37° flare fittings are crucial components in hydraulic systems, known for their high-pressure tolerance, leak resistance, and reusability. These fittings connect tubes and hoses, ensuring fluid integrity and system reliability. Proper assembly of these fittings is essential to prevent leaks and maintain system performance. The Flats Method is a precise technique used to achieve the correct torque when assembling 37° flare cone fittings. By tightening the fitting to a specific number of flats, this method ensures consistent and reliable connections.

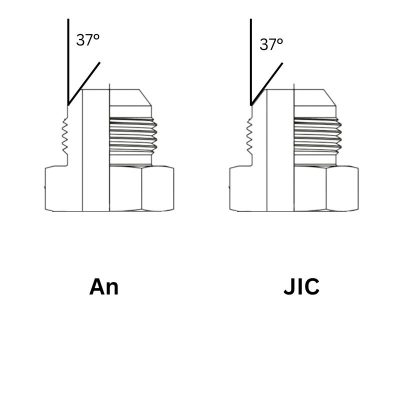

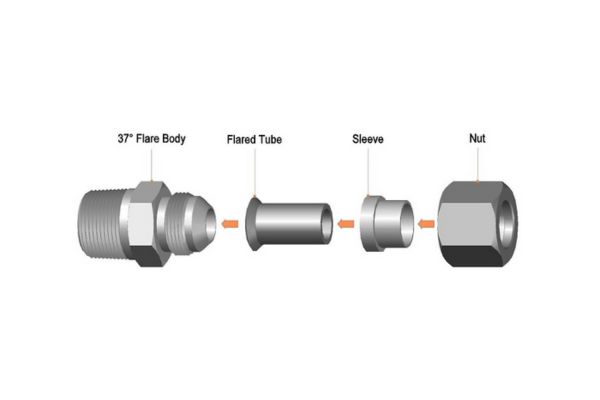

37° fittings, also known as JIC (Joint Industry Council) fittings, are a type of compression fitting used in high-pressure hydraulic systems. These fittings consist of a nut, a sleeve (or ferrule), and a body. The tube end is flared to a 37° angle, which mates with the fitting’s conical seat, creating a tight seal. The main components include:

37° flare cone fittings are widely used in various industries due to their robust design and high-pressure capability.

Common applications include:

37° flare cone fittings offer several benefits that make them a preferred choice in many hydraulic applications:

The Flats Method is a precise technique used to achieve the correct torque when assembling 37° flare cone fittings. By tightening the fitting by a specific number of flats beyond hand-tightening, this method ensures consistent and reliable connections. The flats refer to the flat sides of the hex nut on the fitting.

The importance of the Flats Method lies in its ability to provide a standardized approach to tightening, reducing the risk of under- or over-tightening. Proper torque is crucial in hydraulic systems to maintain leak-free connections and ensure the longevity of the fittings and tubes.

Initial Hand-Tightening of Fittings

Marking the Flats of the Fitting

Tightening the Fitting by the Specified Number of Flats

Proper assembly of 37° flare fittings is crucial for ensuring leak-free and reliable hydraulic connections. By following the Flats Method, you achieve precise and consistent torque, which enhances the durability and performance of your system. This method standardizes the assembly process, reducing the risk of under- or over-tightening, and helps in maintaining optimal system integrity. We encourage you to adhere to the best practices outlined in this guide, including regular inspections and maintenance, to prolong the life of your fittings and tubes.

37° flare cone fittings, also known as JIC fittings, are used in high-pressure hydraulic systems to connect tubes and hoses securely.

The Flats Method is a technique for tightening fittings by a specific number of flats beyond hand-tightening to ensure proper torque and a reliable seal.

Proper assembly prevents leaks, ensures system integrity, and extends the lifespan of hydraulic components.

Hand-tighten the fitting, mark one flat side, then tighten by the specified number of flats using a wrench.

Inspect the fitting and flare for damage, ensure proper alignment, and re-tighten or replace components as necessary.

Regular inspections should be conducted periodically to check for signs of wear, corrosion, or loosening to maintain system performance.