How to Measure SAE Fitting: Step-by-Step Guide

Introduction

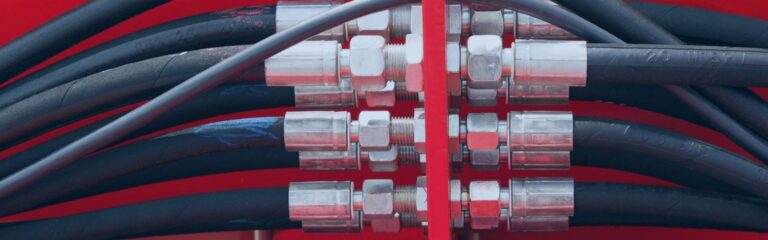

There are several types of SAE fittings, including SAE J512, which is commonly used in automotive and refrigeration systems, and SAE J514, which is commonly used in hydraulics. each type has specific characteristics and applications. The purpose of this guide is to provide a comprehensive, step-by-step approach to accurately measuring SAE fittings. Accurate measurements are critical to ensure proper fitting selection, compatibility, and system integrity, ultimately improving the efficiency and longevity of your hydraulic system.

Understanding SAE Fittings

Definition and Characteristics of SAE Fittings

SAE fittings are standardized connectors established by the Society of Automotive Engineers. SAE fittings are characterized by their precision engineering, which allows them to maintain high performance under varying pressures and temperatures. They are made from robust materials like stainless steel, carbon steel, and brass, which provide durability and resistance to corrosion. The key characteristics of SAE fittings include their specific thread types, sealing methods, and dimensional standards, which ensure compatibility and interchangeability across different hydraulic systems and components.

SAE J512

SAE J512 fittings are widely used in the automotive and refrigeration industries. These fittings are designed for low and medium-pressure applications and are available in flared and inverted flared connection designs. In automotive systems, SAE J512 fittings are used in fuel lines, brake lines, and drivelines to provide secure, leak-proof connections. In refrigeration systems, these fittings are essential for connecting various components such as compressors, evaporators, and condensers to ensure efficient and reliable operation.

SAE J514

SAE J514 fittings are primarily used in hydraulic systems because of their ability to withstand high-pressure environments. These fittings include a variety of connection types, such as straight thread, tapered thread, and four-bolt flange connections. sae j514 fittings are critical in heavy machinery, industrial equipment, and mobile hydraulic applications to ensure the safe and efficient delivery of hydraulic fluid. The design of these fittings includes metal-to-metal or elastomeric seals that provide a reliable barrier against leakage. SAE J514 fittings are ruggedly constructed and precision threaded for demanding hydraulic applications to ensure system life and performance.

SAE J1453

SAE J1453, commonly known as O-Ring Face Seal (ORFS) fittings, are designed for high-pressure hydraulic applications where leak prevention is critical. ORFS fittings feature a flat face and an O-ring seal, which provides a superior seal compared to traditional metal-to-metal contact. This design significantly reduces the risk of leaks, even under high-pressure conditions, making ORFS fittings ideal for use in hydraulic systems exposed to extreme pressures and vibrations. Applications for SAE J1453 fittings include heavy construction equipment, agricultural machinery, and industrial hydraulic systems. The O-ring seal ensures a tight connection, minimizing downtime and maintenance costs associated with hydraulic fluid leaks.

Differences Between SAE Fittings and Other Standard Fittings

NPT Hydraulic Fittings

NPT fittings, standardized under ANSI/ASME B1.20.1, utilize tapered threads to create a seal as they are screwed together, often requiring thread sealant to enhance the seal. Commonly used in plumbing, gas lines, and low-pressure fluid transfer applications, NPT fittings are known for their simple design and ease of use in low to medium-pressure environments. Unlike SAE fittings, which use straight threads and various sealing mechanisms like O-rings, NPT fittings rely on thread interference for sealing, making them distinct in design and function.

BSP Fittings

BSP fittings, standardized under BS 21 and ISO 228, come in two thread types: BSPT (tapered) and BSPP (parallel). These fittings are commonly used in plumbing and hydraulic systems, particularly in Europe and other regions. BSPT fittings create a seal using thread taper, while BSPP fittings require a washer or O-ring for sealing. With a 55° thread angle, BSP threads differ from SAE threads, which have a 60° angle. Additionally, BSP threads include both tapered (BSPT) and parallel (BSPP) designs, whereas SAE fittings typically use straight threads. BSP fittings are widely used internationally and are versatile for various applications.

Metric Fittings

Metric fittings, standardized under ISO 261 and ISO 262, use metric threads (M) measured in millimeters for pitch and diameter. Commonly applied in international hydraulic systems, automotive, and machinery, these fittings often utilize O-rings or bonded seals for sealing. The metric system’s ease of integration and international standardization offer significant advantages. Unlike SAE fittings, which use inches for thread measurement, metric fittings rely on millimeters. Additionally, while metric fittings share some sealing methods with SAE fittings, such as O-rings, they differ from NPT and BSPT fittings, which use thread interference for sealing.

Feature | SAE | JIC | NPT | BSP | Metric |

Thread Type | UN/UNF | UN/UNF | Tapered | Tapered(BSPT), | Metric(M) |

Common | Automotive, | Hydraulic | Plumbing, | Plumbing, | International |

Sealing | Metal-to- | 37°flare | Tapered | Tapered | O-rings, |

Thread | 60° | 37°flare | 60° | 55° | Varies |

Advantages | High reliability, | High | Simple, | Widely used | International |

Step-by-Step Guide

Outer Diameter of the Fitting

Tools Needed:

Calipers (digital or vernier)

Clean cloth or brush

Steps:

Clean the Fitting: Before measuring, ensure that the fitting is clean and free from any debris or corrosion. Use a clean cloth or brush to remove any dirt or residues that might affect the measurement.

Zero the Calipers: If using digital calipers, ensure they are zeroed before measuring. For vernier calipers, ensure they are correctly set to zero.

Position the Calipers: Open the calipers and place them around the outermost part of the fitting’s diameter. Ensure the calipers are perpendicular to the fitting to avoid angled measurements, which can result in inaccuracies.

Measure the Diameter: Gently close the calipers until they touch the fitting’s surface without compressing it. Read the measurement displayed on the digital calipers or from the vernier scale. Record the outer diameter.

Verify the Measurement: Repeat the measurement process a few times to ensure consistency. If the measurements vary, average them to get a reliable diameter.

Length of the Fitting

Tools Needed:

Measuring tape or ruler

Calipers (for smaller fittings)

Steps:

Prepare the Fitting: As with the diameter measurement, ensure the fitting is clean and free from debris.

Select the Measuring Tool: Use a measuring tape for larger fittings or calipers for smaller fittings.

Measure the Length: Place the measuring tool along the length of the fitting, starting from one end to the other. Ensure the measuring tape or ruler is straight and not bent, as this can lead to inaccuracies.

Record the Measurement: Note the length indicated on the measuring tool. For smaller fittings, use calipers for a more precise measurement by placing the jaws at the two ends of the fitting.

Repeat for Accuracy: Measure the length multiple times to ensure accuracy and record the most consistent measurement.

Flare Angle Measurement (If Applicable)

Tools Needed:

Flare gauge or protractor

Calipers (for measuring reference points)

Steps:

Identify the Flare Angle: Determine if the fitting has a flare angle. Common flare angles are 37° (AN/JIC fittings) and 45° (SAE fittings).

Use a Flare Gauge: Place the flare gauge against the fitting’s flare to check the angle. Ensure the gauge is properly aligned with the flare surface.

Measure with a Protractor: If a flare gauge is not available, use a protractor. Place the fitting on a flat surface and align the protractor’s center with the fitting’s center. Measure the angle by aligning the protractor’s baseline with the fitting’s flare surface.

Record the Angle: Note the flare angle measured. Verify the angle by measuring at different points around the flare to ensure uniformity.

Confirm Accuracy: Double-check the flare angle by comparing it with standard flare angles for SAE fittings to confirm it matches the expected angle.

Examine the Threads

Once cleaned, closely examine the threads to identify the type of thread. SAE fittings typically use UN (Unified National) or UNF (Unified National Fine) threads. The type of thread can often be determined by the appearance and feel of the threads, but for precise identification, you may refer to thread charts or standards.

Unified National Fine (UNF)

UNF threads have a finer pitch, meaning the threads are closer together compared to UNC threads. This results in more threads per inch (TPI). UNF threads are available across a range of diameters, typically from small to medium sizes. The finer threads provide a greater surface area in contact with the mating part, which can offer a stronger and more secure hold.

Unified National Coarse (UNC)

UNC threads have a coarser pitch, meaning the threads are spaced further apart compared to UNF threads. This results in fewer threads per inch (TPI). UNC threads are also available in a wide range of diameters, typically from small to large sizes. The coarser threads make UNC fasteners easier to assemble and disassemble, even in less-than-ideal conditions.

Thread Pitch Measurement

Select the Thread Gauge

Thread pitch gauges come with multiple blades, each marked with different pitch values. Select a thread pitch gauge that corresponds to the type of threads you are measuring (UN or UNF). Ensure that the gauge covers the range of thread pitches you might encounter in SAE fittings.

Match the Threads

Take the thread pitch gauge and place one of its blades against the threads of the fitting. Ensure that the blade is aligned with the threads, making full contact along the entire length of the threads.

Slide the blade gently along the threads to see if it matches perfectly. If it does not, try the next blade on the gauge until you find one that fits precisely. The correct blade will nestle perfectly into the threads without any gaps or rocking.

Confirm the Match: A perfect match means that the blade’s teeth align exactly with the thread grooves on the fitting. The gauge should fit snugly into the threads without forcing it.

Read the Pitch

Once you find the blade that matches the threads, look at the markings on the thread pitch gauge. The blade will have a pitch value indicated, usually in threads per inch (TPI) for SAE threads.

Note the pitch value. This value represents the number of threads per inch and is critical for ensuring you have the correct thread specifications for replacement or compatibility checks.

Identifying Thread Types and Sizes

Accurately identifying thread types and sizes is essential for ensuring proper fit and function in hydraulic systems. SAE (Society of Automotive Engineers) fittings commonly use Unified National (UN) and Unified National Fine (UNF) thread types. This section explains these thread types and provides a detailed guide on how to identify thread type and size using thread gauges, understanding thread pitch, and determining thread diameter.

Troubleshooting Common Issues

Accurately measuring SAE fittings is crucial for ensuring the proper fit and function of hydraulic systems. However, several common problems can arise during the measurement process. This section highlights these issues and provides solutions and tips for troubleshooting them.

Incorrect Thread Identification

Issue:

Misidentifying thread type (e.g., UNC vs. UNF) can lead to selecting the wrong fitting, causing leaks or mechanical failures.

Solution:

Clean the Threads: Ensure threads are clean before measuring. Debris can obscure the thread profile.

Use Correct Gauges: Use thread pitch gauges specifically designed for SAE threads. Verify the pitch using multiple gauges if necessary.

Consult Standards: Cross-reference your measurements with standard thread charts to confirm the thread type.

Inaccurate Measurements Due to Tool Errors

Issue:

Calipers, micrometers, and thread gauges can give inaccurate readings if they are not calibrated or used correctly.

Solution:

Calibrate Regularly: Ensure all measurement tools are regularly calibrated according to manufacturer specifications.

Use Quality Tools: Invest in high-quality measuring tools to minimize errors. Cheap tools can be prone to inaccuracies and wear out quickly.

Check Tool Condition: Inspect tools for damage or wear before use. Damaged tools can give false readings.

Misinterpretation of Measurement Data

Issue:

Incorrectly interpreting measurement data can lead to choosing the wrong fitting size or type.

Solution:

Double-Check Readings: Always take multiple measurements and compare them. Averaging multiple readings can help eliminate errors.

Cross-Reference: Use reference materials such as thread size charts and fitting catalogs to verify measurements.

Conclusion

This guide has detailed the process of measuring SAE fittings, covering the identification of thread types and sizes, and the specific methods for measuring internal and external dimensions. Accurate measurement is crucial for maintaining the integrity and performance of hydraulic systems, preventing leaks, and ensuring reliable operation. By practicing and refining your measurement skills, you can ensure proper fitting selection and compatibility. We encourage you to share this guide, and provide feedback.

FAQ

You will need calipers, thread pitch gauges, a measuring tape, and possibly a protractor for measuring flare angles.

Use a clean cloth or brush to remove any dirt, grease, or debris from the fitting’s threads and surfaces.

UNF (Unified National Fine) threads have a finer pitch with more threads per inch, while UNC (Unified National Coarse) threads have a coarser pitch with fewer threads per inch.

Use a thread pitch gauge by matching the threads on the fitting with the corresponding gauge blade until you find a perfect fit.

Ensure your tools are calibrated, measure multiple times, and average the results. Clean the fitting and tools before measuring.

Accurate measurements ensure proper fitting selection, prevent leaks, and maintain the performance and safety of hydraulic systems.