Your HPU is the heart of your operation, but the wrong couplers are strangling its power. This leads to frustratingly slow tool performance, wasted energy, and dangerous levels of heat buildup.

The right quick coupler for a hydraulic power unit (HPU) must match its flow rate (GPM), exceed its maximum pressure rating, and suit the application. Prioritize high-flow designs like flat face or screw-to-connect styles and consider features like pressure-release mechanisms for safe, efficient operation.

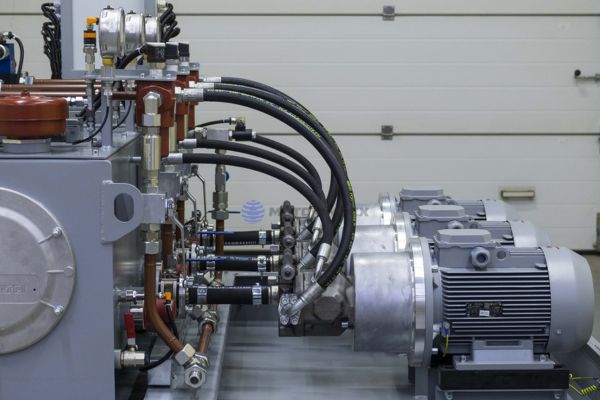

A hydraulic power unit represents a significant investment in power and productivity. It is the central nervous system of your hydraulic equipment, generating the flow and pressure needed to run everything from rescue tools to massive industrial presses. But this power is useless if it cannot be delivered efficiently to the tool. The quick couplers you choose are the gateways to this power. A poor choice creates a bottleneck that not only hinders performance but can also jeopardize the health and longevity of the entire HPU. As a global supplier of hydraulic components, we help our clients look beyond simple thread sizes. We guide them through the critical technical specifications to ensure that every connection enhances, rather than compromises, their system’s power.

Why is Flow Rate the Most Critical Factor for an HPU Coupler?

Your HPU has a high GPM rating, but the attached tool moves sluggishly. This performance gap points directly to a bottleneck in the system, turning expensive hydraulic power into useless heat.

An undersized coupler causes a severe pressure drop as the HPU’s flow is forced through a small opening. This converts hydraulic energy into heat, starving the tool of power and forcing the HPU’s pump to work harder.

A Bottleneck Turns Power into Heat

Think of your HPU as a powerful engine. The quick coupler is the transmission that delivers that power. If the transmission is too small, the engine will strain, overheat, and fail to deliver its full potential. In hydraulics, this strain is measured as pressure drop. Every HPU has a rated flow in Gallons Per Minute (GPM) or Liters Per Minute (LPM). The quick coupler must have an adequate Flow Coefficient (Cv) to allow this flow to pass through with minimal restriction.

When the HPU’s flow rate exceeds the coupler’s capacity, the fluid velocity inside the coupler skyrockets. This creates massive turbulence and friction, and the energy lost is converted directly into heat.

The Cost of Inefficiency

This heat is the number one enemy of a hydraulic system. It degrades the oil, damages seals, and can cause the HPU to shut down on a thermal trip. A high pressure drop also means that the pressure available at the tool is significantly lower than the pressure generated by the HPU. A 100 PSI drop at the coupler is 100 PSI that is simply not available to do work. Choosing a coupler with a high Cv value that is properly sized for the HPU’s flow rate is the most important step in ensuring that the power you are paying for is the power you are getting at the tool.

| HPU Flow Rate | Coupler A (Cv=5.0) | Coupler B (Cv=8.0) | Performance Impact |

| 10 GPM | 4 PSI Drop | 1.5 PSI Drop | Both are acceptable. |

| 20 GPM | 16 PSI Drop | 6 PSI Drop | Coupler B is significantly more efficient. |

| 30 GPM | 36 PSI Drop | 14 PSI Drop | Coupler A is generating excessive heat. |

| 40 GPM | 64 PSI Drop | 25 PSI Drop | Coupler A is severely undersized and damaging the system. |

Which Coupler Type is Best for HPU Applications?

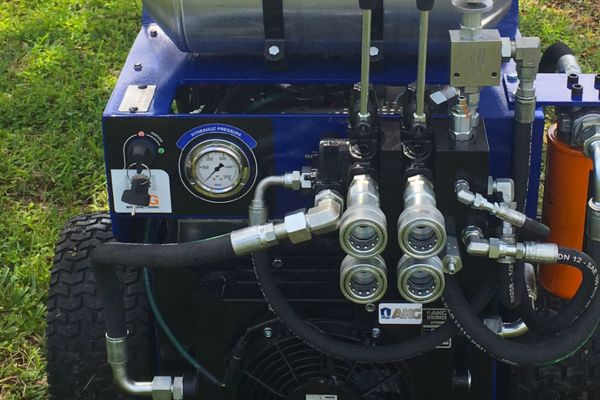

You are constantly dealing with messy fluid spills and fear dirt getting into your HPU. The standard couplers you use are a known weak point, compromising both safety and system cleanliness.

Flat face (ISO 16028) couplers are excellent for general HPU use due to their non-spill design and easy cleaning. For high-impulse or extreme-pressure applications, screw-to-connect couplers offer the most secure connection.

Matching the Design to the Demand

Not all quick couplers are built the same. The internal valve design dramatically affects their performance, cleanliness, and suitability for different HPU jobs. Choosing the right type is key to reliability.

Poppet Style (ISO 7241 A/B)

These are the most common and economical couplers. However, their poppet valve design allows for significant fluid spillage upon disconnection and creates a cavity that traps dirt, which can then be injected into the HPU. While acceptable for some applications, they are not ideal for systems where cleanliness and minimal spillage are priorities.

Flat Face Style (ISO 16028)

This design is a major upgrade. The mating surfaces are flush, allowing them to be wiped perfectly clean before connection. Upon disconnection, the valves close right at the face, resulting in near-zero fluid spillage. This makes them the superior choice for most HPU applications, drastically reducing contamination risk and keeping the work area clean and safe. They also typically offer better flow characteristics than poppet styles of the same size.

Screw-to-Connect Style (ISO 14541)

When the HPU powers high-impulse tools like hydraulic breakers or high-tonnage jacks, screw-to-connect couplers are the best option. The threaded sleeve provides a rock-solid mechanical connection that cannot be accidentally disconnected and is highly resistant to the pressure spikes (impulses) and vibration that can damage other coupler types.

| Coupler Type | Pros | Cons | Best HPU Application |

| Poppet (ISO-A/B) | Low cost, widely available. | High spillage, traps dirt, lower flow. | General, low-priority systems where cost is the main driver. |

| Flat Face (ISO 16028) | Minimal spillage, easy to clean, prevents contamination. | Higher initial cost. | Most standard HPU pressure and return lines. |

| Screw-to-Connect | Extremely secure, resists high impulse and pressure. | Slower to connect/disconnect. | High-pressure jacks, hydraulic hammers, and demolition tools. |

How Do You Deal with Trapped Pressure When Connecting to an HPU?

The hose simply will not connect to the HPU coupler. The immense effort required to force the connection risks damaging the coupler and is a major source of frustration and downtime.

Trapped pressure makes connection very difficult. The best solution is to use quick couplers specifically designed to connect under pressure. These have integrated valves or sleeves that safely bleed off the pressure during connection.

The Trapped Pressure Problem

This is one of the most common problems in mobile hydraulics. A hydraulic hose left disconnected in the sun can experience a huge increase in internal pressure due to thermal expansion of the oil. This trapped pressure can easily reach several hundred or even thousands of PSI, making it physically impossible to push the male tip into the female coupler against that force. The traditional, unsafe solution is to crack open a fitting to bleed the pressure, spilling oil and creating a hazard.

A far better solution is to choose a coupler built to handle this.

- Vented Internal Valves: Some modern couplers have small, integrated pressure-release valves. As you mate the two halves, this valve opens first, safely venting the trapped pressure into the return line before the main valve opens.

- Screw-to-Connect Mechanism: The act of threading a screw-to-connect coupler together provides a strong mechanical advantage. This design can overcome high levels of trapped pressure in both the male and female halves, forcing the connection safely.

- Push-Pull Sleeves: Common in agriculture, these couplers are mounted to a bulkhead and allow the operator to connect or disconnect under residual pressure by simply pushing or pulling the hose.

When we consult with clients who operate HPUs in outdoor environments, we always highlight the availability of these connect-under-pressure solutions. They are a crucial feature for improving operator safety, reducing downtime, and preventing damage to equipment.

Can the Right Coupler Really Protect Your HPU from Contamination?

A tiny particle of dirt can destroy a multi-thousand-dollar HPU pump. You know that cleanliness is key, but the connection point itself seems like a major weak spot for ingression.

Yes, absolutely. A flat face (ISO 16028) coupler is a frontline defense against contamination. Its flush, non-spill design allows it to be wiped perfectly clean, preventing the injection of dirt into the HPU’s sensitive hydraulic system.

Designing for Cleanliness

Hydraulic contamination is the leading cause of component failure. Over 75% of hydraulic system failures can be traced back to contaminants in the fluid. While filtration systems are essential, preventing dirt from entering in the first place is a far more effective strategy. The quick coupler is the most common entry point for dirt.

The Flaw of the Poppet Design

A traditional poppet-style coupler has a recessed cavity around the valve. When disconnected, this cavity inevitably collects dust, grit, and moisture. Wiping it with a rag is ineffective, as the dirt is pushed deeper into the recess. The moment you connect this coupler, the incoming rush of hydraulic fluid flushes all that trapped grime directly into the HPU’s reservoir, where it can wreak havoc on pumps, valves, and seals.

The Superiority of the Flat Face Design

The flat face coupler was engineered specifically to solve this problem. Because the mating surfaces are completely flush when disconnected, there are no cavities to trap dirt. A simple wipe with a clean cloth is all that is needed to ensure a sterile connection surface. Furthermore, the non-spill design means that no sticky residue of oil is left on the coupler to attract more dust. Investing in flat face couplers for an HPU is one of the most cost-effective reliability upgrades you can make. It is a small price to pay to protect a very expensive asset.

Do Pressure and Return Lines on an HPU Need Different Couplers?

You have always used the same model of coupler for both the pressure and return lines. This seems logical, but it may be causing unseen problems like sluggish performance or leaking cylinder seals.

Yes, they have different demands. The pressure line needs a coupler rated for high pressure and impulses. The return line coupler needs an exceptionally high flow capacity (low pressure drop) to prevent back-pressure. Using different sizes is also a good safety practice.

A Tale of Two Lines

While they work together, the pressure (P) line and the tank/return (T) line perform very different functions, and their couplers should be chosen accordingly. Mistaking their requirements is a common design flaw.

The Pressure Line’s Job

The pressure line coupler has the tough job. It must safely contain the HPU’s maximum system pressure, which can be 3000 PSI, 5000 PSI, or even higher. It must also withstand the intense pressure spikes, or impulses, generated by the rapid cycling of valves and hydraulic tools. Here, strength and pressure rating are the top priorities.

The Return Line’s Job

The return line coupler has a different primary goal: get the oil back to the tank with as little restriction as possible. Any significant pressure drop in the return line creates back-pressure. This back-pressure works against the entire system. It can cause cylinder rod seals to fail, slow down actuator speeds, and generate unwanted heat. For the return line, you should select the largest coupler possible with the highest Cv value you can find to ensure the return path is free-flowing. Its pressure rating is less critical (as long as it meets minimal system requirements), but its flow capacity is paramount. Many engineers oversize the return line coupler for this very reason. It is also best practice to use different sizes for the P and T lines (e.g., 1/2″ for pressure, 3/4″ for return) to make it physically impossible to connect them incorrectly.

What Role Do Materials and Plating Play in an HPU Coupler’s Lifespan?

The couplers on your HPU are showing signs of rust after just one season of use. This corrosion looks bad, but it also threatens to seize the coupler and contaminate the hydraulic system.

The material and plating are crucial for durability. Standard couplers are carbon steel with zinc plating to resist rust. For wet or corrosive environments, a superior plating like Zinc-Nickel or a full 316 stainless steel body is necessary.

A Shield Against the Elements

A quick coupler’s body is its first line of defense against the operating environment. While the internal mechanics are vital for performance, the external material determines its lifespan in the face of moisture, salt, and chemicals.

The Standard: Plated Carbon Steel

Most hydraulic couplers are made from high-strength carbon steel. This provides excellent pressure containment but will rust very quickly if left unprotected. To prevent this, manufacturers apply a protective plating. Standard Zinc plating with a clear trivalent chromate (Cr3+) passivate is common. It offers basic protection, often rated for around 72-96 hours in a salt spray test before showing significant rust.

High-Performance Plating: Zinc-Nickel

For HPUs used outdoors, on marine equipment, or in winter conditions where road salt is present, a standard plating is not enough. We strongly recommend upgrading to a Zinc-Nickel alloy plating. This advanced finish provides a much tougher barrier against corrosion, often lasting over 700 hours in a salt spray test. This preserves the coupler’s functionality and professional appearance for years.

The Ultimate Solution: Stainless Steel

For the most demanding environments, such as chemical plants, offshore oil rigs, or food processing applications, 316 stainless steel is the best choice. While more expensive, stainless steel offers complete resistance to rust and superior resistance to a wide range of chemicals. It eliminates any risk of plating flaking off and contaminating the system, providing the ultimate in longevity and peace of mind.

Conclusion

Selecting the right quick coupler for your HPU is a critical decision. It requires a balanced consideration of flow rate, pressure, coupler type, material, and specialized features to ensure maximum safety and performance.

At Topa, we specialize in helping customers navigate these choices. We provide a vast range of high-performance quick couplers—from certified flat face to robust screw-to-connect models—in the materials and platings your application demands. Our expert team can help you select the perfect component to unleash the full power of your hydraulic power unit. Contact us today to ensure your connections are as strong as your system.