Introduction

Hydraulic systems are vital for many industries, but their efficiency is often hindered by incorrect hydraulic hose inner diameter selection. This can lead to insufficient flow, high pressure loss, and increased energy consumption. This guide explores the crucial link between hose inner diameter and fluid flow, offering hydraulic system designers and engineers strategies to boost system efficiency by up to 45% through optimized flow.

Fundamentals of Hydraulic Flow and Pressure

Hydraulic Flow Defined

Flow is the volume of hydraulic fluid moved through the system over time, typically measured in gallons per minute (GPM) or liters per minute (LPM).

Hydraulic Pressure Explained

Pressure is the force the fluid exerts per unit area (usually PSI or bar), resulting from resistance to the flow within the system.

Flow vs. Pressure Relationship

Flow creates pressure when it encounters resistance; likewise, pressure is required to overcome that resistance and maintain flow continuity.

Power Transmission Principle

In hydraulic systems, effective power transmission relies on the right balance of flow and pressure to move actuators efficiently.

Impact of Hose Sizing

Undersized hoses increase resistance, reduce flow, and generate excessive pressure drops, leading to power loss and heat buildup.

System Efficiency Focus

An efficient hydraulic system minimizes energy losses during fluid transmission from pump to actuator by optimizing both flow and pressure pathways.

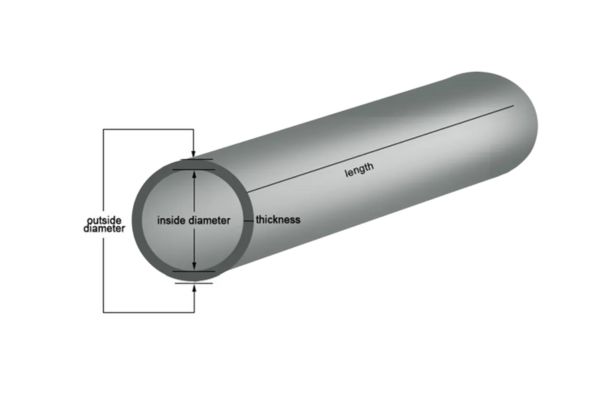

The Critical Role of Inner Diameter

The inner diameter (ID) of a hydraulic hose plays a vital role in determining the efficiency and performance of a hydraulic system. It directly affects the cross-sectional area through which fluid flows, influencing flow rate, velocity, and pressure loss. A larger inner diameter reduces flow resistance and minimizes pressure drop, while a smaller inner diameter increases fluid velocity but can lead to excessive energy loss and heat generation. Choosing the correct hose ID is not just about meeting minimum flow requirements — it’s about optimizing fluid dynamics to ensure smooth, energy-efficient power transmission with minimal system strain.

Understanding Pressure Loss in Hydraulic Hoses

Pressure loss, or pressure drop, is an inevitable consequence of fluid flowing through a conduit. In hydraulic hoses, this loss is primarily due to friction between the fluid and the hose”s inner wall, as well as turbulence within the fluid itself. Several factors contribute to pressure loss:

- FluidViscosity: Thicker fluids (higher viscosity) create more internal friction and thus higher pressure loss.

- Hose Length: Longer hoses result in greater cumulative friction and therefore higher pressure loss.

- Hose Roughness: The internal surface roughness of the hose contributes to frictional resistance.

- Flow Velocity: As fluid velocity increases, so does the energy lost due to friction and turbulence. This relationship is often non-linear, with turbulent flow causing significantly higher pressure losses than laminar flow.

- Inner Diameter: This is where inner diameter plays a pivotal role. For a given flow rate, a smaller inner diameter necessitates a higher fluid velocity. This increased velocity, in turn, leads to a disproportionately higher pressure loss due to increased friction and turbulence. Conversely, a larger inner diameter allows for lower fluid velocities, significantly reducing pressure drop and conserving energy.

The Darcy-Weisbach equation is a fundamental formula used to calculate pressure loss due to friction in a pipe or hose:

ΔP = f * (L/D) * (ρv²/2)

Where:

ΔP = Pressure loss

f = Darcy friction factor (dimensionless, depends on Reynolds number and relative roughness)

L = Length of the hose

D = Inner diameter of the hose

ρ = Fluid density

v = Fluid velocity

This equation clearly illustrates the inverse relationship between pressure loss and inner diameter (D). A larger D directly reduces pressure loss, highlighting the importance of proper sizing.

Flow Characteristics of Different Inner Diameter Hoses

The flow characteristics of hydraulic hoses vary significantly with their inner diameter. To achieve optimal system performance, it”s crucial to select an inner diameter that allows for efficient fluid velocity, minimizing pressure drop while accommodating the required flow rate. The ideal fluid velocity in hydraulic lines is typically recommended to be within certain ranges to prevent excessive pressure drop, heat generation, and noise, while also ensuring adequate power transmission. Below is a simplified table illustrating typical recommended maximum flow rates for various hose inner diameters in pressure lines. These values are general guidelines and can vary based on specific fluid types, system pressures, and application requirements.

Note: These values are approximate and for illustrative purposes only. Actual performance will depend on specific hose construction, fluid properties, and system design. Always consult manufacturer”s data for precise specifications.

Impact of Improper Hose Sizing: Common Pain Points

Improper hydraulic hose sizing is a pervasive issue that leads to a cascade of problems, directly impacting system performance, longevity, and operational costs. Hydraulic system designers and performance optimization engineers frequently encounter these pain points:

Undersized Hoses

Insufficient Flow and Reduced System Speed: When the hose ID is too small for the required flow rate, the fluid velocity becomes excessively high. This restricts the volume of fluid that can pass through, leading to sluggish actuator movement and overall reduced system speed. The machinery operates below its design capacity, impacting productivity.

- Excessive Pressure Loss: High fluid velocity in undersized hoses dramatically increases frictional losses and turbulence. This translates directly into a significant pressure drop along the hose length. The pump has to work harder to maintain the desired pressure at the actuator, leading to wasted energy.

- Increased Heat Generation: The energy lost due to friction and turbulence is converted into heat. This excessive heat can degrade the hydraulic fluid, reducing its viscosity and lubricating properties, and accelerating the wear of seals and other components. Overheating is a major cause of hydraulic system failures.

- Higher Energy Consumption and Operating Costs: To compensate for pressure losses and maintain performance, the hydraulic pump consumes more power. This directly translates to higher electricity bills and increased fuel consumption for mobile equipment, driving up operational costs.

- Noise and Vibration: Turbulent flow and high fluid velocities can generate excessive noise and vibration within the hydraulic system, indicating inefficient operation and potentially leading to component fatigue.

Oversized Hoses

While less detrimental than undersizing, using hoses with an excessively large inner diameter also presents challenges:

- Increased Cost: Larger hoses are inherently more expensive due to increased material usage. This adds unnecessary capital expenditure to the system.

- Installation Challenges: Larger hoses are less flexible and require more space for routing, making installation more difficult and potentially increasing labor costs.

- Sluggish Response (in some cases): In certain dynamic systems, an overly large hose can lead to a slight delay in response due to the larger volume of fluid that needs to be moved or pressurized. However, this is generally less critical than the issues caused by undersizing.

Strategies for Optimizing Hydraulic System Efficiency through Hose Selection

Optimizing hydraulic system efficiency, particularly achieving that 45% improvement in flow, begins with a meticulous approach to hose inner diameter selection. This involves balancing technical requirements with practical considerations to ensure peak performance and longevity. Here are key strategies:

A. Calculate Required Flow Velocity

The first step is to determine the ideal fluid velocity for each section of the hydraulic circuit. Different parts of the system (suction lines, pressure lines, return lines) have different recommended velocity ranges. For instance, suction lines typically require lower velocities to prevent cavitation, while pressure lines can handle higher velocities but must be balanced against pressure drop considerations.

Pressure Lines: Generally, 15-20 ft/s (4.5-6 m/s)

Return Lines: Generally, 10-15 ft/s (3-4.5 m/s)

Suction Lines: Generally, 2-4 ft/s (0.6-1.2 m/s)

Use the following formula to relate flow rate, velocity, and inner diameter:

Q = A * v

Where:

Q = Flow rate (e.g., GPM or L/min)

A = Cross-sectional area of the hose (π * (ID/2)²)

v = Fluid velocity

Rearranging for ID:

ID = √( (4 * Q) / (π * v) )

Ensure consistent units for accurate calculation.

B. Consult Manufacturer”s Data and Standards

Always refer to the hydraulic hose manufacturer”s technical specifications and recommended flow charts. These resources provide precise data for their products, including pressure ratings, temperature ranges, and flow characteristics for various inner diameters. Adhere to industry standards (e.g., SAE, ISO) that often provide guidelines for hose sizing based on application and pressure.

C. Consider System Pressure and Fluid Type

Higher system pressures often necessitate hoses with stronger reinforcement, but the inner diameter selection remains crucial for flow efficiency. The type of hydraulic fluid (e.g., mineral oil, synthetic, water-glycol) also influences viscosity and, consequently, pressure drop. Account for these factors in your calculations and selections.

- Mineral Oil-Based Hydraulic Fluid: Most widely used; good lubricity and cost-effective.

- Synthetic Hydraulic Fluid: Engineered for extreme temperatures or fire resistance (e.g., phosphate esters, PAOs).

- Water-Glycol Based Fluid: Fire-resistant and used in applications with high ignition risk; lower lubrication properties.

- Water-Oil Emulsions: Mixture of water and oil; used in mining and steel industries for fire resistance.

- Biodegradable Hydraulic Fluid: Derived from vegetable oils or synthetic esters; used in environmentally sensitive areas.

D. Minimize Bends and Optimize Routing

While not directly related to inner diameter, minimizing sharp bends and optimizing hose routing can significantly reduce localized pressure losses and turbulence, thereby complementing the benefits of correct ID selection. Each bend adds resistance, so a well-routed system enhances overall flow efficiency.

E. Account for Hose Length

Longer hoses inherently lead to greater pressure drops. If a long hose run is unavoidable, consider increasing the inner diameter slightly to compensate for the increased frictional losses over distance. This is a critical aspect of hydraulic hose sizing for efficiency.

F. Conduct System Audits and Performance Monitoring

For existing systems, conduct regular audits to assess actual flow rates, pressure drops, and energy consumption. Utilize flow meters and pressure gauges to gather real-world data. This data can reveal inefficiencies and guide re-sizing efforts. Performance monitoring helps identify deviations from optimal operation, allowing for timely adjustments and hydraulic system optimization.

G. Leverage Simulation and Modeling Tools

Advanced hydraulic system design software can simulate fluid flow and predict pressure drops for various hose configurations. These tools can be invaluable for complex systems, allowing engineers to virtually test different inner diameter options and optimize the design before physical implementation.

H. Consider Total Cost of Ownership (TCO)

While larger hoses might have a higher initial cost, the long-term savings from reduced energy consumption, extended component lifespan, and minimized downtime due to optimized flow often far outweigh the initial investment. Focus on the total cost of ownership rather than just the upfront purchase price when making sizing decisions.

Conclusion

Achieving up to 45% greater hydraulic system efficiency hinges on correctly selecting hose inner diameter. By understanding the relationship between inner diameter, flow, and pressure loss, and applying strategic sizing, engineers can significantly boost performance, cut energy use, and extend component life. Prioritizing proper hose sizing is a strategic investment in reliability and profitability.

Ready to change the efficiency of your hydraulic system? Our team of expert hydraulic optimization consultants offers customized procurement services. Contact us today for personalized consulting services and take the first step toward a more efficient and cost-effective hydraulic system.

FAQ

What happens if my hydraulic hose is too small?

An undersized hydraulic hose leads to excessive fluid velocity, high pressure loss, increased heat generation, reduced system speed, and higher energy consumption.

How does hose inner diameter affect system efficiency?

The correct hose inner diameter minimizes pressure drop and heat generation, allowing the hydraulic system to transmit power more efficiently and reduce energy waste.

Can I use a larger hose than recommended?

While less harmful than an undersized hose, an oversized hose can increase initial costs, make installation more challenging, and in some dynamic systems, lead to slightly sluggish response.

How often should I check my hydraulic hoses for optimal flow?

Regular system audits and performance monitoring, including checking flow rates and pressure drops, are recommended to ensure continuous optimal flow and efficiency.

What is the ideal fluid velocity for hydraulic pressure lines?

The ideal fluid velocity for hydraulic pressure lines is generally between 15-20 feet per second (4.5-6 meters per second) to balance flow and minimize pressure drop.

How does hose length impact hydraulic performance?

Longer hoses increase frictional losses, resulting in greater pressure drops and reduced efficiency, which may require upsizing the inner diameter to maintain proper flow.

References

[1] Machinery Lubrication. (n.d.). Hydraulic Pressure vs. Flow: Understanding the Difference.

[2] Dultmeier Sales. Fluid Flow & Pressure Loss through Hose. Retrieved from

[3] Gates Corporation. (n.d.). Pressure Drop. Retrieved from