How to Remove a Broken Grease Fitting

Table of Contents

Introduction

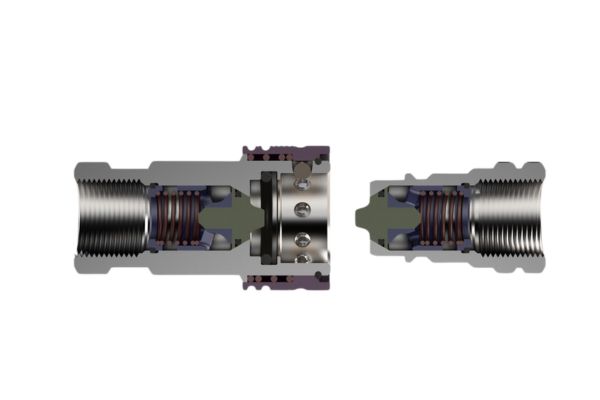

Grease fittings, also known as grease nipples or Zerk fittings, are small but crucial components in machinery maintenance. They provide a pathway for lubricants to reach various parts of a machine, ensuring smooth operation and reducing wear and tear. Despite their small size, grease fittings are prone to several issues, such as clogging, corrosion, and, most commonly, breakage. When a grease fitting breaks, it can disrupt maintenance routines and potentially lead to more significant mechanical problems if not addressed promptly. This comprehensive guide aims to equip you with the knowledge and tools necessary to effectively remove broken grease fittings, ensuring your machinery remains well-maintained and operational.

Causes of Broken Grease Fittings

Over-tightening

One of the most common causes of broken grease fittings is over-tightening. When excessive force is applied during installation or maintenance, it can shear off the fitting, causing it to snap. This is particularly problematic because it can leave part of the fitting lodged in the machinery, making removal difficult. Over-tightening can occur due to the misconception that tighter fittings ensure better lubrication. However, it is crucial to follow the manufacturer’s torque specifications to prevent this issue.

Corrosion and Wear

Corrosion and wear are natural processes that can compromise the integrity of grease fittings over time. Exposure to moisture, chemicals, and other harsh environmental conditions can cause the metal to rust and weaken. Additionally, the continuous flow of grease through the fittings can lead to wear and tear, especially if the grease contains abrasive particles. Regular inspection and maintenance are essential to identify and replace corroded or worn fittings before they fail.

Accidental Impact

Machinery operates in environments where accidental impacts are common. Grease fittings, which often protrude from surfaces, are susceptible to being struck by moving parts, tools, or other equipment. Even a minor impact can bend, crack, or break a fitting, especially if it is already weakened by corrosion or wear. Protective covers and strategic placement of fittings can help mitigate this risk.

Improper Installation

Improper installation is another frequent cause of broken grease fittings. This can include using the wrong type or size of fitting for the application, not aligning the fitting correctly, or failing to secure it properly. Incorrect installation can create stress points on the fitting, making it more vulnerable to breakage under normal operating conditions. It can also lead to improper lubrication, which can further damage both the fitting and the machinery. Ensuring that fittings are installed according to the manufacturer’s guidelines is crucial for their longevity and performance.

Additional Factors

Several additional factors can contribute to the breakage of grease fittings:

Material Fatigue: Repeated cycles of pressurization and depressurization can cause material fatigue, leading to cracks and eventual failure of the fitting.

Temperature Extremes: Extreme temperatures can cause expansion and contraction of the metal, leading to stress fractures.

Contamination: Dirt and debris can accumulate around the fitting, causing it to clog or become difficult to remove, increasing the risk of breakage during maintenance.

Vibration: Continuous vibration from the machinery can loosen fittings over time, making them more susceptible to breaking.

Step-by-Step Guide to Removing a Broken Grease Fitting

Preparation

Inspect the Broken Fitting

Detailed Examination: Start by taking a close look at the broken grease fitting to understand the extent and nature of the breakage. Check if the fitting is flush with the surface or if there is a portion protruding. Identifying whether the break is clean or jagged will help determine the best removal method.

Assessment: Use a flashlight and magnifying glass if necessary to ensure you do not miss any small details. This can help you avoid causing further damage during removal.

Clean the Area

Initial Cleaning: Wipe the area around the broken fitting with a clean cloth or rag to remove loose dirt, grease, and debris. This initial cleaning helps to see the fitting.

Deep Cleaning: Use a degreaser or a solvent if needed to ensure the area is thoroughly clean. This reduces the risk of contaminating the machinery during the removal process and provides a better grip for the tools you will use.

Using a Grease Fitting Removal Tool

How to Use

Tool Selection: Choose the appropriate grease fitting removal tool for the size and type of fitting. These tools are specifically designed for extracting broken grease fittings.

Insertion: Insert the removal tool into the broken fitting, ensuring it is properly seated. Turn the tool counterclockwise to engage with the fitting.

Tips

Steady Pressure: Apply steady, even pressure while turning the tool to avoid slipping or causing additional damage to the fitting.

Penetrating Oil: If the fitting is tight or corroded, apply a small amount of penetrating oil around the base and allow it to sit for a few minutes. This can help to loosen the fitting and make removal easier.

Extraction with Pliers or Vise Grips

Technique

Tool Selection: If you do not have a specialized removal tool, pliers or vise grips can be used as an alternative. Select pliers or vise grips that can firmly grip the broken fitting.

Grip and Turn: Grip the broken fitting tightly with the pliers or vise grips and turn counterclockwise. Ensure you have a firm hold to prevent slipping.

Handling Tight or Corroded Fittings

Penetrating Oil: For fittings that are particularly tight or corroded, apply penetrating oil around the base and allow it to seep in for several minutes. This can help to break down rust and loosen the fitting.

Heat Application: If the fitting still does not budge, use a heat gun to gently heat the area around the fitting. The heat will cause the metal to expand slightly, potentially loosening the fitting. Be cautious not to overheat, as this can damage the machinery.

Drilling Out the Fitting

Drill Bit Size

Selection: Choose a drill bit that is slightly smaller than the diameter of the broken fitting. This helps to avoid damaging the threads of the fitting hole.

Drilling Process

Centering the Drill: Position the drill bit at the center of the broken fitting. Ensure it is aligned properly to avoid drilling at an angle.

Drilling Technique: Drill slowly and steadily, applying consistent pressure. Avoid using excessive force as it can cause the drill bit to slip or damage the fitting hole.

Removing Debris

Metal Shavings: After drilling, use a magnet or vacuum to remove any metal shavings from the hole. This prevents debris from interfering with the installation of the new fitting.

Cleaning the Area: Thoroughly clean the area to ensure no debris remains, which could compromise the new fitting’s installation.

Using an Easy Out or Screw Extractor

How to Use

Tool Insertion: Easy Out tools, also known as screw extractors, are designed to remove broken bolts and fittings. Insert the extractor into the drilled hole in the broken fitting.

Proper Seating: Ensure the extractor is properly seated in the hole before applying any force.

Secure Grip

Tapping the Extractor: Tap the extractor lightly with a hammer to ensure it is securely lodged in the fitting. This helps to create a firm grip.

Turning the Extractor: Turn the extractor counterclockwise. The reverse threads on the extractor will grip the fitting more tightly as you turn.

Gentle Removal

Applying Force: Apply steady, gentle force to avoid breaking the extractor or damaging the fitting hole. Rapid or excessive force can lead to further complications.

Complete Removal: Once the fitting begins to turn, continue applying gentle pressure until it is fully removed. Be patient, as forcing the process can cause more damage.

Dealing with Stubborn or Complicated Cases

Removing broken grease fittings can sometimes be more challenging, especially in cases where the fitting is severely corroded, tightly lodged, or situated in a difficult-to-reach area. Here are detailed strategies for handling such stubborn or complicated cases:

Applying Heat

Heat Gun Usage:

Purpose: Heating the area around the broken fitting can cause the metal to expand slightly, breaking the bond and making removal easier.

Procedure:

Set the heat gun to a medium setting to avoid overheating.

Direct the heat at the surrounding area, not directly on the fitting itself.

Move the heat gun in a circular motion to distribute the heat evenly.

Heat the area for a few minutes until it is sufficiently warm.

Caution:

Avoid applying too much heat directly to the fitting, as this can cause it to become brittle or warp.

Be mindful of nearby components that could be damaged by heat.

Alternative Heating Methods:

If a heat gun is unavailable, a propane torch can be used with caution.

Always have a fire extinguisher nearby when using open flame tools.

Heat the area gently and progressively to prevent overheating and potential damage.

Using Penetrating Oil

Penetrating Oil Application:

Purpose: Penetrating oil helps to break down rust and corrosion, loosening the fitting.

Procedure:

Apply a generous amount of penetrating oil around the base of the broken fitting.

Allow the oil to seep in for several minutes to penetrate deep into the threads.

For heavily rusted fittings, apply the oil and let it sit overnight for maximum effectiveness.

Types of Penetrating Oil:

Popular brands like WD-40, PB Blaster, and Liquid Wrench are effective choices.

Use oils specifically designed for rust and corrosion to achieve the best results.

Enhanced Penetration Techniques:

After applying the oil, gently tap around the fitting with a hammer to help the oil penetrate further.

Reapply the oil periodically to ensure continuous penetration, especially in very tight or corroded situations.

Avoiding Damage

Protecting Surrounding Components:

Assess the Area: Before starting the removal process, examine the surrounding components to identify any that might be vulnerable to damage.

Shielding:

Use heat-resistant materials to shield sensitive parts from the heat gun or torch.

Place a barrier or protective cover over nearby components to prevent oil splatter or tool impact.

Gentle Handling:

Controlled Force: Apply force gently and gradually when using tools to avoid slipping and damaging adjacent parts.

Tool Choice: Use tools that are appropriately sized and suited for the specific fitting to ensure precise application of force.

Alternative Removal Methods:

Cold Chisel and Hammer: For fittings that do not respond to heat or oil, a cold chisel and hammer can be used to create a notch in the fitting. This notch can then be used to turn the fitting with a tool.

Rotary Tools: Use a rotary tool with a cutting or grinding attachment to remove excess material around the fitting, providing better access to extraction tools.

Professional Assistance:

If the fitting is particularly stubborn and at risk of causing significant damage during removal, consider seeking assistance from a professional mechanic or machinist. They have specialized tools and expertise for handling such challenging cases.

Preventing Future Breakages

Preventing future breakages of grease fittings is crucial for maintaining the efficiency and longevity of your machinery. Implementing proper installation techniques, regular maintenance, and selecting the right fittings are key steps in ensuring that your grease fittings remain in optimal condition.

Proper Installation

Follow Manufacturer Guidelines:

Torque Specifications: Always adhere to the manufacturer’s recommended torque settings when installing grease fittings. Over-tightening can shear off the fitting while under-tightening can lead to leaks and improper lubrication.

Alignment: Ensure that the fitting is properly aligned with the hole before starting the installation process. Misalignment can cause cross-threading, which weakens the fitting and makes it prone to breakage.

Clean Threads: Before installation, clean the threads of both the fitting and the hole to remove any debris or old lubricant. This ensures a secure and proper fit.

Use Appropriate Tools:

Wrenches and Sockets: Use wrenches or sockets that are correctly sized for the fitting to avoid damaging the hex or causing slippage.

Avoid Using Pliers: Pliers can deform the fitting and lead to improper installation. Always use the proper tools for the job.

Regular Maintenance

Routine Inspections:

Visual Checks: Regularly inspect grease fittings for signs of wear, damage, or corrosion. Look for cracks, bends, or any signs that the fitting may be compromised.

Functional Testing: Periodically test the fittings by applying grease and ensuring it flow freely. If a fitting is clogged or not accepting grease, it should be replaced immediately.

Cleaning and Lubrication:

Keep Fittings Clean: Wipe down grease fittings regularly to prevent the buildup of dirt and debris, which can lead to blockages.

Use Quality Lubricants: Use high-quality lubricants that are compatible with both the fitting and the machinery. Avoid using lubricants with abrasive particles that can cause wear.

Timely Replacement:

Replace Worn Fittings: Do not wait for a fitting to break before replacing it. If a fitting shows signs of wear or damage, replace it immediately to prevent failure.

Stock Spares: Keep a stock of spare fittings on hand to ensure quick replacement when needed, minimizing machinery downtime.

Conclusion

Maintaining grease fittings is crucial for the longevity and efficiency of machinery. By following this guide, you can effectively remove broken grease fittings, prevent future issues, and ensure smooth operation. Always prioritize safety and use the proper tools to achieve the best results. Regular maintenance and timely inspections are key to avoiding problems and keeping your equipment in top condition.

FAQ

Grease fittings, also known as Zerk fittings, are small metal components used in machinery to allow easy application of lubricants to moving parts. They help ensure smooth operation and reduce wear and tear.

A broken grease fitting may be visibly damaged, such as being sheared off, bent, or cracked. It may also fail to accept grease during lubrication, indicating an internal blockage or breakage.

To remove a broken grease fitting, you may need wrenches, pliers, grease fitting removal tools, a drill with appropriate bits, penetrating oil, and possibly an Easy Out or screw extractor for more stubborn cases.

To prevent grease fittings from breaking, follow proper installation guidelines, regularly inspect fittings for wear or damage, and choose the right type of fitting for your machinery and operating environment. Avoid over-tightening and ensure correct alignment during installation.

If a grease fitting won’t accept grease, try cleaning the fitting and the area around it. Apply penetrating oil to loosen any blockages. If the fitting is still blocked, it may need to be replaced.

It is generally not recommended to reuse a grease fitting after removal, especially if it was broken or damaged. Always replace with a new fitting to ensure proper function and avoid potential issues.