Quick Connect Sizes Explained: A Comprehensive Comparison

Introduction

Quick-connect fittings are essential components used in a wide range of industries, including hydraulics, plumbing, and automotive sectors. These fittings are designed to create secure and efficient connections without the need for tools, enabling quick and easy assembly and disassembly. Their versatility and convenience make them indispensable for applications where speed and reliability are crucial. Quick connect fittings come in various sizes and configurations, each tailored to specific needs and systems. Understanding these sizes is paramount to ensuring compatibility, preventing leaks, and optimizing system performance.

What Are Quick Connect Fittings?

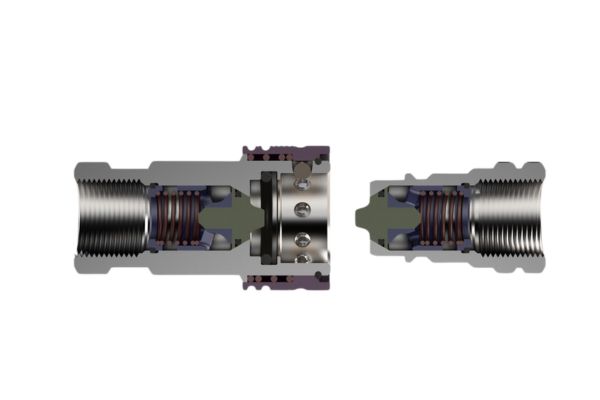

Quick connect fittings, also known as quick disconnects or quick release couplings, are specialized connectors designed to join or separate fluid lines rapidly and effortlessly. These fittings consist of two main components: a plug (or male part) and a socket (or female part). When these two components are pushed together, they form a secure and leak-proof connection. The release mechanism allows for quick disconnection without the need for tools, making them highly efficient for applications where frequent assembly and disassembly are required.

Common Uses in Various Industries

Hydraulic Systems

- Used to quickly connect/disconnect hoses and components.

- Helps reduce downtime during maintenance or equipment changes.

Plumbing

- Commonly used for connecting pipes, faucets, and appliances.

- Speeds up installation and makes repairs more convenient.

Automotive Industry

- Found in fuel lines, brake systems, and A/C units.

- Offers fast, leak-proof connections essential for safety and efficiency

Benefits of Using Quick Connect Fittings

Time and Labor Savings

- Instant connection and disconnection reduces setup and maintenance time.

- No need for wrenches or sealants during installation.

- Ideal for frequent assembly/disassembly tasks.

Ease of Use

- Requires minimal training or technical expertise.

- Simplifies field operations and emergency servicing.

- Suitable for both professionals and non-specialists.

Reliable, Leak-Proof Connections

- Engineered for secure sealing under pressure.

- Maintains fluid or gas system integrity.

- Reduces the risk of contamination or system failure.

Enhanced Safety and Efficiency

- Prevents accidental disconnection or leakage.

- Supports safe handling of high-pressure or hazardous fluids.

- Contributes to consistent system performance.

Cost Effectiveness

- Reduces equipment downtime and labor costs.

- Low maintenance requirements due to durable design.

- Fewer replacements = long-term savings.

Types of Quick Connect Fittings

Push-to-Connect Fittings

Push-to-connect fittings, also known as push-fit fittings, are designed for simplicity and ease of use. These fittings feature a collet with stainless steel teeth that grip the pipe when it is inserted into the fitting. Inside, an O-ring ensures a watertight seal. To connect, simply push the pipe into the fitting until it clicks into place. Disconnection is equally straightforward, usually requiring the user to depress a release ring while pulling the pipe out.

Threaded Quick Connect Fittings

Threaded quick connect fittings utilize a threaded connection to secure the fitting to the pipe or hose. These fittings can be male or female and come in various thread standards such as NPT (National Pipe Thread), BSP (British Standard Pipe), and metric threads. The threaded design ensures a robust and secure connection capable of withstanding high pressures and stresses. Installation requires screwing the fitting onto the corresponding threaded component, often using thread sealant or tape to ensure a leak-proof connection.

Barbed Quick Connect Fittings

Barbed quick connect fittings are designed to connect flexible hoses to rigid pipes or other fittings. These fittings have barbs or ridges that grip the inside of the hose, providing a secure connection. The hose is typically secured onto the barbed fitting using a hose clamp for added security. Barbed fittings are commonly used in low-pressure applications such as irrigation systems, automotive vacuum lines, and various fluid transfer applications. Their design allows for a secure connection even when the hose expands and contracts due to changes in pressure or temperature.

Importance of Correct Sizing

Ensuring Compatibility and Preventing Leaks

Selecting the correct size for quick connect fittings is critical to ensuring compatibility between different components within a fluid or gas system. Properly sized fittings form tight seals, which are essential for preventing leaks. Leaks can lead to fluid loss, which not only reduces the efficiency of the system but also poses potential safety hazards, especially in systems handling hazardous or pressurized fluids. A fitting that is too small or too large can result in poor connections, leading to frequent maintenance issues and potential system failures. Ensuring that the fittings are appropriately sized eliminates these risks and enhances the overall reliability of the system.

Impact on Performance and Safety

The performance and safety of any system that uses quick-connect fittings heavily depend on correct sizing. Properly sized fittings ensure that the flow rate is maintained as per the design specifications, which is crucial for the optimal functioning of the system. For instance, in hydraulic systems, an incorrect fitting size can cause significant pressure drops, leading to inefficient performance and increased wear and tear on system components. Additionally, in safety-critical applications, such as in medical or aerospace industries, the consequences of using incorrectly sized fittings can be catastrophic, potentially leading to system failures and endangering lives. Hence, correct sizing is not just a matter of efficiency but also of ensuring the highest safety standards.

Cost Implications of Incorrect Sizing

Using incorrectly sized quick connect fittings can lead to significant cost implications. Leaks caused by improper fitting sizes result in the wastage of fluids and increased maintenance costs due to frequent repairs and replacements. The downtime associated with fixing these issues can further add to operational costs, as it impacts productivity and efficiency. Moreover, the wear and damage caused to other system components by improper sizing can lead to premature failures, necessitating costly replacements and repairs.

Measurement Standards and Systems

Imperial vs Metric Systems

When dealing with quick connect fittings, it is crucial to understand the two main measurement systems used globally: the Imperial system and the Metric system. The Imperial system, primarily used in the United States, measures dimensions in inches, feet, and pounds. Conversely, the Metric system, used by most other countries, measures in millimeters, centimeters, meters, and kilograms. Understanding these systems is essential for ensuring compatibility and accuracy when selecting and installing quick-connect fittings.

Common Measurement Standards

Several standardized measurement systems are used for quick connect fittings, each with unique characteristics and applications:

- NPT (National Pipe Thread): This is a U.S. standard for tapered threads used on threaded pipes and fittings. NPT threads are angled at 60 degrees and provide a tight, leak-proof seal. They are commonly used in the plumbing and hydraulic industries.

- BSP (British Standard Pipe): BSP is a standard used internationally, especially in the UK and former British territories. It includes BSPT (tapered) and BSPP (parallel) threads. BSP threads have a 55-degree angle and are widely used in plumbing and industrial applications.

- JIC (Joint Industry Council): JIC fittings use a 37-degree flare to form a metal-to-metal seal, providing high pressure and vibration resistance. They are commonly used in hydraulic systems, especially in the automotive and aerospace industries.

- SAE (Society of Automotive Engineers): SAE fittings, similar to JIC fittings, often use a 45-degree flare. They are standard in automotive and refrigeration applications.

How to Measure Quick Connect Sizes Accurately

Accurately measuring quick connect sizes is critical for ensuring a proper fit and function within your systems. Incorrect measurements can lead to leaks, system failures, and increased maintenance costs. Here are the detailed steps to measure these sizes accurately:

Identify the Type of Fitting

The first step in measuring quick connect sizes is to determine the type of fitting you are dealing with. Quick-connect fittings can be push-to-connect, threaded, or barbed.

Measure the Diameter

The next step is to measure the diameter of the fitting. This measurement varies depending on the type of fitting:

- Threaded Fittings: Use a pair of calipers to measure the outside diameter (OD) of the male threads or the inside diameter (ID) of the female threads. This ensures that you get an accurate measurement of the thread size.

- Push-to-Connect and Barbed Fittings: Measure the OD of the part that connects to the hose or pipe. For barbed fittings, this means measuring the widest part of the barb.

Accurate diameter measurement is crucial for ensuring compatibility with hoses, pipes, and other system components.

Determine the Thread Pitch

For threaded fittings, the thread pitch is a critical measurement. The thread pitch is the distance between threads and is measured in threads per inch (TPI) for Imperial systems or in millimeters between threads for Metric systems:

- Use a thread pitch gauge to measure the thread pitch. This tool has multiple blades, each marked with different pitches. Match the threads of your fitting with the appropriate blade on the gauge.

- Ensure that the gauge fits snugly into the threads without any gaps to get an accurate measurement.

Consult Standard Charts

Once you have your diameter and thread pitch measurements, consult standard charts to correlate these measurements with the correct fitting size and type. These charts are often available from manufacturers and industry organizations:

- Find the section of the chart that corresponds to the type of fitting you are measuring.

- Locate your diameter and thread pitch measurements on the chart to determine the correct size.

- These charts are invaluable for ensuring that you select the right fitting size, especially when dealing with various thread standards and measurement systems.

Factors to Consider When Choosing Size

Pressure

The operating pressure of your system is one of the most critical factors when selecting a quick connect fitting. Each fitting is designed to withstand a specific range of pressures. Using a fitting that is not rated for your system’s pressure can lead to catastrophic failures, including bursts, leaks, and safety hazards. It is essential to:

- Identify Maximum and Minimum Operating Pressure: Understand both the maximum and minimum operating pressures your system will encounter. This ensures that the fitting can handle extreme conditions without compromising safety or performance.

- Check Pressure Ratings: Manufacturers provide pressure ratings for their fittings. Compare these ratings to your system requirements to ensure compatibility. High-pressure systems may require fittings made from more robust materials, such as stainless steel, to prevent deformation or failure.

Flow Rate

The flow rate of your system dictates how much fluid or gas moves through the fitting over a given period. The internal diameter of the fitting plays a significant role in determining the flow rate. To ensure optimal system efficiency:

- Measure Required Flow Rate: Calculate the flow rate needed for your application. This information is crucial for selecting a fitting with an appropriate internal diameter.

- Consider Pressure Drop: A fitting that is too small for the required flow rate can cause a significant pressure drop, reducing system efficiency and potentially leading to operational issues. Ensure the selected fitting maintains the desired flow rate without causing unnecessary pressure loss.

Application Specifics

Each application has unique requirements that influence the selection of quick connect fittings. Consider the following specifics:

- Type of Fluid or Gas: Different materials and designs are suited for various fluids and gases. For example, corrosive fluids may require fittings made from corrosion-resistant materials like stainless steel or specialized plastics.

- Temperature Ranges: High or low temperatures can affect the integrity of the fitting material. Ensure the fitting can withstand the temperature extremes of your application without degrading.

- Environmental Conditions: Consider the environment where the fitting will be used. Factors such as exposure to chemicals, moisture, UV light, and physical impacts can influence the choice of fitting material and design.

Compatibility

Ensuring compatibility with existing system components is crucial for maintaining a leak-proof and secure connection. Compatibility considerations include:

- Thread Types and Sizes: Different thread standards (e.g., NPT, BSP, JIC, SAE) must match exactly to prevent leaks and ensure a tight seal. Verify the thread type and size of both the fitting and the components it will connect to.

- Material Compatibility: The material of the fitting should be compatible with the materials of the hoses, pipes, and other fittings in your system to avoid reactions that could weaken connections or cause leaks.

- System Components: Ensure the selected quick-connect fitting integrates seamlessly with other system components, such as valves, pumps, and filters, to maintain overall system integrity and performance.

By thoroughly considering these factors—pressure, flow rate, application specifics, and compatibility—you can select the right quick connect size for your needs. This careful selection process helps ensure your system operates efficiently, safely, and reliably, minimizing downtime and maintenance costs

Common Mistakes to Avoid

Ignoring Pressure Ratings:

Do not overlook the pressure rating of the fitting. Using a fitting with a lower pressure rating than required can lead to dangerous system failures.

Overlooking Thread Compatibility:

Ensure the thread type and size match exactly with existing system components. Mismatched threads can cause leaks and disconnections.

Incorrect Measurements:

Take accurate measurements using the correct tools, such as calipers and thread pitch gauges. Inaccurate measurements can result in selecting the wrong fitting size.

Neglecting Material Compatibility:

Choose a fitting material that is compatible with the fluid or gas and environmental conditions. Incompatible materials can lead to corrosion, degradation, and system failures.

Conclusion

Understanding the various aspects of quick connect sizes is crucial for ensuring the efficiency, safety, and reliability of any fluid or gas system. Throughout this post, we have explored the definition and types of quick-connect fittings, the importance of correct sizing, and the critical factors to consider when selecting the right size. By accurately measuring fittings and comprehending the different measurement standards, you can prevent leaks, maintain optimal performance, and reduce maintenance costs.

FAQ

Quick connect fittings are connectors designed to join or separate fluid or gas lines quickly and easily without the need for tools. They are commonly used in various industries, including hydraulics, plumbing, and automotive.

To measure a quick connect fitting, use calipers to measure the outside diameter (OD) of male threads or the inside diameter (ID) of female threads. For push-to-connect and barbed fittings, measure the OD of the part that connects to the hose or pipe. Use a thread pitch gauge for threaded fittings to determine the thread pitch.

NPT (National Pipe Thread) and BSP (British Standard Pipe) threads differ in thread angle and pitch. NPT threads have a 60-degree angle and are used mainly in the United States, while BSP threads have a 55-degree angle and are used internationally, especially in the UK and former British territories.

Choosing the correct quick connect size is essential for ensuring compatibility, preventing leaks, and maintaining the system’s performance and safety. Incorrect sizing can lead to fluid loss, pressure drops, and potential system failures.

Yes, quick connect fittings can be used with both liquids and gases. However, it is crucial to choose fittings made from materials compatible with the specific fluid or gas and the application’s pressure and temperature requirements.

Quick connect fittings are made from various materials, including brass, stainless steel, plastic, and aluminum. The choice of material depends on the application’s specific requirements, such as pressure, temperature, and chemical compatibility.