How to Measure Pipe Thread NPT Fittings

Table of Contents

Introduction

Accurate measurement of NPT fittings is crucial because even slight discrepancies can lead to significant issues. Precise measurement ensures a proper fit and prevents leaks, which can cause system failures, safety hazards, and costly repairs. Incorrect measurements can result in poor thread engagement, leading to weak connections that might fail under pressure. Moreover, ensuring accurate measurements helps maintain the integrity of the entire piping system, ensuring it operates efficiently and safely.

Tools Required for Measurement

Thread Gauges

Plug Gauges: Used to check the accuracy of the internal threads of a fitting. Plug gauges have a threaded section that matches the thread profile and pitch of the fitting being measured.

Ring Gauges: Used to measure the external threads of a fitting. Ring gauges are essentially threaded rings that can be screwed onto the fitting to verify thread accuracy.

Calipers

Digital Calipers: Provide a digital readout of the measurement, making them easy to use and read.

Dial Calipers: Use a dial indicator to show measurements. They are precise but require manual reading.

Vernier Calipers: Feature a sliding scale for measurements. They are very precise but require practice to read accurately.

Pitch Gauges: Pitch gauges are used to measure the distance between threads, known as the pitch. They consist of a set of blades with different thread profiles and pitches.

Rulers: Useful for quick, rough measurements of length and diameter. Ensure the ruler has fine markings for better accuracy.

Micrometers: Provide very precise measurements of small dimensions, such as thread pitch diameter. They are ideal for high-precision applications.

Step-by-Step Guide to Measuring NPT Fittings

Preparing the Fitting

Cleaning and Inspecting the Fitting:

Clean the Fitting: Use a brush and a suitable cleaning solution to remove any dirt, grease, or debris from the threads. This ensures that measurements are not affected by contaminants.

Inspect the Fitting: Examine the threads for any signs of damage, such as nicks, flattening, or corrosion. Damaged threads can lead to inaccurate measurements and poor fit.

Ensuring the Fitting is Free from Damage or Deformities:

Visual Inspection: Look for visible deformities or wear. Ensure the threads are intact and not worn out.

Check for Roundness: Use calipers to check the fitting’s roundness by measuring diameters at multiple points along the threads. Variations can indicate deformities.

Measuring the Thread Diameter

Internal and External Thread Measurement:

Internal Threads:

Procedure: Insert the caliper jaws into the fitting and gently expand them until they contact the internal threads. Ensure the caliper is perpendicular to the fitting’s axis to avoid skewed measurements.

Best Practices: Take multiple measurements at different points within the internal thread to ensure accuracy and consistency.

External Threads:

Procedure: Close the caliper jaws around the external threads, making sure they are perpendicular to the fitting’s axis. Measure at multiple points along the threads to ensure consistency.

Best Practices: Rotate the fitting and measure the external diameter at several points to verify uniformity. This helps in detecting any tapering or irregularities.

Using Calipers for Accurate Readings:

Digital Calipers:

Procedure: Turn on the caliper and zero it out before taking any measurements. Place the caliper jaws on the threads and read the digital display for an accurate measurement.

Advantages: Digital calipers are user-friendly and provide quick, precise readings, reducing the chance of human error.

Dial Calipers:

Procedure: Read the measurement from the dial indicator and the main scale. Combine these readings for the final measurement.

Advantages: Dial calipers offer reliable readings and are particularly useful in environments where digital tools might fail due to dust or moisture.

Vernier Calipers:

Procedure: Align the vernier scale with the main scale and read the measurement by noting where the scales align. This method requires more skill but can be very precise.

Advantages: Vernier calipers are highly accurate and do not rely on batteries, making them dependable in various conditions.

Determining the Thread Pitch

Using Pitch Gauges to Measure the Thread Pitch:

Select the Correct Blade:

Procedure: Choose a pitch gauge blade that appears to match the thread pitch. Place it against the threads and ensure it fits snugly without gaps.

Verification: If the blade fits perfectly, you have identified the correct pitch. If not, try another blade until you find the one that matches.

Verify Fit:

Procedure: Place the pitch gauge on the threads and ensure that it meshes perfectly with the thread profile. The blade should fit snugly into the threads without any movement or gaps.

Confirmation: Check multiple points along the thread length to confirm that the pitch is consistent throughout.

Common Pitches for NPT Fittings:

Standard Pitches:

Details: Common NPT thread pitches include 11.5 TPI (Threads Per Inch) for 1/2″ NPT, 14 TPI for 1/4″ NPT, and 8 TPI for 1″ NPT. These pitches are standardized and can be verified using a pitch chart.

Procedure: Refer to a pitch chart to verify standard pitches for different sizes. This chart helps in quickly identifying the correct pitch for your specific fitting size.

Using a Thread Gauge

Verifying Thread Compatibility:

Internal Threads:

Procedure: Insert a plug gauge into the fitting. It should screw in smoothly and stop at the correct depth. Check for tightness without forcing.

Best Practices: Ensure the gauge is not forced into the threads, as this can damage both the gauge and the fitting.

External Threads:

Procedure: Screw a ring gauge onto the fitting. It should engage easily and fit snugly.

Best Practices: Rotate the gauge gently to ensure a proper fit. If resistance is encountered, inspect the threads for damage or debris.

Checking for Proper Fit and Alignment:

Procedure:

Ensure the gauge engages without cross-threading. A properly aligned gauge will screw on evenly and smoothly.

Rotate the gauge a few times to check for consistent engagement. If it feels uneven, recheck the thread measurements and alignment.

Recording and Interpreting Measurements

Documenting Measurements:

Procedure:

Record all measurements, including internal and external diameters, thread pitch, and gauge fit. Use a standardized form or spreadsheet for consistency.

Note any observations about the condition of the threads, such as damage or wear. This documentation helps in maintaining quality control and traceability.

Comparing Against Standard NPT Dimensions:

Procedure:

Compare the recorded measurements to standard NPT dimension charts. Ensure all dimensions fall within the acceptable range for the specific NPT size.

Identify any discrepancies and re-measure if necessary to confirm accuracy. Consistent measurements across different points help in verifying the fitting’s compliance with standards.

Common Challenges and Solutions

Dealing with Worn or Damaged Threads

Identifying Worn or Damaged Threads:

Visual Inspection: Examine the threads closely for signs of wear, such as flattening, nicks, or corrosion. Use a magnifying glass if necessary to spot minor damages.

Feel Test: Run your fingers over the threads. Rough or uneven areas can indicate wear or damage.

Thread Engagement: Attempt to engage a thread gauge. If the gauge does not fit smoothly or stops prematurely, the threads may be worn or damaged.

Solutions for Accurate Measurement Despite Wear:

Use of Thread Restoration Tools: Consider using a thread file or thread chaser to restore slightly damaged threads before measurement.

Selecting Undamaged Areas: If possible, measure undamaged sections of the thread to get more accurate readings.

Gauge Verification: Use multiple types of gauges (plug and ring) to cross-check measurements and confirm thread integrity.

Digital Profiling: Employ advanced digital thread profiling tools to capture the thread’s dimensions accurately despite wear.

Handling Large or Small Fittings

Techniques for Measuring Large Diameter Fittings:

Large Calipers or Micrometers: Use specialized large calipers or micrometers designed for measuring large diameters. Ensure they have the range and accuracy needed for the fitting size.

Segmented Measurements: For very large fittings, take measurements in segments and combine them to get the overall dimension. Use a flexible tape measure for circumference and convert to diameter using the formula (Diameter = Circumference / π).

Support and Stability: Ensure the fitting is properly supported and stable during measurement to avoid inaccuracies due to movement.

Precision Methods for Small Fittings:

Fine-Tipped Calipers: Use calipers with fine tips that can accurately fit into small threads without damaging them.

Micrometers for Small Threads: Employ micrometers designed for small threads to ensure precision.

Magnification: Use a magnifying tool or microscope to assist in reading measurements on small fittings, ensuring clarity and accuracy.

Interpreting Ambiguous Results

Addressing Inconsistent or Unclear Measurements:

Re-Measurement: Re-measure the fitting using different tools and techniques to verify initial readings. Consistency across multiple measurements indicates reliability.

Cross-Reference with Standards: Compare measurements with standard dimensions for NPT fittings to identify any anomalies.

Third-Party Verification: If measurements remain ambiguous, seek third-party verification using calibrated instruments or professional metrology services.

Best Practices for Re-Measurement:

Calibrate Instruments: Ensure all measurement tools are calibrated correctly before re-measuring to eliminate tool-related errors.

Consistent Environment: Perform measurements in a consistent environment, avoiding changes in temperature or humidity that might affect readings.

Multiple Points: Measure at multiple points along the thread to average out any minor discrepancies. This practice helps in identifying true dimensions versus localized wear or damage.

How to Select the Right Size NPT Thread Fitting

Selecting the correct size NPT (National Pipe Tapered) thread fitting is crucial for ensuring a secure and leak-proof connection in your piping system. Here is a step-by-step guide to help you choose the right size NPT fitting for your application.

Understand NPT Sizing

Nominal Pipe Size (NPS):

NPT fittings are designated by their nominal pipe size (NPS), which does not directly correspond to the actual outside diameter (OD) of the pipe.

The NPS system is used to standardize the sizing of pipes and fittings, making it easier to match components.

Thread Pitch:

NPT threads have a specific pitch, which is the number of threads per inch (TPI). Common pitches include 11.5 TPI for 1/2″ NPT, 14 TPI for 1/4″ NPT, and 8 TPI for 1″ NPT.

Determine the Application Requirements

Pressure Rating

Identify the Operating Pressure:

Determine the maximum pressure that the piping system will experience during operation. This includes considering any potential pressure spikes or surges.

Typical applications, such as residential plumbing, industrial processes, or hydraulic systems, will have different pressure requirements.

Select the Appropriate Pressure Rating:

NPT fittings are available in various pressure ratings, often indicated by the manufacturer. These ratings are based on the material and construction of the fitting.

Ensure the selected fitting can handle the operating pressure without risk of failure. For high-pressure applications, opt for fittings made from robust materials like stainless steel.

Material Compatibility

Evaluate the Fluid or Gas Being Transported:

Consider the chemical properties of the fluid or gas flowing through the pipes. This includes its corrosiveness, temperature, and any potential reactivity with the fitting material.

Choose the Appropriate Material:

Brass: Ideal for water, oil, and air applications due to its corrosion resistance and durability.

Stainless Steel: Suitable for harsh environments, high-pressure systems, and corrosive substances.

Plastic: Often used for low-pressure applications and when chemical compatibility with specific fluids is required (e.g., in chemical processing or potable water systems).

Temperature Considerations

Ensure the fitting material can withstand the operating temperatures of the system. High temperatures can affect the strength and integrity of some materials, particularly plastics.

End Connections:

Identify Connection Types:

Determine whether the system requires male or female NPT threads. Male threads fit into female threads, and vice versa.

Consider if the fitting needs to connect to other types of fittings or adapters, such as JIC, BSP, or SAE.

Consider the System Configuration:

Evaluate the layout and configuration of the piping system. Ensure the selected fitting type aligns with the connection points in your system for a seamless and secure fit.

Select the Correct Fitting

Match the Size:

Measure and Verify:

Using the previously gathered measurements (outside diameter, thread pitch), select the fitting size that matches the nominal size and thread pitch of your pipes.

Use standardized size charts to cross-reference and ensure compatibility.

Ensure Compatibility:

Double-check that the fitting type (male or female) matches the connection points in your system. Misalignment can lead to leaks and system failure.

Verify the Fit:

Test Assembly:

Assemble the fitting with the pipe to verify a proper fit. The threads should engage smoothly without excessive force. If there is resistance or cross-threading, the fitting size or thread type might be incorrect.

Check that the fitting threads fully engage and create a tight seal when properly torqued. The fitting should be snug but not overtightened, which can strip threads or cause damage.

Evaluate Thread Engagement:

Ensure that the fitting threads are properly aligned and engage uniformly. Misaligned threads can compromise the seal and lead to leaks.

Conclusion

Ensuring accuracy and consistency throughout this process is vital to maintaining the integrity and functionality of piping systems. Precise measurements prevent leaks, ensure proper fit, and enhance the overall performance and safety of the system. Prioritizing accurate measurement is essential for the efficiency and safety of any piping system. By adopting best practices and utilizing advanced measurement tools, professionals can ensure that their systems operate smoothly and effectively.

FAQ

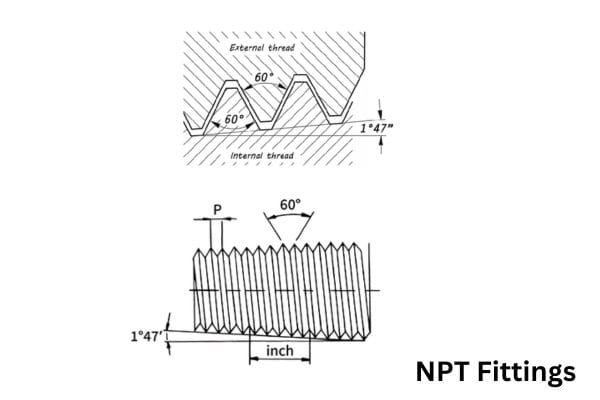

NPT stands for National Pipe Tapered. It is a standard for tapered threads used to create a tight seal in pipe fittings.

To measure the thread size, you need to measure the outside diameter (OD) of the male thread or the inside diameter (ID) of the female thread and determine the thread pitch using a thread pitch gauge.

The primary tools required are calipers (digital, dial, or vernier), thread pitch gauges, and thread plug or ring gauges. These tools help ensure precise measurements of the diameter and pitch.

Accurate measurements ensure a proper fit and a tight seal, preventing leaks and system failures. Incorrect measurements can lead to poor thread engagement and potential safety hazards.

NPT fittings are not compatible with BSP or SAE threads due to differences in thread design and pitch. Using the correct type of fitting for each specific thread standard is crucial.

NPT fittings are commonly made from materials such as brass, stainless steel, and plastic. The choice of material depends on the application, environmental conditions, and the substances being transported through the pipes.