Topa specializes in the research, development, and manufacturing of high-quality one-piece hydraulic fittings, aiming to provide efficient and reliable hydraulic system connection solutions to customers worldwide. Our range of one-piece hydraulic fittings covers a wide variety of specifications and types to meet the demands of different working conditions and application scenarios.

The main product categories include, but are not limited to: JIC 37° flare one-piece fittings compliant with international standards, ORFS flat-face seal one-piece fittings, BSPP/BSPT threaded one-piece fittings, DIN metric light/heavy series one-piece compression fittings, Custom-designed non-standard one-piece hydraulic connectors tailored to specific customer requirements. These products are compatible with and can replace Danfoss 4S series one-piece fittings. They offer superior quality at competitive prices. We welcome your inquiries and purchases!

Discover the versatility and precision of Topa’s crimped hydraulic fittings in this comprehensive video presentation. We will highlight our wide range of expertly designed crimp fittings, demonstrating their robust construction and ability to be used in a wide range of demanding hydraulic applications.

From standard configurations to specialized designs, every detail has been meticulously considered to ensure optimal performance and leak-free connections. We believe this intuitive insight will be invaluable in your selection process.

We invite you to click and watch a video that gives you a comprehensive overview of Topa’s crimping hydraulic accessories. Witness how our solutions can improve the reliability and efficiency of your hydraulic system. If you have any specific questions or detailed specifications, our team is ready to assist you further after your viewing.

Crimp hydraulic hose fittings play a pivotal role in a myriad of applications, underpinning the performance and reliability of hydraulic systems across diverse industries.

Used in various automated production lines, CNC machines, hydraulic presses, and robotic systems, Topa’s integrated hydraulic fittings offer compact design, precise connections, and long-lasting sealing performance. They deliver stable and reliable power transmission to these high-precision industrial systems, helping improve machining accuracy and the operational efficiency of automated production lines.

Modern agricultural machinery—such as tractors, combine harvesters, and seeders—relies increasingly on hydraulic systems to enable precision operations and efficient output. Topa’s integrated hydraulic fittings are well-suited to complex agricultural environments, which are often dusty, humid, and subject to wide temperature fluctuations. Their superior sealing performance and corrosion resistance ensure consistent reliability in the field.

In heavy-duty construction equipment such as excavators, loaders, and cranes, hydraulic systems endure high pressure and frequent dynamic loads. Topa’s integrated hydraulic fittings, with their exceptional high-pressure resistance, vibration tolerance, and zero-leakage performance, significantly reduce downtime caused by fitting failures. They ensure smooth project execution and maintain stable operation even in the harshest working conditions.

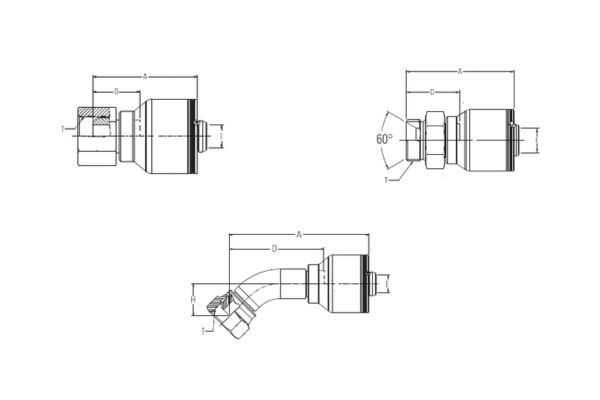

The core of Topa's one-piece hydraulic fittings lies in their highly integrated design concept. Unlike traditional multi-component fittings—which typically consist of separate parts such as the fitting body, nut, ferrule, O-rings, and flared or compression sealing elements—Topa’s one-piece fittings consolidate these functional components into a single, robust metal unit through precision manufacturing processes.

A typical one-piece fitting structure generally includes:

Main Connection End

Port Connection End

Integrated Sealing Structure

At Topa, we understand that material quality is a critical factor in determining the performance and lifespan of hydraulic fittings. That’s why we carefully select high-grade engineering materials for our one-piece hydraulic fittings to meet the demands of a wide range of complex and harsh industrial environments.

High-Grade Carbon Steel

Stainless Steel

Topa’s hydraulic crimp fittings are engineered to outperform in the most demanding applications, providing you with reliability and peace of mind.

Feature

Topa’s one-piece hydraulic fittings are manufactured using advanced integrated precision forging or CNC machining processes, combining the fitting body, nut, and ferrule/flared components into a single, solid structure.

Advantage

This design eliminates gaps between parts, preventing potential micro-movements and leak paths caused by vibration, pressure fluctuations, or improper installation.

Benefit

You get a highly reliable hydraulic system that significantly reduces fluid leakage, equipment downtime, and environmental risks—ultimately lowering maintenance costs and improving overall operational safety and efficiency.

Feature

The one-piece design eliminates the need for on-site assembly of multiple small components, making installation much simpler.

Advantage

Fewer installation steps and less dependency on operator skill reduce the chances of assembly errors and system failure.

Benefit

Shorter assembly times and greater production line efficiency reduce labor costs. For field repairs, replacements are faster, minimizing equipment downtime to the greatest extent.

Feature

Manufactured from high-quality materials such as premium carbon steel (e.g., 45#) or stainless steel (e.g., SUS304, SUS316, SUS316L), with corrosion-resistant surface treatments like zinc plating.

Advantage

These materials offer excellent mechanical strength, high-pressure resistance, corrosion resistance, and wear resistance—ideal for harsh industrial environments and various media.

Benefit

Enjoy longer service life and more reliable performance, reducing replacement frequency and related costs, while ensuring the long-term stability of your hydraulic system.

Feature

Topa one-piece fittings are developed based on the dimensional and interface standards of mainstream global hydraulic systems and are compatible with leading series such as Danfoss 4S.

Advantage

Fully compatible with existing systems—no need to modify original layouts or components, making installation easier.

Benefit

Achieve plug-and-play system upgrades without extra investment. This lowers procurement and maintenance complexity while enhancing overall system flexibility and adaptability.

When selecting and using hydraulic fittings, certain common mistakes and oversights can lead to decreased system performance, fluid leaks, or even safety incidents. Based on years of industry experience and technical expertise, Topa is committed to helping customers identify and avoid these potential pitfalls—ensuring your hydraulic system operates at its best from day one. Below are key risk points that Topa’s one-piece fittings and expert support help you sidestep with ease:

Hydraulic fittings come in a variety of thread standards (e.g., metric, imperial, unified; tapered vs. parallel threads). A frequent cause of connection failure is force-fitting incompatible male and female threads. Even when threads appear similar, differences in thread angle, pitch, or sealing method can lead to leakage or damage.

We provide clearly labeled product models and professional selection guidance to ensure full compatibility with your system’s thread type.

Different working conditions—such as pressure rating, fluid type, temperature range, and vibration level—require different sealing methods. For example, in environments with frequent disassembly or high vibration, O-ring face seal (e.g., ORFS) is often more reliable than metal-to-metal seals. Choosing the wrong sealing method can lead to early leakage or premature failure.

Our engineers will recommend the most suitable sealing technology based on your specific application scenario.

Under-tightening can lead to loose connections and leaks; over-tightening may damage threads, seals, or the fitting body, causing similar issues. Each fitting type and size has a recommended torque value for safe and effective installation.

We provide detailed installation manuals with torque specifications and recommend the use of torque wrenches for standardized assembly.

Fitting selection must be matched to the hydraulic hose type, size, pressure rating, and crimping process. Using incompatible fittings or improperly assembled hose assemblies is one of the leading causes of hydraulic system failure.

Our one-piece fittings are designed with full compatibility in mind for mainstream hose brands and types. We also offer expert advice on correct hose assembly configurations.

Every hydraulic crimp fitting we produce is backed by our comprehensive quality assurance process and reliability guarantee. We're so confident in our products that we offer extended warranties and technical support to ensure your hydraulic systems operate at peak performance.

At Topa, we go beyond manufacturing to provide comprehensive support throughout your entire project lifecycle. Our dedicated team of professionals ensures you receive the highest level of service from initial inquiry to post-installation support.

Our engineering team creates custom hydraulic fitting solutions tailored to your specific application requirements.

Rigorous testing protocols ensure every product meets our exacting standards for performance and reliability.

Dedicated project managers coordinate your order from design approval through production and delivery.

Efficient logistics solutions deliver your products worldwide with tracking and customs documentation support.

Our expert team provides comprehensive technical assistance for product selection, installation, and troubleshooting.

Request sample products for evaluation and testing in your specific application environment before large orders.

Specialized manufacturing services for OEMs with consistent volume requirements and custom specifications.

Every product is backed by our comprehensive warranty and commitment to customer satisfaction.

Topa’s one-piece hydraulic fittings are manufactured using advanced integrated precision forging or CNC machining processes, combining the fitting body, nut, and ferrule/flared components into a single, solid structure.

With over 20 years of experience in hydraulic fitting manufacturing, Topa has established itself as a leading producer of high-quality crimp fittings for global industrial markets. Our state-of-the-art manufacturing facility combines advanced technology with rigorous quality control to deliver products that consistently exceed industry standards.

Our ISO certification ensures consistent quality through every stage of production, from material sourcing to final inspection.

Our factory features the latest CNC machining equipment, automated quality control systems, and specialized testing facilities.

By controlling the entire production process in-house, we deliver superior products at competitive prices with reliable lead times.

Our experienced engineers and technicians bring decades of combined expertise in hydraulic component design and manufacturing

Topa's comprehensive manufacturing process is designed to deliver exceptional value to our customers. By controlling every aspect of production from raw material to finished product, we ensure consistent quality, competitive pricing, and responsive service. Our vertical integration allows us to maintain strict quality standards while optimizing efficiency throughout the manufacturing cycle.

Topa's comprehensive manufacturing process is designed to deliver exceptional value to our customers. By controlling every aspect of production from raw material to finished product, we ensure consistent quality, competitive pricing, and responsive service. Our vertical integration allows us to maintain strict quality standards while optimizing efficiency throughout the manufacturing cycle.

Units Daily Production

CNC Machines

In-House Testing

Workers

A hydraulic crimp fitting is a one-piece fitting where the ferrule and the connector body are integrated. It’s easier to install and does not require a separate sleeve.

One-piece fittings have an integrated design that saves assembly time. Two-piece fittings require a separate ferrule, allowing for more flexible combinations.

Not all hoses are compatible. They are commonly used with SAE 100R1AT, R2AT, 4SP hoses, but compatibility should always be confirmed before use.

They are widely used in agriculture machinery, construction equipment, mining, industrial automation, and hydraulic repair applications.

A hydraulic crimping machine with the correct die set is required to ensure proper crimping angle and pressure.

They are available in a variety of thread standards, including JIC, BSP, NPT, ORFS, and Metric, to match different regional system requirements.

They are typically made from carbon steel or stainless steel. Brass or zinc-plated versions are used for corrosion resistance in special environments.

Reduced inventory complexity

Faster assembly

Lower risk of leakage

Increased system stability

Yes, many suppliers offer OEM customization including laser engraving, color variations, custom bags, boxes, and labels.

Generally, no. Once crimped, the fitting deforms permanently, which may compromise the seal and safety if reused.