Tired of messy hydraulic fluid spills or connection failures? Choosing the wrong quick coupler costs you time and money, and it can even damage your equipment. This choice matters.

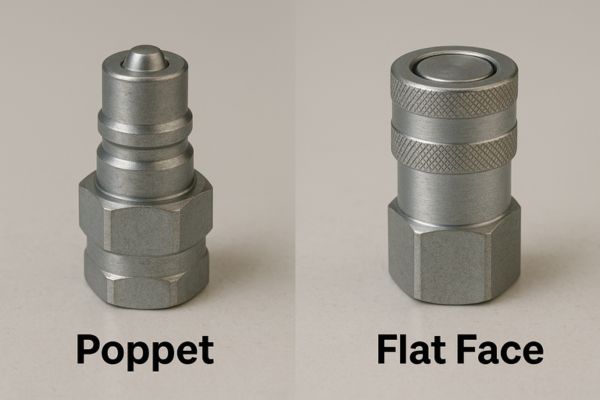

The right hydraulic quick coupler depends entirely on your application’s needs. Flat face couplers are best for clean environments to prevent spills and contamination. Poppet couplers are a durable, cost-effective choice for general-purpose applications where minor fluid loss is acceptable.

What Exactly is a Flat Face Coupler?

Are you working in an environment where even a small oil leak is a big problem? Contamination and spills can shut down a job site and lead to costly cleanups.

A flat face coupler is a type of hydraulic quick connect designed for zero leakage during connection and disconnection. Its flush mating surfaces are easy to clean, preventing dirt from entering the hydraulic system and oil from contaminating the environment. They are the modern standard for sensitive applications.

Flat face couplers are a marvel of simple, effective engineering. When I explain it to new buyers, I always focus on the “no-spill” design. It’s the most important feature.

How Does It Work?

Both the male and female halves of a flat face coupler feature smooth, flush-mounted valve surfaces that align perfectly when disconnected. This design eliminates cavities where oil could leak or where dirt could collect.

When the two halves are pushed together, the internal valves retract in a synchronized motion, allowing hydraulic fluid to flow freely through the connection. Because the valves retract only after the faces are fully sealed against each other, the system avoids the sudden spray or drips that are common with older coupler designs.

During disconnection, the process works in reverse. The valves close before the couplers separate, instantly sealing off both sides of the line. This means that virtually no oil escapes into the environment, and no air, dust, or moisture can enter the hydraulic system.

Key Advantages You Should Know

The benefits go beyond just being clean. I remember a customer in the construction industry who switched to flat face couplers on all his excavators. He told me his maintenance costs dropped because his hydraulic systems were running much cleaner.

| Feature | Benefit | Why It Matters for You |

| No-Spill Design | Prevents fluid loss upon disconnection. | Reduces environmental impact, saves costly hydraulic fluid, and improves site safety. |

| Easy to Clean | The flat surface can be wiped clean easily. | Dramatically lowers the risk of introducing dirt or grit into your hydraulic system. |

| Prevents Contamination | The flush connection minimizes air inclusion and dirt entry. | Protects sensitive components like pumps and valves, extending equipment life. |

| Push-to-Connect | Many designs allow for simple one-handed connection. | Faster and easier aattachment changes, especially under pressure. |

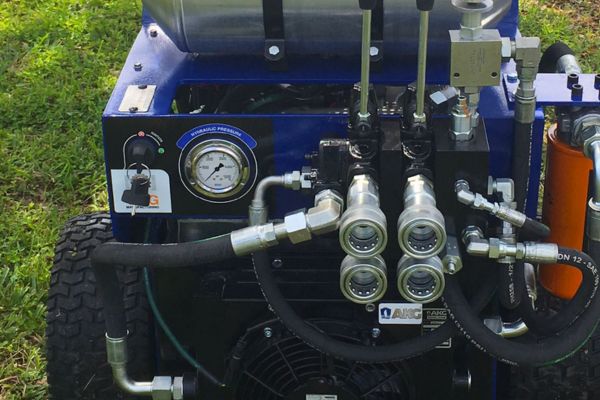

Applications of Flat Face Quick Couplers

Construction Machinery

Excavators, skid steers, and loaders for hydraulic attachments (buckets, breakers, augers).

Agricultural Equipment

Tractors and harvesters for implements like plows, seeders, and hydraulic-driven sprayers.

Forestry Machinery

Used on harvesters, forwarders, and log splitters where hydraulic tools are swapped often.

Mining & Heavy Equipment

Hydraulic power units, drills, and underground machinery.

Oil & Gas / Industrial Applications

Hydraulic power packs, subsea tools, and offshore rigs.

Material Handling

Forklifts, cranes, and attachments needing quick hydraulic connections.

What is a Poppet Coupler?

Do you need a reliable, proven, and budget-friendly connection for your hydraulic tools? For many, the traditional poppet coupler has been the go-to solution for decades.

A poppet coupler is a common style of hydraulic quick connect that uses a ball or poppet-style valve to control flow. It’s a robust and cost-effective design that has been a workhorse in industries around the world for many years.

The poppet coupler is a classic for a reason. Here in our factory, we’ve manufactured these for years, and their simple, strong design is valued by many of our long-term clients, especially those in demanding environments like farming in Africa or mobile equipment maintenance in South America.

The Mechanics of a Poppet Valve

When a poppet coupler is disconnected, a spring-loaded mechanism keeps a small ball or cone-shaped “poppet” tightly pressed against its seat. This creates a seal that blocks hydraulic fluid from leaking out of the system while the coupler is not in use. The spring ensures that the poppet remains in position, even if the hose or equipment is under residual pressure.

During connection, the process is straightforward but effective. As the male and female halves come together, a probe on the male half pushes directly against the poppet, forcing it off the seat. This action opens the fluid passage and allows hydraulic oil to flow freely through the system. Because the design minimizes internal restrictions, poppet couplers can deliver very high flow rates, making them well-suited for equipment that requires large volumes of hydraulic fluid.

Main Benefits to Consider

| Feature | Benefit | Why It Matters for You |

| Cost-Effective | Generally lower in price than flat face couplers. | Saves you money on the initial purchase, especially when outfitting multiple machines. |

| High Flow Rate | The simple valve design often allows for less restricted flow. | Can provide better performance for high-flow hydraulic attachments and systems. |

| Wide Availability | One of the most common and interchangeable styles available. | Easy to find replacements or connect to existing equipment from various manufacturers. |

| Durable | The simple and robust internal design can withstand rough use. | A reliable choice for tough environments where couplers might get banged around. |

Where It’s Used Most

Poppet couplers are extremely common in agriculture, general industrial use, and on older mobile equipment.

Agriculture

Tractors, combines, and sprayers.

Construction Equipment

Backhoes, loaders, and small excavators.

Industrial Hydraulics

Hydraulic presses, test stands, and machine tools.

Forestry & Logging

Used in sawmills, log splitters, and skidders.

Oil & Gas

Hydraulic power units and drilling rigs.

Transportation / Mobile Equipment

Truck-mounted hydraulic systems (dump trucks, cranes, tow trucks).

How Do They Compare Head-to-Head?

Feeling stuck choosing between modern cleanliness and traditional reliability? This direct comparison will clear things up and help you decide which is truly better for your work.

Flat face couplers excel in preventing spills and contamination, making them ideal for sensitive environments. Poppet couplers are more budget-friendly and offer robust, high-flow performance for general-purpose use where minor drips are not a major concern. The best choice depends on your priority.

Spillage and System Contamination

This is the biggest difference.

- Flat Face: Designed for near-zero spillage. The surfaces can be wiped clean before connection, virtually eliminating the chance of dirt, dust, or water entering your hydraulic lines. This is critical for modern, high-pressure systems with sensitive valves.

- Poppet: Will spill a small amount of fluid on disconnection. The recessed valve area can also trap dirt, which may be pushed into the system during connection. For older, more robust systems, this is often acceptable.

Pressure and Flow Dynamics

Performance under pressure is key.

- Flat Face: Modern flat face designs, like our ISO 16028 series, handle high pressures exceptionally well. While older designs had lower flow rates, new ones are highly efficient and compete well with poppets. Some can even be connected under residual pressure.

- Poppet: Traditionally known for excellent flow rates due to their simpler internal path. They are very effective in systems that need to move a lot of fluid quickly.

The True Cost: Price vs. Longevity

Your budget is always a factor.

- Poppet: The initial purchase price is lower. They are a great value and, being made from high-quality steel, are very durable.

- Flat Face: The initial cost is higher due to the more complex design and precise manufacturing. However, many customers find the total cost of ownership is lower over time due to saved hydraulic fluid, reduced cleanup, and longer life for other hydraulic components.

Here is a simple breakdown:

| Factor | Flat Face Coupler | Poppet Coupler | The Winner Is… |

| Spillage | Near-zero | Minor spillage | Flat Face |

| Contamination Risk | Very Low | Moderate | Flat Face |

| Initial Cost | Higher | Lower | Poppet |

| Flow Rate | Good to Excellent | Excellent | Poppet (Slightly) |

| Ease of Cleaning | Excellent | Difficult | Flat Face |

| Durability | Very Good | Very Good | Tie |

Which Applications Demand a Specific Coupler?

Worried you’ll buy the wrong coupler for your machine? Matching the coupler to the job and environment is critical for safety, efficiency, and avoiding costly mistakes.

Use flat face couplers for high-end construction, food processing, or any job where spills are unacceptable. Stick with poppet couplers for general agriculture, older industrial machinery, and applications where budget and interchangeability with existing equipment are your primary concerns.

We’ve shipped couplers to nearly every type of industry you can imagine. This experience has given us clear insights into where each type performs best. Let me share a couple of real-world examples that illustrate this perfectly.

Case Study: A Construction Firm in the USA

I remember working with a procurement manager, for a large construction company in the US. They were using poppet couplers on their skid steer loaders. They had a recurring problem: when operators changed attachments like buckets and breakers, hydraulic fluid would drip onto finished concrete and asphalt, leaving ugly stains. This led to customer complaints and costly pressure-washing services. We recommended they switch to our ISO 16028 flat face couplers. The problem disappeared overnight. The slightly higher initial cost was quickly recovered by eliminating cleanup costs and improving their professional image.

When to Stick with Poppet Couplers

On the other hand, I spoke with a small farm owner in the Philippines a few months ago. He runs older tractors and uses several different attachments. His priority was simple: he needed a reliable coupler that was inexpensive and compatible with his existing equipment. For his work in the open field, a few drops of oil were not a concern. He needed durability and value. We supplied him with standard poppet couplers, and he was extremely happy. It was the right tool for his job and his budget.

Industry-Specific Recommendations

To make it even simpler, here is a list of industries and our typical recommendation:

- Construction:Flat Face is preferred for excavators, skid steers, and tools to prevent site contamination.

- Agriculture:Poppet is common and cost-effective for tractors and implements. However, Flat Face is gaining popularity on newer, more advanced machinery.

- Forestry: A mix. The durability of Poppet couplers is beneficial, but the no-spill feature of Flat Face is better for environmental regulations.

- Manufacturing & Indoor Use:Flat Face is almost always the right choice to maintain a clean and safe workspace.

- Mining:Poppet couplers are often chosen for their robust build and high-flow characteristics in very harsh conditions.

Conclusion

Ultimately, the right coupler is the one that fits your application, environment, and budget. Flat face offers modern cleanliness, while poppet provides traditional, cost-effective reliability.

At Topa, we offer high-quality hydraulic quick couplings in both flat-face and spring-valve designs, engineered for construction, agricultural, and industrial systems to ensure reliable, leak-free performance. Contact Topa today for a quick quote.

FAQ

What is the main difference between flat face and poppet couplers?

Flat face couplers prevent fluid spills and contamination, while poppet couplers are more cost-effective but allow minor leakage.

Which coupler is better for high-pressure systems?

Flat face couplers are designed for modern high-pressure applications and can often be connected under residual pressure.

Are poppet couplers still widely used?

Yes, they remain popular in agriculture, forestry, and older equipment due to durability, affordability, and wide availability.

Do flat face couplers cost more?

The initial price is higher, but they reduce cleanup costs, fluid loss, and equipment wear—lowering long-term expenses.

Can I interchange flat face and poppet couplers?

No, they use different designs and standards. Always match coupler types for compatibility

Which industries typically choose flat face couplers?

Construction, manufacturing, and food processing industries prefer flat face for clean, leak-free operations.