Developed by Parker Hannifin, Series 43 hydraulic crimp fittings are seamlessly compatible with a wide range of hose types, including Parker’s no-slip hose. Slipless technology simplifies assembly by eliminating the need for sliding, reduces the risk of premature hose failure, and ensures a secure, leak-free connection. In hydraulic systems, choosing the right range of fittings is critical to maintaining efficiency and safety. Different fittings are designed for specific pressures, environments, and fluid types.

Overview of 43 Series Hydraulic Crimp Fittings

The 43 Series Crimp Fittings are a versatile range of hydraulic fittings used across various industrial sectors. They are specifically designed to simplify assembly processes by eliminating the need to remove the hose’s outer cover during installation. This technology, known as no-skive, allows for faster, more efficient assembly while minimizing the risk of hose failure due to improper skiving. By ensuring that the hose remains intact, these fittings provide a reliable and secure connection, suitable for numerous hydraulic systems and applications.

Historical Background

The development of the 43 Series Crimp Fittings was driven by the need for a more user-friendly and efficient fitting solution in the hydraulic industry. Responding to demands for streamlined installation and reduced maintenance time, this series was introduced as a versatile option that integrates easily into various systems. Over time, these fittings have become a widely accepted standard for professionals seeking durable, adaptable, and efficient fittings for hydraulic equipment and machinery. Their design continues to evolve to meet the needs of various sectors, reflecting the industry’s trend towards efficiency and reliability.

Key Features of the 43 Series Crimp Fittings

No-Skive Technology

A key innovation of the 43 Series is its no-skive technology, which allows for quick and error-free assembly. By eliminating the need to remove the hose’s outer cover, users can ensure a faster installation process that reduces the risk of incorrect skive lengths—a common issue that can lead to leaks or premature hose failure. This feature not only enhances productivity but also increases the reliability of hydraulic systems by maintaining the integrity of the hose during fitting attachment.

“Bite-the-Wire” Design

The 43 Series also incorporates a “bite-the-wire” mechanism. During crimping, this feature ensures the fitting bites directly into the hose’s wire reinforcement, creating a robust, leak-free connection capable of withstanding high-pressure environments. This design increases the fitting’s grip strength, offering a secure attachment that remains reliable even under dynamic conditions where hoses are subject to vibration and movement. This feature makes the 43 Series ideal for applications requiring high durability and resilience in challenging or high-pressure environments.

Corrosion-Resistant Plating

The 43 Series fittings are made with advanced plating options, such as chromium-free coatings, enhancing their resistance to corrosion. These coatings not only protect the fittings from environmental damage but also ensure that they remain compliant with stringent environmental and safety regulations. The corrosion-resistant feature makes these fittings suitable for various harsh environments, including outdoor applications and systems exposed to moisture or chemicals, ensuring long-lasting durability and minimal maintenance needs.

Compatibility and Application Scope

The 43 Series Crimp Fittings offer broad compatibility across a variety of hose types, making them a versatile and practical choice for hydraulic systems in multiple industries. Engineered to integrate seamlessly with various standard hoses, these fittings support both single and double-braided hydraulic hoses, as well as spiral and thermoplastic options that meet industry standards such as SAE and DIN. This versatility allows users to choose the best hose for their specific application, providing a flexible solution for professionals and reducing the need for system overhauls when using different hose brands.

Hose Compatibility

Hoses Meeting Industry Standards

The 43 Series fittings are designed to work with hoses that conform to widely accepted standards like SAE and DIN, offering secure connections without the need for additional customization. This flexibility allows these fittings to be integrated into existing systems effortlessly.

Wide Range of Hose Types

These fittings can be used with various types of hoses, including braided and spiral hoses, which are common in high-pressure hydraulic systems, as well as thermoplastic hoses that offer flexibility and resilience under challenging conditions. This adaptability ensures that users can choose the most appropriate hose type for their operational needs, enhancing the efficiency and reliability of the hydraulic system.

Applications

Industry Applications

The adaptability and robust construction of the 43 Series Crimp Fittings make them suitable for diverse applications across multiple industries. Their ability to provide strong, leak-free connections ensures optimal hydraulic performance and system reliability in several key areas:

Hydraulic Systems

In hydraulic power units (HPUs) and other hydraulic applications, these fittings are used to create secure, high-pressure connections that maintain efficient fluid flow. They are ideal for applications where constant pressure and reliable performance are critical, such as in manufacturing and industrial processing.

Industrial Machinery

Industrial equipment like presses, molding machines, and automation systems depend heavily on hydraulic power. The 43 Series fittings are designed to withstand the vibrations and continuous operation inherent in these machines, ensuring uninterrupted performance and reducing downtime caused by hydraulic failures.

Construction Equipment

Construction machinery, including excavators, loaders, and cranes, operates in demanding environments where exposure to dirt, extreme temperatures, and heavy mechanical loads is common. The 43 Series Crimp Fittings are designed to handle these conditions, providing durable, corrosion-resistant solutions that enhance the safety and efficiency of construction equipment.

Agriculture

In agriculture, hydraulic systems are widely used for machinery like tractors, harvesters, and sprayers. These machines often function in harsh outdoor environments, requiring fittings that can handle frequent movement, dirt, and exposure to elements. The 43 Series fittings, compatible with fluids such as phosphate-ester and petroleum-based options, provide reliable, leak-free connections that support efficient operation in these demanding conditions.

Types of Fluids Compatible

The versatility of the 43 Series Crimp Fittings extends beyond just hose compatibility; they are also engineered to work with a broad spectrum of hydraulic fluids, ensuring they meet the requirements of various applications:

Petroleum-Based Fluids

These are the most common types of fluids used in hydraulic systems due to their lubrication properties and thermal stability. The 43 Series fittings are designed to work seamlessly with petroleum-based oils, making them ideal for a wide array of standard hydraulic applications across different industries.

Phosphate Ester Fluids

In applications where fire resistance is critical, such as aviation or heavy industrial machinery, phosphate ester fluids are often used. The 43 Series fittings are compatible with these fluids, ensuring safety and high performance in systems where minimizing fire risk is essential.

Synthetic Oils

Synthetic hydraulic fluids, known for their temperature resistance and biodegradability, are also compatible with the 43 Series fittings. These fluids are often chosen for environmentally sensitive applications and systems operating under extreme temperature variations, providing additional flexibility for users.

Water-Glycol Fluids

For applications that prioritize environmental safety and non-toxicity, water-glycol fluids are a popular choice. The 43 Series fittings support the use of these fluids, ensuring compatibility with systems designed to reduce environmental impact or operate in areas with stringent safety regulations.

Technical Specifications of the 43 Series

Size Range

The 43 Series fittings come in a comprehensive range of sizes, typically from ¼ inch to 2 inches in diameter. This size variety allows the fittings to be used across a wide array of hydraulic systems, accommodating different hose types and system requirements. Smaller sizes are often ideal for applications requiring precision, such as compact industrial equipment or light machinery, while larger sizes are suited for high-flow systems found in construction and agricultural machinery.

Material Options

To meet the demands of various operating environments, the 43 Series fittings are available in two primary material options:

Carbon Steel

Carbon steel is the standard material for the 43 Series Crimp Fittings. It offers a balance of strength and durability, making it ideal for general industrial use where the environment is less corrosive. Carbon steel provides the robustness needed to handle high pressures and dynamic loads in hydraulic systems, ensuring long-term performance in typical conditions like factory settings or controlled outdoor environments.

Stainless Steel

For applications in highly corrosive environments or where the fittings will be exposed to harsh chemicals, the 43 Series offers stainless steel options. Stainless steel provides superior corrosion resistance, making it suitable for use in marine settings, offshore applications, and areas where exposure to chemicals, saltwater, or other corrosive substances is a concern. This material option ensures that the fittings maintain their integrity and performance over an extended period, even in aggressive environments.

Thread Types

The 43 Series Crimp Fittings are available in various thread types, allowing them to integrate seamlessly with a wide range of systems and hoses. The most common thread types include:

NPT (National Pipe Thread): NPT threads are widely used in North America and are often found in general-purpose hydraulic applications. These threads are designed for pressure-tight sealing and are a staple for many standard hydraulic systems.

BSP (British Standard Pipe): Commonly used in Europe and other regions, BSP threads are essential for compatibility with hydraulic systems outside of North America. The availability of BSP threads ensures that the 43 Series fittings can be integrated globally, offering flexibility for multinational operations.

JIC (Joint Industry Council): JIC threads provide a flare connection commonly used in high-pressure applications. They are known for their reliability and ease of assembly, making them suitable for equipment like construction machinery and industrial hydraulics.

Metric and Other Specialized Threads: The 43 Series also supports metric threads and other specialized thread types, ensuring compatibility with specific regional and industry standards.

The diversity in thread options means that users can select the appropriate fitting type for their hydraulic systems without worrying about compatibility issues, allowing for streamlined maintenance and installation.

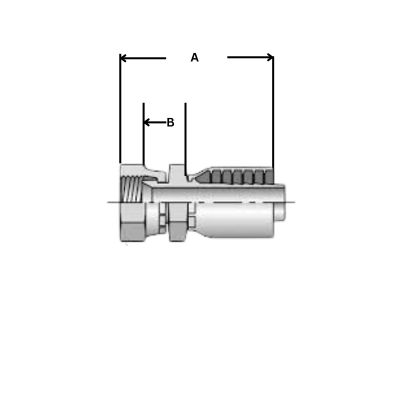

Configurations

The 43 Series Crimp Fittings are available in over 2,500 configurations, offering an extensive range of options to suit nearly any hydraulic application. These configurations include various shapes, orientations, and end types, allowing for maximum flexibility and adaptability in complex hydraulic systems. Some of the most common configurations include:

Straight Fittings: These are ideal for straightforward, linear connections, often used in systems where space is not a constraint and a simple, direct flow path is required.

Elbow Fittings (45° and 90°): Elbow fittings are designed for situations where hoses need to navigate tight spaces or change direction sharply. These configurations are essential for fitting hoses into compact machinery or equipment with limited clearance.

Tee and Cross Fittings: These are used in systems that require multiple branch connections. Tee fittings allow for fluid flow to split into two paths, while cross fittings facilitate four-way connections. Such configurations are often employed in complex machinery or systems that distribute hydraulic power to multiple components.

Flange Fittings: For high-pressure or large-diameter applications, flange fittings are used to secure hoses and fittings securely. These are typically found in heavy industrial and construction equipment, where maintaining a strong, leak-proof connection is critical.

Specific Applications

The wide array of configurations and thread types available in the 43 Series Crimp Fittings allows for their use in various applications:

High-Pressure Systems: The strong grip provided by the “bite-the-wire” technology and robust material options ensure that these fittings can handle high-pressure hydraulic systems, such as those used in heavy construction machinery.

Compact and Mobile Equipment: With options for smaller sizes and various elbow configurations, the 43 Series is suitable for compact equipment like forklifts and mobile hydraulic systems that require space-efficient routing.

Corrosive and Extreme Environments: Stainless steel versions provide the durability needed in corrosive environments like offshore rigs, marine applications, or chemical processing plants, where exposure to harsh substances is common.

Comparing 43 Series with Other Parker Fitting Series

Comparison with 71 Series

The 71 Series fittings differ from the 43 Series primarily in material use and targeted applications:

Material Use

The 71 Series fittings are typically designed for high-pressure and extreme applications, using more robust materials like stainless steel and higher-grade alloys, which offer increased resistance to stress and environmental factors.

The 43 Series, while also available in stainless steel for corrosion resistance, offers a broader range of standard materials such as carbon steel, making it more versatile for general applications.

Applications

The 71 Series is more commonly used in applications demanding higher pressure ratings, such as heavy industrial machinery, oil and gas, and mobile hydraulic systems operating under severe conditions.

In contrast, the 43 Series is designed for a wider range of uses, including hydraulic systems in construction equipment, agriculture, and general industrial machinery. It balances cost-effectiveness and performance, making it an ideal choice for less extreme but still demanding conditions.

Comparison with 56 Series

The 56 Series fittings are another popular option, but they differ in several ways from the 43 Series:

Assembly and Installation

The 56 Series requires more specific tools and assembly techniques, which may not be as accessible to all users. This series typically involves skiving for certain applications, which can increase installation time and the likelihood of assembly errors if not done correctly.

The 43 Series, with its no-skive technology, allows for a quicker and simpler installation process, making it easier to achieve a secure connection without the need for specialized tools. This feature makes the 43 Series a preferred choice for those seeking a streamlined installation process without compromising system integrity.

Versatility and Applications

The 56 Series fittings are more specialized and targeted at systems that involve very high temperatures and pressures, which can limit their general use.

On the other hand, the 43 Series is designed to offer broad compatibility with various hydraulic hoses and systems, including those requiring high-pressure performance as well as those in general industrial applications. Its flexibility makes it an advantageous option for a wide range of equipment and conditions, without the need for additional adaptations.

How to Choose the Right Fitting Series

When selecting the right fitting series for a specific application, several factors should be considered:

Application Environment

Corrosive Environments: If the fitting will be exposed to corrosive substances or harsh weather conditions, stainless steel versions of the 43 or 71 Series would be appropriate due to their enhanced resistance. The 43 Series offers flexibility, while the 71 Series is ideal for extreme conditions.

General Industrial Use: For standard industrial or construction equipment applications, the 43 Series is a cost-effective and reliable option due to its broad compatibility and ease of assembly.

Pressure and Temperature Requirements

Systems operating under very high pressures and temperatures may benefit from the additional robustness of the 71 Series or the specialized construction of the 56 Series.

For systems requiring constant high pressure but not at extreme levels, the 43 Series provides a good balance of performance and durability, making it suitable for most moderate to high-pressure systems.

Ease of Installation

Users seeking a straightforward, no-skive installation process should consider the 43 Series. Its design simplifies assembly and reduces potential errors, which is beneficial for maintenance teams looking to maximize efficiency and minimize downtime.

If the application involves a highly technical setup or the availability of specialized tools is not an issue, the 56 or 71 Series may be used, as they are designed to handle more extreme conditions.

Conclusion

The 43 Series Crimp Fittings offer unmatched versatility and reliability, making them a top choice for various hydraulic applications. Their no-skive technology simplifies installation, ensuring efficient and error-free assembly, while the “bite-the-wire” design provides secure, leak-free connections even under high pressure. With options in carbon and stainless steel, these fittings are suitable for diverse environments, from industrial machinery to agriculture. The extensive size range and compatibility with multiple hose types make them a flexible, durable, and cost-effective solution. Consider the 43 Series for dependable performance and ease of use in your hydraulic systems.

FAQ

What are 43 Series Crimp Fittings used for?

They are used for creating secure, leak-free connections in hydraulic systems across various industries, such as construction, agriculture, and industrial machinery.

Are the 43 Series Crimp Fittings compatible with different hoses?

Yes, they are compatible with multiple hose types, including those meeting SAE and DIN standards.

What materials are available for the 43 Series Crimp Fittings?

They are available in carbon steel and stainless steel for enhanced corrosion resistance.

What is the size range for the 43 Series Crimp Fittings?

The fittings are available in sizes ranging from ¼ inch to 2 inches.

Do 43 Series Crimp Fittings require skiving during installation?

No, they feature no-skive technology, allowing for quick and easy installation without removing the hose cover.

What thread types are available in the 43 Series?

They come in various thread types, including NPT, BSP, and JIC, to suit different system requirements.