making it suitable for harsh environments.

Brass: Brass fittings are typically used in lower pressure applications and are known for their corrosion resistance and ductility.

Thermoplastics: These are used in less demanding applications and offer good resistance to chemicals and corrosion. They are lightweight and economical.

Considerations for Material Choice: The selection should be based on factors like the type of hydraulic fluid used, environmental conditions (corrosive or extreme temperatures), and application-specific requirements.

Tips for Purchasing the Correct Fittings

Selecting the right hydraulic quick connect fittings is crucial for the efficiency and safety of your hydraulic system. Here are some essential tips to consider when purchasing fittings:

Guidance on Selecting the Right Fittings After Measurement

Verify Measurements: Cross-check the measurements taken with the specifications needed for your application. Ensure that the diameters, thread types, and sizes align with your system requirements.

Application-Specific Requirements: Consider the specific demands of your application. For instance, if the fitting is for a high-vibration environment, choose a fitting designed to withstand such conditions.

Standard vs. Custom Fittings: Determine if standard fittings meet your needs or if you require custom-made fittings for specialized applications.

Conclusion

In choosing the perfect hydraulic quick connect coupling, it is important to fully understand its type, take proper measurements, recognize common mistakes, and be able to grasp high-level considerations such as pressure ratings and material suitability. Every step of the way, from initial measurements to final selection, requires attention to detail and an understanding of the system’s operating environment and requirements.

FAQ

To measure hydraulic quick connect fittings, you’ll need a caliper or micrometer to measure the diameter, and a thread gauge for checking the thread size.

Measure the outside diameter of the fitting’s male or female threads to determine its size, and check the thread pitch using a thread gauge.

Accurate thread measurement ensures compatibility between the fitting and the mating part, preventing leaks or connection issues.

Measure the overall length of the fitting from end to end, excluding any external features like sleeves or collars.

The coupling mechanism, such as the locking sleeve, should be measured for proper alignment and functionality, ensuring it securely locks the fitting in place.

Ensure that both the size (diameter, thread) and pressure rating of the hydraulic quick connect fitting match the requirements of your hydraulic system.

Topa Blog

Find out more about Topa Blog and learn more about specialized hydraulic fittings.