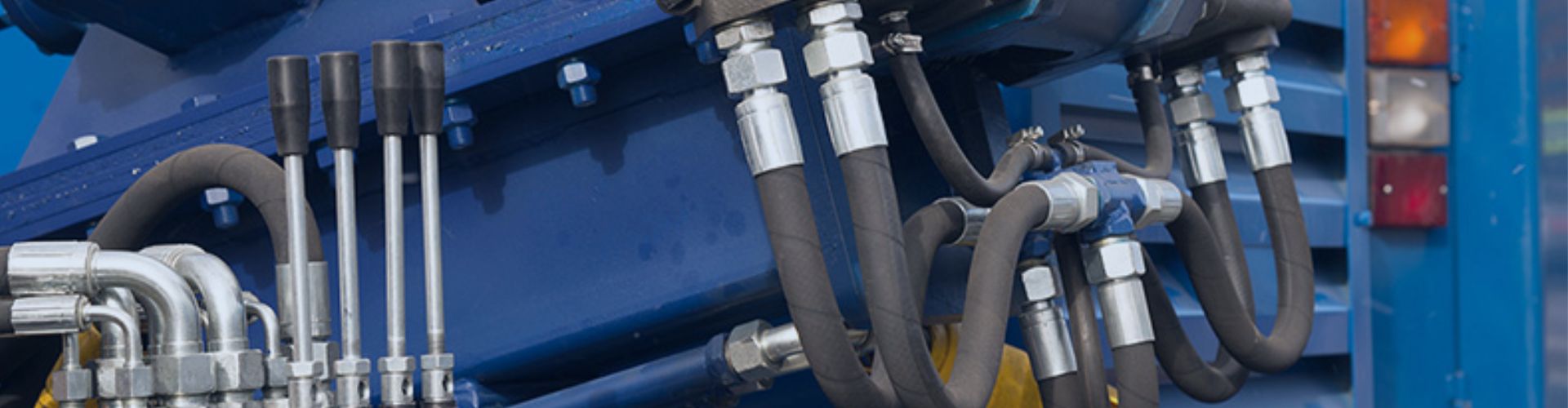

Your equipment vibrates intensely, shaking hydraulic fittings loose. This constant battle with leaks causes unplanned downtime, creates safety hazards, and erodes your confidence in the machine’s reliability.

Reusable fittings combat vibration by using a threaded two-piece design to mechanically compress and grip the hose’s wire braid. This strong, 360-degree mechanical lock resists the forces that try to loosen the connection.

What Defines a Reusable Hydraulic Fitting?

You need to repair a hydraulic hose in the field, far from a workshop. Using a permanent fitting isn’t an option, as you don’t have a large crimping machine.

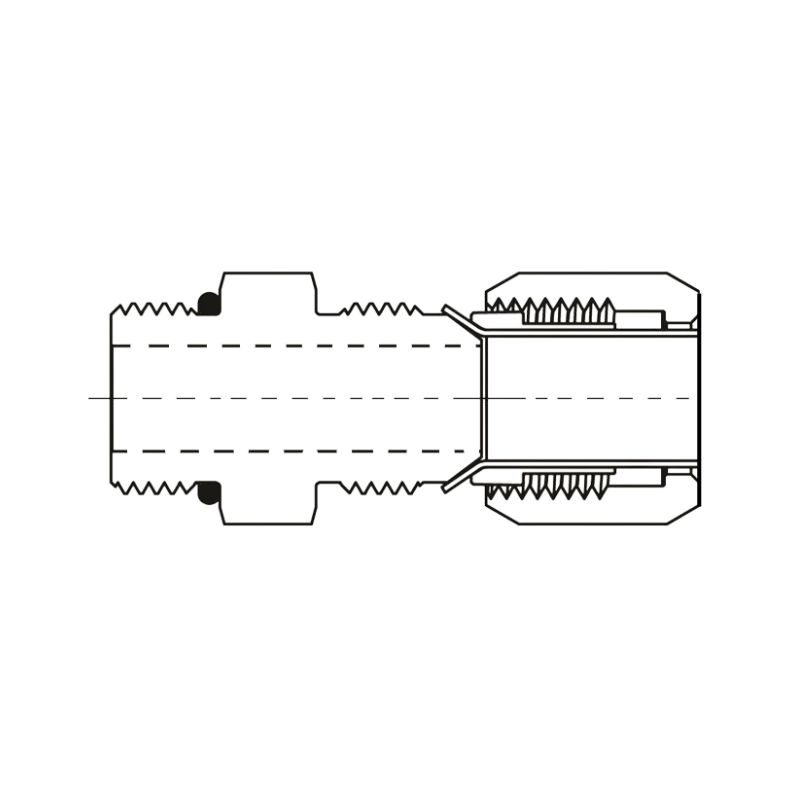

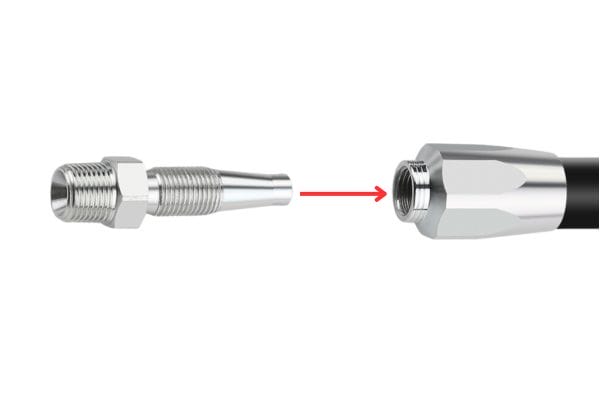

A reusable fitting, also called a field-attachable fitting, is a mechanical assembly that can be attached to a hydraulic hose using only basic hand tools. It consists of two main parts—a socket and a nipple—that thread together to create the seal.

The Core Mechanical Components

The design is simple but effective.

- The Socket: This is the outer piece with internal threads. It screws onto the outside of the hydraulic hose. For some hose types, it may require the outer rubber cover to be “skived” or removed first.

- The Nipple: This is the inner piece. It has a tapered thread on one end that screws into the socket. The other end has the standard fitting connector, such as a JIC or BSPP male or female end.

The Skive vs. No-Skive Designs

There are two primary categories of reusable fittings, defined by how they interact with the hose cover.

- Skive-Type: This design requires the user to peel away a section of the hose’s outer rubber cover to expose the steel wire braid. The fitting is designed to grip the wire braid directly, which can provide a very strong connection.

- No-Skive-Type: This is a more modern and user-friendly design. The internal threads of the socket are sharp and aggressive enough to bite through the rubber cover and engage the wire braid without a separate skiving step.

How Is the Vibration-Resistant Grip Created?

You see the threads, but the real magic is hidden. How does turning a wrench create a connection strong enough to withstand thousands of PSI and constant shaking?

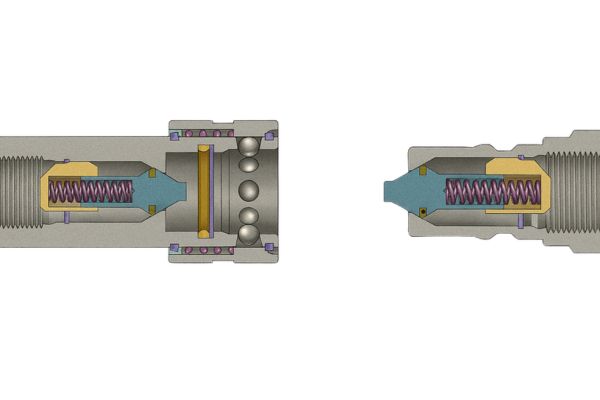

The vibration resistance comes from intense compression. As the nipple is threaded into the socket, its tapered threads force the hose material outward against the socket’s inner wall, creating an incredibly tight, 360-degree mechanical grip.

Think of it as a mechanical vise. The socket holds the outside of the hose, and the nipple acts as a wedge that screws into the middle, expanding the hose and locking it in place. The main gripping force is not on the soft rubber but on the high-tensile steel wire reinforcement within the hose. The fitting is specifically designed to engage with this strong inner core.

The Role of Tapered Threads

The threads on the nipple are not standard parallel threads. They are tapered, meaning they get wider along their length. As you tighten the nipple into the socket, this wedge-like action progressively squeezes the hose. The deeper you thread it, the tighter the compression becomes. This creates a secure, pre-loaded connection that actively resists being shaken loose.

Engaging Wire Reinforcement

A hydraulic hose gets its strength from its steel wire braid layers. The reusable fitting is engineered to leverage this. The sharp threads of the nipple and socket bite into the hose and anchor themselves to this wire. It’s no longer just a rubber connection; it’s a steel-on-steel grip, mediated by the hose itself. The rubber is compressed to create the seal, but the wire provides the mechanical strength to hold the fitting securely in place against end-pulls and vibration.

What Causes Reusable Fittings to Fail Under Vibration?

Your field-repaired hose assembly is leaking from the fitting. You used the right parts, so is the fitting itself faulty, or did something else go wrong?

The most common cause of failure is improper assembly, specifically incorrect tightening. If it’s too loose, it will leak and separate. If it’s overtightened, it can damage the hose’s wire reinforcement, leading to a failure under vibration.

While reusable fittings are robust, they are not foolproof. Their reliability is directly tied to the skill of the person assembling them. Unlike a hydraulic crimper that applies a measured, repeatable force every time, manual assembly introduces human variables. We always emphasize that following the correct procedure is not optional; it is essential for a safe and durable connection. Most failures we analyze are not due to a defect in the part, but rather an error in the assembly process. Understanding these common mistakes is the first step to preventing them.

Incorrect Assembly Torque

This is the number one issue.

- Under-tightening: If the nipple isn’t sufficiently tightened into the socket, the compression on the hose is inadequate. Vibration and pressure spikes can easily cause the fitting to weep fluid or, in a worst-case scenario, blow off the hose entirely.

- Over-tightening: Some believe “tighter is better,” but this is dangerous. Overtightening can cut or fracture the steel wire braids inside the hose. This weakens the hose’s structure right at the fitting, creating a focal point for failure when subjected to vibration.

Mismatched Hose and Fitting Components

Reusable fittings are designed as a matched system with specific hoses. Using a fitting designed for a 100R2AT hose on a 100R1AT hose, for example, will not work reliably. The dimensions and tolerances are different. The grip will be compromised, and the connection will not have the specified pressure rating or vibration resistance. Always verify that the fitting series matches the hose designation.

How Do Reusable Fittings Help Handle Vibrations?

Hydraulic systems face constant motion, shocks, and vibration. Over time, these forces can damage fittings and hoses — unless you use the right components. Reusable hydraulic fittings are uniquely built to survive vibration-prone environments. Let’s explore how.

Thread and Seal Design: The First Line of Defense Against Vibration

Reusable hydraulic fittings use durable, precisely engineered thread profiles and sealing mechanisms that are ideal for resisting vibration-induced failures.

Here are three common seal types used in vibration-resistant reusable fittings:

O-Rings

These are elastomer rings seated in a groove, providing a tight and flexible seal.

- Ideal for medium-pressure systems

- Compensate for minor movement or misalignment

- Common in ORFS (O-ring Face Seal) fittings

Double Ferrules

Two rings grip the hose and the fitting body, distributing force evenly.

- Excellent in high-pressure or heavy-vibration zones

- Prevent slippage

- Common in instrumentation and high-frequency vibration areas

Compression Sleeves

These compress onto the hose when tightened.

- Common in reusable hose barb fittings

- Provide basic vibration damping for lower-pressure use

These sealing systems are designed to absorb small vibrations before they translate into leaks or loosening. Unlike permanent fittings, reusable ones do not rely solely on crimp strength — instead, they leverage flexible seals and thread design to absorb movement.

Torque Adjustment and Retightening: Built for Maintenance Under Stress

One of the standout benefits of reusable fittings in high-vibration settings is that you can inspect, retighten, and reuse them without destroying the connection.

Here’s why that matters:

Re-tightening Capability

When vibration loosens threads, reusable fittings can simply be re-tightened with a wrench.

- No need for machine shop support

- Fast on-site adjustments

- No downtime for hose replacement

Easy Visual Inspection

Reusable fittings can be:

- Disconnected and checked for wear

- Cleaned and re-installed

- Inspected without cutting the hose

This makes them ideal for:

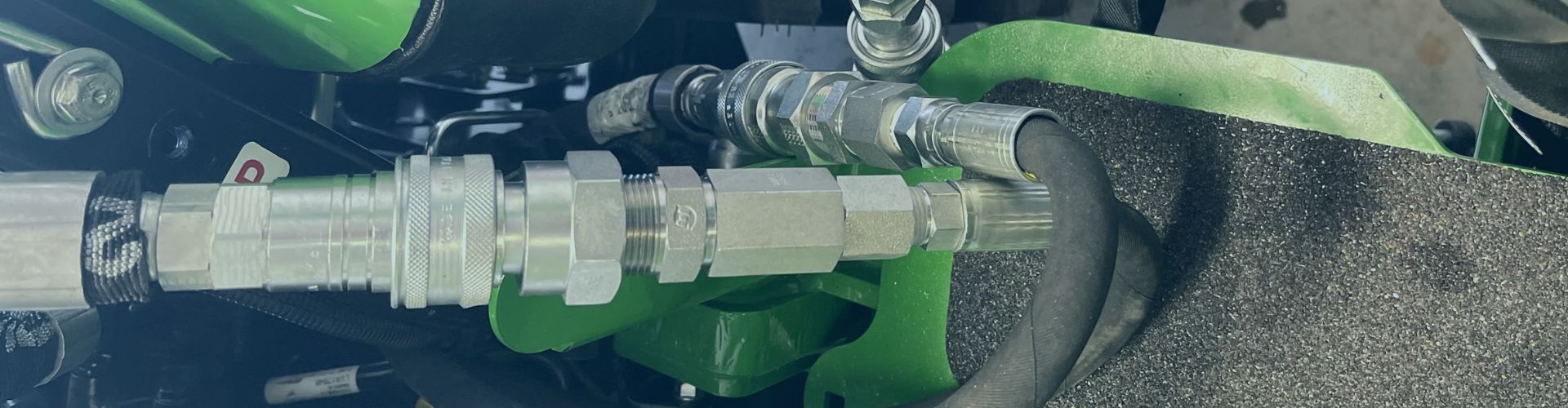

- Mobile equipment like excavators

- Factory floor systems exposed to 24/7 motion

- Marine hydraulics, where vibration and corrosion are both concerns

Flexible Hose Compatibility: Your Natural Vibration Dampener

Even the best fitting won’t survive long without a proper hose. Reusable fittings are typically used with flexible hydraulic hoses, which already act as shock absorbers in the system.

Common Hose Types Used with Reusable Fittings:

| Hose Type | Material | Vibration Resistance |

| Braided Rubber | Nitrile or EPDM | High |

| Thermoplastic | Nylon or Polyurethane | Medium–High |

| Spiral Reinforced | Synthetic rubber + steel | Very High |

Flexible hoses reduce:

- Sudden pressure spikes

- Oscillation transfer

- Hose whip (dangerous rebound)

The flexibility of the hose absorbs kinetic energy, sparing the fitting from repeated stress. This pairing makes reusable fittings the ideal choice for equipment exposed to cyclic or random vibration — like mobile cranes or industrial robots.

How Do They Compare to Crimp Fittings in High-Vibration Areas?

For a critical application on vibrating machinery, should you trust a field-attachable fitting, or is a permanent crimp fitting the only safe choice?

Crimp fittings generally offer superior and more consistent vibration resistance. A hydraulic crimper applies uniform, radial force to permanently deform a ferrule, creating a solid, one-piece assembly. A reusable fitting’s reliability depends entirely on proper manual assembly.

This is a crucial distinction. In a factory setting, crimping is the preferred method. It is faster, highly repeatable, and less prone to human error. The crimped ferrule becomes a solid mass of steel around the hose, which is inherently excellent at dampening vibration and resisting fatigue.

However, in the field, this advantage is irrelevant if you don’t have a crimper. The reusable fitting offers a very high level of vibration resistance *when assembled correctly*, making it the superior choice for on-site repairs. The best choice depends on the context: factory production versus field maintenance.

The Consistency of Machine Crimping

A hydraulic crimper is calibrated to a specific crimp diameter, down to a hundredth of a millimeter. Every assembly made with that machine and die set will have the exact same amount of compression. This consistency is its greatest strength. It eliminates the guesswork and variability of manual tightening, which is a significant advantage in high-volume or critical OEM applications.

Assembly Decision Matrix

| Feature | Crimp Fitting | Reusable Fitting |

| Vibration Resistance | Excellent & Highly Consistent | Very Good (when properly assembled) |

| Assembly Speed | Very Fast (seconds) | Slow (minutes) |

| Required Tools | Hydraulic Crimper, Dies | Hand Wrenches, Vise |

| Field Serviceability | Not Possible | Excellent |

What Are Best Practices for a Vibration-Proof Assembly?

You’re assembling a reusable fitting in the field. How do you ensure the connection is as strong and vibration-resistant as possible?

To maximize vibration resistance, you must follow a precise procedure. This includes a clean hose cut, proper lubrication, and—most importantly—tightening the socket to the correct position relative to the nipple.

A successful assembly is a repeatable process, not a guess. We provide these guidelines to ensure that our customers can create a connection that is safe and performs to specification. Taking a few extra moments to follow these steps correctly will pay dividends in reliability and prevent failures caused by vibration.

Critical Assembly Steps

- Cut the Hose: Use a fine-tooth hose saw to ensure the cut is clean, square, and does not fray the wire braid.

- Skive (If Required): If using skive-type fittings, use a skiving tool to remove the outer rubber cover to the specified length.

- Lubricate: Apply a light coat of hydraulic oil or thread lubricant to the threads of the socket and the hose end.

- Install the Socket: Place the socket in a vise. Screw the hose into the socket counter-clockwise until it bottoms out cleanly.

- Install the Nipple: Lubricate the nipple threads. Screw the nipple into the socket clockwise.

- Tighten to Spec: Tighten the nipple until the hex on the nipple meets the socket. Some manufacturers specify leaving a small, defined gap. Always follow the manufacturer’s specific instructions.

Add Vibration Dampeners or Mounts

When working with high-vibration machinery (e.g. in construction, mining, or marine environments), it’s wise to add external support to absorb shock before it reaches the fittings.

Common Anti-Vibration Accessories:

- Rubber isolators: Placed between system components and the mounting surface

- Grommets: Reduce hose friction where it passes through walls or panels

- Cushioned clamps: Secure hoses while allowing some movement

- Flexible mounts: Support pumps or actuators without transmitting all vibrations

| Accessory Type | Best For | Installation Point |

| Rubber isolators | Base-mounted components | Equipment feet or base |

| Grommets | Wall pass-throughs | Panel holes or cutouts |

| Cushioned clamps | Mid-hose support | Frame or wall mounting |

| Flexible mounts | Heavy vibrating components | Under motors/pumps |

Routine Inspections and Retightening

Vibration doesn’t stop. So even if you did everything right during installation, fittings can still loosen over time. That’s why routine checks are critical, especially for reusable fittings.

Inspection Tips:

- Check monthly in high-vibration or mobile systems

- Look for signs of weeping, hose wear, or thread exposure

- Re-torque any loose fittings using a torque wrench

- Keep a log to monitor frequent trouble spots

When Are Reusable Fittings the Wrong Choice?

You value the convenience of reusable fittings, but are there situations where using them, even in a pinch, is too risky or impractical?

Yes. Reusable fittings should be avoided in mass-production OEM environments. They are also less suitable for systems with extreme or rapid pressure impulses and where maintenance staff may not be properly trained on the exact assembly procedures.

Recognizing a tool’s limitations is just as important as knowing its strengths. While reusable fittings are a fantastic solution for field service, they are not the universal answer for every hydraulic application. We are honest with our partners about this. In a factory producing hundreds of machines, the speed, consistency, and lower unit cost of crimp fittings are unbeatable. The risk of one improperly assembled reusable fitting out of hundreds is too high in a production context. The choice of fitting must always match the operational environment.

Original Equipment Manufacturing (OEM)

In a factory setting, time is money. A hydraulic crimper can assemble a hose in less than 30 seconds. A reusable fitting takes several minutes. For an OEM building thousands of assemblies, crimping is the only logical choice for efficiency and ensuring every single unit meets the exact same quality standard.

Extreme Impulse Applications

Systems with very high-frequency pressure spikes (like those found in some advanced hydrostatic transmissions or injection molding machines) place enormous stress on the hose fitting. In these extreme cases, the solid, uniform nature of a high-quality crimped fitting often provides a longer fatigue life than a threaded mechanical connection. This is a very specific, high-performance area where crimping has a distinct engineering advantage.

Conclusion

Reusable fittings handle vibration effectively through a strong mechanical grip, but their reliability is directly tied to correct assembly. They excel in field repairs, while crimp fittings remain best for factory production.

Whether you need standard sizes or tailor-made fittings in stainless steel, carbon steel, or brass, our team is ready to support your project with expert advice and fast production.

FAQ

Can reusable hydraulic fittings be used in high-pressure applications?

Yes, many reusable fittings are rated for medium to high-pressure systems, depending on the material and thread type. However, always check the pressure rating from the manufacturer, especially in vibration-heavy environments.

Do reusable fittings require thread sealant or PTFE tape?

Not always. Many reusable fittings, especially O-ring face seal (ORFS) or flare fittings, are designed to seal without extra thread sealant. Using PTFE tape improperly can even damage threads or lead to leaks in high-vibration conditions.

How often should reusable hydraulic fittings be replaced?

Reusable fittings can last for several installation-removal cycles if properly maintained. However, if you notice visible wear, corrosion, or thread damage, it’s safer to replace them—even if they still seem functional.

Are reusable fittings compatible with steel-braided hoses?

Yes, most reusable fittings are compatible with steel-braided or wire-reinforced hoses, which are ideal for absorbing vibration. Just ensure you’re using the correct fitting style and insertion depth for a secure grip.

Can reusable fittings be used with hydraulic fluids other than oil?

Absolutely. Reusable fittings can be used with various fluids like water-glycol, phosphate esters, or synthetic fluids, depending on the fitting material and seal type. Always confirm fluid compatibility to avoid chemical degradation.

Do reusable fittings support 360° swivel movement?

Most standard reusable fittings do not swivel, but some specialized versions (like swivel adapters or live swivels) are designed to rotate and absorb torsional motion, reducing stress on the hose in vibrating systems.