Safety is the cornerstone of any operation involving gas, a highly volatile and potentially hazardous substance. Whether in industrial settings or residential environments, the margin for error is slim, and the consequences of negligence can be catastrophic. When it comes to gas-related applications, the choice of materials and equipment is not just a matter of efficiency—it’s a matter of life and death.

Understanding Hydraulic Hoses

Definition and Function

Hydraulic hoses are specialized flexible tubes designed to transport hydraulic fluids, such as oil, within a hydraulic system. These systems are widely used in various industrial, agricultural, and construction applications where high pressure is required to transmit power through fluid. Hydraulic hoses play a critical role in these systems by enabling the movement of fluid between different components, such as pumps, cylinders, valves, and motors, facilitating the transfer of force and motion.

Hydraulic hoses are engineered to handle the high pressures and dynamic movements typical of hydraulic systems. They are constructed to provide flexibility, strength, and durability, allowing them to operate efficiently in environments where rigid piping might fail due to movement, vibration, or space constraints. The primary function of a hydraulic hose is to ensure a secure and reliable fluid connection between various parts of a hydraulic system, enabling smooth and controlled operation.

Overview of Materials Used in Hydraulic Hose Construction

Hydraulic hoses are made from a variety of materials, each selected for specific performance characteristics. The choice of material impacts the hose’s flexibility, durability, temperature resistance, and chemical compatibility. The most common materials used in hydraulic hose construction include:

Rubber: Rubber is one of the most widely used materials in hydraulic hoses. It provides excellent flexibility and resistance to abrasion, making it suitable for applications where the hose may be exposed to harsh environmental conditions. Rubber hoses are also known for their ability to absorb shocks and vibrations, which is crucial in dynamic applications.

Thermoplastics: Thermoplastic materials, such as nylon and polyurethane, are often used in hydraulic hoses for their lightweight properties and resistance to chemicals. These materials provide good flexibility and can withstand high-pressure applications. Thermoplastic hoses are also preferred in environments where low temperatures are a concern, as they maintain their flexibility in cold conditions.

PTFE (Polytetrafluoroethylene): PTFE, commonly known by the brand name Teflon, is used in hydraulic hoses that require high resistance to chemicals and extreme temperatures. PTFE hoses offer low friction and excellent resistance to corrosion, making them ideal for specialized applications where chemical exposure or high temperatures are factors. They are often used in situations requiring precise fluid control and long service life.

Design and Specifications

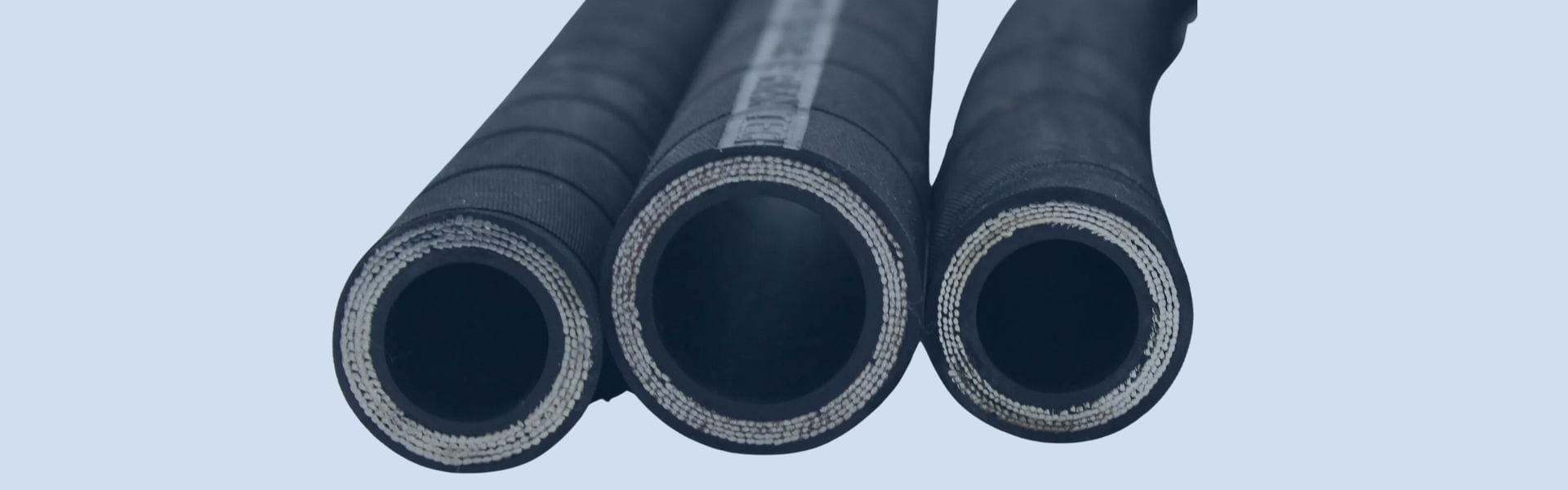

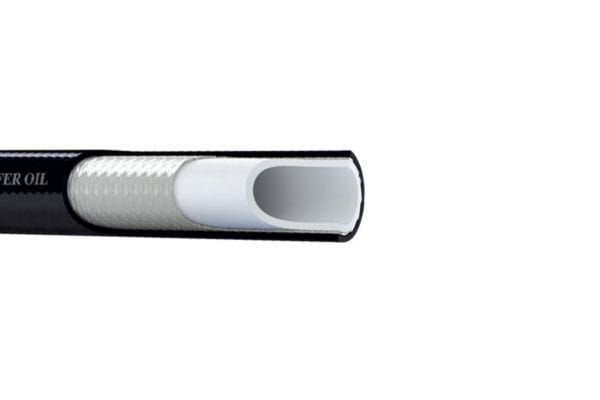

Hydraulic hoses are designed to withstand the rigorous demands of hydraulic systems, which operate under high pressure and in variable temperature conditions. The design of a hydraulic hose includes multiple layers, each contributing to the hose’s overall strength and durability. Typically, a hydraulic hose consists of an inner tube that carries the fluid, a reinforcement layer that provides strength, and an outer cover that protects against environmental damage.

Pressure Ratings: Hydraulic hoses are categorized based on their pressure ratings, which indicate the maximum pressure the hose can safely handle. These ratings are critical as they ensure the hose can withstand the operational pressures without bursting. Pressure ratings are usually given in pounds per square inch (PSI) or bar, and they vary depending on the hose’s construction and intended use. Standard hydraulic hoses are available in a range of pressure ratings, from low-pressure applications under 500 PSI to ultra-high-pressure hoses capable of handling pressures exceeding 10,000 PSI.

Temperature Tolerances: Hydraulic hoses must also withstand varying temperature conditions. The materials used in their construction determine their ability to function in extremely hot or cold environments. For instance, rubber hoses can typically handle temperatures ranging from -40°C to 100°C, while PTFE hoses can endure even higher temperatures, often exceeding 200°C. Ensuring that a hose is suitable for the operating temperature of a system is essential to prevent material degradation and potential hose failure.

Natural Gas Hoses

Definition and Purpose

Natural gas hoses are specially designed flexible conduits used to transport natural gas from one point to another, typically in industrial, commercial, and residential applications. These hoses must meet stringent requirements to safely contain and convey natural gas, a highly flammable and volatile substance. The primary purpose of natural gas hoses is to ensure the safe and efficient delivery of natural gas from supply lines to appliances, machinery, or storage systems while preventing leaks and minimizing the risk of fire or explosion.

Due to the unique properties of natural gas, including its high flammability and tendency to seep through small openings, hoses used in these applications must be constructed from materials that are not only resistant to gas permeation but also capable of withstanding the operational pressures and temperatures typical of natural gas systems. The design and construction of natural gas hoses are therefore focused on ensuring the highest levels of safety, durability, and reliability under varying environmental and operational conditions.

Materials Typically Used in Natural Gas Hoses

The materials used in natural gas hoses are chosen for their ability to contain natural gas without degradation, leakage, or permeation. These materials must also be resistant to the effects of temperature fluctuations, UV exposure, and other environmental factors. The most common materials used in the construction of natural gas hoses include:

Stainless Steel: Stainless steel is a popular material for natural gas hoses due to its excellent resistance to corrosion, high temperatures, and mechanical stress. Stainless steel hoses are often used in high-pressure applications where durability and long service life are critical. The metal construction provides a strong barrier against gas permeation, ensuring that the gas remains safely contained within the hose.

Special Polymers: In addition to stainless steel, special polymers are also used in natural gas hose construction. These polymers, such as thermoplastic elastomers (TPE) or polyvinyl chloride (PVC), are selected for their flexibility, resistance to chemical exposure, and ability to maintain integrity under pressure. Polymer-based hoses are typically used in applications where flexibility is important, such as in residential settings or where the hose needs to be routed around obstacles. These materials are also chosen for their cost-effectiveness and ease of installation.

Composite Materials: Some natural gas hoses are constructed using composite materials that combine the properties of both metals and polymers. These composite hoses are designed to offer the strength and durability of stainless steel with the flexibility and lightweight characteristics of polymers. Composite hoses are often used in industrial applications where both high performance and flexibility are required.

Importance of Pressure and Temperature Ratings Specific to Natural Gas

Natural gas hoses must be carefully rated for the specific pressures and temperatures they will encounter in service. Unlike hydraulic hoses, which are designed for the transfer of liquids, natural gas hoses must accommodate the unique properties of gas, including its compressibility and tendency to expand and contract with temperature changes. The pressure rating of a natural gas hose is a critical factor, as it determines the maximum pressure the hose can safely contain without risk of rupture or leakage. This rating must be matched to the operating pressure of the gas system to prevent failures.

Temperature ratings are equally important, as natural gas hoses must remain flexible and secure across a range of temperatures. In cold climates, hoses must resist becoming brittle and cracking, while in hot environments, they must avoid softening or losing their structural integrity. The materials and construction of the hose are chosen to ensure that it can withstand these temperature variations without compromising safety or performance.

Risks of Using Hydraulic Hoses for Natural Gas

Material Incompatibility

One of the most critical risks of using hydraulic hoses for natural gas applications stems from the material incompatibility between the two. Hydraulic hoses are specifically designed to transport hydraulic fluids, which are typically oils and other similar substances. The chemical composition of these hoses is optimized for resistance to the properties of hydraulic fluids, including their viscosity, lubricating nature, and moderate chemical reactivity. Hydraulic hoses are commonly made from materials such as synthetic rubber, thermoplastics, and PTFE (Polytetrafluoroethylene), all of which perform excellently in hydraulic applications.

However, these same materials are not suitable for natural gas, a substance that has very different chemical properties. Natural gas is a volatile, low-viscosity, and highly permeable substance that can easily seep through materials that are not specifically designed to contain it. Hydraulic hoses, made from materials optimized for oil and other hydraulic fluids, do not have the necessary resistance to natural gas’s permeability. Over time, the gas can slowly permeate through the hose material, leading to leaks that may not be immediately detectable.

Moreover, natural gas can react with the rubber and synthetic materials in hydraulic hoses, leading to material degradation. This degradation can manifest as cracking, hardening, or softening of the hose, compromising its structural integrity. As the hose deteriorates, the risk of gas leaks increases, creating a potentially hazardous situation. The use of hydraulic hoses for natural gas is, therefore, fundamentally unsafe due to this material incompatibility.

Pressure and Temperature Mismatch

Another significant risk of using hydraulic hoses for natural gas is the mismatch in pressure and temperature ratings between the two applications. Hydraulic hoses are engineered to handle the high pressures and temperatures typical of hydraulic systems, which are designed to transmit power through fluids. These hoses are rated for specific pressure ranges, often ranging from a few hundred PSI (pounds per square inch) to several thousand PSI, depending on the application.

Natural gas systems, however, operate under different pressure and temperature conditions. While the pressures in natural gas systems can vary, they are generally lower than those found in hydraulic systems, but the requirements for pressure containment are more stringent due to the gas’s high flammability. Additionally, the temperature variations in natural gas systems can be more extreme, especially in outdoor environments where temperatures can fluctuate widely.

Using a hydraulic hose that is not rated for the specific pressures and temperatures of a natural gas system can lead to catastrophic failures. For example, if a hydraulic hose is used in a natural gas application and is exposed to temperatures beyond its rated tolerance, the material may become brittle or lose its strength, leading to cracks or ruptures. Similarly, if the hose is subjected to pressures it was not designed to handle, it could burst, releasing a large volume of gas into the environment.

Safety Hazards

The most severe risks associated with using hydraulic hoses for natural gas are the safety hazards that can arise from leaks or hose ruptures. Natural gas is highly flammable, and any leak in a gas system can quickly lead to a dangerous situation. When a hydraulic hose, which is not designed to contain natural gas, begins to leak, the escaping gas can accumulate in confined spaces, creating an explosive atmosphere. All it takes is a single spark—a static discharge, a hot surface, or an electrical fault—for the gas to ignite, leading to an explosion or fire.

In addition to the immediate risk of fire or explosion, leaks from hydraulic hoses used in natural gas systems can also lead to contamination of the gas supply. As the hose degrades, particles of rubber, plastic, or other materials can be carried along with the gas, potentially contaminating the gas supply. This contamination can cause problems in downstream equipment, leading to further safety risks and operational issues.

Proper Hose Selection for Natural Gas

Criteria for Selecting Natural Gas Hoses

Choosing the right hose for natural gas applications is critical to ensuring safety and efficiency. The selection process should be guided by several key criteria:

Material Compatibility: The hose material must be compatible with natural gas. Look for hoses made from materials that are resistant to the permeation of gas, such as stainless steel, PTFE (Teflon), or specialized polymers like TPE (Thermoplastic Elastomers). These materials provide a strong barrier against leaks and are less likely to degrade when exposed to natural gas.

Pressure Rating: Ensure that the hose is rated for the specific pressure of the natural gas system. This rating should exceed the maximum operating pressure to provide a margin of safety. It’s crucial to select a hose that can handle both the static and dynamic pressures in the system, preventing potential failures due to over-pressurization.

Temperature Range: The hose must be capable of withstanding the temperature extremes of the operating environment. Check the hose’s temperature rating to ensure it can operate safely in the expected conditions, whether in a hot, outdoor installation or a cold climate. The material should remain flexible and structurally sound across this temperature range.

Flexibility and Bend Radius: The hose should have sufficient flexibility to accommodate the installation environment without kinking or bending excessively, which can cause stress and lead to premature failure. The bend radius, or the minimum curve a hose can handle without damage, should be suitable for the application.

Certification and Compliance: Look for hoses that meet industry standards and certifications, such as ANSI, ISO, or CSA. These certifications ensure the hose has been tested for safety and performance in gas applications. Compliance with these standards is crucial for regulatory approval and long-term safety.

Durability and Longevity: Consider the hose’s durability and expected lifespan. Hoses in natural gas applications are often exposed to harsh environmental conditions, so it’s important to choose one with a robust construction that will endure wear and tear over time.

Conclusion

I urge you to take a moment to review the hoses currently used in your gas systems. Are they the right type for the job? Are they certified and rated for natural gas? If there’s any doubt, it’s essential to consult with industry experts or suppliers who can provide the guidance needed to ensure that your equipment complies with safety standards. Don’t wait for a failure to happen—proactively assess your hose applications and make the necessary adjustments to secure your operations.

FAQ

Can I use hydraulic hoses for natural gas applications?

No, hydraulic hoses are not designed for natural gas and can pose serious safety risks if used in such applications.

What are the risks of using hydraulic hoses for natural gas?

The risks include leaks, hose degradation, potential fires, explosions, and environmental contamination.

Why are hydraulic hoses unsuitable for natural gas?

Hydraulic hoses are made from materials that are not compatible with natural gas and lack the necessary pressure and temperature ratings for gas applications.

What materials should natural gas hoses be made of?

Natural gas hoses are typically made of stainless steel, specialized polymers, or composite materials that resist gas permeation and withstand the required pressures and temperatures.

How can I ensure I’m using the right hose for natural gas?

Consult with industry experts or suppliers and choose hoses that are certified and rated specifically for natural gas applications.

What should I do if I suspect a hydraulic hose is being used for natural gas?

Immediately consult with a professional to assess the situation and replace the hose with one that is appropriate and safe for natural gas use.