How to Install An Fitting on Braided Line

Table of Contents

Introduction

Ensuring the proper installation of hydraulic components is crucial for the performance and safety of any hydraulic system. A correctly installed fitting can mean the difference between a smooth operation and a catastrophic failure. AN fittings, renowned for their reliability and versatility, are widely used across various industries, including automotive, aerospace, and industrial applications. These fittings, originally developed by the military, have become a standard for high-performance fluid transfer. In this post, we aim to provide a comprehensive step-by-step guide on how to install AN fittings on braided lines, ensuring a secure and leak-free connection for your hydraulic systems.

Understanding AN Fittings and Braided Lines

Definition of AN Fittings

AN fittings, short for Army-Navy fittings, have a rich history that dates back to World War II. These fittings were developed by the military to meet the rigorous demands of aviation and other high-performance applications. The standards for AN fittings were established to ensure uniformity, reliability, and interchangeability across different branches of the military, making them a trusted choice for critical fluid transfer systems. Common materials used for AN fittings include aluminum, steel, and stainless steel, each chosen for their specific properties such as strength, corrosion resistance, and weight.

Types of AN Fittings

AN fittings come in a variety of sizes and configurations to accommodate different needs. The sizes are designated by a dash number, which corresponds to the outside diameter of the tubing in sixteenths of an inch. For example, a -6 AN fitting is designed for a tube with a 6/16 inch outside diameter. In addition to sizes, AN fittings are available in various angles, such as 45 degrees and 90 degrees, to allow for flexible routing of lines in tight spaces. The material options for AN fittings, including aluminum, steel, and stainless steel, provide choices for different applications based on factors like pressure requirements, environmental conditions, and weight considerations.

Braided Lines

Braided lines are a critical component in many high-performance hydraulic and fluid transfer systems. These lines consist of an inner core, typically made from synthetic rubber or Teflon, surrounded by a braided layer of stainless steel or nylon. The braided construction provides several advantages, including enhanced durability, flexibility, and resistance to abrasion and corrosion. Braided lines can handle higher pressures compared to standard rubber hoses, making them ideal for use in demanding applications such as automotive fuel lines, oil and coolant lines, and industrial hydraulic systems. The flexibility of braided lines also allows for easier installation in complex routing scenarios, ensuring reliable performance even in the most challenging environments.

Tools and Materials Needed

Essential Tools

To install AN fittings on braided lines, having the right tools is crucial for a successful and hassle-free process. Here’s a list of the essential tools you’ll need:

AN-Specific Wrenches: These wrenches are specially designed to fit AN fittings and provide the proper grip without damaging the anodized finish. Using standard wrenches can mar the fittings and affect their performance.

Vise: A sturdy vise is essential for holding the braided line and fittings securely in place during the installation process. This ensures precision and stability.

Cutting Tools: High-quality cutting tools, such as a hose cutter or a fine-toothed hacksaw, are necessary to make clean, straight cuts on the braided line. Clean cuts help to prevent fraying and ensure a better fit.

Masking Tape: Applying masking tape around the area to be cut helps to hold the braid together and minimize fraying during the cutting process.

AN Fitting Assembly Tool: This tool simplifies the process of installing the fitting into the hose and ensures a proper and secure fit.

Lubricant: A suitable lubricant, such as assembly lube or light oil, helps to ease the fitting into the braided line and reduce the risk of damage.

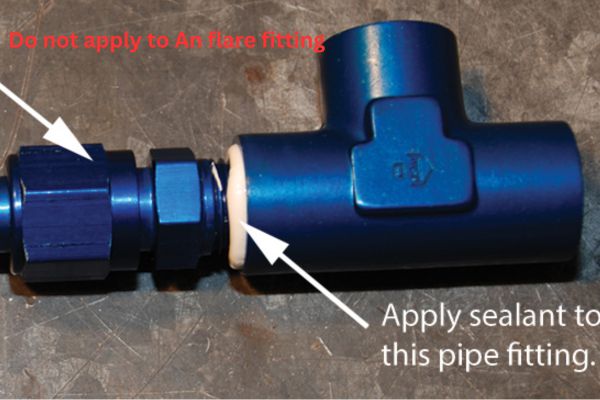

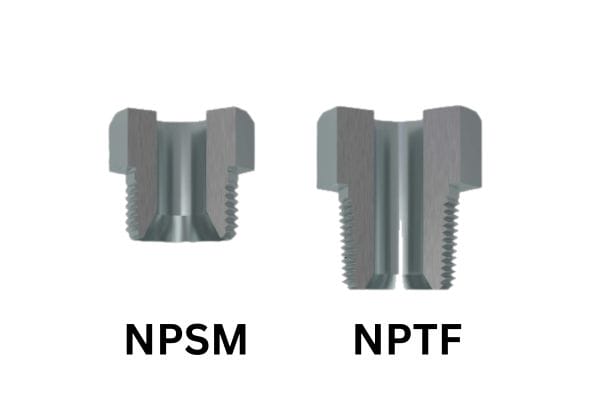

Thread Sealant: If your application requires sealing the threads to prevent leaks, having a high-quality thread sealant on hand is essential.

Materials

In addition to the tools, you will need the following materials:

AN Fittings: Choose the appropriate size and type of AN fittings for your application. Ensure they are made from a suitable material for your specific requirements, such as aluminum, steel, or stainless steel.

Braided Line: Select a braided line that matches the size of your AN fittings and is suitable for the fluid and pressure of your application.

Lubricant: As mentioned, a lubricant is crucial for a smooth installation process.

Thread Sealant: Depending on your application, you might need a thread sealant to ensure a leak-free connection.

Preparing the Braided Line

Measuring and Cutting

Accurate measurement and clean cutting are the first crucial steps in preparing your braided line for AN fitting installation:

Measure the Line: Use a tape measure to determine the exact length of the braided line required for your installation. Be precise to ensure that the line fits perfectly within your system without being too short or excessively long.

Mark the Cut: Once you have measured the correct length, use a marker or a piece of masking tape to mark the spot where the cut will be made. Applying masking tape around the cutting area can help keep the braid intact and reduce fraying.

Cut the Line: Using a sharp hose cutter or a fine-toothed hacksaw, carefully cut the braided line at the marked spot. Ensure that the cut is straight and clean. A clean cut minimizes fraying and ensures a better fit for the AN fitting.

Cleaning the Line

After cutting the braided line, it is essential to clean it thoroughly to remove any debris or particles that could compromise the integrity of the system:

Remove Debris: Inspect the inside of the braided line for any debris or particles left from the cutting process. Use compressed air or a small brush to remove any foreign material.

Flush the Line: For added assurance, you can flush the inside of the line with a suitable cleaning agent or solvent to ensure it is completely free of contaminants. Allow the line to dry completely before proceeding.

Taping the End

To further prevent fraying and ease the installation of the AN fitting, taping the end of the braided line is a helpful step:

Apply Masking Tape: Wrap a small piece of masking tape tightly around the end of the braided line. This helps to keep the braid intact and prevents the individual strands from unraveling during the fitting installation.

Ensure a Tight Wrap: Make sure the tape is applied tightly and smoothly to provide a solid foundation for the AN fitting to grip onto. This will facilitate a smoother and more secure installation process.

Installing the AN Fitting on the Braided Line

Disassembling the Fitting

Separation

The first step in installing an AN fitting on a braided line is to disassemble the fitting into its components. AN fittings typically consist of three main parts: the nut, the hose end, and the socket.

Separate the Components: Begin by unscrewing the nut from the hose end. Carefully remove the hose end and set it aside. You should now have three distinct pieces: the nut, the hose end, and the socket.

Organize Your Workspace: Place the components in an organized manner to avoid losing any small parts. Keeping everything in a clean and orderly fashion will make the assembly process smoother and more efficient.

Inspection

Before proceeding with the installation, it’s crucial to inspect each component of the fitting for any defects or debris.

Visual Inspection: Examine the nut, hose end, and socket for any signs of damage, such as cracks, dents, or deformities. Pay special attention to the threads to ensure they are not stripped or damaged.

Clean the Components: If any debris or foreign particles are present, clean the components thoroughly. Use a clean cloth or compressed air to remove any dirt or residue. Ensuring that the components are clean will help to create a secure and leak-free connection.

Fitting the Hose into the Socket

Positioning

Proper alignment of the braided line with the socket is essential for a secure fit. Misalignment can lead to difficulties in threading and may compromise the integrity of the connection.

Align the Hose: Hold the braided line and align it with the socket. Make sure that the end of the braided line is straight and not frayed, as this will make insertion easier.

Prepare for Insertion: If necessary, trim any loose strands or frayed ends to ensure a clean and straight edge.

Insertion

Easing the braided line into the socket without damaging it requires careful handling and technique.

Start the Insertion: Gently push the end of the braided line into the socket. Apply steady pressure and avoid forcing the line, as this can damage the inner core or the braid.

Twist and Push: To facilitate insertion, you can twist the braided line slightly as you push it into the socket. This can help to seat the line more securely within the socket.

Attaching the Hose End

Lubrication

Applying a suitable lubricant to the hose end can significantly ease the installation process and reduce the risk of damaging the components.

Apply Lubricant: Use a light oil or assembly lube to coat the hose end. Ensure that the lubricant is evenly distributed over the surface of the hose end.

Avoid Over-Lubrication: While lubrication is helpful, avoid applying too much, as excess lubricant can attract dirt and debris.

Threading

Correctly threading the hose end into the socket is crucial for a secure and leak-free connection. Cross-threading can damage the threads and compromise the fitting.

Initial Threading: Begin by hand-threading the hose end into the socket. This helps to ensure that the threads are properly aligned and reduces the risk of cross-threading.

Tighten by Hand: Continue to thread the hose end by hand until it becomes snug. This step ensures that the threads are properly engaged before applying any additional torque with tools.

Securing the Fitting

Tightening

Using the appropriate tools to secure the fitting without over-tightening is essential to maintain the integrity of the connection.

Use AN Wrenches: Employ AN-specific wrenches to tighten the fitting. These wrenches are designed to fit AN fittings precisely and minimize the risk of damaging the anodized finish.

Apply Steady Pressure: Tighten the fitting gradually, applying steady and even pressure. Avoid over-tightening, as this can strip the threads or damage the fitting.

Double-Checking

Ensuring that the fitting is properly seated and secure is the final step in the installation process.

Inspect the Connection: Visually inspect the fitting to ensure it is seated correctly and that there are no gaps or misalignments.

Test the Fitting: If possible, perform a preliminary pressure test to check for any leaks. This step helps to confirm that the installation was successful and that the fitting is secure.

Testing the Installation

Pressure Test

Performing a pressure test is a critical step in ensuring the integrity and leak-free performance of your AN fitting installation. Here’s how to conduct a thorough pressure test:

Setup for Testing: Connect the assembled braided line with AN fittings to a pressure testing rig or the actual system it will be used in. Ensure that all connections are secure and properly seated.

Apply Pressure: Gradually apply pressure to the system, starting at a low pressure and slowly increasing to the operating pressure. This gradual increase helps to identify any weaknesses or leaks without causing sudden failures.

Monitor the System: While applying pressure, closely monitor the entire assembly for any signs of leaks. This can be done visually by looking for fluid escaping from any part of the fitting or hose.

Hold the Pressure: Maintain the operating pressure for a specified period (usually 10-15 minutes) to ensure the system can hold pressure without any drops. A steady pressure reading indicates a secure installation.

Check for Leaks: Use a soapy water solution or leak detection fluid to spray on the connections. Bubbles forming at any point indicate a leak that needs to be addressed.

Release Pressure Safely: After completing the pressure test, carefully release the pressure from the system before disconnecting the testing rig. This ensures safety and prevents any sudden releases of high-pressure fluid.

Inspection

Beyond the pressure test, a detailed visual and manual inspection is necessary to confirm the installation’s integrity:

Visual Inspection: Examine the fittings and hoses closely for any signs of damage, wear, or improper installation. Look for gaps, misalignments, or areas where the hose may not be fully seated in the fitting.

Manual Check: Gently tug on the fittings and hoses to ensure they are securely connected. There should be no movement or looseness at the connection points.

Check for Contaminants: Ensure that no debris, dirt, or foreign materials are present on the fittings or within the hose. Contaminants can compromise the seal and lead to leaks.

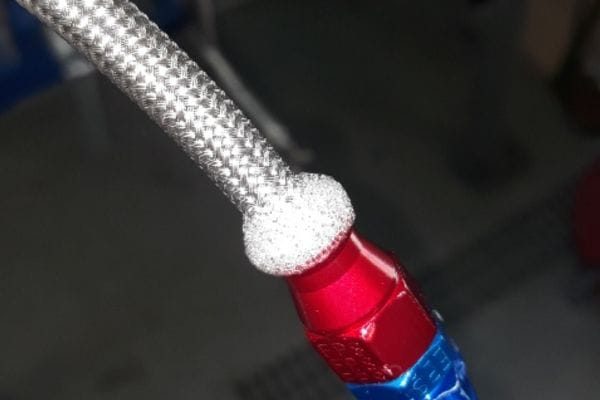

Inspect for Fraying: Look for any signs of fraying at the ends of the braided line. Frayed ends can indicate a poor cut or installation and may lead to future issues.

Troubleshooting Common Issues

Leaks

Leaks can occur due to several reasons, including improper installation, damaged components, or contamination. Here’s how to identify and fix leaks:

Identifying Leaks: During the pressure test, use a soapy water solution to detect leaks. Bubbles forming at any connection point indicate a leak.

Fixing Leaks: If a leak is detected, disassemble the fitting and inspect the threads and sealing surfaces for damage. Replace any damaged components. Reassemble the fitting, ensuring proper alignment and tightness. Reapply thread sealant if required.

Re-Test: After fixing the leak, re-test the system to ensure the issue has been resolved.

Fraying

Fraying of the braided line can lead to poor sealing and potential leaks. Address fraying issues as follows:

Cutting the Line: Ensure the braided line is cut cleanly using a high-quality hose cutter. Apply masking tape around the cutting area to minimize fraying.

Taping the End: After cutting, wrap the end of the braided line with masking tape to hold the braid together during installation.

Reassemble: If fraying occurs, cut the line again and re-tape the end before reassembling the fitting.

Cross-Threading

Cross-threading can damage the threads and compromise the connection. Prevent and address cross-threading with these steps:

Proper Alignment: Always start threading the fitting by hand to ensure proper alignment. This reduces the risk of cross-threading.

Lubrication: Apply a small amount of lubricant to the threads to facilitate smooth threading.

Disassemble and Inspect: If cross-threading occurs, disassemble the fitting and inspect the threads for damage. Use a thread file or tap to clean up any minor thread damage. Replace the fitting if the threads are severely damaged.

Reassemble with Care: Reassemble the fitting carefully, ensuring proper alignment and hand-threading before using tools to tighten.

Conclusion

In summary, the proper installation of AN fittings on braided lines is crucial for ensuring the safety and performance of hydraulic systems. Following the detailed steps outlined in this guide helps to prevent leaks, fraying, and other common issues, thereby extending the longevity and reliability of your setup. We encourage you to follow this guide meticulously for successful installations.

FAQ

AN fittings, short for Army-Navy fittings, are standardized fittings used for high-performance fluid transfer systems, commonly found in automotive, aerospace, and industrial applications.

Lubrication helps to ease the insertion of the hose end into the socket, reducing friction and the risk of damaging the components.

Wrap masking tape tightly around the area to be cut, use a sharp hose cutter or fine-toothed hacksaw, and make a clean, straight cut to minimize fraying.

Disassemble the fitting, inspect the components for damage or contamination, clean or replace parts as needed, and reassemble ensuring proper alignment and tightness.

It is recommended to use AN-specific wrenches to avoid damaging the anodized finish and ensure a secure fit.

AN fittings are typically made from aluminum, steel, or stainless steel, each chosen based on factors like strength, corrosion resistance, and weight.